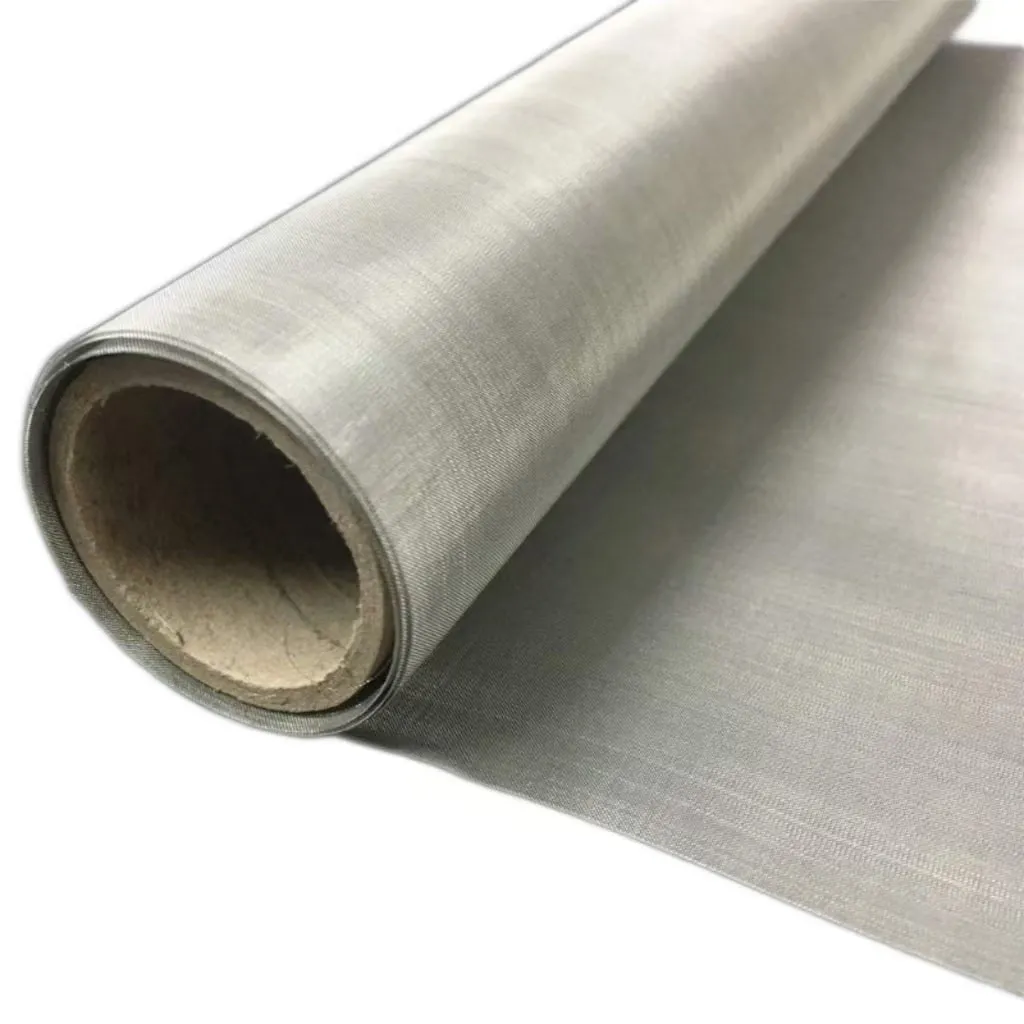

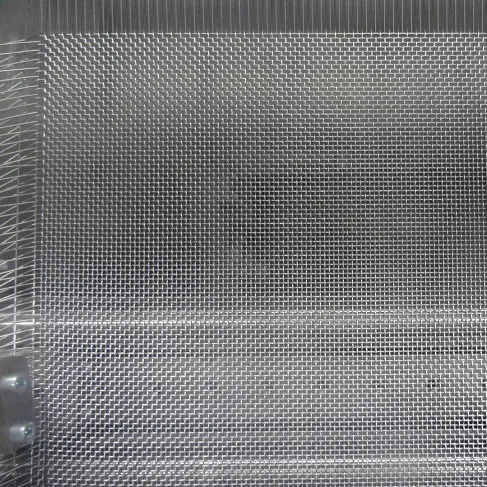

Our high-quality stainless steel wire mesh---plain weave

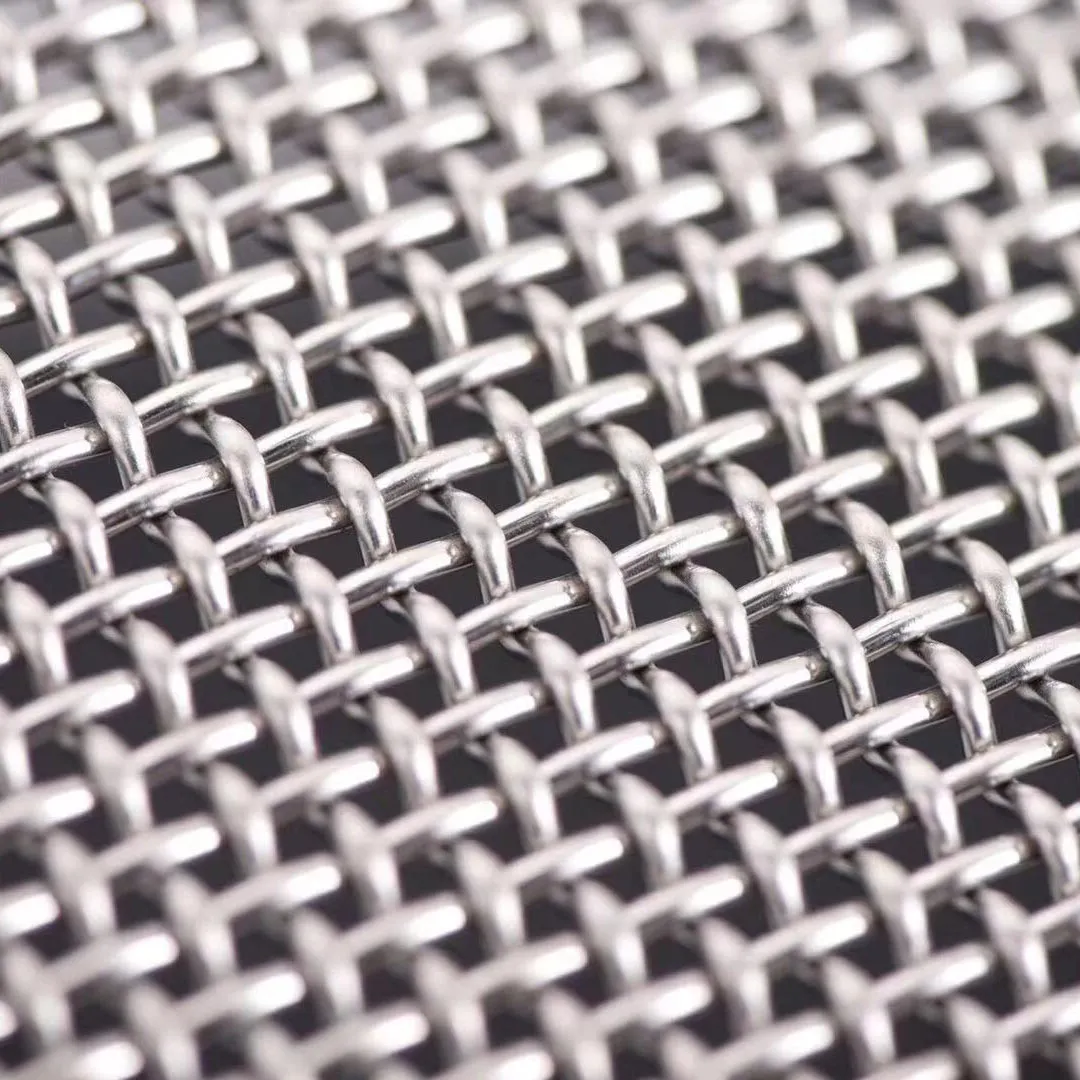

-Choose high-quality stainless steel materials such as 304, 316, etc., which have good corrosion resistance, oxidation resistance, and high strength, and can adapt to different environments.

