1. Manufacturing Process:

- Welding Technique: Wires (typically steel, stainless steel, or other alloys) are arranged in perpendicular rows and columns. The intersections are fused using electric resistance welding creating strong, permanent bonds.

- Materials: Common options include:

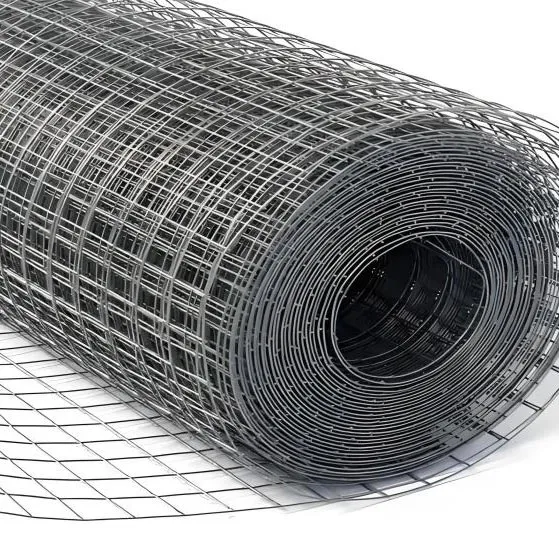

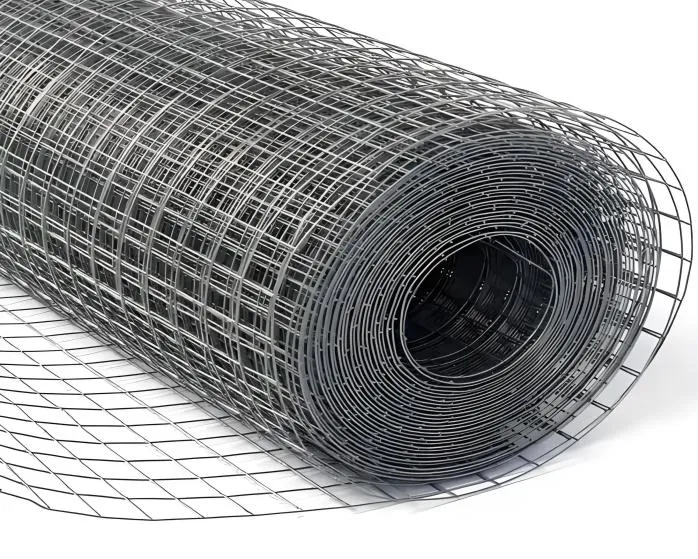

- Galvanized steel: Rust-resistant for outdoor use.

