As industrial development accelerates worldwide, perforated metal for sale stands out as a foundational material driving innovation across industries, from petrochemical and water treatment to architectural and energy applications. Perforated Metal Mesh—with its precise apertures, superior strength, and highly customizable formats—is at the heart of this progress.

I. Market & Industry Trends: The Surge in Demand for Perforated Metal Mesh Solutions

According to IndustryARC, the perforated metal mesh market is projected to reach USD 5.5 billion by 2028, registering a CAGR exceeding 5.7% (2024-2028). This demand surge is powered by wide adoption in filtration, architectural facades, noise barriers, and advanced mechanical engineering.

Key Industry Drivers:

- Energy-Efficient Construction: Perforated sheets enable daylight optimization & thermal regulation.

- ESG & Sustainability: 80% of buyers cite corrosion resistance and recyclability as pivotal (Source: Mordor Intelligence).

- Customization Needs: Industry-specific aperture/control for flow, strength, weight, and filtration precision.

II. Understanding Perforated Metal Types, Parameters & Selection (Comparison Table)

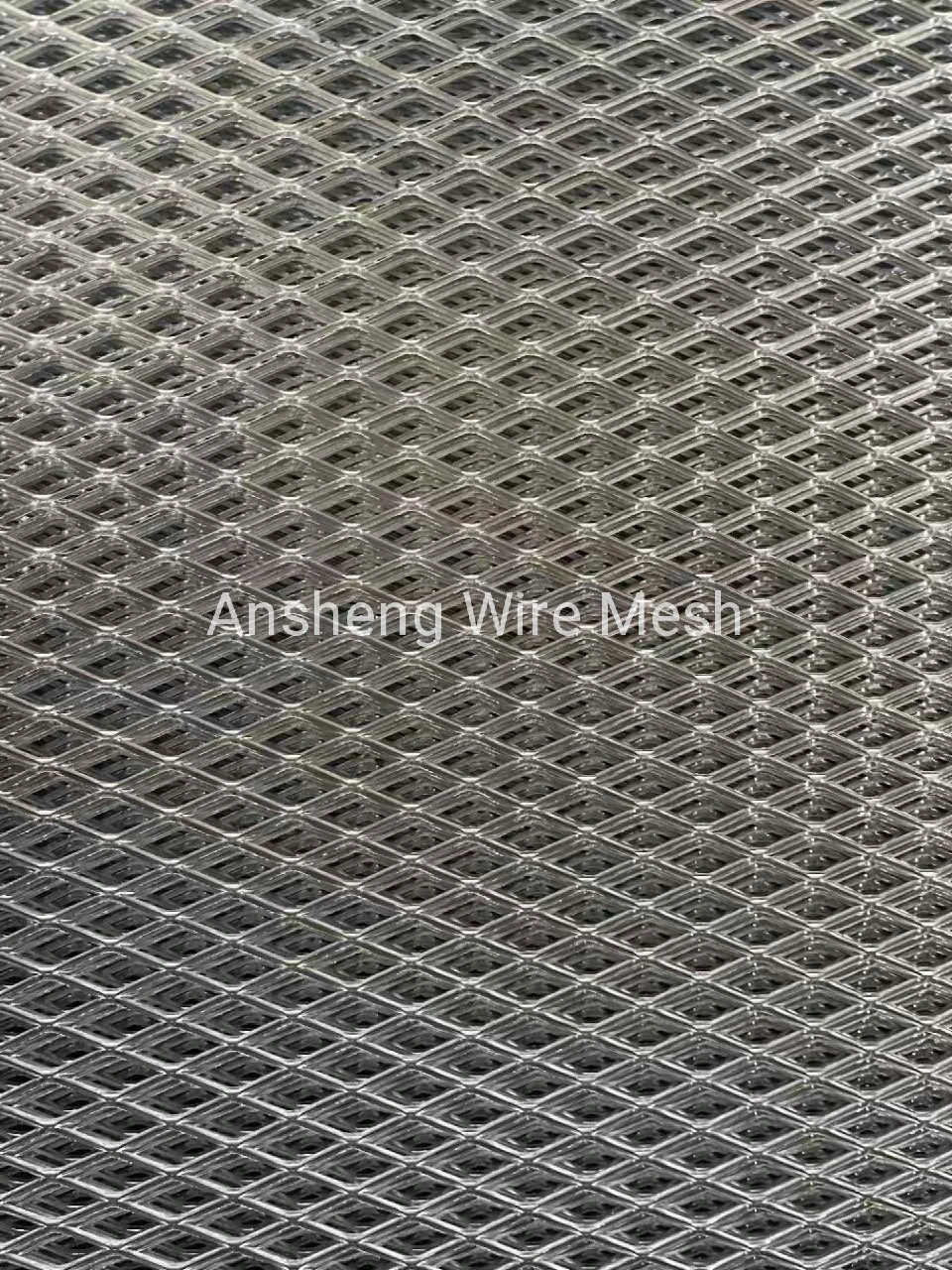

Whether selecting perforated mesh for filtration or perforated metal sheet for architectural panels, technical understanding and parameter comparison are crucial.

