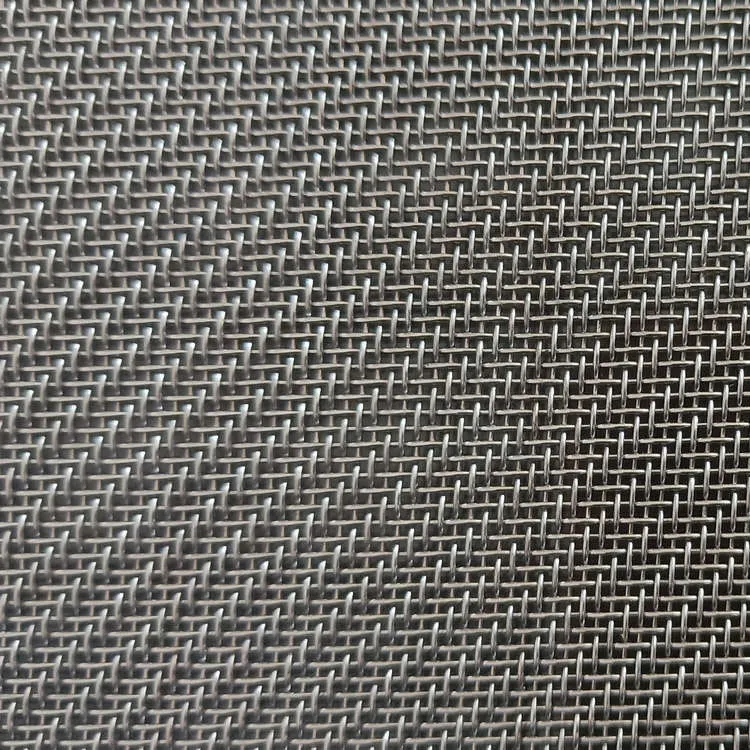

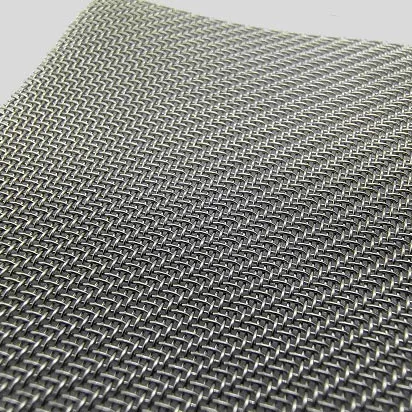

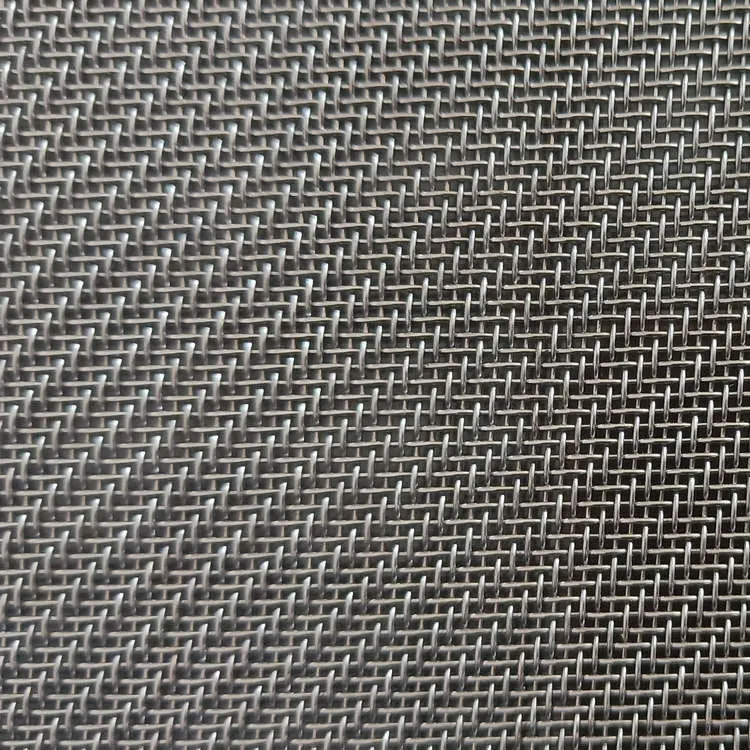

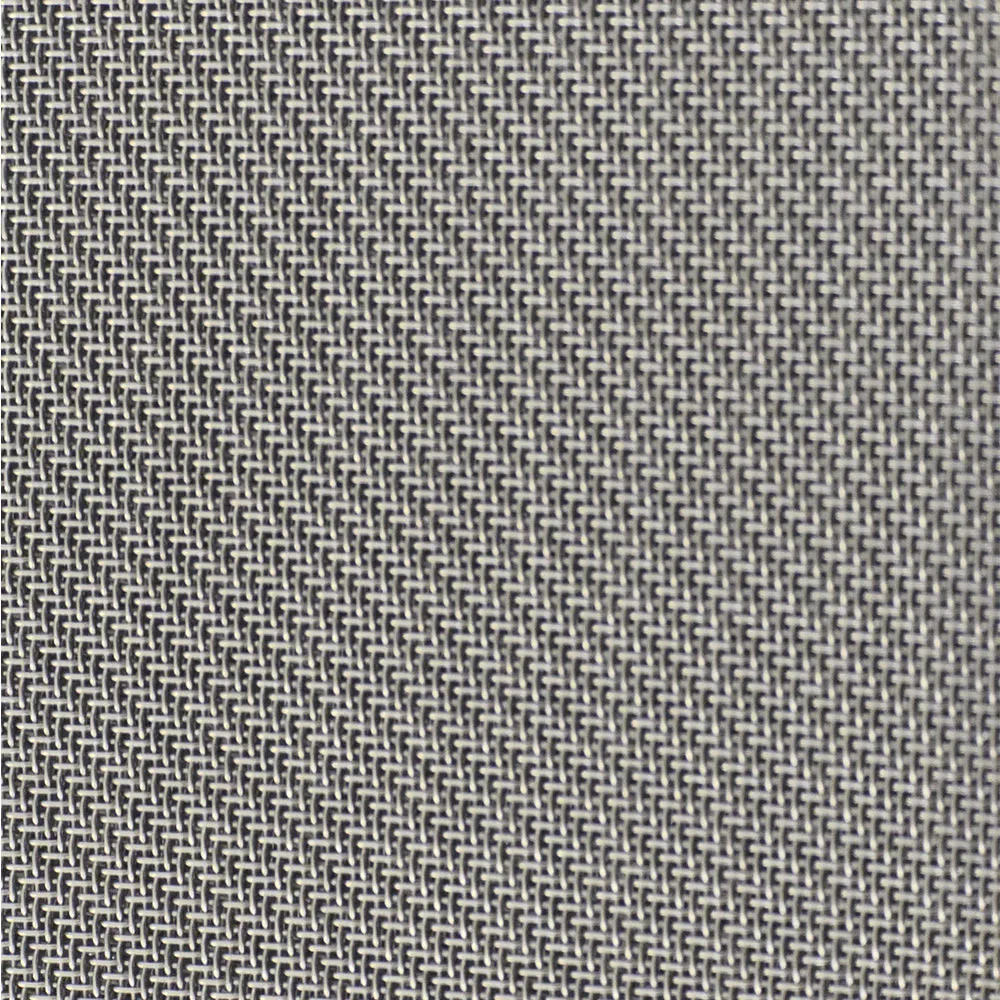

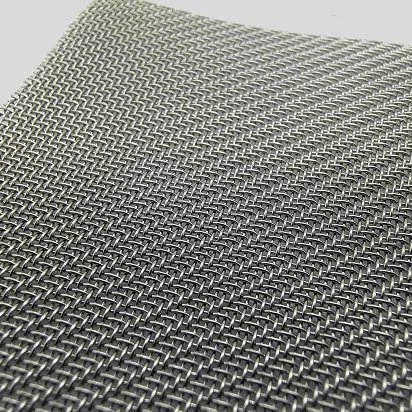

Our high-quality stainless steel wire mesh---twill weave

Material Characteristics: Made from high - quality stainless steel, it exhibits excellent corrosion resistance. It can withstand humid, acidic, alkaline and other complex environments, maintaining stable performance for a long time and extending its service life.

Based on the different usage environments and price considerations, we have a variety of stainless steel materials for you to choose from, including 201, 304, 316, 316L and other stainless steel materials.

Filtration Precision: With a wide range of mesh sizes available, it can precisely intercept impurities of different particle sizes, from coarse to fine filtration, meeting various filtration requirements and ensuring accurate and reliable filtration results.

Our wire mesh has extremely precise wire diameters and mesh numbers. We use computer-controlled machines to strictly control the production process, ensuring that the steel wire diameter is accurate to the standard value and the mesh number is evenly distributed. This provides a stable guarantee for your use. Every detail can withstand strict inspection.