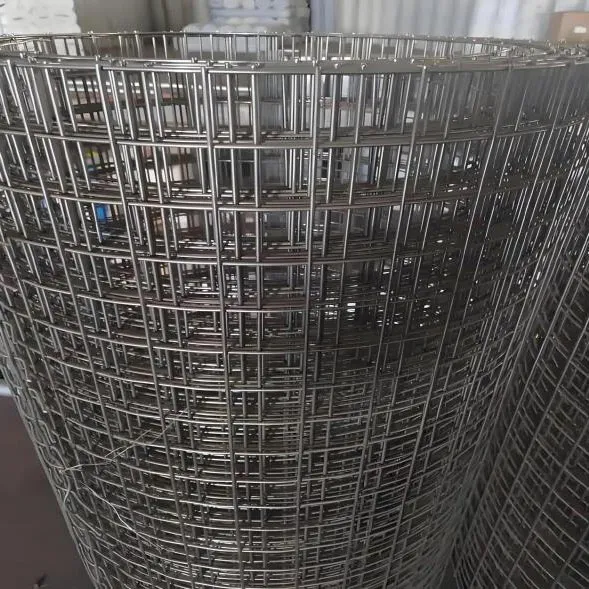

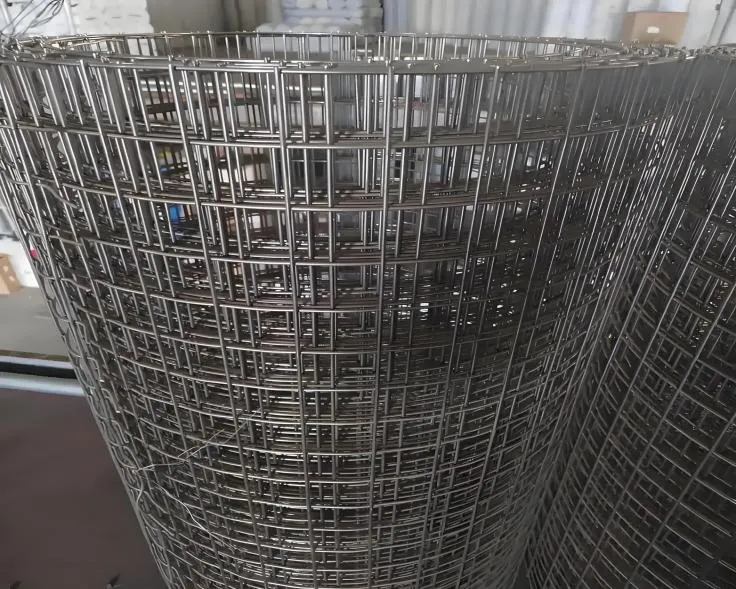

- Stainless steel: Corrosion-resistant for harsh environments.