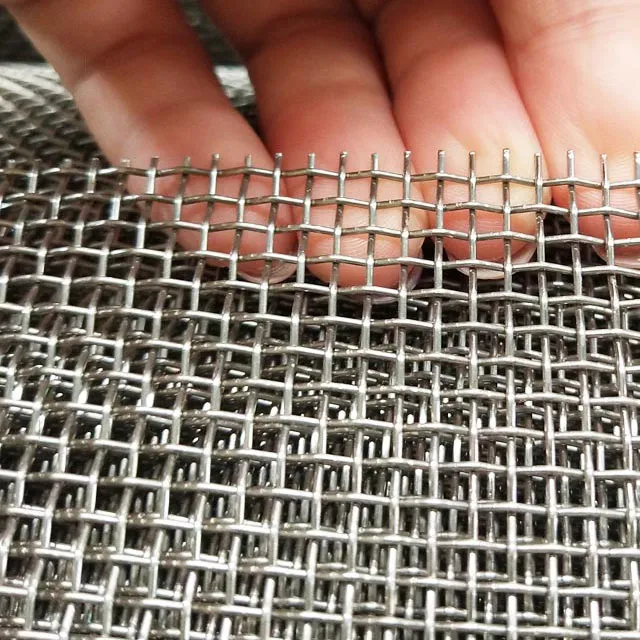

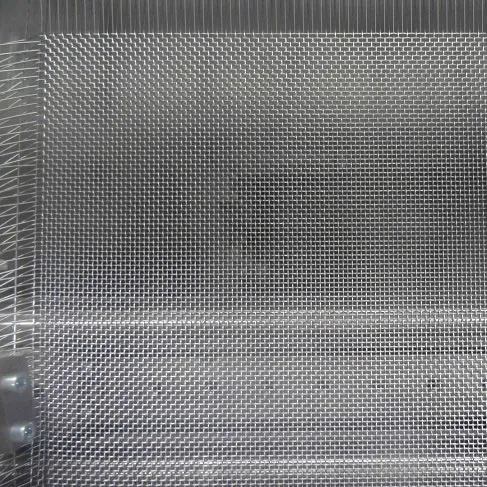

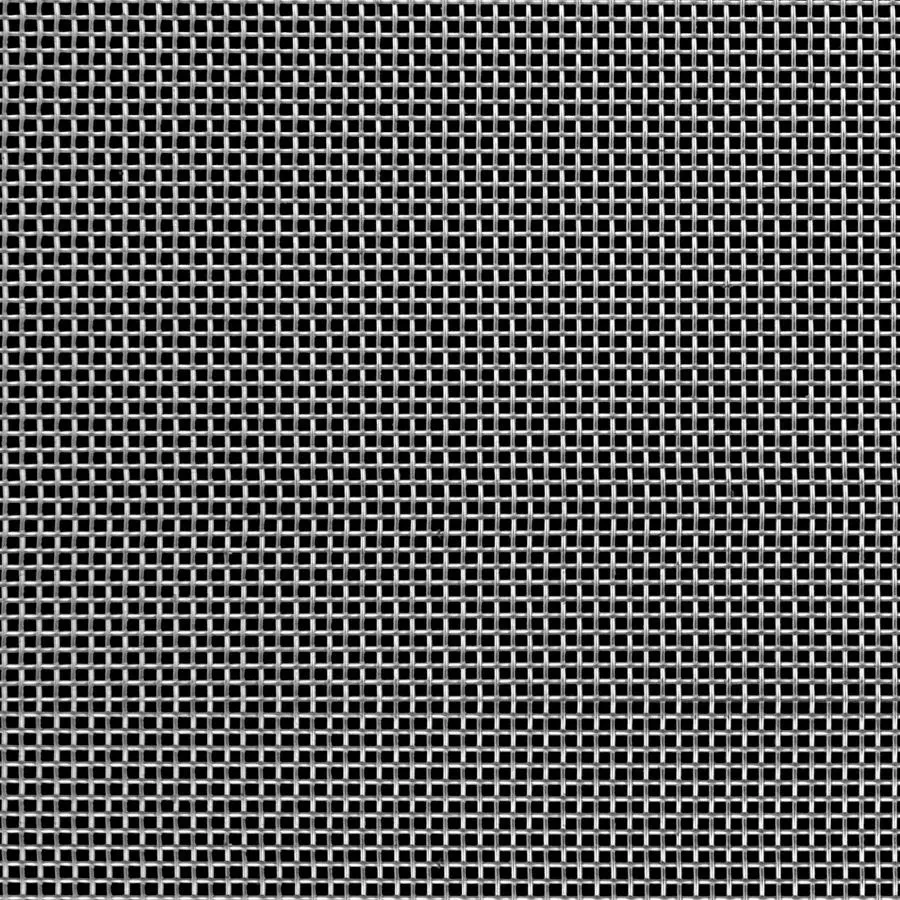

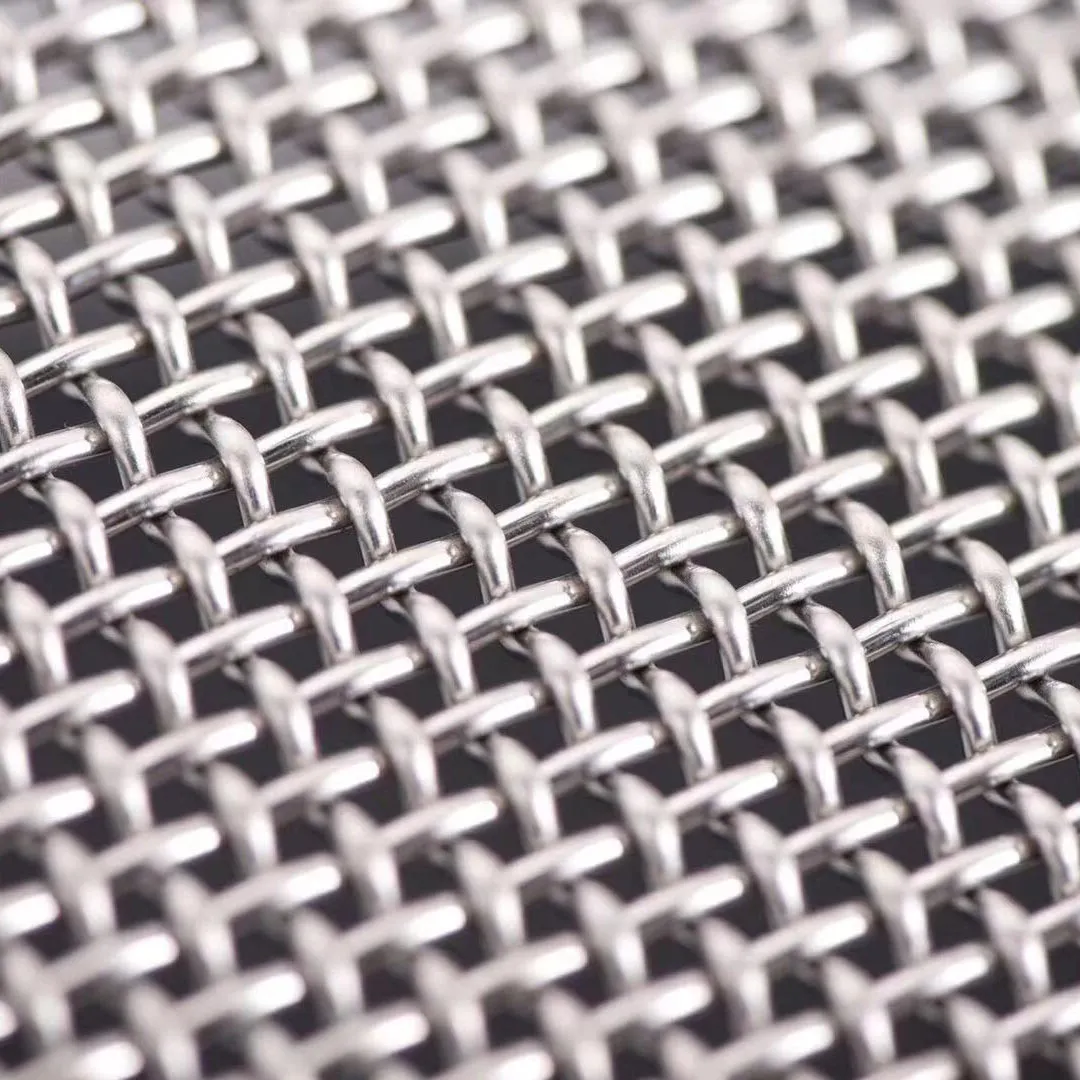

