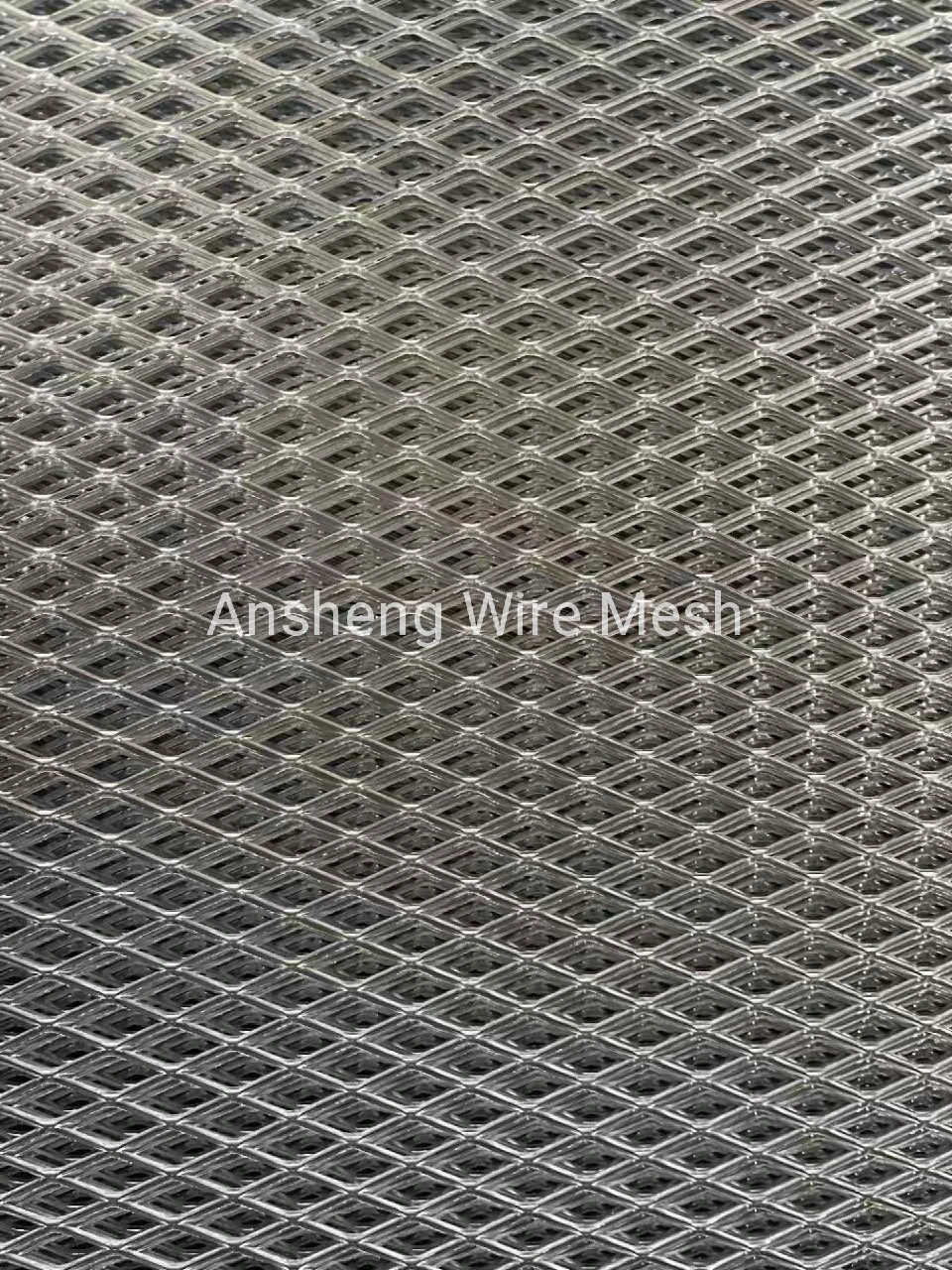

Expanded metal mesh has become a cornerstone material in various industries, providing strength, versatility, and cost-effectiveness. Its unique structure—created by cutting and stretching metal sheets—offers durability and excellent ventilation, making it an ideal choice for applications ranging from architectural facades to security fencing. Understanding the 4 x 8 expanded metal cost and factors influencing pricing is essential for anyone planning to incorporate this material into their projects. By carefully selecting suppliers and comparing options, users can ensure they get the best value without compromising quality.

Factors Influencing the 4 x 8 Expanded Metal Cost in Bulk Orders

When considering the 4 x 8 expanded metal cost, several key elements come into play that affect the final price. The thickness of the metal sheet, the size of the openings, and the type of metal—whether steel, aluminum, or stainless steel—all contribute to cost variability. Bulk orders often reduce unit price, but the complexity of the mesh pattern and any finishing treatments like galvanization or powder coating can increase expenses. Additionally, transportation and delivery fees impact overall budgeting, especially when sourcing from overseas factories. By understanding these components, buyers can make informed decisions that balance cost and performance.

Comparing Market Offers for Expanded Wire Mesh Price

The expanded wire mesh price fluctuates based on market demand, raw material availability, and production capacity. Prices tend to rise when steel and aluminum prices spike globally or when supply chains face disruption. However, competitive markets encourage manufacturers to offer discounts and value-added services to attract customers. Comparing prices from various suppliers—while ensuring quality certifications and manufacturing standards—can lead to better procurement outcomes. It is also crucial to evaluate whether the price includes customization options, such as specific sheet sizes or mesh patterns, which may add to overall expenses but enhance project suitability.

