In the demanding world of plastic and polymer processing, filtration is the foundation of quality. Whether you're producing film, fiber, or sheet, maintaining product purity and process consistency is non-negotiable. That's where advanced extrusion screen systems come into play. These vital components act as the first line of defense, ensuring contaminants are effectively removed before they impact final product performance.

The Role of extruder screens in Delivering Superior Melt Filtration

Modern plastic processing relies heavily on extruder screens to filter out foreign particles, gels, and unmelted resin. Positioned between the extruder and die, these screens prevent contaminants from reaching the mold, safeguarding the structural integrity and surface finish of the extruded product. Whether used in single-layer or multi-layer configurations, their design directly affects filtration precision and flow resistance. Fine mesh screens provide excellent filtration but can increase back pressure—making the right balance essential.

Custom screen extrusion Frames for Consistency and Clean Output

One of the critical innovations in recent years is the use of modular screen extrusion frames. These aluminum or stainless-steel housings hold screen packs in place and allow for easy replacement during operation. Their durability, combined with tight fit and seal design, reduces melt leakage and contamination risk. Engineers appreciate the way screen frames contribute to operational uptime, as they reduce changeover times and enhance repeatability during high-output production runs.

Advanced extrusion screens Engineering Optimizes Flow and Pressure

It’s not just about filtration—it’s about smart flow management. High-quality extrusion screens are engineered with multiple mesh layers, spot-welded or sintered together, to optimize polymer flow and distribute pressure evenly. This prevents localized screen failure and improves the consistency of the melt. Screen packs can also be customized in terms of mesh size, diameter, and configuration, allowing process engineers to fine-tune the system according to the resin and end-product requirements.

Selecting the Right extruder screens suppliers for Your Process Goals

Working with reliable extruder screens suppliers is key to maintaining a consistent supply of quality components. A good supplier will offer screens with minimal tolerance variation, corrosion resistance, and tailored filtration ratings. When evaluating vendors, look for technical support, customization capabilities, and material traceability. Consistent screen performance reduces maintenance costs and enhances production yield over time.

Optimize Your Equipment with Rugged screen extrusion Assemblies

If your operation demands fast throughput with minimal interruptions, investing in premium screen extrusion assemblies will pay dividends. These systems are built for high thermal stability and mechanical endurance. They integrate seamlessly with most extrusion lines, from blown film to sheet extrusion, and they are available in custom sizes. A well-designed assembly boosts production consistency while helping to reduce the rate of screen clogging and subsequent shutdowns.

Reinforce Output Quality with Durable extrusion screens Structures

For applications that process recycled or mineral-filled materials, robust extrusion screens are essential. These heavy-duty screens are often reinforced with high-tensile wire mesh or stainless steel to handle abrasive contamination. Their layered construction ensures longer service life and reduces the frequency of replacement, especially in harsh processing environments. Selecting a reinforced screen design can also reduce scrap rates and improve overall product quality.