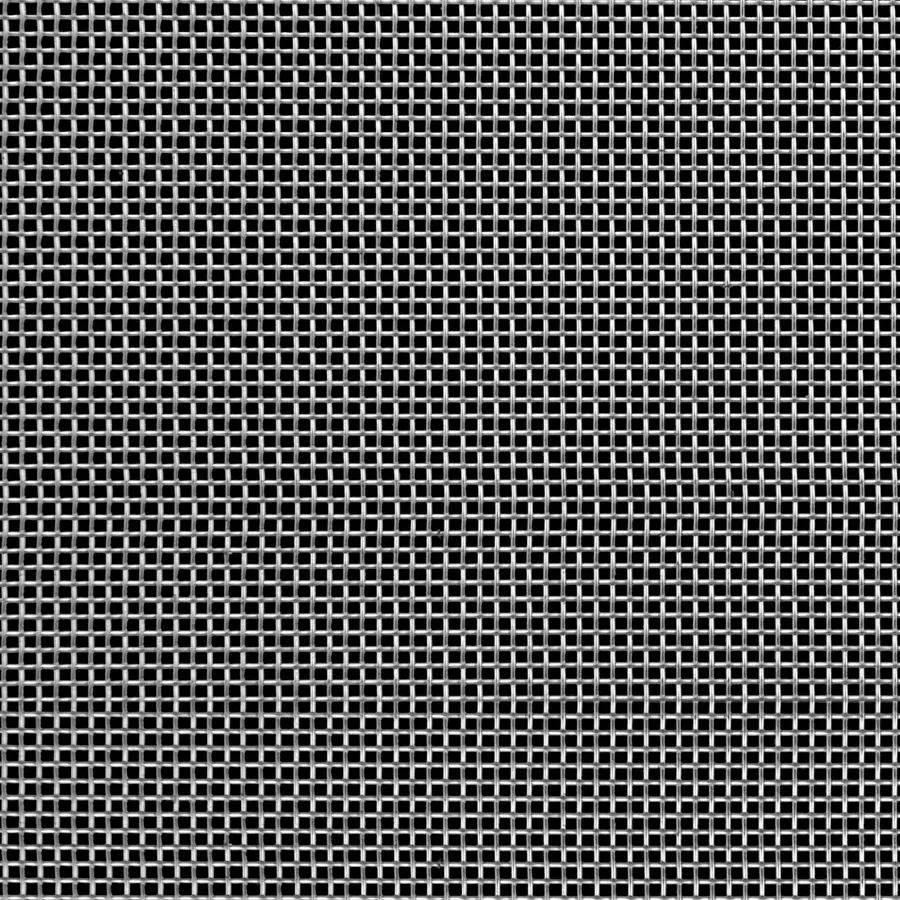

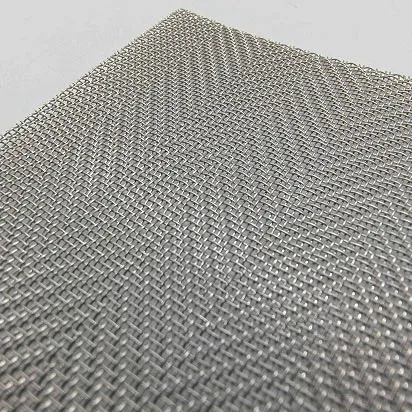

-The mesh surface is flat, without obvious bumps, wrinkles or deformations, the overall structure is uniform, the wire diameter is consistent, the mesh size is uniform and meets the standard requirements to ensure the accuracy of filtration, screening and other functions.

