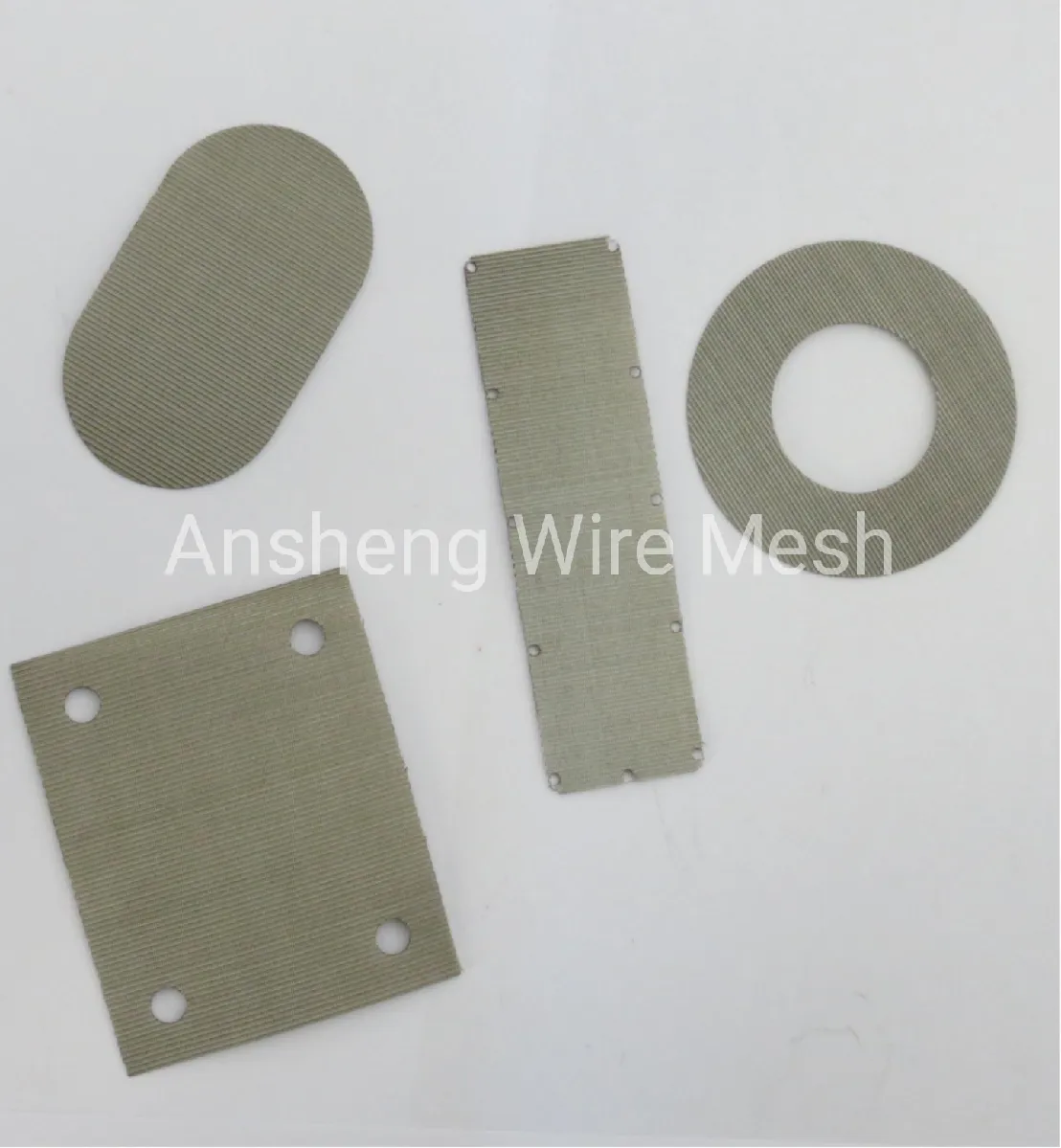

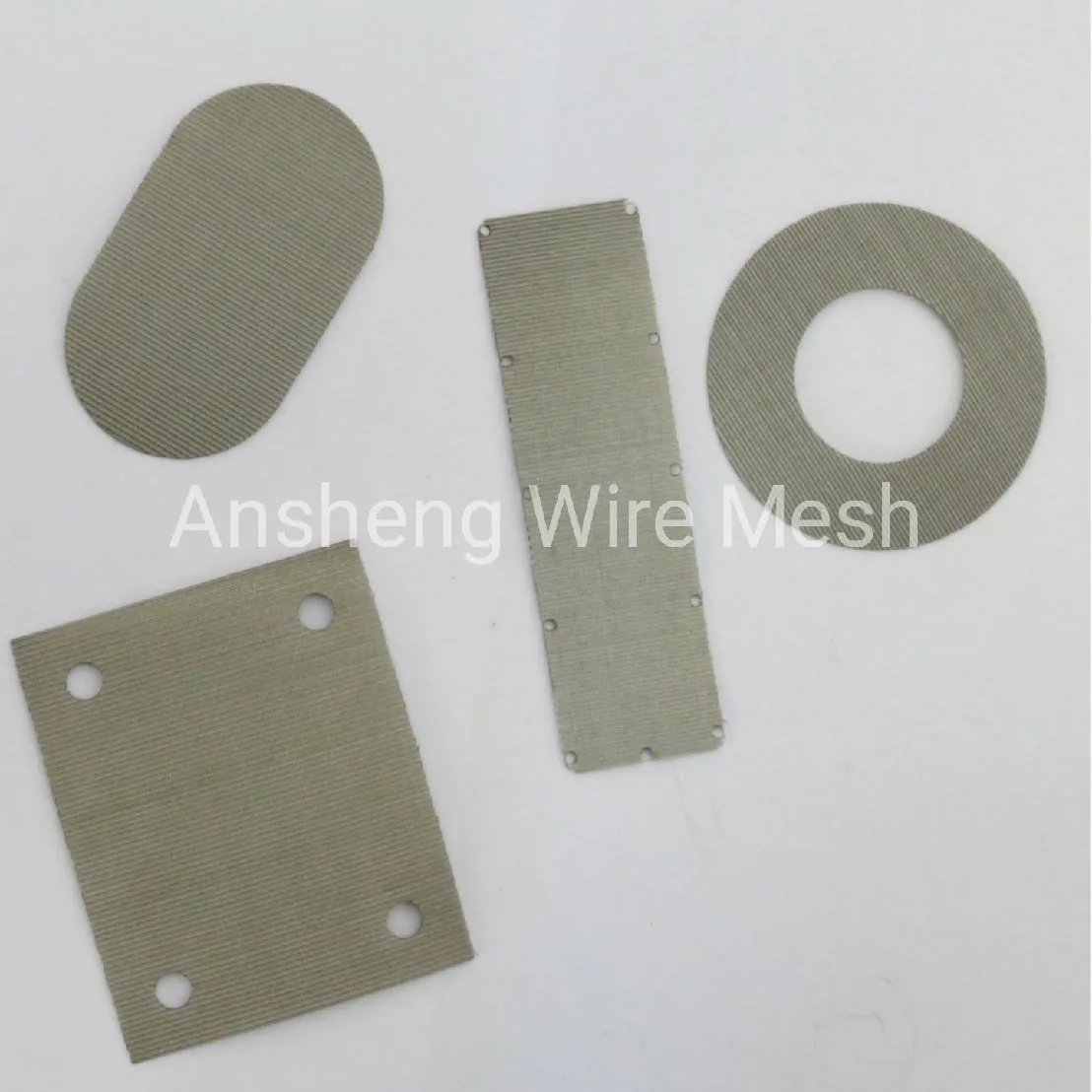