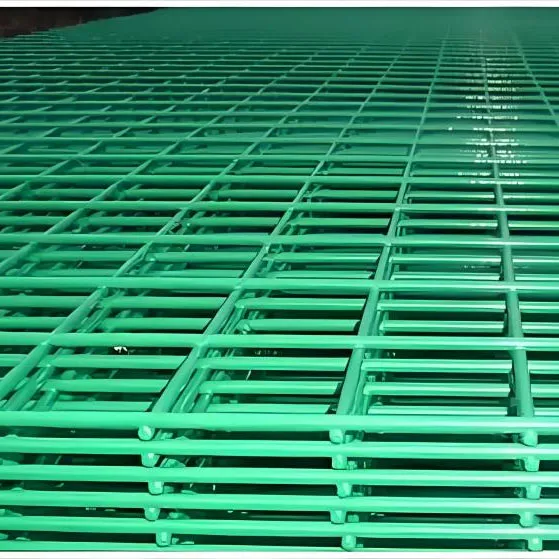

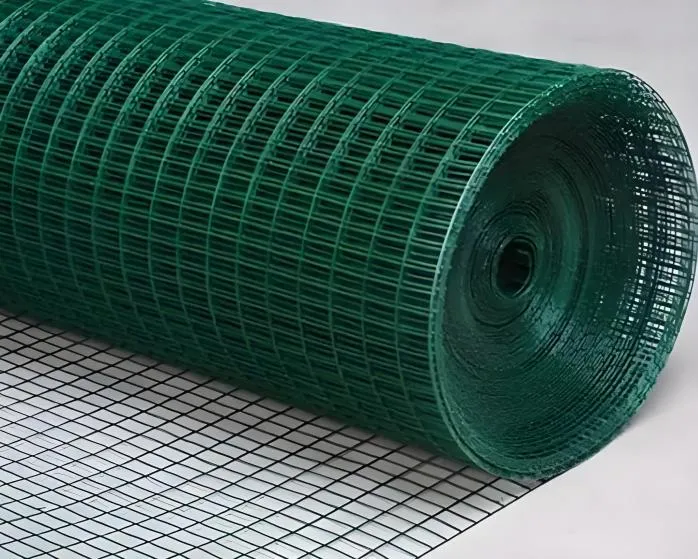

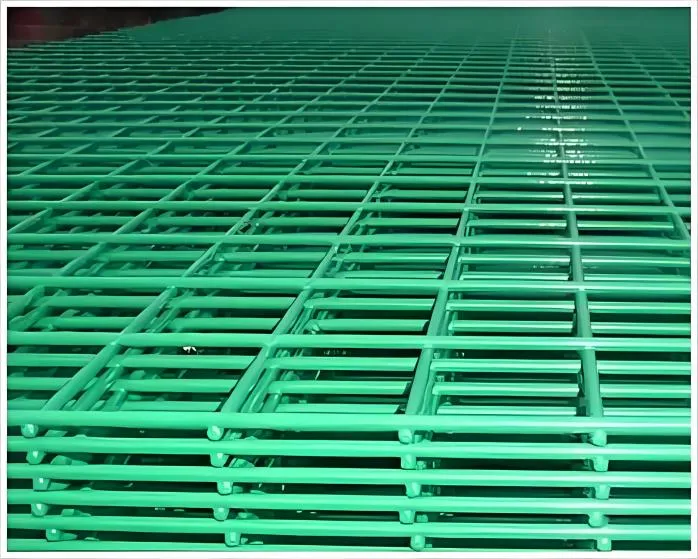

- PVC-coated: Adds extra protection and color for aesthetics.

- Aluminum: Lightweight and non-corrosive.

2. Key Features:

- Strength & Rigidity: The welded joints provide structural integrity, making it resistant to bending or deformation.

- Uniformity: Precise grid patterns (square, rectangular, or custom shapes) with consistent spacing.

- Customization: Wire thickness (gauge), aperture size (hole dimensions), and sheet size can be tailored to specific needs.

- Cost-Effective: Mass-produced and easy to install, reducing labor costs.

1. Wire Gauge (Thickness)

Measured in SWG (Standard Wire Gauge) or AWG (American Wire Gauge), with lower numbers indicating thicker wires:

- Light-Duty:

- 20–16 gauge (0.9–1.6 mm): Used for lightweight applications like garden fencing, insect screens, or decorative panels.

- Medium-Duty:

- 14–10 gauge (1.6–3.4 mm): Common in concrete reinforcement, partitions, and industrial shelving.

- Heavy-Duty:

- 8–4 gauge (4–6 mm): Used for security fencing, gabions, or heavy-load structures.

2. Aperture Sizes (Hole Dimensions)

The spacing between wires, measured in inches or millimeters:

- Small Apertures (for precision/filtration):

- 1/4" x 1/4" (6 mm x 6 mm) to 1" x 1" (25 mm x 25 mm): Used in rodent control, plaster reinforcement, or fine screening.

- Medium Apertures (general-purpose):

- 2" x 2" (50 mm x 50 mm) to 4" x 4" (100 mm x 100 mm): Ideal for concrete slabs, poultry cages, and partitions.

- Large Apertures (for visibility/ventilation):

- 6" x 6" (150 mm x 150 mm) or larger: Used in perimeter fencing, trellising, or livestock enclosures.

3. Sheet/Roll Dimensions

- Standard Panels:

- 4' x 8' (1.2 m x 2.4 m) or 5' x 10' (1.5 m x 3 m) for construction or fencing.

- Rolls:

- 3'–5' wide x 50'–100' long (0.9–1.5 m x 15–30 m) for agricultural or industrial uses.

4. Common Applications by Size

|

Application |

Typical Size |

Example Uses |

|

Concrete Reinforcement |

10–12 gauge, 2"x2" or 6"x6" apertures |

Driveways, slabs, walls |

|

Security Fencing |

6–8 gauge, 2"x4" or 4"x4" apertures |

Prisons, warehouses, property boundaries |

|

Gardening/Agriculture |

16–14 gauge, 1"x1" or 2"x2" apertures |

Chicken coops, trellises, compost bins |

|

Industrial Shelving |

12–10 gauge, 1"x1" or 2"x2" apertures |

Warehouse racks, machine guards |

|

Decorative Panels |

20–16 gauge, 1/2"x1/2" apertures |

Room dividers, facades, light fixtures |

5. Material-Specific Sizes

- Galvanized Steel: Common in 14–8 gauge for outdoor fencing.

- Stainless Steel: Often 16–12 gauge for food processing or marine environments.

- PVC-Coated: Typically 14–10 gauge with 1"–4" apertures for aesthetic fencing.

Welded wire mesh is a versatile material used in a wide range of applications due to its strength, durability, and customizable design. Below is a detailed breakdown of how it is used across industries, along with specific examples:

1. Construction & Civil Engineering

- Concrete Reinforcement:

- How: Embedded in concrete slabs, walls, or pavements to prevent cracking and add tensile strength.

- Example: Driveways, foundations, and precast concrete panels.

