Nickel has good chemical stability and can resist corrosion from various corrosive media such as acids, alkalis, and salts. It can maintain stable performance in harsh chemical environments and has a long service life.

At the same time, it also has excellent high temperature resistance, which can maintain good strength and stability in high temperature environments, withstand high temperatures without deformation or melting, and is suitable for high-temperature work scenarios.

And in chemical reactions, pure nickel woven wire mesh is not prone to chemical reactions with other substances, and can serve as a stable structural material or carrier, ensuring the safety of the production process and the stability of product quality.

In the field of filtration, it is used for gas and liquid filtration under corrosive environmental conditions such as acid and alkali, as well as other medium separation, such as filtering corrosive liquids and gases in the chemical and petroleum industries, removing impurities and solid particles;

In battery manufacturing, it can be used as an electrode material for batteries, providing the functions of current conduction and carrying electrochemical reactions, as well as improving the cycle life and charge discharge performance of batteries;

In the field of electronics, it is used for electromagnetic shielding, anti-static and thermal management in electronic products, and can also be used as a substrate for electric heating elements such as heating wires and electric heating plates;

In chemical catalysis, it can be used as a catalyst carrier for catalytic reactions, especially in hydrogen production by electrolysis of water, and its electrode performance is very stable;

It also plays an important role in high-tech fields such as aerospace and shipbuilding, as well as in the alkali production industry, chlor alkali chemical industry, and organic chloride production;

It can also be used to manufacture protective masks, gloves, and other protective equipment, providing protection and breathability.