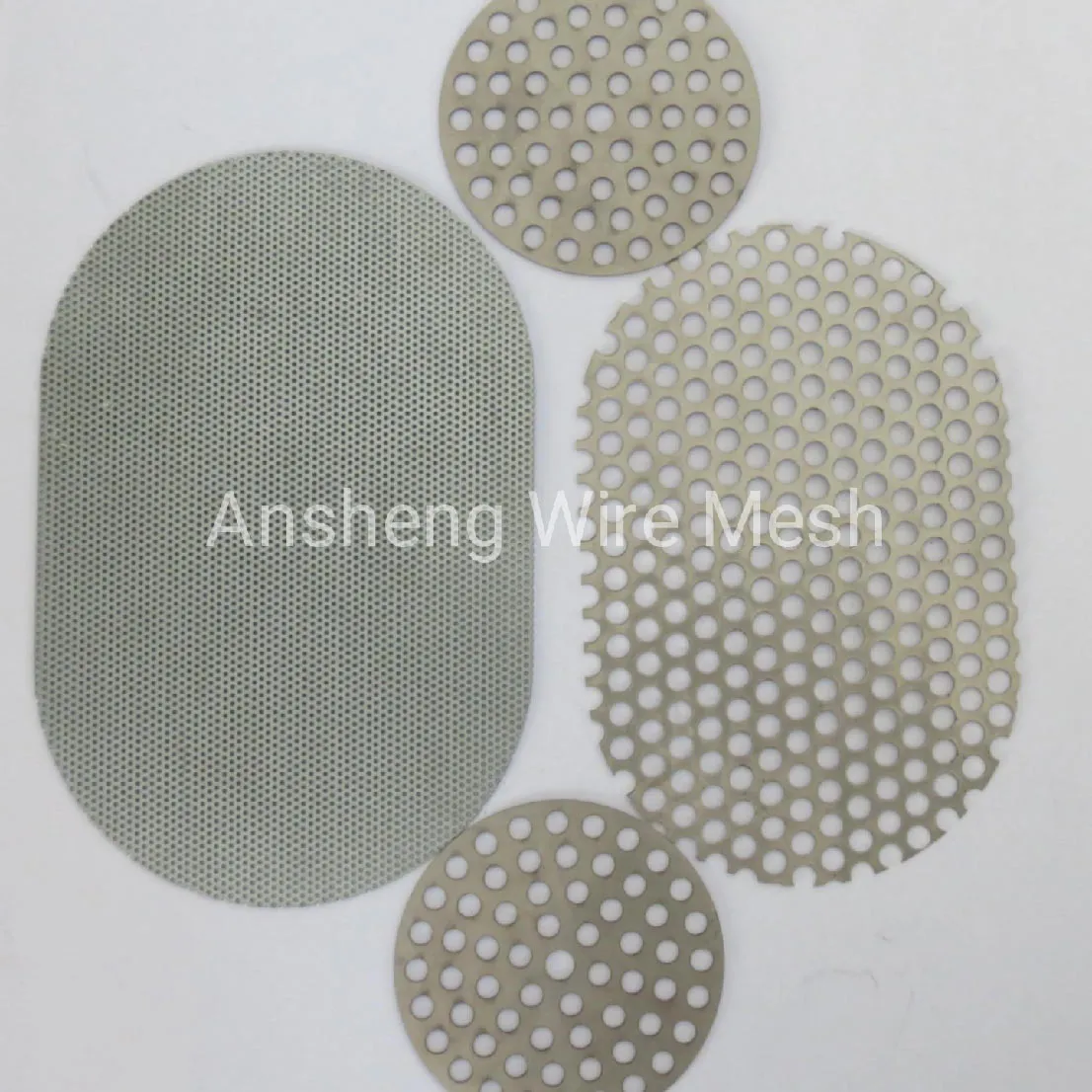

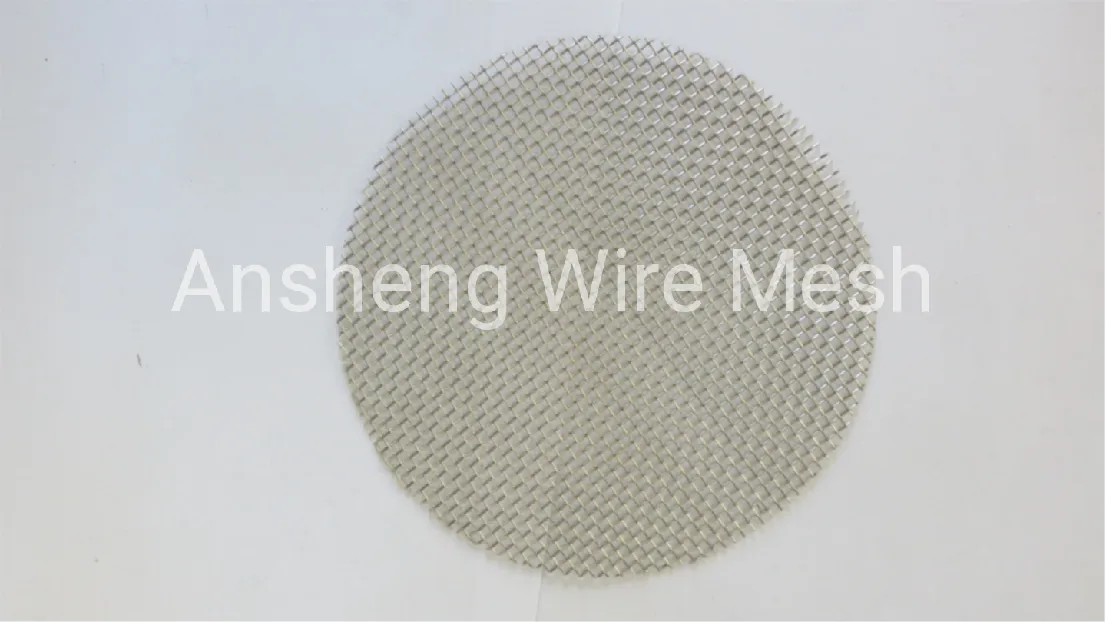