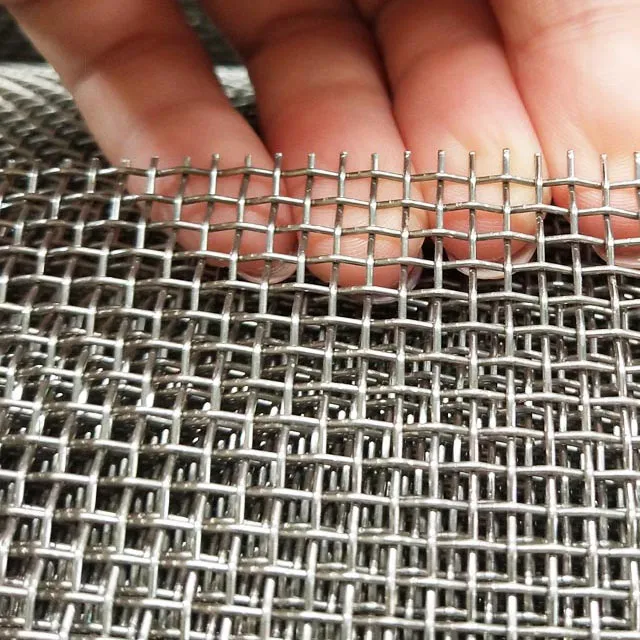

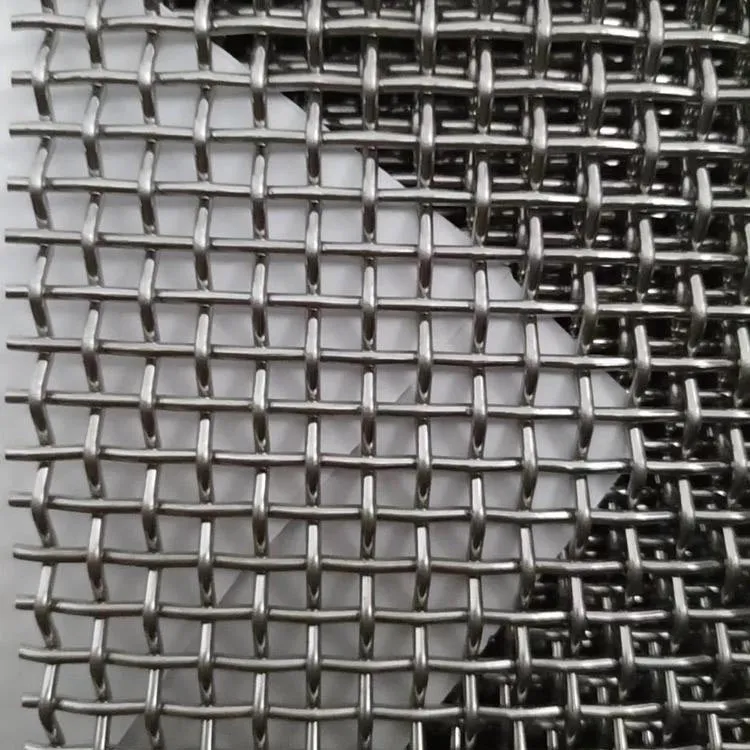

-The weaving is tight, the connection between the steel wires is firm, without looseness or detachment, and can withstand large tensile and compressive forces during use, making it less prone to damage.It can stably perform filtration functions even under high - pressure and high - flow working conditions.

Filtration Precision: With a wide range of mesh sizes available, it can precisely intercept impurities of different particle sizes, from coarse to fine filtration, meeting various filtration requirements and ensuring accurate and reliable filtration results.

Cleaning and Maintenance: The smooth surface of the stainless steel material prevents impurities from adhering easily. It is easy to clean and can be reused, effectively reducing usage costs and enhancing filtration efficiency.

Application Areas

It is used for the purification of oil products and chemical raw materials in the petrochemical industry; ensures product purity in the food and beverage industry; contributes to pharmaceutical production in the pharmaceutical field; and purifies water quality in water treatment. It is a key element for various industries to ensure product quality and stable production.In the rubber and plastic industries, it can be used for the filtration of recycled materials or raw materials.

Advantages of plain weave mesh:

In terms of structural strength

The plain weave structure is the most compact, and is less prone to relative displacement when subjected to external forces. The overall structural stability is good, such as when filtering high-pressure fluids, it can better maintain its shape and is less prone to deformation. The force distribution of the wire is uniform, and there are no weak points of local force, which makes the strength of the plain weave mesh consistent in all directions. It can uniformly withstand tensile and compressive forces from different directions, and can be applied in situations where uniform strength requirements are needed.

