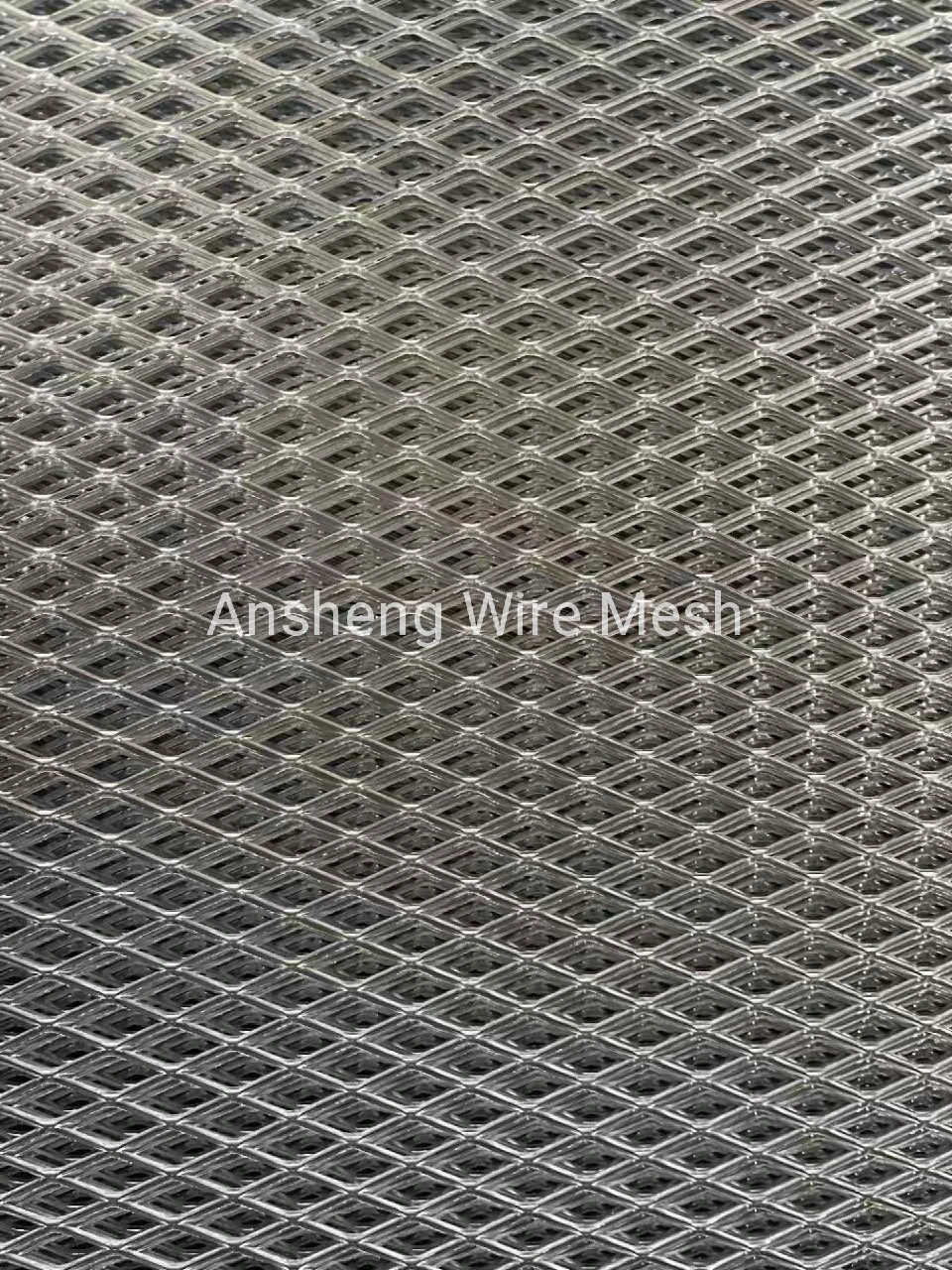

Stainless steel reverse dutch weave wire mesh, an essential filtration component in both industrial and daily life applications, is widely used across various fields due to its outstanding performance.

