Expanded metal mesh has become an indispensable material in modern architecture and engineering, offering a unique combination of strength, flexibility, and aesthetic appeal. Its distinctive diamond-shaped patterns not only enhance the visual aspects of structures but also provide functional benefits such as ventilation, light diffusion, and structural reinforcement. As industries continue to seek materials that balance performance with design, expanded metal mesh stands out as a solution that meets diverse requirements across various applications.

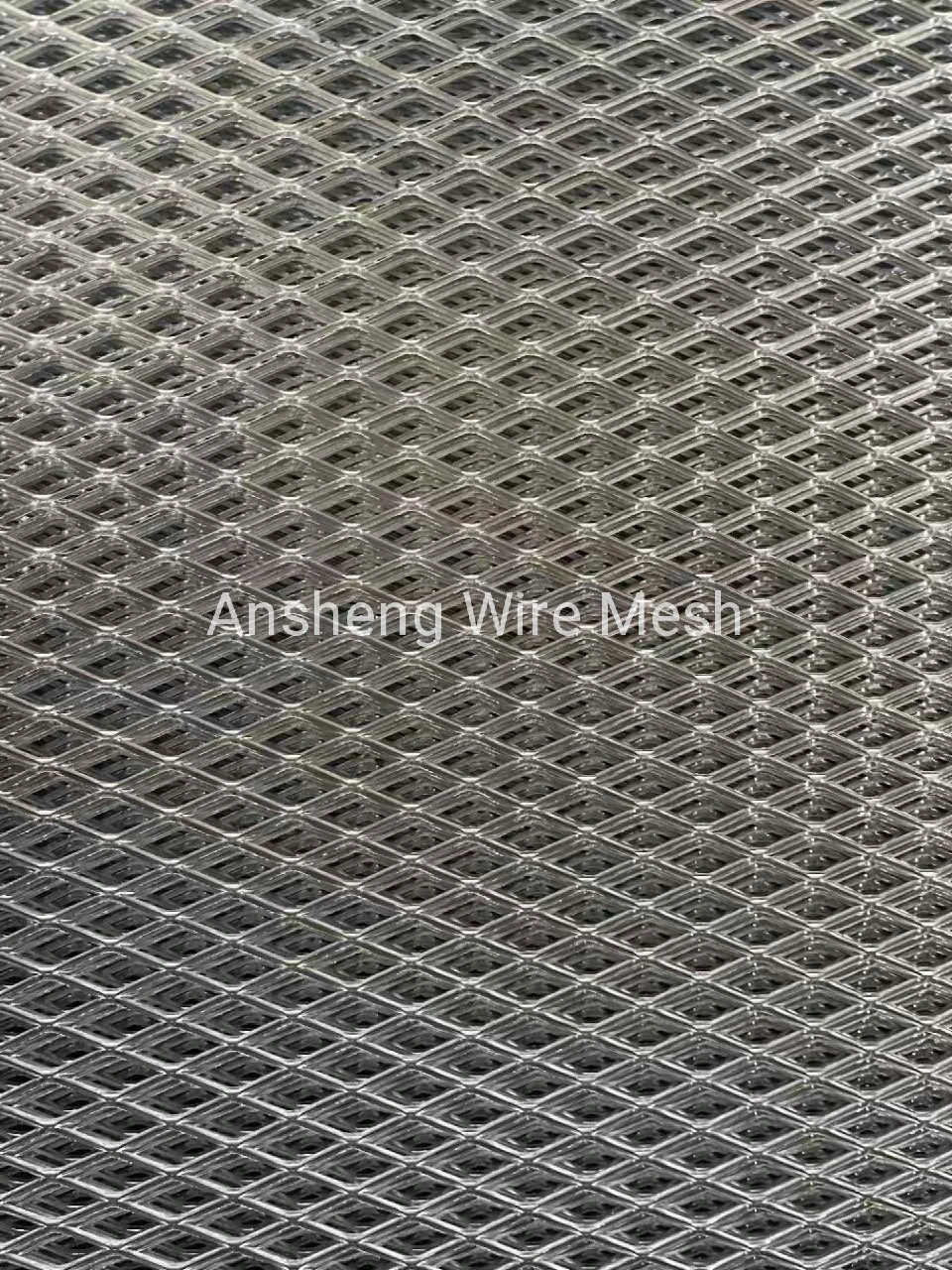

Understanding the Range of Expanded Metal Mesh Sizes

The versatility of expanded metal mesh is largely attributed to the variety of sizes available, catering to specific project needs. Standard mesh sizes are defined by the dimensions of the diamond-shaped openings, typically measured by the short way of the diamond (SWD) and the long way of the diamond (LWD). These measurements determine the mesh's open area, affecting factors like weight, strength, and airflow. For instance, a mesh with a larger open area allows for better ventilation and light transmission, making it ideal for applications such as sunshades or facades. Conversely, meshes with smaller openings provide enhanced strength and are suitable for security screens or walkways. By selecting the appropriate mesh size, designers and engineers can optimize the material's performance for their specific applications.

