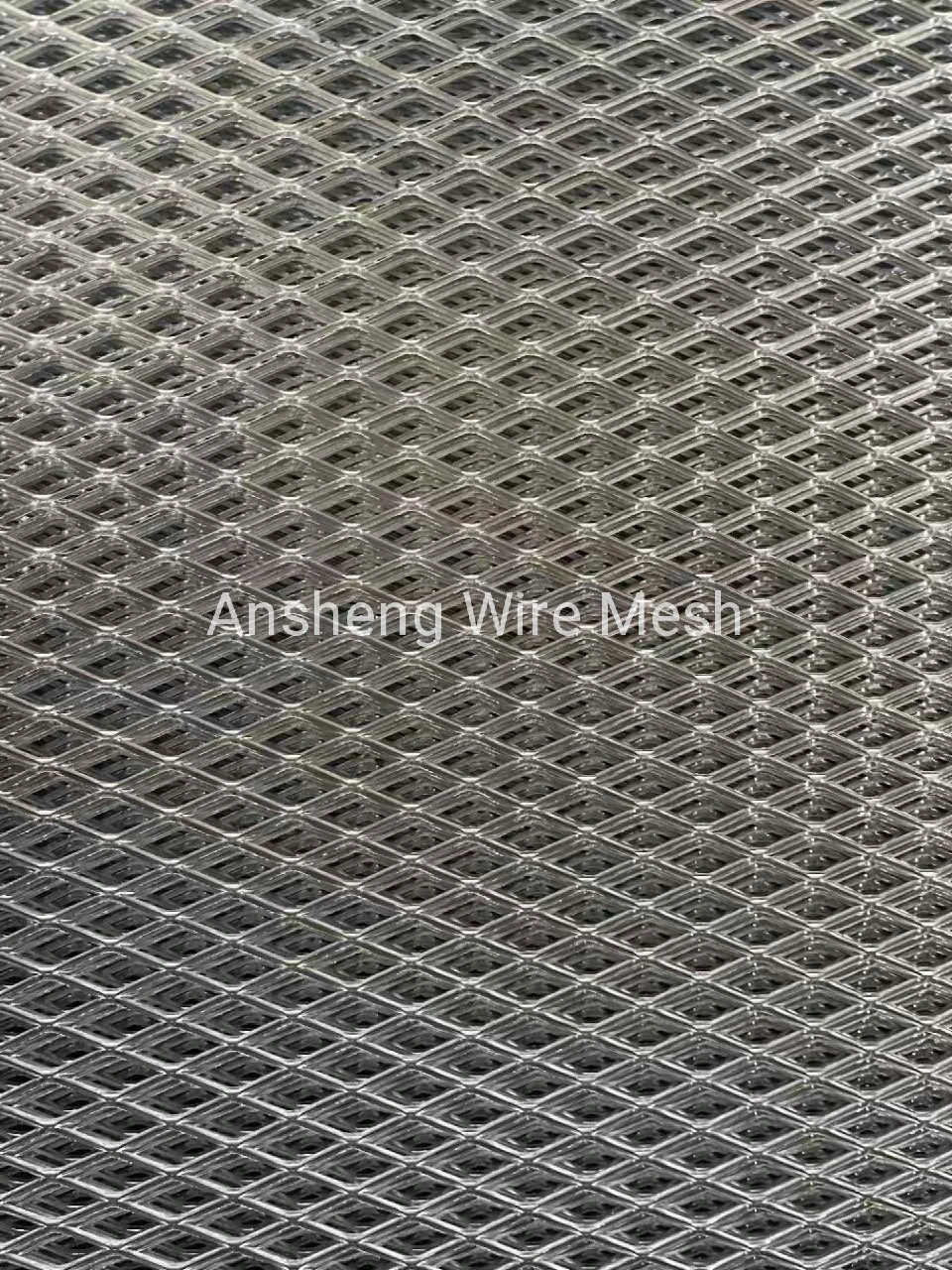

Expanded metal mesh is an indispensable material across industries, offering unparalleled strength, versatility, and cost-effectiveness. Whether used in construction, security fencing, or architectural design, understanding the factors that influence the expanded metal mesh price can help buyers make informed decisions that maximize both budget and performance. This guide delves into the critical aspects of expanded metal products, offering insights on purchasing strategies and market trends, ensuring you get the best value whether you are looking to buy expanded metal for a small project or large-scale industrial use.