Key Attributes of Leading Expanded Metal Mesh Manufacturers

Reliable expanded metal mesh manufacturers distinguish themselves through consistent product quality, innovative design capabilities, and responsive customer service. Top manufacturers invest in advanced machinery that allows precise control over mesh size, thickness, and shape. They also adhere to strict quality control processes to ensure every batch meets industry standards and client specifications. Moreover, these manufacturers often provide engineering support to help clients select the right mesh type for structural or aesthetic applications. Choosing reputable manufacturers reduces risks related to product defects or delivery delays and enhances project success.

Production Processes in a Professional Expanded Metal Mesh Factory

A well-equipped expanded metal mesh factory employs modern automated systems to ensure precision and efficiency in production. The process begins with high-quality metal sheets, which are then simultaneously slit and stretched to form diamond-shaped openings. This method creates a single piece of metal with enhanced strength and rigidity without adding extra weight. Factories may offer additional services such as cutting to size, coating, or welding to meet specific client demands. Factory capabilities influence turnaround time and cost, making it important to select facilities that can handle both standard and custom orders with consistent quality.

The Role of Geographic Location in Choosing Expanded Metal Mesh China Suppliers

Sourcing expanded metal mesh China suppliers offers advantages including competitive pricing and a wide range of products due to the country’s extensive manufacturing infrastructure. China has developed a strong reputation as a global supplier of expanded metal mesh, serving clients in construction, transportation, and industrial sectors. However, buyers should carefully assess the supplier’s compliance with international standards and their export experience. Communication efficiency, shipping logistics, and after-sales support also play critical roles in ensuring smooth transactions. Selecting the right Chinese supplier can lead to substantial cost savings without sacrificing quality.

Balancing Quality and Price When Evaluating 4 x 8 Expanded Metal Cost

Achieving the best value in 4 x 8 expanded metal cost involves more than just opting for the cheapest option. Buyers must consider product longevity, resistance to corrosion, and maintenance needs over the material’s lifespan. A higher upfront investment in superior materials or coatings often translates to lower long-term costs by minimizing repairs and replacements. Additionally, partnering with suppliers who offer warranties or certifications can provide peace of mind. Understanding the balance between initial price and functional performance helps prevent costly mistakes and ensures that the expanded metal mesh meets project requirements.

Customization Trends Among Modern Expanded Wire Mesh Price Structures

Modern architectural and industrial projects increasingly demand customized expanded wire mesh solutions that cater to unique design and functional criteria. This trend influences the expanded wire mesh price, as custom patterns, sizes, and finishes require specialized production techniques and quality checks. Customization enhances aesthetic appeal and can improve ventilation, safety, or filtration effectiveness depending on the application. Although customized products generally command higher prices, the added value in project outcomes often justifies the investment. Early consultation with manufacturers facilitates understanding pricing structures and achievable design parameters.

Strategic Sourcing from Reputable Expanded Metal Mesh Manufacturers

Choosing the right expanded metal mesh manufacturers is a strategic decision impacting project timelines, costs, and quality assurance. Top manufacturers maintain transparency in pricing, offer technical consultations, and provide samples or prototypes to verify product suitability before full-scale production. Building long-term partnerships with such manufacturers can unlock preferential pricing, priority scheduling, and tailored support. For large-scale or recurring projects, these relationships foster reliability and innovation, helping clients stay competitive and responsive to changing market needs.

Logistics and Supply Chain Considerations When Purchasing from an Expanded Metal Mesh Factory

Working with an expanded metal mesh factory requires careful coordination of logistics to ensure timely delivery and cost efficiency. Shipping large or heavy expanded metal sheets involves considerations such as packaging methods, freight options, and customs clearance procedures. Factories with export experience can guide clients through these complexities, minimizing delays and unexpected charges. Efficient supply chain management also involves tracking order status and handling returns or damages professionally. Understanding these factors improves overall procurement effectiveness and customer satisfaction.

Global Sourcing Opportunities with Trusted Expanded Metal Mesh China Producers

Engaging with expanded metal mesh China producers offers access to cutting-edge manufacturing technologies and a vast product selection. Global buyers benefit from competitive price points and the ability to scale orders quickly to meet demand. However, selecting producers with strong international reputations and verified compliance with export standards is essential. Thorough due diligence, including factory audits and client references, ensures the quality and reliability of shipments. Leveraging China’s manufacturing strengths can significantly enhance project cost-efficiency and material availability.

Expanded Metal Mesh FAQs

Q1: What determines the price of 4 x 8 expanded metal?

The price depends on metal type, sheet thickness, mesh opening size, surface treatments, and order volume. Custom finishes and expedited shipping may increase costs.

Q2: How do I verify the quality of expanded wire mesh?

Quality is ensured by checking manufacturer certifications, inspecting sample products, and reviewing third-party testing reports.

Q3: Can expanded metal mesh be customized?

Yes, most manufacturers offer custom sizes, shapes, patterns, and coatings tailored to project requirements, affecting price accordingly.

Q4: What advantages do Chinese expanded metal mesh suppliers provide?

They offer competitive pricing, large production capacity, and a variety of products, but careful supplier evaluation is necessary for quality assurance.

Q5: How should I handle logistics when ordering large quantities?

Coordinate closely with the factory on packaging, shipping method, customs, and delivery schedules to avoid delays and reduce costs.

Post time: Aug . 05, 2025 14:44