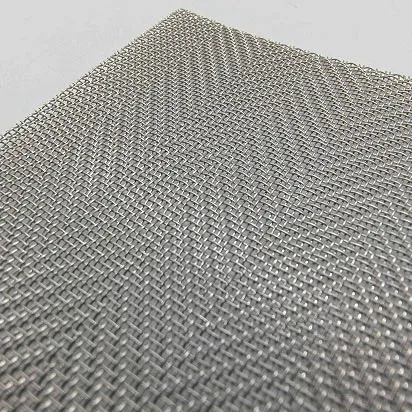

Our high-quality stainless steel wire mesh---herringboneweave

-Mesh surface: The overall surface is flat, without any undulations or distortions, the mesh surface is clean, and there is no oil stains or impurities attached.

-Color: The color is uniform and consistent, presenting a silver white bright color unique to stainless steel, without any signs of yellowing, blackening, rusting, etc.

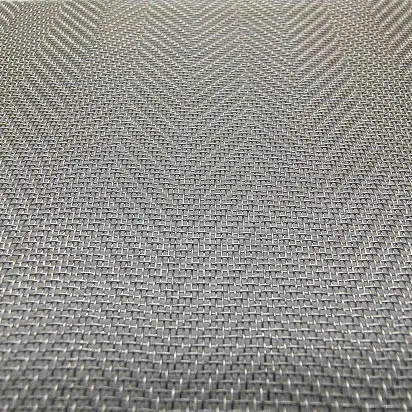

-Wire diameter and mesh size: The wire diameter is uniform with minimal error; The mesh holes are in a regular herringbone shape, with uniform size, neat arrangement, and no deformed or skewed mesh holes.

-Tight weaving: Stainless steel wires are tightly woven and firmly connected, without looseness or detachment. Even if pulled hard, there will be no sliding between wires.

-Mesh edge treatment: The mesh edge is finely processed, neat and smooth, without burrs or flying edges, to avoid scratching the user or other objects during use.

-Strength and toughness: It has high strength and good toughness, and can withstand a certain degree of tension, bending, and impact without fracture or deformation, maintaining a stable structure in long-term use.

-Corrosion resistance: It has excellent corrosion resistance and can resist corrosion for a long time under different environmental conditions, such as humidity, acidity, alkalinity, and other corrosive environments. It is not easy to rust or be corroded, ensuring the service life and performance of the net.

Advantages of herringbone weavingmesh:

-Directional diversion characteristics: The herringbone pattern guides the fluid through the mesh in a spiral shape, reducing the probability of blockage. When the liquid flows through the herringbone mesh, the herringbone pattern forces the water flow in a specific direction. Under the guidance of herringbone patterns, passing through the mesh in a spiral or regular diagonal direction can effectively avoid the formation of turbulence and dead zones in local areas, making the filtration process smoother.

-Dynamic self-cleaning ability: Particles are more easily washed away when rolling on the mesh surface, especially suitable for handling liquids containing fiber impurities. When the water flows along the herringbone pattern, it generates a scouring force on the impurities attached to the mesh surface. For impurities such as fibers and particles that are prone to clogging the mesh, directed flow of water can carry them away from the mesh surface, achieving self-cleaning effect.

-Wire diameter adaptability: Using thicker wire diameters within the same mesh size results in higher tensile strength and pressure resistance. Taking 30 mesh as an example, herringbone mesh can use a wire diameter of 0.40mm, while plain mesh generally uses a wire diameter of 0.25mm. The thicker wire diameter greatly enhances the tensile strength of the herringbone mesh.

-Anti deformation ability: The herringbone structure maintains a flat mesh surface under high pressure difference and is suitable for frequent backwashing conditions (such as sewage treatment). Even after long-term use and frequent cleaning and maintenance, the herringbone mesh can still maintain good shape and filtering performance, greatly extending the service life of the filter and reducing replacement costs.

-High viscosity medium: The herringbone pattern can reduce liquid resistance (such as honey, etc.). The herringbone pattern can generate special shear force when passing through high viscosity medium. When high viscosity media such as honey and syrup flow through the herringbone mesh, the liquid comes into oblique contact with the grooves, and the herringbone structure cuts and divides the liquid in an orderly manner. This effectively reduces the viscous resistance inside the liquid, allowing the liquid to pass through the filter more smoothly.

Whether you are in search of a reliable filtration solution for industrial processes or domestic use, our stainless steel filter mesh is your optimal choice. With its superior quality, excellent performance, and wide range of applications, it is bound to meet your specific requirements.

The commonly used specifications are as follows.

|

Mesh |

Wire diameter (mm) |

|

30 |

0.4 |

|

40 |

0.3 |

|

50 |

0.16 |

|

60 |

0.12 |

In addition to these standard specifications, our inventory is also stocked with a wide variety of other specifications. And if you still can't find what you need, we're more than happy to offer customized services to precisely meet your unique requirements.