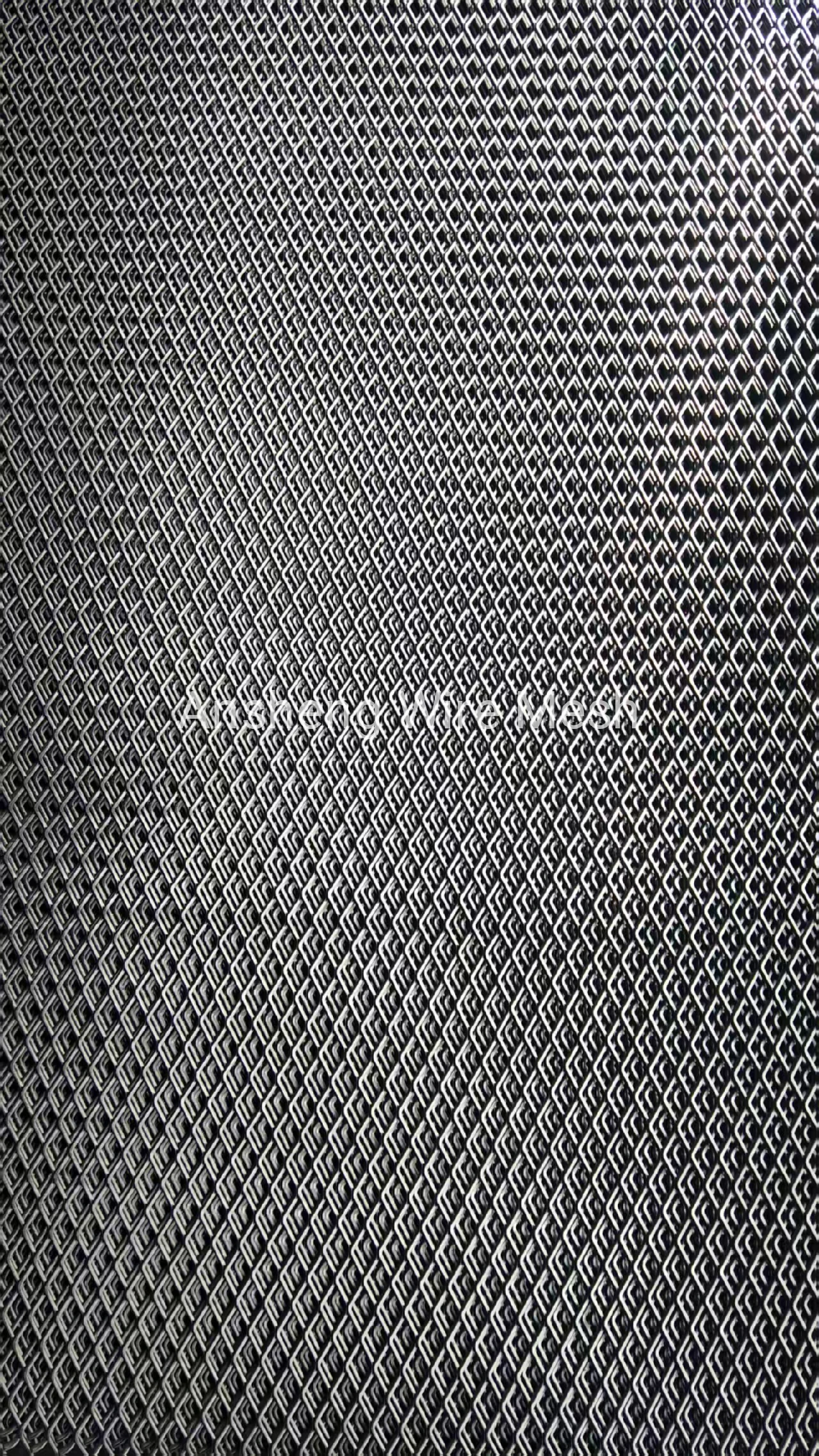

Innovative rim mesh Solutions for Custom Filtration Demands

For unique die geometries and specialty extrusion processes, rim mesh filters provide a flexible and customizable alternative. These mesh screens, bordered with a steel or aluminum ring, maintain dimensional stability and enable secure placement. They’re especially useful in applications where precise filtration is needed within confined geometries, such as small-diameter tubing or high-tolerance profiles.

Balancing Flow Dynamics with Modular screen extrusion Systems

Efficient screen extrusion systems go beyond filtration—they are engineered for optimal melt distribution, pressure balance, and material throughput. The modular nature of these systems allows manufacturers to easily replace or upgrade individual components, adapting quickly to changes in resin grade or product specifications. As sustainability goals become increasingly important, these systems also contribute to energy efficiency by maintaining lower back pressure and reducing waste.

Partnering with Leading extruder screens suppliers Ensures Long-Term Success

Ultimately, the quality of your output reflects the quality of your inputs—and that includes your extruder screens suppliers. Trusted manufacturers offer not only precision mesh components but also support in selecting the best configurations for your applications. Their insight into material compatibility, flow behavior, and screen longevity ensures that you get more than just a product—you get a partner in process improvement.

Extruder Screens and Screen Extrusion FAQs

What materials are commonly used for extruder screens?

Most extruder screens are made from stainless steel due to its corrosion resistance, heat tolerance, and strength. For specialized applications, materials like nickel alloys or titanium may be used.

How often should extrusion screens be changed?

Screen change intervals depend on the material processed and contamination levels. For clean materials, screens may last days, while recycled or filled resins may require changeouts every few hours.

Can screen extrusion systems be customized for unique applications?

Absolutely. Modular screen extrusion systems can be tailored in size, shape, mesh configuration, and housing design to suit a wide range of extrusion applications.

What’s the difference between rim mesh and standard screen packs?

Rim mesh screens have a rigid metal border that improves screen integrity and handling, especially in high-pressure or complex dies. Standard packs are typically mesh layers spot-welded or sintered without a frame.

Why is it important to work with specialized extruder screens suppliers?

Reputable extruder screens suppliers provide consistent quality, traceable materials, and expert technical guidance—ensuring your filtration system remains reliable and efficient across production cycles.

Post time: Aug . 05, 2025 14:46