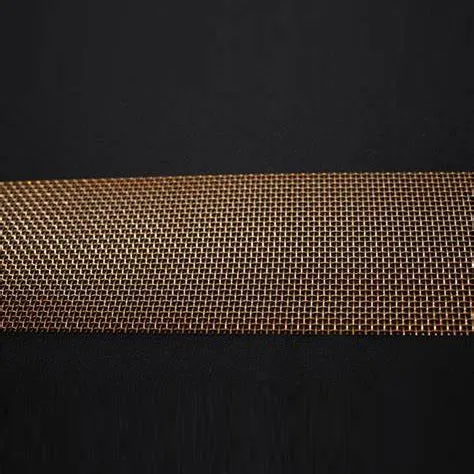

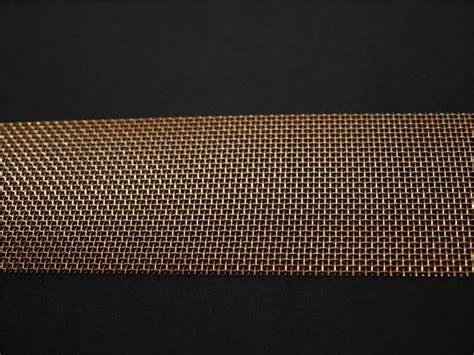

Our high-qualityphosphor copper wire mesh

-Uniform color: The surface presents a uniform purple red color, without obvious color differences, black spots, or white spots, with a bright color and a metallic texture.

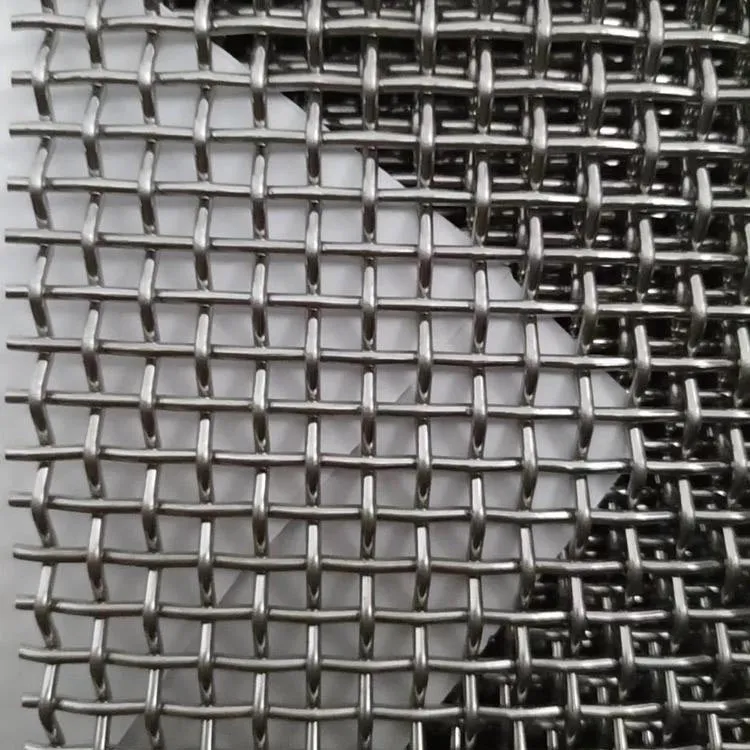

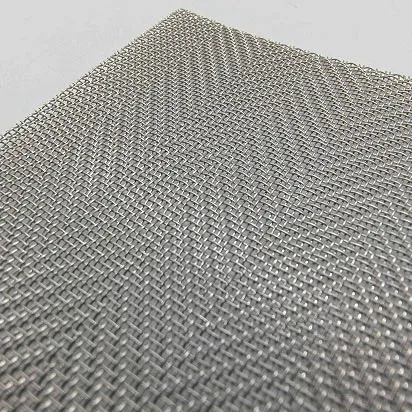

-Smooth mesh surface: The mesh is overall smooth, without unevenness, wrinkles, or distortion. The edges of the mesh are neat, without burrs or flying edges, and will not scratch objects or human bodies in contact.

-High purity: The phosphorus copper content is high and the impurity content is low. Generally, high-quality phosphorus copper mesh has a copper content of over 90% and a phosphorus content between 0.03% and 0.35% to ensure good conductivity, thermal conductivity, and corrosion resistance.

-Consistent size: The mesh size is precise, uniform, and the error is controlled within a very small range. For example, for a common 100 mesh phosphor copper mesh, the error in mesh edge length may be within ± 0.05mm to meet different screening, filtering, and other usage requirements.

Advantage of phosphor copper wire mesh:

-High strength and toughness: Phosphorus copper mesh has high strength and good toughness, can withstand large tensile and impact forces, is not easy to break, and can maintain a stable structure during use.

-Excellent conductivity and thermal conductivity: Phosphorus copper has good conductivity and thermal conductivity, so phosphorus copper mesh can effectively transmit current and heat in electrical, electronic and other fields, which is conducive to the efficient operation of equipment.

-Corrosion resistance: It has good corrosion resistance to chemicals such as acids and alkalis, and can be used for a long time in harsh chemical environments. It is not easily damaged by corrosion and extends its service life.

-Good wear resistance: The surface hardness is high, and the wear resistance is good. Even under frequent friction, it can maintain the smoothness and integrity of the mesh surface, ensuring its usability.

Application area

-In the field of electronics and electrical engineering, it is commonly used for electromagnetic shielding, which can effectively block the interference of electromagnetic waves and ensure the normal operation of electronic devices; It can also be used to manufacture shielding layers for wires and cables, electrodes for electronic components, etc.

-In the field of chemical engineering, as a filtering material, it is used for the filtration of chemical solutions and suspensions, which can effectively separate impurities and liquids and ensure the quality of chemical products.

-In the field of mechanical manufacturing, it can be used to manufacture parts that require high strength and wear resistance, such as gears, bearings, etc., to improve the service life and performance of the parts.

-In the field of architectural decoration, protective nets, decorative nets, etc. used in buildings have both protective functions and aesthetic effects.

As a professional copper mesh manufacturer, we use high - purity copper to produce products with excellent conductivity, corrosion resistance and precise filtering. Our advanced equipment, strict quality control and customizable options ensure top - notch quality. We also offer great pre - and after - sales service. Choose us for a reliable and efficient solution, and let's cooperate!

The commonly used specifications are as follows.

|

Mesh |

Wire Diameter(mm) |

|

6 |

0.7 |

|

8 |

0.6 |

|

10 |

0.5 |

|

20 |

0.3 |

|

30 |

0.25 |

|

40 |

0.2 |

|

50 |

0.17 |

|

60 |

0.17 |

|

80 |

0.12 |

|

100 |

0.1 |

|

150 |

0.06 |

|

200 |

0.05 |

In addition to these standard specifications, our inventory is also stocked with a wide variety of other specifications. And if you still can't find what you need, we're more than happy to offer customized services to precisely meet your unique requirements.