Material Characteristics: Made from high - quality stainless steel, it exhibits excellent corrosion resistance. It can withstand humid, acidic, alkaline and other complex environments, maintaining stable performance for a long time and extending its service life.

Based on the different usage environments and price considerations, we have a variety of stainless steel materials for you to choose from, including 201, 304, 316, 316L and other stainless steel materials.

Filtration Precision: With a wide range of mesh sizes available, it can precisely intercept impurities of different particle sizes, from coarse to fine filtration, meeting various filtration requirements and ensuring accurate and reliable filtration results.

Our wire mesh has extremely precise wire diameters and mesh numbers. We use computer-controlled machines to strictly control the production process, ensuring that the steel wire diameter is accurate to the standard value and the mesh number is evenly distributed. This provides a stable guarantee for your use. Every detail can withstand strict inspection.

Structural Advantages: Manufactured by precision weaving processes, the mesh surface is flat and the structure is sturdy, making it highly resistant to deformation. It can stably perform filtration functions even under high - pressure and high - flow working conditions.

Cleaning and Maintenance: The smooth surface of the stainless steel material prevents impurities from adhering easily. It is easy to clean and can be reused, effectively reducing usage costs and enhancing filtration efficiency.

Advantages of reverse dutch weaving mesh:

-Good load-bearing capacity: The structure of the reverse dutch weaving mesh gives it high strength and rigidity, capable of withstanding large weights and loads, suitable for conveying various materials, including heavy materials such as ore, coal, and building materials, ensuring that the conveyor belt will not deform or be damaged due to excessive load-bearing during operation.

-Excellent wear resistance: The reverse dutch weaving mesh will rub against various objects during operation, and it has good wear resistance, which can resist material wear and friction between the mesh and components such as rollers and idlers, prolong the service life of the conveyor belt, reduce replacement frequency, thereby improving production efficiency and reducing costs.

-Good dimensional stability: During the rubber processing, it may experience environmental changes such as high temperatures. The reverse dutch weaving mesh is stable in size at different temperatures and is not prone to thermal expansion and contraction. It can maintain the normal operation of the reverse dutch weaving mesh, prevent problems such as deviation and relaxation caused by dimensional changes, and ensure the continuity and stability of production.

-Smooth surface and non stick material: Rubber and plastic materials are prone to adhesion during transportation, while the reverse dutch weaving mesh has a smooth surface and is less likely to adhere. This can prevent materials from sticking to the reverse dutch weaving mesh, affecting product quality and transportation efficiency, reducing cleaning work, and improving production efficiency.

The reverse dutch weaving mesh is also divided into two types: RPD and TRD.Reverse Plain Dutch Weave(RPD) and Twilled Reverse Dutch Weave(TRD).

Whether you are in search of a reliable filtration solution for industrial processes or domestic use, our stainless steel filter mesh is your optimal choice. With its superior quality, excellent performance, and wide range of applications, it is bound to meet your specific requirements.

The commonly used specifications are as follows.

|

Mesh per inch Warp x weft |

Wire dia (mm) |

Wire dia (mm) |

Porosity (%) |

Thickness (mm) |

Weight |

Micron |

|

72x15 |

0.45 |

0.55 |

58 |

1.75 |

4.43 |

400 |

|

132x18 |

0.35 |

0.45 |

58 |

1.24 |

4.9 |

250 |

|

152x24 |

0.315 |

0.355 |

42 |

1.20 |

4.53 |

165 |

|

160x24 |

0.305 |

0.40 |

39 |

1.09 |

4.68 |

150 |

|

260x40 |

0.15 |

0.22 |

53 |

0.62 |

1.98 |

125 |

In addition to these standard specifications, our inventory is also stocked with a wide variety of other specifications. And if you still can't find what you need, we're more than happy to offer customized services to precisely meet your unique requirements.