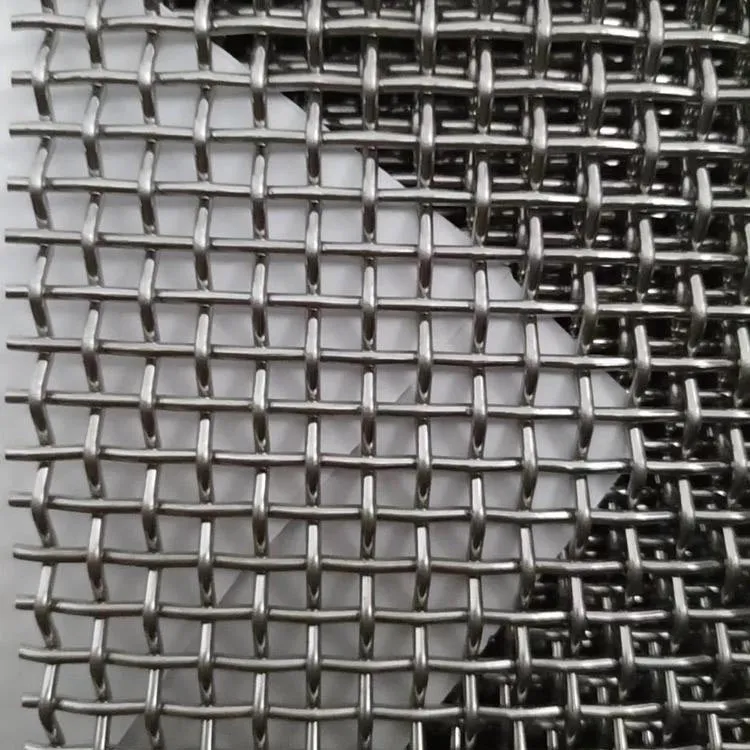

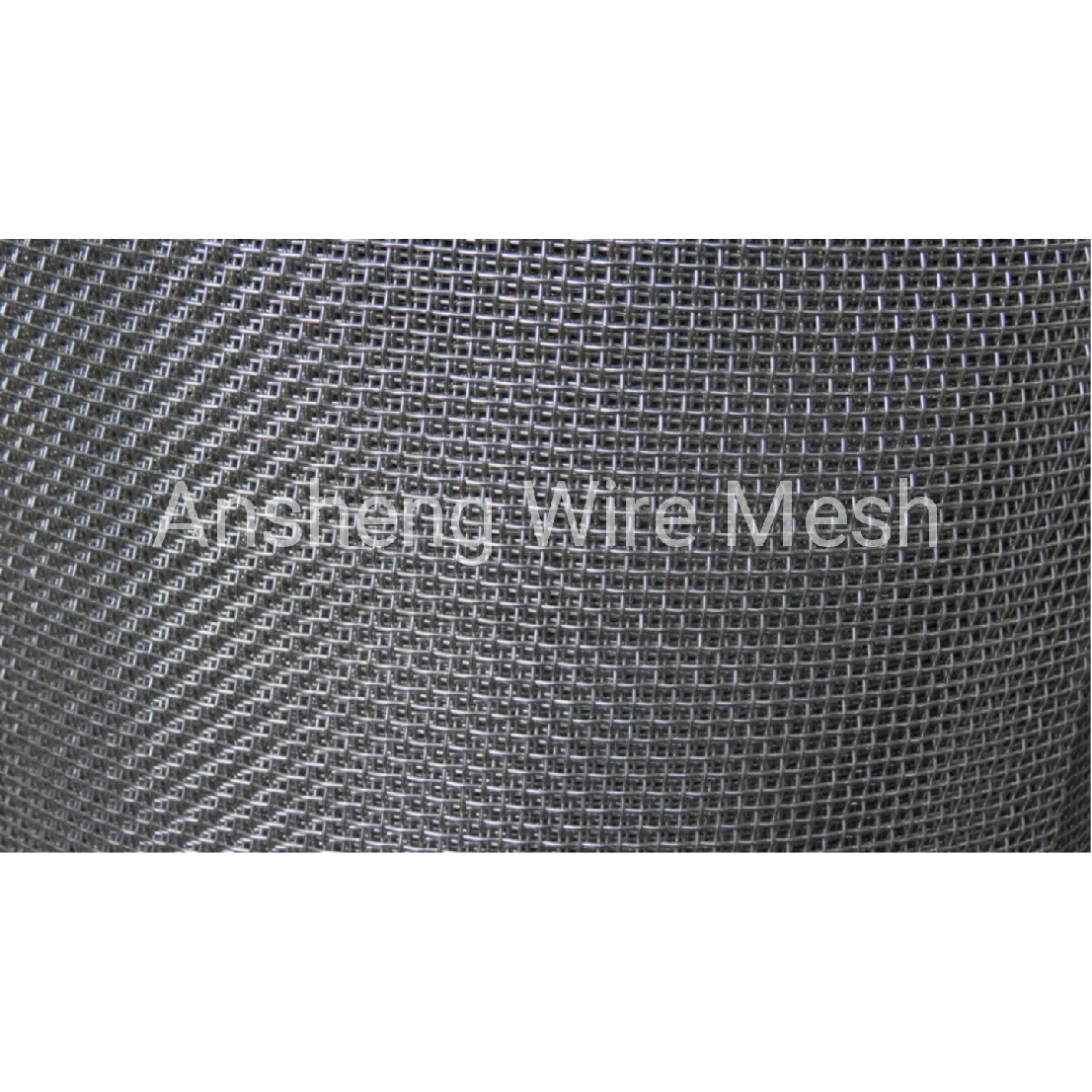

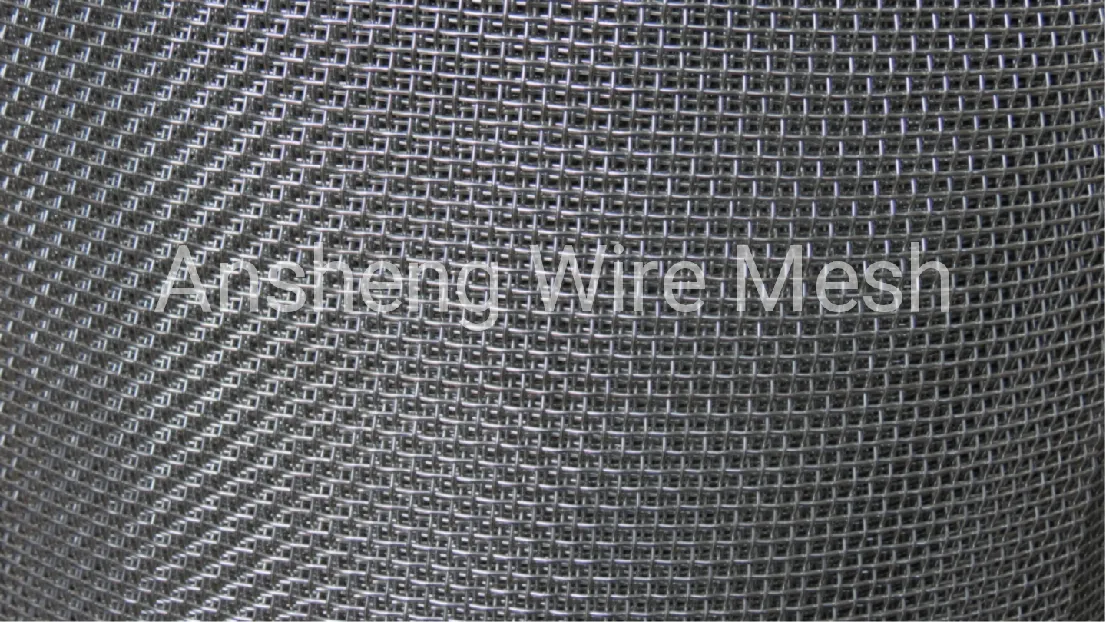

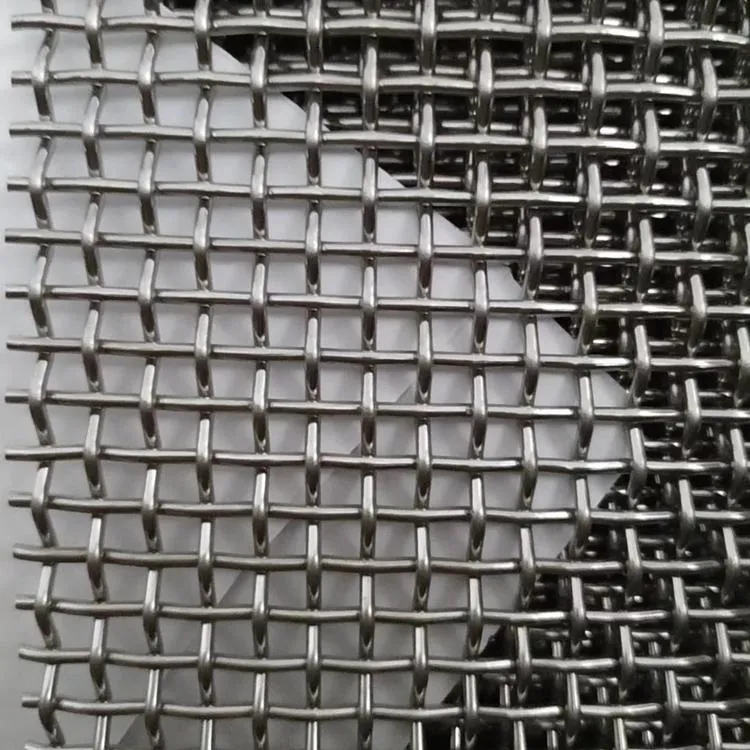

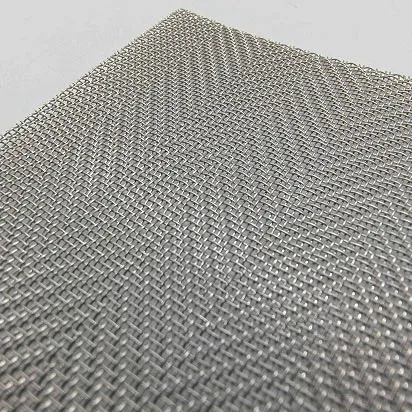

Galvanized mesh is made by galvanizing low-carbon steel wire and then weaving it.

Compared with low-carbon steel wire mesh, it has strong corrosion resistance: the zinc layer effectively isolates air and moisture, prevents steel wire rusting, extends service life, and is suitable for harsh environments.

Compared with stainless steel wire mesh, the price is lower, and choosing it can significantly reduce material procurement costs while meeting performance requirements. This allows enterprises to have more cost optimization space while ensuring product quality, and gain an advantage in fierce market competition.

Advantages of our galvanized wire mesh:

-Accurate mesh size: The weaving process is precise, and the mesh size is uniform. Different aperture sizes can be customized according to needs to achieve high-precision filtering and screening.

-High strength and good toughness: The steel wire material has high strength, and the woven structure further enhances its overall strength. It also has a certain degree of toughness and can withstand tension, bending, and impact.

-Good breathability: The mesh holes are interconnected and have good breathability, ensuring smooth fluid flow and improving filtration efficiency.

The commonly used specifications are as follows.

|

mesh |

Wire diameter(mm) |

|

10 |

0.8 |

|

10 |

0.6 |

|

16 |

0.6 |

|

16 |

0.4 |

|

20 |

0.5 |

|

20 |

0.45 |

|

20 |

0.4 |

|

25 |

0.4 |

|

30 |

0.3 |

|

40 |

0.25 |

|

40 |

0.2 |

|

50 |

0.18 |

|

60 |

0.18 |

|

80 |

0.13 |

In addition to these standard specifications, our inventory is also stocked with a wide variety of other specifications. And if you still can't find what you need, we're more than happy to offer customized services to precisely meet your unique requirements.