Exploring the Fundamentals: What Is Expanded Metal Mesh

At its core, expanded metal mesh is created by simultaneously slitting and stretching a sheet of metal, transforming it into a mesh with uniform openings. This process not only enhances the material's strength but also ensures that it remains a single, continuous piece without any welds or joints. The resulting mesh exhibits a high strength-to-weight ratio, making it both durable and lightweight. Additionally, the open design facilitates excellent airflow and light passage, which is particularly beneficial in applications requiring ventilation or filtration. The absence of welds also means fewer points of weakness, contributing to the mesh's overall structural integrity.

Utilizing the Expanded Metal Size Chart for Precise Selection

Selecting the appropriate expanded metal mesh for a project requires a thorough understanding of the available specifications, which is where the expanded metal size chart becomes invaluable. This chart provides detailed information on various mesh patterns, including SWD, LWD, strand width, and thickness. By consulting the size chart, professionals can match the mesh's characteristics to their specific needs, ensuring optimal performance. For example, a project requiring high load-bearing capacity would benefit from a mesh with thicker strands and smaller openings, while a design emphasizing aesthetics might opt for a mesh with larger openings and a finer strand width. The size chart serves as a comprehensive guide, facilitating informed decisions in material selection.

Selecting the Right Expanded Metal Mesh Material for Your Application

The choice of material for expanded metal mesh significantly influences its performance, durability, and suitability for specific environments. Common materials include carbon steel, stainless steel, aluminum, and copper, each offering distinct advantages. Carbon steel meshes are known for their strength and are often used in industrial applications. Stainless steel provides excellent corrosion resistance, making it ideal for outdoor or marine environments. Aluminum meshes are lightweight and resistant to corrosion, suitable for applications where weight is a concern. Copper meshes offer superior electrical conductivity and are used in specialized applications. By understanding the properties of each material, professionals can select the most appropriate mesh to meet their project's specific requirements.

Insights into Expanded Metal Mesh Production Techniques

The production of expanded metal mesh involves a precise process of slitting and stretching metal sheets to create the desired mesh pattern. This method ensures that the mesh is formed from a single piece of material, enhancing its strength and eliminating the need for welding. Advanced machinery allows for the customization of mesh patterns, sizes, and materials, catering to a wide range of applications. Quality control is paramount during production, with stringent checks to ensure consistency in mesh dimensions and structural integrity. Innovations in production techniques continue to expand the possibilities for using expanded metal mesh in various industries, from construction to automotive manufacturing.

Advantages of Diverse Expanded Metal Mesh Sizes in Design

The availability of various expanded metal mesh sizes offers designers and engineers the flexibility to tailor materials to specific functional and aesthetic requirements. Smaller mesh sizes provide enhanced strength and security, suitable for protective barriers or filtration systems. Larger mesh sizes allow for greater light and air passage, ideal for architectural facades or decorative elements. This versatility enables the integration of expanded metal mesh into diverse projects, balancing performance with visual appeal.

Innovations in Expanded Metal Mesh Production for Modern Applications

Recent advancements in expanded metal mesh production have led to the development of more precise and efficient manufacturing processes. These innovations allow for greater customization in mesh patterns and materials, meeting the evolving demands of modern applications. Enhanced production techniques also contribute to improved product quality, ensuring that the mesh meets stringent industry standards. As technology continues to advance, expanded metal mesh remains a dynamic and adaptable material in various sectors.

Expanded Metal Mesh FAQs

Q: What factors should be considered when selecting expanded metal mesh sizes?

A: Consider the application's requirements for strength, airflow, and aesthetics. The SWD and LWD dimensions, along with strand width and thickness, determine the mesh's performance characteristics.

Q: How does the material choice affect the performance of expanded metal mesh?

A: Different materials offer varying properties. For instance, stainless steel provides corrosion resistance, aluminum is lightweight, and carbon steel offers high strength. The choice depends on environmental conditions and specific application needs.

Q: Can expanded metal mesh be customized for unique applications?

A: Yes, manufacturers can produce custom mesh patterns, sizes, and materials to meet specific project requirements, ensuring optimal functionality and design integration.

Q: What maintenance is required for expanded metal mesh installations?

A: Maintenance depends on the material and environment. Generally, regular inspections and cleaning are recommended to ensure longevity and performance, especially in corrosive or high-traffic areas.

Q: Where can I find detailed information on expanded metal mesh specifications?

A: Refer to the expanded metal size chart provided by manufacturers, which includes comprehensive details on mesh dimensions, materials, and performance characteristics to guide selection.

Post time: Aug . 05, 2025 14:52