In terms of filtering performance

The plain weave mesh has a regular shape and uniform size, which can accurately control the filtration particle size and has a good interception effect on small particles. It can be used in industries that require extremely high filtration accuracy, such as high-precision liquid filtration in the electronics industry. Due to the uniform mesh size, there will be no situation where some areas are filtered too quickly or too slowly due to different mesh sizes, and the filtering efficiency is stable, ensuring the consistency and reliability of the filtering process.

In terms of appearance

The plain weave mesh surface is very flat and smooth, with a neat and beautiful appearance. It not only gives a good visual impression, but also facilitates the smooth transportation of materials on the mesh surface in practical applications, reducing material residue and accumulation.

Cleaning aspect

The flat surface and regular mesh make it difficult for impurities to remain, making it easier to wash away impurities attached to the mesh surface during cleaning. The maintenance cost is low, and it can be reused, extending its service life.

Whether you are in search of a reliable filtration solution for industrial processes or domestic use, our stainless steel filter mesh is your optimal choice. With its superior quality, excellent performance, and wide range of applications, it is bound to meet your specific requirements.

The commonly used specifications are as follows.

|

Mesh |

Wire diameter (mm) |

|

10 |

0.6 |

|

15 |

0.5 |

|

20 |

0.4 |

|

30 |

0.3 |

|

40 |

0.2 |

|

60 |

0.16 |

|

80 |

0.12 |

|

100 |

0.1 |

|

120 |

0.08 |

|

150 |

0.06 |

|

180 |

0.06 |

|

200 |

0.05 |

|

250 |

0.04 |

|

300 |

0.03 |

|

400 |

0.018 |

|

500 |

0.015 |

In addition to these standard specifications, our inventory is also stocked with a wide variety of other specifications. And if you still can't find what you need, we're more than happy to offer customized services to precisely meet your unique requirements.