In the field of industrial design and construction, the choice of materials can make all the difference between lasting performance and premature failure. Among the most innovative and versatile solutions available today is titanium expanded metal mesh, a product that combines strength, corrosion resistance, and lightweight properties in one unique material. This mesh has become essential for industries ranging from aerospace to architectural design, where durability and precision are paramount. The advanced manufacturing techniques behind titanium expanded metal mesh create a product that delivers exceptional mechanical properties while remaining flexible enough for complex applications. Over time, its use has expanded across sectors demanding both aesthetic appeal and unmatched functional integrity.

Advantages of Weldlok Expanded Mesh for Heavy-Duty Applications

Among the variety of expanded metal meshes, weldlok expanded mesh stands out due to its robust construction and enhanced bonding capabilities. Unlike traditional expanded metal, this mesh incorporates welding technology that reinforces each junction, resulting in increased load-bearing strength and resistance to deformation under stress. When integrated into construction frameworks or machinery guards, weldlok expanded mesh provides not only structural support but also added safety, thanks to its high impact tolerance. The welded design minimizes the risk of mesh fatigue, making it an ideal choice for environments exposed to vibrations, heavy loads, or harsh weather conditions. Industries such as manufacturing plants and infrastructure projects increasingly rely on weldlok expanded mesh for long-term performance.

Enhancing Visual Appeal and Functionality with White Expanded Metal

While durability is critical, many applications also require an element of design, and this is where white expanded metal proves its worth. The clean, bright finish of this mesh variant makes it perfect for architectural facades, decorative panels, and interior design accents. More than just aesthetic, white expanded metal also benefits from coatings that improve weather resistance and reduce maintenance needs. The mesh’s precise patterning allows for optimal light diffusion and ventilation without compromising security or privacy. Whether used in commercial buildings or residential landscaping, white expanded metal delivers an elegant balance of form and function, transforming ordinary spaces into visually compelling environments.

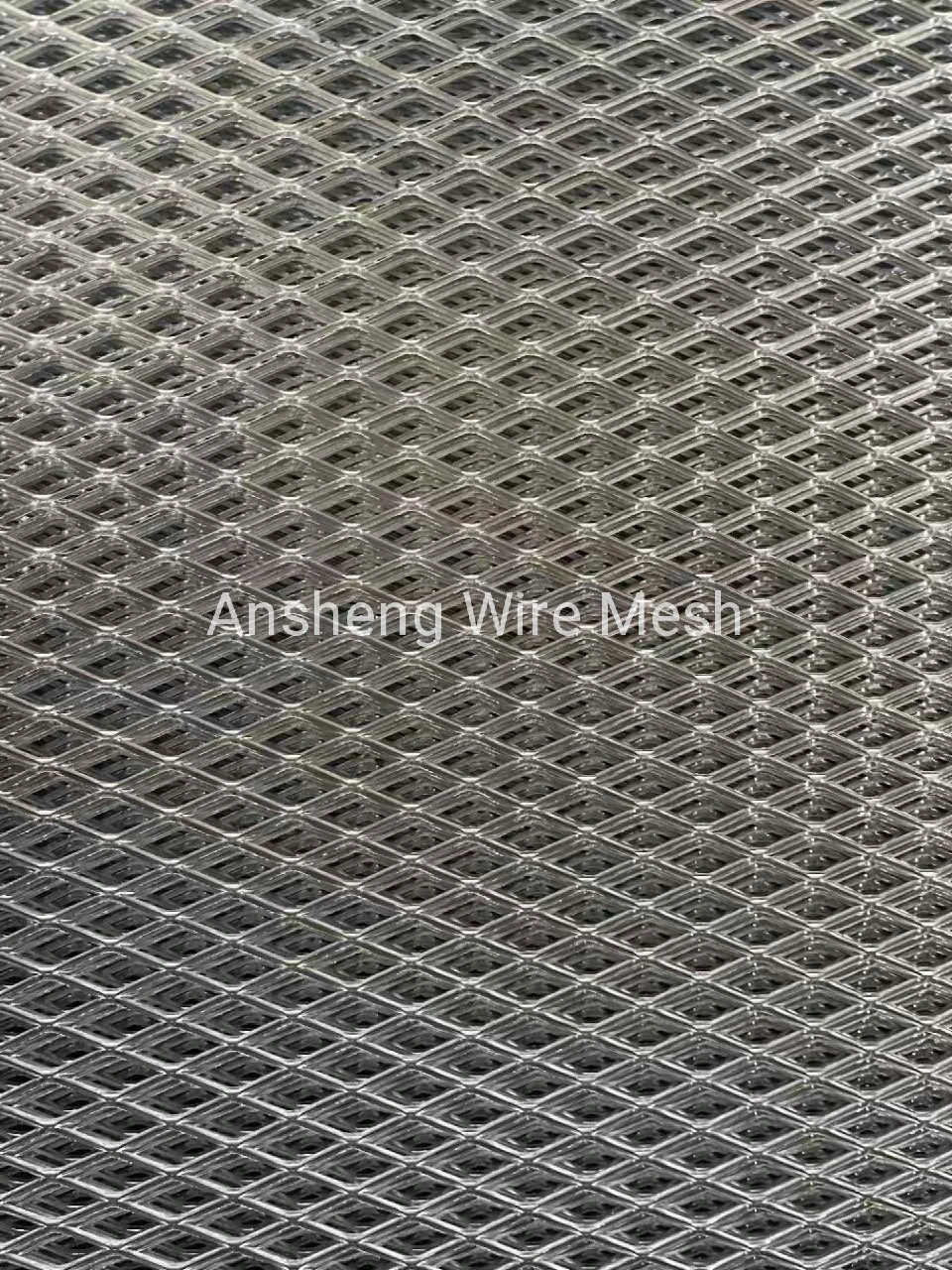

Durability Factors of Wire Mesh Expanded Metal

Understanding the durability of wire mesh expanded materials is crucial for selecting the right product. The quality of wire and the expansion process directly affect tensile strength and resistance to environmental damage. High-grade steel wire used in wire mesh expanded configurations ensures that the mesh withstands heavy wear and tear over time. Additionally, treatments like galvanization or powder coating significantly enhance corrosion resistance, which is vital for outdoor applications or chemical exposure. Such durability allows wire mesh expanded to maintain structural integrity across industries such as agriculture, security, and transportation, where reliable fencing and filtration systems are essential.