Our high-quality meshdisc

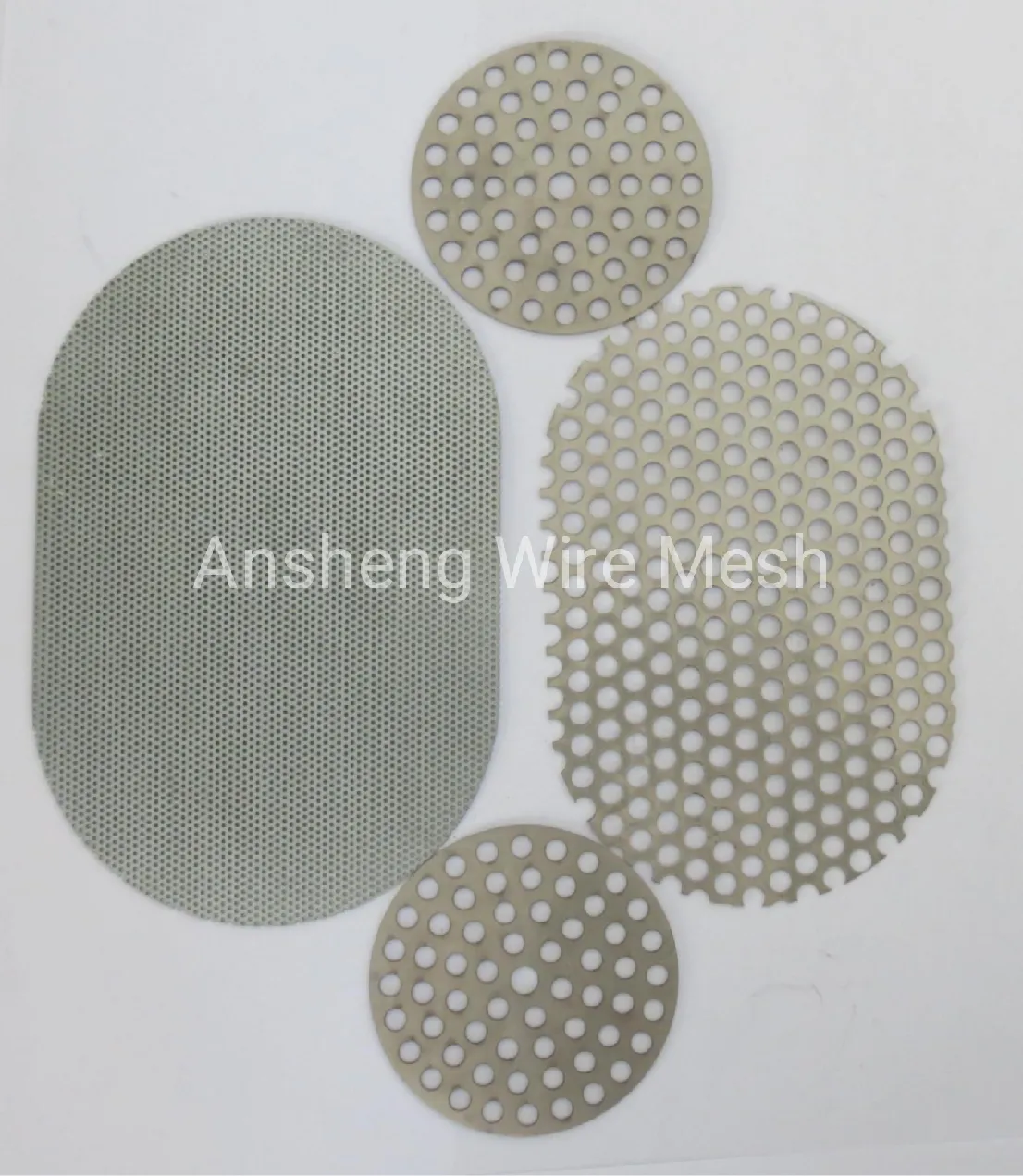

-Shape regularity: The edges of the mesh are neat, without distortion or deformation, in a regular shape, easy to install and use, and can ensure its stability during use.