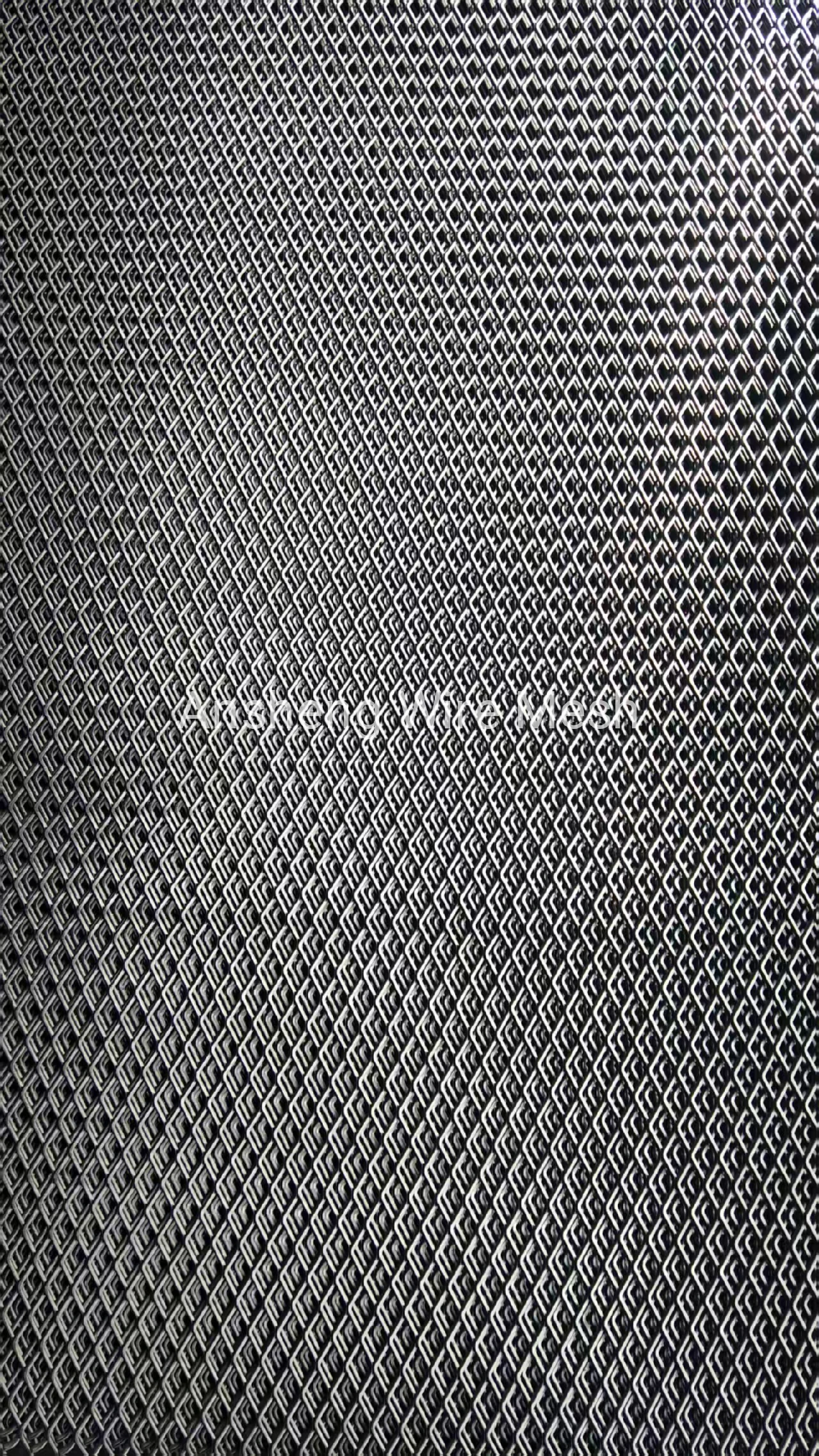

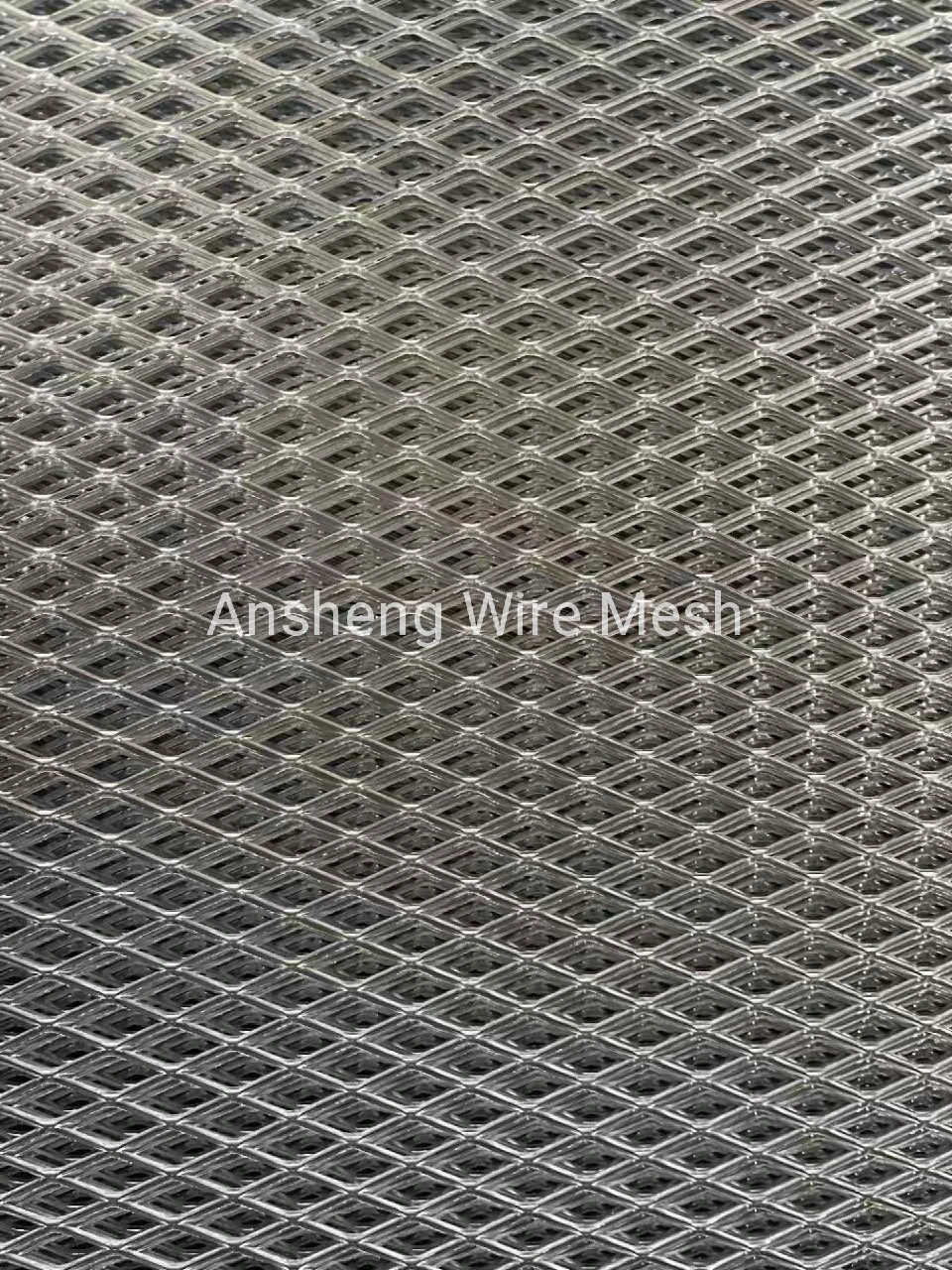

Structural Advantages: Manufactured by precision weaving processes, the mesh surface is flat and the structure is sturdy, making it highly resistant to deformation. It can stably perform filtration functions even under high - pressure and high - flow working conditions.

Cleaning and Maintenance: The smooth surface of the stainless steel material prevents impurities from adhering easily. It is easy to clean and can be reused, effectively reducing usage costs and enhancing filtration efficiency.

Application Areas: It is used for the purification of oil products and chemical raw materials in the petrochemical industry; ensures product purity in the food and beverage industry; contributes to pharmaceutical production in the pharmaceutical field; and purifies water quality in water treatment. It is a key element for various industries to ensure product quality and stable production.In the rubber and plastic industries, it can be used for the filtration of recycled materials or raw materials.

Advantages of twillweave mesh:

Thicker wire diameter, balancing strength and mesh flexibility

Under the same mesh size conditions, the twill weaving method can use thicker wire diameters without causing mesh deformation or density reduction due to excessive wire diameter. The combination of coarse wire diameter and diagonal structure enhances the load-bearing capacity of single wire, resulting in higher overall tensile and impact resistance than plain weave mesh. It is suitable for scenarios that require high wear resistance and load-bearing capacity.

Low overall cost

The weaving method is simplified, and mechanized production has higher efficiency, shorter production cycle, and relatively lower price, which is particularly evident in high mesh. The coarse wire diameter and high-strength structure extend the service life of diagonal mesh, reduce replacement frequency, and significantly lower maintenance costs than plain mesh, especially in harsh environments.

Whether you are in search of a reliable filtration solution for industrial processes or domestic use, our stainless steel filter mesh is your optimal choice. With its superior quality, excellent performance, and wide range of applications, it is bound to meet your specific requirements.

The commonly used specifications are as follows.

|

Mesh |

Wire diameter (mm) |

|

30 |

0.4 |

|

40 |

0.3 |

|

60 |

0.19 |

|

80 |

0.14 |

|

100 |

0.12 |

|

120 |

0.10 |

|

150 |

0.09 |

|

200 |

0.06 |

|

250 |

0.045 |

|

300 |

0.04 |

|

400 |

0.03 |

|

500 |

0.025 |

In addition to these standard specifications, our inventory is also stocked with a wide variety of other specifications. And if you still can't find what you need, we're more than happy to offer customized services to precisely meet your unique requirements.