- Benefits: Reduces shrinkage cracks, improves load-bearing capacity.

- Gabion Baskets:

- How: Filled with stones or gravel to create retaining walls or erosion control structures.

- Example: Riverbank stabilization, highway embankments.

- Benefits: Flexible, permeable, and environmentally friendly.

- Flooring & Ceiling Support:

- How: Used as a base for stucco, plaster, or tile work.

- Example: Underfloor heating systems, suspended ceilings.

2. Agriculture & Farming

- Animal Enclosures:

- How: Built into cages, pens, or fencing to safely contain livestock or poultry.

- Example: Chicken coops, rabbit hutches, cattle feedlots.

- Benefits: Durable, rust-resistant (galvanized or PVC-coated options).

- Plant Support:

- How: Used as trellises for climbing plants (e.g., tomatoes, vines).

- Example: Vertical farming, greenhouse structures.

- Benefits: Provides airflow and sunlight penetration.

- Compost Bins & Grain Storage:

- How: Forms ventilated walls for organic waste or grain silos.

- Benefits: Prevents rodents while allowing airflow.

3. Industrial & Manufacturing

- Machine Guards & Safety Barriers:

- How: Installed around machinery to protect workers while allowing visibility.

- Example: Factory equipment, conveyor belt enclosures.

- Benefits: Meets OSHA safety standards, lightweight.

- Shelving & Storage:

- How: Used in pallet racks, warehouse shelves, or tool organizers.

- Benefits: High load capacity, easy to clean.

- Filtration & Screening:

- How: Acts as a sieve for aggregates, coal, or industrial materials.

- Example: Mining operations, wastewater treatment.

4. Security & Perimeter Fencing

- How: Woven into rigid panels for high-security fencing.

- Example: Prisons, military bases, residential boundaries.

- Benefits: Difficult to cut or climb, long-lasting.

5. Home & Decorative Use

- Garden Fencing:

- How: Protects plants from pests or defines garden beds.

- Example: Raised bed borders, deer fencing.

- Decorative Panels:

- How: Cut into artistic designs for façades, room dividers, or light fixtures.

- Example: Modern interior design, balcony railings.

- Benefits: Combines aesthetics with functionality.

- DIY Projects:

- How: Crafted into furniture, pet enclosures, or compost bins.

- Example: Wire mesh tables, bird feeders.

6. Infrastructure & Transportation

- Road Reinforcement:

- How: Laid under asphalt to reduce potholes and extend road life.

- Example: Highways, airport runways.

- Bridge Construction:

- How: Reinforces concrete in bridge decks or barriers.

7. Retail & Commercial

- Shopping Carts & Baskets:

- How: Molded into lightweight, durable frames.

- Benefits: Corrosion-resistant (stainless steel or coated).

- Display Racks:

- How: Used in supermarkets or warehouses for product organization.

Key Considerations

- Strength vs. Open Area: Smaller apertures increase strength but reduce airflow/visibility.

- Custom Sizes: Many suppliers offer tailored gauges, apertures, and sheet dimensions.

Installation Tips

1. Measure & Cut: Use bolt cutters or angle grinders to size the mesh.

2. Secure Edges: Bind sharp edges with PVC coating or caps to prevent injuries.

3. Fasten Properly: Use wire ties, clamps, or welding for structural projects.

4. Corrosion Protection: Choose galvanized, stainless steel, or PVC-coated mesh for outdoor/moist environments.

Material Selection Guide

|

Application |

Recommended Material |

|

Outdoor fencing |

Galvanized steel or PVC-coated |

|

Marine environments |

Stainless steel (316 grade) |

|

Decorative panels |

Powder-coated or aluminum |

|

High-temperature areas |

Stainless steel or heat-resistant alloys |

Key Advantages

- Cost-effective: Cheaper than solid metal sheets.

- Customizable: Available in various gauges, apertures, and sheet sizes.

- Low Maintenance: Resists wear, rust, and deformation.

Welded wire mesh is a go-to solution for projects requiring strength, airflow, visibility, or design flexibility. Whether reinforcing concrete, securing a farm, or creating art, its adaptability makes it indispensable. Let me know if you need help with a specific project!