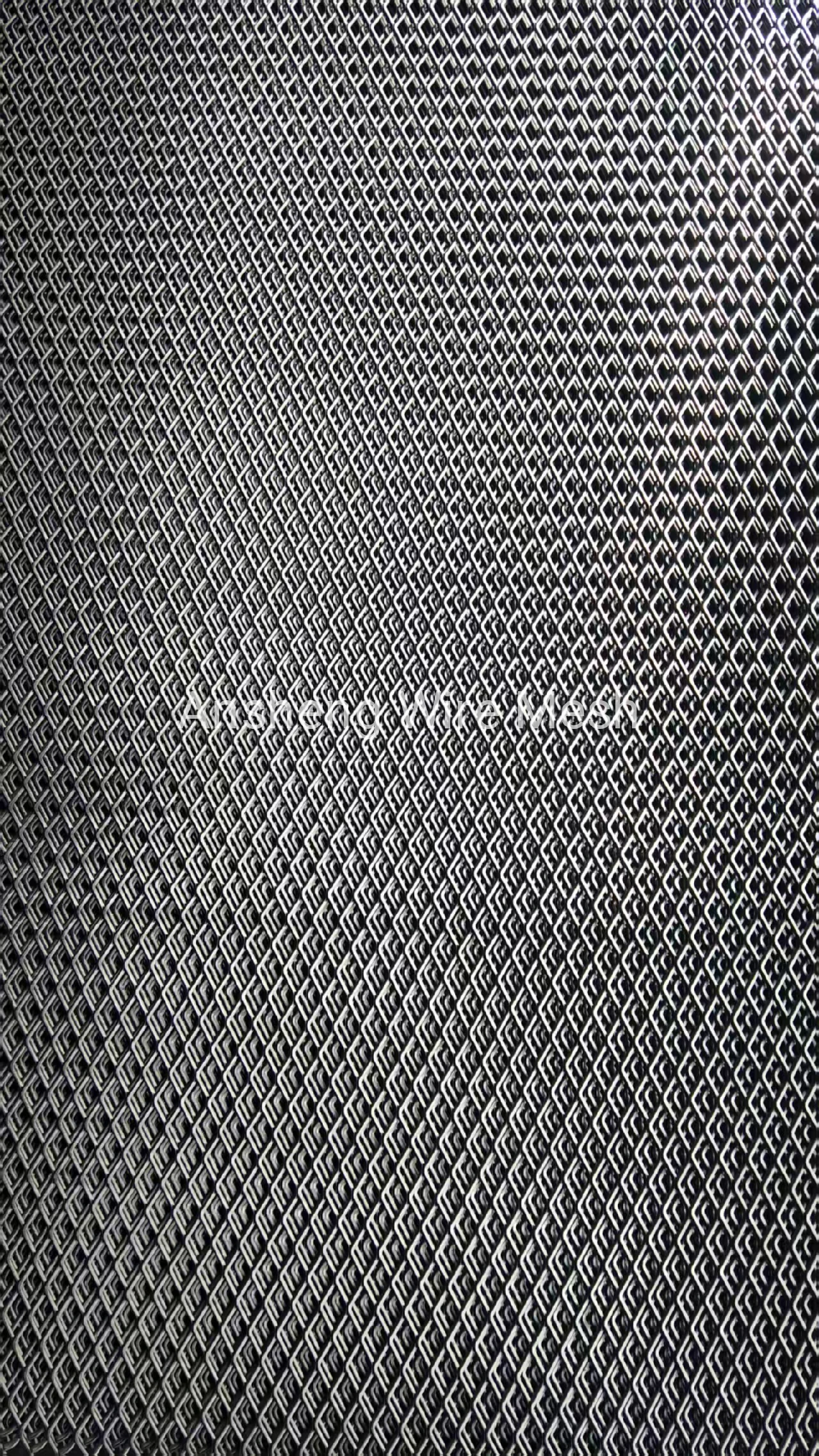

-High quality material selection: Using high-purity and high-quality raw materials, such as high-grade stainless steel , high-quality galvanized iron , etc., to ensure that the mesh has good corrosion resistance, strength, and toughness.