The following table summarizes leading specifications and available options for perforated metal for sale:

| Parameter | Perforated Metal Mesh | Perforated Metal Sheet | Custom Perforated Mesh |

|---|---|---|---|

| Material | 304/316 Stainless Steel, Carbon Steel, Aluminum | Galv. Steel, SS, Copper, Aluminum | Brass, Monel, Titanium, Superalloy (on request) |

| Thickness | 0.2–12.0 mm | 0.5–15 mm | 0.1–30 mm |

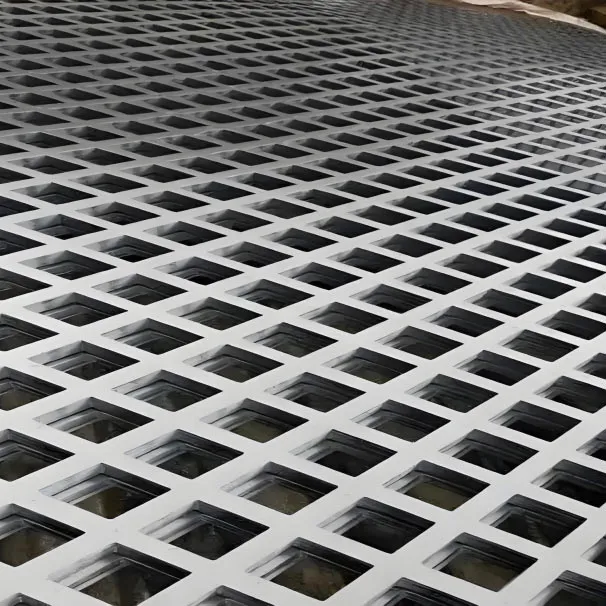

| Hole Shape | Round, Square, Hex, Slotted, Decorative | Round, Slot, Oblong, Custom | Precision Geometries (CNC, Laser) |

| Open Area (%) | 8%–70% | 4%–60% | 1%–85% |

| Standard Sheet Size | 1000x2000mm; 1220x2440mm; 1500x3000mm | 1000x2000mm; 1250x2500mm | Up to 2000x6000mm or coil |

| Finish | Mill, Anodized, Powder Coated, Polished | Mill, PVC Coated, Painted | Per customer spec |

| Certifications | ISO 9001, SGS, CE | ISO/ANSI | ISO, ASTM, EN 10204-3.1 |

| Applications | Filtration, Industrial, Acoustic Panels | Cladding, Security, Ventilation | High-precision, Aerospace, Medical |

Data collated from B2B portals, manufacturer catalogs, and AnshengFilterScreen technical sheets (2024).

III. Manufacturing Process of Perforated Metal for Sale

Manufacturing Highlights

- Material Selection: Prime 304/316 stainless steel, aluminum, or custom upon request.

- Cutting & Perforation: CNC punching, laser/EMT, rotary tools for micron-to-mm accuracy.

- Post-processing: Flattening, deburring, surface treatments (Electro-polishing, Anodizing, Powder Coat, Passivation, etc.)

- Test & Inspection: ISO 9001:2015, EN 10204-3.1/b, ANSI B36.10(M), edge/diameter/hole gauge verification, flatness, visual, and corrosion resistance testing.

- Double Quality Assurance: Digital archiving, traceable batches, and independent 3rd party random audit.

IV. Technical Superiority: Material Performance & Certified Quality

- Premium Alloy Materials: Certified stainless steel (DIN 1.4301, 1.4404), aluminum, galvanized, copper, titanium grades.

- ISO & ASTM Standards: Entire supply manufactured under ISO 9001:2015, supported by EN, ASTM, ANSI and, for food or pharmaceutical, FDA-compliant finish options.

- Longevity: Typical service life 15–30 years depending on environment—backed by 2–5 year product warranty and lab salt-spray tests (ASTM B117: >500h, guaranteeing anti-corrosion resilience).

- Advanced Process: Laser-perforation for ultra-fine apertures (as small as 0.2 mm), burr-free and high-strength.

(Data Source: Ansheng Lab, 2024 Q1; ISO 6892-1, ASTM B117)

V. Application Scenarios: Real-World Use Cases for Perforated Metal Mesh

Perforated metal for sale is central to projects requiring specific air/fluid flow, strength, and corrosion resistance.

- Petrochemical Filter Elements: Deep-well screens and pipeline strainers, filter cartridges, sand control meshes.

- Metallurgy: Blast furnace wind screens, mining sieves, ore/aggregate sorting.