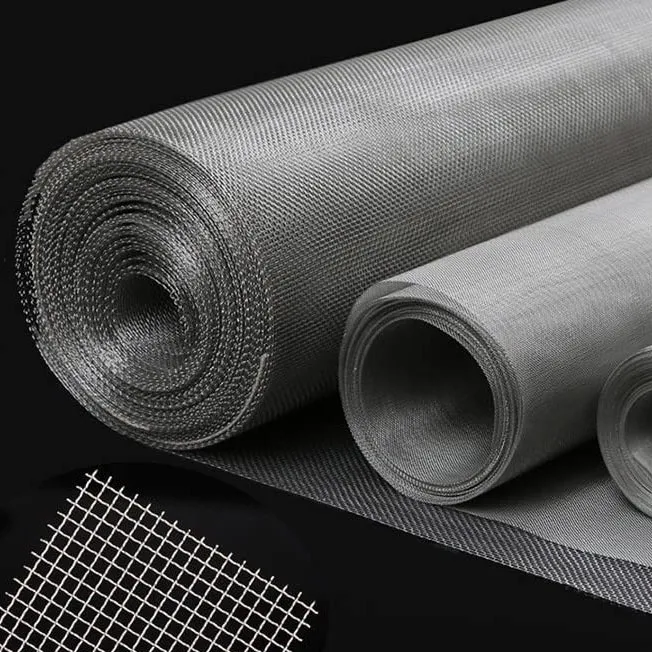

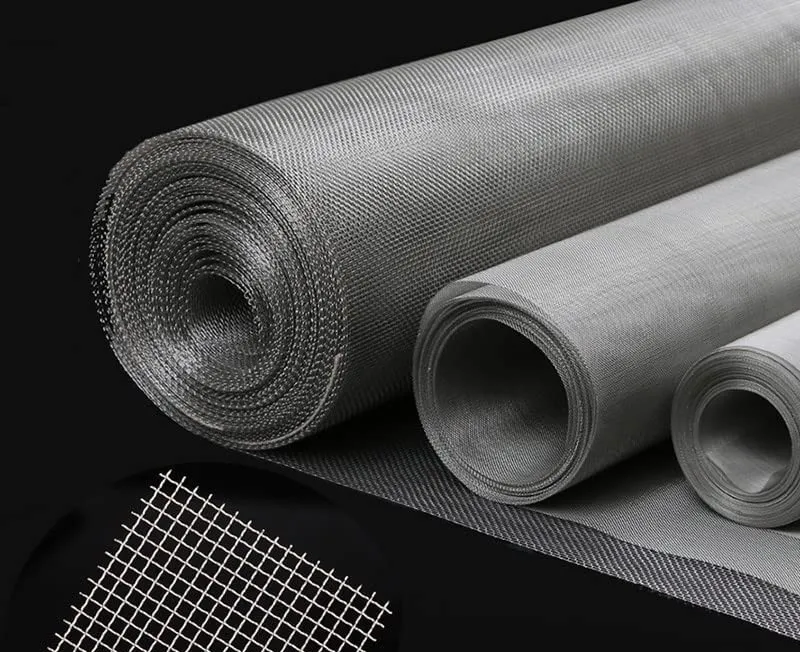

Our company's nickel mesh uses high-quality pure nickel raw materials with high nickel content, ensuring excellent product performance. During the production process, strict quality control and the use of advanced technology ensure the high quality of nickel mesh.

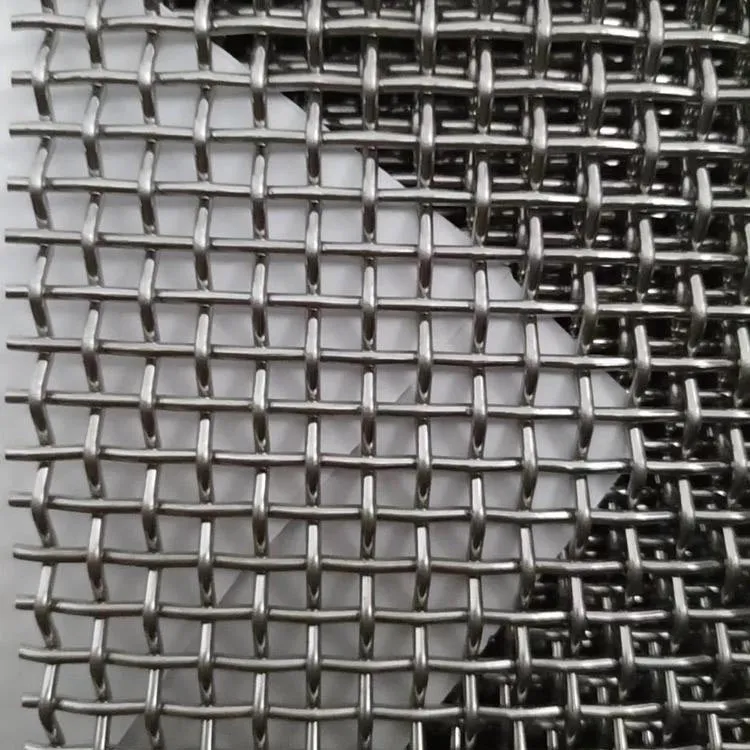

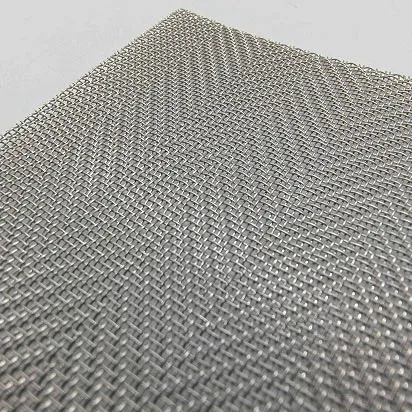

The commonly used specifications are as follows.

|

mesh |

Wire diameter(mm) |

|

10 |

0.5 |

|

20 |

0.35 |

|

35 |

0.18 |

|

40 |

0.15/0.16/0.18 |

|

50 |

0.15 |

|

60 |

0.12 |

|

60 |

0.15 |

|

80 |

0.10 |

|

100 |

0.095 |

|

100 |

0.07 |

|

120 |

0.07 |

|

140 |

0.07 |

|

140 |

0.05 |

|

180 |

0.05 |

|

200 |

0.05 |

|

300 |

0.03 |

|

400 |

0.028 |

In addition to these standard specifications, our inventory is also stocked with a wide variety of other specifications. And if you still can't find what you need, we're more than happy to offer customized services to precisely meet your unique requirements.