In today's high-performance industrial environments, filtration, separation, and surface refinement demand the highest precision. Whether used in chemical processing, fluid control, or abrasive applications, advanced mesh disc technologies play a crucial role in ensuring process consistency and quality. Their robust construction and versatility have made them indispensable in various sectors, including manufacturing, automotive, petrochemicals, and food processing.

Enhanced Performance Begins with Precision-Crafted Wire Mesh Disc Components

One of the most widely used filtration products, the wire mesh disc, provides reliable and efficient separation for liquids, gases, and even fine solids. Available in a range of mesh counts, these discs are constructed using stainless steel or other corrosion-resistant alloys, ensuring compatibility with harsh chemicals and extreme temperatures. The fine weave of a quality wire mesh disc ensures accurate retention while maintaining optimal flow rates. Industries rely on these discs not only for their mechanical integrity but also for their low maintenance needs and longevity.

Sanding Applications See New Efficiency with Mesh Sanding Discs at Their Core

While traditionally overlooked, the mesh sanding discs market has rapidly evolved due to increased demand for cleaner finishes and dust-free work environments. Unlike traditional sandpaper, mesh sanding discs utilize a net-like abrasive structure that allows continuous dust extraction, improving operator visibility and extending disc life. These discs are compatible with orbital and random orbital sanders and excel in automotive refinishing, woodwork, and composite material prep. Professionals value the uniform scratch pattern, reduced clogging, and smoother finishes delivered by mesh sanding discs.

Filtration Reliability Is Reinforced by Stainless Steel Frit Disc Applications

Where chemical resistance and pressure stability are required, the stainless steel frit disc shines. Used extensively in gas and liquid chromatography, laboratory filtration, and catalyst support, these fritted metal discs combine porosity with structural strength. Manufactured through sintering, frit discs offer consistent pore size distribution and high dirt-holding capacity. Their stainless steel construction resists corrosion, abrasion, and thermal stress, making them ideal for high-purity filtration processes and critical systems that cannot tolerate particle leakage.

Specialized Systems Demand the Precision of a Custom Metal Filter Disc

Industrial systems requiring particle filtration under demanding operating conditions often utilize a metal filter disc for its durability and adaptability. These discs are used in fuel systems, hydraulic circuits, air compressors, and chemical processing lines where mesh integrity is paramount. Manufactured from stainless steel, monel, hastelloy, or brass, metal filter discs can be tailored in size, mesh count, and layer configuration to meet specific operational requirements. Their resistance to pressure drops, corrosion, and fouling ensures long-term reliability and system protection.

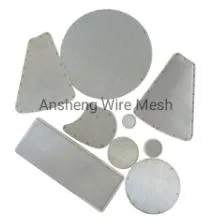

Custom Mesh Disc Designs Improve Versatility Across Industry Applications

Beyond standard shapes and sizes, customized mesh disc solutions enable manufacturers to meet unique processing and performance demands. Customization may involve multi-layer construction, spot welding, edge wrapping, or pleating to enhance surface area and durability. Sectors such as aerospace, pharmaceuticals, and marine engineering benefit from tailored designs that deliver both functionality and longevity. Whether flat, cylindrical, or disc-shaped, these custom mesh components allow systems to operate efficiently under extreme mechanical and environmental stresses.

Surface Finishing Operations Gain New Life Through Mesh Sanding Discs Innovation

Advanced mesh sanding discs not only improve material removal rates but also reduce the risk of over-sanding and heat damage. The open-mesh abrasive format maintains cooler operation and less loading, particularly on materials like hardwoods, aluminum, and fiberglass. These discs are essential for achieving a high-quality final surface with fewer passes, lowering labor time and material waste. With the addition of ceramic or zirconia grains, mesh sanding discs now match or exceed traditional abrasives in cutting speed and durability.

Consistent Quality Starts with Wire Mesh Disc Engineering Standards

Each wire mesh disc must be manufactured to strict tolerance levels to ensure consistency in filtration and separation processes. Factors such as aperture size, mesh count, alloy type, and weave pattern directly influence performance metrics. Quality assurance processes including optical inspection, tensile testing, and flatness evaluation guarantee that each disc can perform under its specified load and flow conditions. These engineering controls make wire mesh discs suitable for critical applications in pharmaceuticals, electronics, and cleanroom technologies.

What Materials Are Used to Manufacture Metal Filter Discs?

Metal filter discs are most commonly made from stainless steel due to its corrosion resistance and strength. Other options include brass, hastelloy, and titanium, selected based on application-specific chemical or thermal needs.

What Is the Difference Between a Frit Disc and a Wire Mesh Disc?

Frit discs are made by sintering powdered metal into a porous structure, suitable for fine filtration and high-pressure systems. In contrast, wire mesh discs use woven or welded wire and are more versatile in coarser filtration or screening.

Mesh Disc and Related Products FAQs

Q: What mesh count is ideal for my application when choosing a mesh disc?

A: It depends on the particle size you need to filter. Higher mesh counts mean smaller openings and finer filtration. Consult technical specifications or a filtration engineer for the ideal match.

Q: Are wire mesh discs reusable?

A: Yes. With proper cleaning methods like ultrasonic baths or chemical rinses, wire mesh discs can be reused multiple times, especially when constructed from stainless steel or high-performance alloys.

Q: Do mesh sanding discs fit standard sanding equipment?

A: Most mesh sanding discs are designed with universal hook-and-loop backing and fit standard orbital and rotary sanders, making them easy to integrate into existing workflows.

Q: How long do stainless steel frit discs last in lab use?

A: Frit discs can last years if used within recommended pressure and temperature ranges. However, replacement frequency depends on cleaning protocol and filtration load.

Q: Can I order custom dimensions for a metal filter disc?

A: Absolutely. Many manufacturers offer bespoke sizing, mesh layering, and mounting options to accommodate your unique filtration or flow requirements.

Post time: Aug . 18, 2025 09:38