Versatility and Adaptability of Wire Mesh Expanded Metal in Various Industries

The multifunctional nature of wire mesh expanded metal has made it a preferred choice across a wide range of industrial and commercial uses. Its open pattern design facilitates airflow and light passage, which is beneficial in HVAC systems, machine guards, and shelving units. Moreover, wire mesh expanded metal can be customized in thickness, strand width, and opening size to fit specific engineering requirements. This adaptability allows manufacturers and architects to tailor solutions that optimize performance without sacrificing cost efficiency. As a result, wire mesh expanded metal plays a pivotal role in sectors that demand both versatility and high performance, from electronics enclosures to urban infrastructure.

Choosing the Right Titanium Expanded Metal Mesh for Your Project Needs

Selecting the ideal titanium expanded metal mesh involves considering several factors, including mesh size, thickness, and surface finish. Due to titanium’s natural corrosion resistance, this mesh is especially suited for marine environments, chemical plants, and high-temperature applications. The lightweight nature of titanium also reduces structural loads, making it an excellent option for aerospace components and architectural cladding. When designing your system, understanding the mechanical stresses and environmental conditions helps ensure that the chosen titanium expanded metal mesh meets all operational demands while providing long service life. Collaborating with material specialists can further refine the selection process, maximizing performance and cost-effectiveness.

Innovations Driving the Production of Advanced Weldlok Expanded Mesh

Recent advancements in manufacturing have revolutionized the production of weldlok expanded mesh, enabling finer control over mesh patterns and welding precision. Computer-controlled laser welding techniques ensure consistent joint quality and minimal distortion during fabrication. These innovations reduce waste and improve material utilization, making weldlok expanded mesh a more sustainable choice for large-scale industrial projects. Enhanced welding processes also allow for combining different metal types or coatings to achieve specific mechanical or environmental resistances. Consequently, the modern weldlok expanded mesh not only performs better but also offers designers more freedom to create complex, high-strength structures that meet increasingly stringent industry standards.

Long-Term Maintenance and Care for White Expanded Metal

To preserve the look and longevity of white expanded metal, proper maintenance practices are essential. Regular cleaning removes dirt and pollutants that can degrade the surface coating, while inspections help identify early signs of wear or corrosion. Protective finishes applied during manufacturing, such as powder coating, provide excellent resistance to UV radiation and moisture but may require touch-ups in harsh conditions. Implementing a routine maintenance schedule ensures that white expanded metal panels continue to perform well as architectural elements or security barriers. Their upkeep supports both aesthetic appeal and functional durability, protecting your investment over many years.

Exploring Customization Options with Wire Mesh Expanded Metal

Customization is a key advantage of working with wire mesh expanded metal, enabling tailored solutions that meet unique project specifications. Whether you require specific strand thicknesses, opening sizes, or mesh geometries, manufacturers can adjust production processes accordingly. Such flexibility allows this mesh type to serve niche applications, including filtration media, acoustic panels, and specialized safety guards. Additionally, various finishing options such as galvanizing, painting, or powder coating add to the adaptability of wire mesh expanded metal, allowing it to integrate seamlessly into diverse environments. Customization ensures optimal performance while meeting aesthetic and regulatory requirements.

Applications and Benefits of Using Wire Mesh Expanded in Modern Infrastructure

The role of wire mesh expanded in modern infrastructure cannot be overstated. Its strength, combined with lightness and airflow capabilities, makes it ideal for reinforcing concrete, protecting equipment, and enhancing security measures. The mesh facilitates efficient ventilation in tunnels, bridges, and buildings, reducing the risk of corrosion and structural damage due to trapped moisture. Its widespread use in fencing, stair treads, and machine guarding highlights its essential contribution to safety and durability in industrial settings. The longevity and cost-effectiveness of wire mesh expanded materials provide a reliable backbone for sustainable infrastructure development worldwide.

Titanium Expanded Metal Mesh + FAQs

Q1: What makes titanium expanded metal mesh superior to other metals?

Titanium expanded metal mesh combines excellent corrosion resistance, high strength-to-weight ratio, and temperature tolerance, making it ideal for demanding applications where longevity and performance are critical.

Q2: Can weldlok expanded mesh be used outdoors?

Yes, weldlok expanded mesh is particularly suited for outdoor use due to its enhanced joint strength and resistance to environmental wear, especially when coated or treated for corrosion protection.

Q3: How is white expanded metal maintained?

White expanded metal requires periodic cleaning and inspections to maintain its finish and protective coatings. Routine upkeep helps prevent corrosion and preserves its aesthetic qualities.

Q4: Are wire mesh expanded metals customizable?

Absolutely. Wire mesh expanded metals can be tailored in size, thickness, and pattern to meet the specific needs of various industrial and commercial applications.

Q5: What industries benefit most from wire mesh expanded metal?

Industries such as construction, transportation, agriculture, and manufacturing rely on wire mesh expanded metal for its strength, versatility, and durability in fencing, filtration, reinforcement, and safety guarding.

Post time: Aug . 05, 2025 14:50