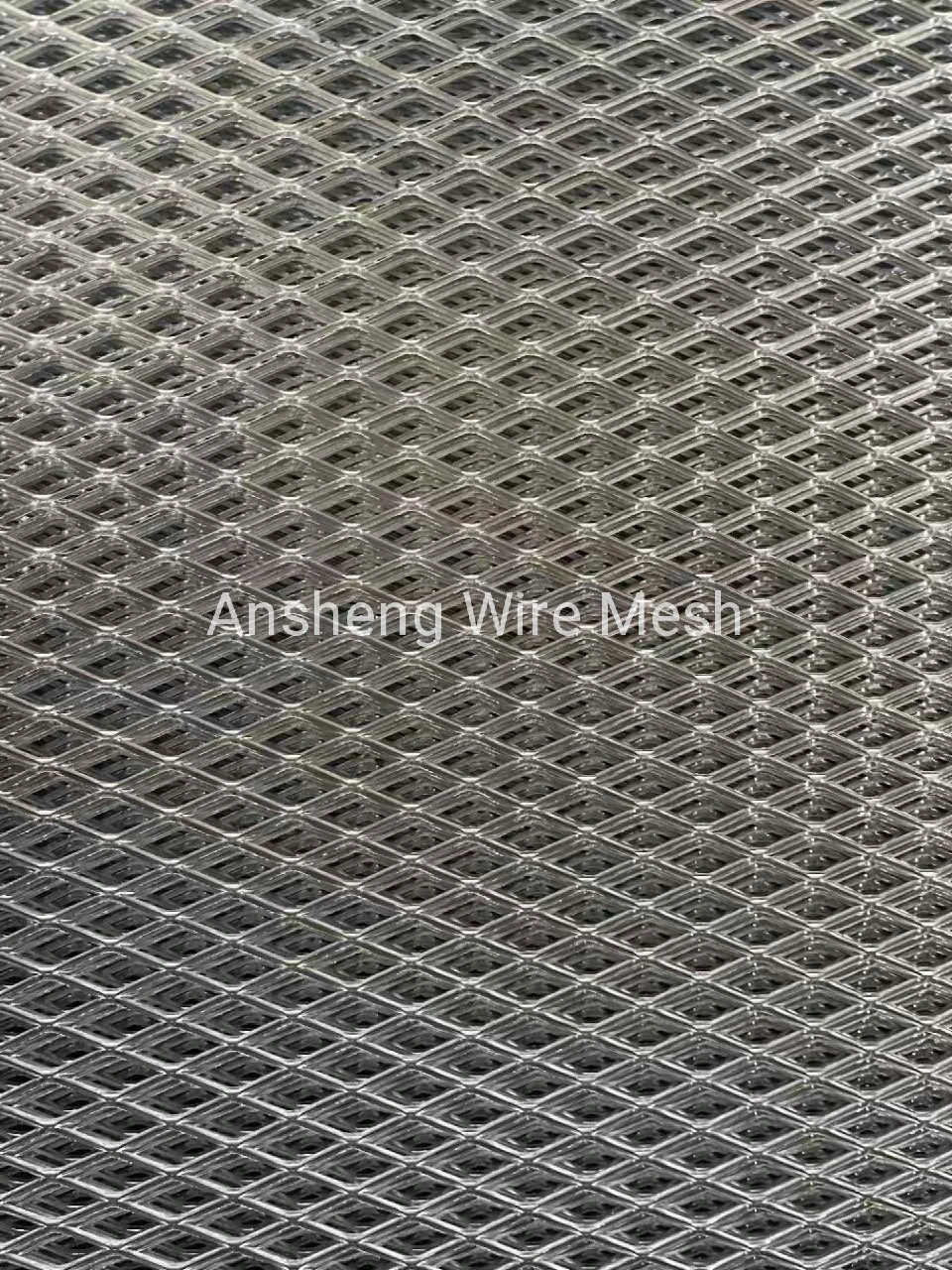

-Fine weaving of mesh: The mesh is tightly and evenly woven, with consistent mesh sizes and no defects such as skipping or leaking, ensuring the filtration accuracy and overall aesthetics of the mesh.

-Accurate specifications: The length, width, aperture and other dimensions of the mesh meet the design requirements, with deviations controlled within the allowable range, ensuring that the mesh can be accurately installed in the predetermined position and well coordinated with other equipment or components.

We introduce advanced CNC machining equipment, work with an experienced technical team, and implement strict production standards and testing processes to ensure that every mesh meets your expectations, saving time and costs for your project, eliminating the need for rework, and making installation more worry free.

When purchasing web footage, if you choose to purchase the entire roll and cut it yourself, it may not only result in a large amount of waste due to cutting errors, causing waste of raw materials and increasing material costs; We also need to bear the high freight cost of transporting the entire roll, resulting in a significant increase in transportation costs. And choosing our directly customized mesh, the factory specializes in cutting, with high precision and no waste generated. We also deliver according to your actual needs, plan logistics reasonably, and greatly reduce shipping costs. The purchase cost has significantly decreased, making it worry free and cost-effective, far surpassing self cutting.