Factors Influencing the Expanded Metal Mesh Price in Today’s Market

One key to smart purchasing is knowing what drives the expanded metal mesh price. Several variables contribute, including material thickness, mesh size, and surface finish. Heavier gauge metals generally cost more but provide greater durability and strength. The dimensions of the mesh openings also affect pricing—smaller openings typically require more material and labor, raising the cost. Additionally, surface treatments such as galvanizing or powder coating to resist corrosion influence the final price. Market demand and raw material costs also fluctuate, making it essential to monitor pricing trends if you plan to buy expanded metal regularly or in bulk.

The Advantage of Understanding the 4x8 Expanded Metal Price for Project Budgeting

When planning projects, especially those requiring standard sheet sizes, awareness of the 4x8 expanded metal price is crucial. This common sheet size is widely used because it offers convenience and compatibility with many fabrication and installation processes. The cost for a 4x8 sheet will vary depending on the metal type, thickness, and mesh pattern, but its popularity often means better availability and competitive pricing. Buyers should compare prices from multiple suppliers to ensure they receive a fair deal. Strategic purchasing of the 4x8 expanded metal price sheet size can result in significant savings while ensuring the right fit for structural or decorative applications.

How the Expanded Mesh Price Reflects Quality and Application Versatility

It is important to note that the expanded mesh price does not merely reflect cost but also the quality and intended use of the product. Higher-priced meshes are usually fabricated from premium materials such as stainless steel or aluminum, which offer superior corrosion resistance and strength. These meshes are ideal for demanding applications in harsh environments or architectural projects where aesthetics matter. Conversely, more affordable meshes made from mild steel suit temporary installations or indoor applications. Understanding the balance between cost and performance when considering the expanded mesh price ensures that buyers get the right material without overpaying for unnecessary features.

Strategic Tips for Buyers Looking to Buy Expanded Metal Efficiently

Purchasing expanded metal mesh requires careful consideration to balance quality, quantity, and price. One should first identify the exact specifications needed for their project, including gauge, mesh pattern, and sheet size. Establishing clear requirements helps prevent overbuying or selecting the wrong type of mesh. It’s also beneficial to request quotes from multiple vendors, as competition often drives better pricing. Bulk purchases typically result in lower expanded metal mesh price per unit, so consolidating orders can be cost-effective. Buyers should also inquire about delivery options and lead times to align procurement with project schedules, ensuring that the materials arrive on time without incurring storage costs.

Understanding the Impact of the Price of Expanded Metal on Project Feasibility

The overall price of expanded metal can have a substantial impact on project feasibility, especially for large-scale industrial or commercial developments. The cumulative cost of materials must be factored into the total budget alongside labor and installation expenses. Choosing the right grade and thickness is essential—overspending on unnecessarily heavy mesh can inflate costs without proportional benefits, while opting for a lower-grade material might compromise durability and safety. By evaluating the price of expanded metal in conjunction with project requirements, stakeholders can make balanced decisions that optimize performance and cost efficiency, contributing to successful project completion within budget.

Comparing Market Prices for Expanded Metal

Comparing prices across different suppliers and regions can reveal significant variations in the expanded metal mesh price. Factors such as local availability, import tariffs, and supplier specialization affect quotes. Buyers should consider total costs including shipping, handling, and any custom fabrication fees. Leveraging market research tools and building relationships with reliable suppliers can unlock competitive pricing and better service, enabling smarter procurement decisions.

Material Selection and Its Effect on Pricing

The choice of metal—whether steel, aluminum, or stainless steel—directly influences the expanded metal mesh price. Steel is generally more affordable but less resistant to corrosion unless treated. Aluminum offers a lightweight alternative with natural corrosion resistance but at a higher price point. Stainless steel commands the highest price due to its strength and longevity. Understanding the trade-offs between cost and material properties is vital to selecting the right mesh for specific environmental conditions and load requirements.

Expanded Metal Mesh Price FAQs

To further assist buyers in navigating the market, here are answers to some of the most common questions about expanded metal mesh price and purchasing:

What factors most affect the expanded metal mesh price?

Material type, thickness, mesh size, surface treatment, and market demand are the main drivers of price variation.

Is buying expanded metal in bulk more cost-effective?

Yes, bulk purchases usually reduce the per-unit cost and may also lower shipping expenses.

How do I know which expanded metal type fits my project?

Assess your project’s strength, durability, and environmental exposure requirements before selecting the metal type and mesh pattern.

Does the 4x8 expanded metal price differ much from other sizes?

The 4x8 sheet is a standard size and often competitively priced due to its popularity, but prices vary by material and specifications.

Can I get customized expanded metal mesh?

Many manufacturers offer custom sizes and patterns, though this may affect the overall price and lead time.

By understanding these factors and staying informed, buyers can make confident, cost-effective decisions that meet their needs precisely.

Post time: Aug . 05, 2025 14:48