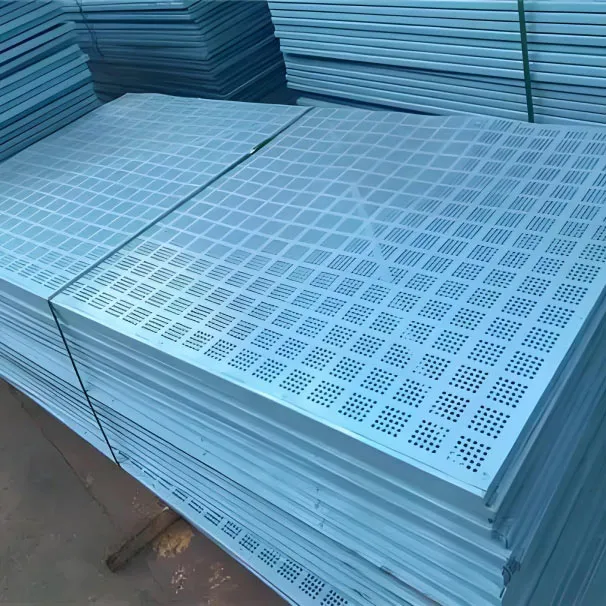

- Building & Architecture: Facade shading, sun protection panels, decorative cladding, ceiling and ventilation panels.

- Municipal Water Treatment: Intake screens, filter beds, water dispersal trays.

- Acoustic Engineering: Noise barriers (road/rail), sound-absorbing baffle plates/passive mufflers.

- Other: Security panels, anti-slip stair treads, food processing, automotive, aerospace, medical device housing.

VI. Manufacturer Comparison: Industrial Benchmarking for Perforated Metal

| Brand | Main Material | Certifications | Lead Time | Customization | Warranty | Client Base | Website |

|---|---|---|---|---|---|---|---|

| Ansheng (China) | 304/316 SS, AL, Special Alloys | ISO 9001, SGS | 10–18 days | Flexible (CNC/Laser/Design) | 3–5 yrs | Petro, Water, OEM | Profile |

| McNichols (USA) | SS, AL, Carbon, Brass | ISO 9001 | 12–20 days (stock: 48h) | Moderate (Std. Patterns) | 1–2 yrs | Construction, Gov | Profile |

| Sefar (EU) | SS, AL, Polymer | ISO, FDA (food) | 18–28 days | Limited | 2 yrs | OEM, Pharma | Profile |

| RMIG (EU) | SS, CS, AL | ISO 9001, EN | 15–24 days | Flexible | 2–3 yrs | Arch., Industry | Profile |

Analysis: Ansheng offers rapid delivery, superior customization, and robust warranty, with full ISO/SGS compliance and a comprehensive client support system internationally.

VII. Product Specification Visualization: Key Data at a Glance

Thickness

Hole Size

Material

Finish

VIII. Customization, Ordering & Delivery: Tailored Perforated Metal Solutions

- Cooperative Customization: Design support for hole geometries, patterns, tolerance, size, finish, and specialized anti-corrosion/food/cleanroom requirements.

- Rapid Prototyping: Digital prototyping, 24–48h sample dispatch (expedite program).

- Production & Lead Time: Standard orders shipped in 10–15 working days; urgent batch orders via express channel.

- Support & Value Added: Cutting, bending, rolling, welding, slotting, powder coating, anodizing, laser-engraving, QC docs & 3rd party inspection upon request.

- Warranty: 3–5 years against structural or corrosion failures under proper installation and standard usage.

- After Sales: Dedicated engineer support, 48h response, technical troubleshooting, free training videos, and extended product traceability.

Professional FAQ: Perforated Metal Mesh Terminologies & Best Practices

-

Q: What is the difference between open area and hole size in perforated mesh?

A: Open area (%) is the total percentage of aperture in the mesh, affecting flow rate and transparency. Hole size is the diameter or width of a single perforation. Both are specified for each project. -

Q: Which material is best for anti-corrosion applications?

A: 316 stainless steel performs best in corrosive or saline environments, meeting ASTM A240 and EN 10088-2 requirements. Aluminum is used where lightweight is crucial, but may require anodizing. -

Q: What is the standard tolerance for hole and pitch?

A: Typical industry tolerance is ±0.10 mm for CNC punching and up to ±0.05 mm for laser-cut holes. Pitch tolerance generally follows ISO 2768-m standards. -

Q: How are sheets installed and what mounting standards apply?

A: Installation is tailored: façade panels may use hidden clip systems; industrial mesh is bolted/welded per EN 1993 (Eurocode 3) or AISC standards. Custom fixings are available for unique projects. -

Q: Are there fire or water certifications for these products?

A: Yes, materials meet Class A fire resistance (EN 13501, DIN 4102) and can be supplied with WRAS or NSF61 approval for potable water applications. -

Q: Does surface treatment affect mesh lifespan?

A: Absolutely: anodizing, powder coating, passivation, or specialized food-grade treatments can extend outdoor lifespan by 2–4x and enhance chemical/rust resistance. -

Q: What details are required for custom perforated metal for sale orders?

A: Key details: material grade, hole/pitch size, open area, thickness, finish, sheet/coiling dimension, quantity, and any relevant standards. Drawings and technical specs are highly recommended.

IX. FAQ, Delivery & Trust Guarantee

- MOQ: From 10 m²; trial orders welcome.

- Standard Delivery: 10–15 working days for general specifications. Air/sea shipping worldwide.

- Warranty: Structural & anti-corrosion warranty (3–5 years) per contract; full compliance with ISO 9001:2015; inspection reports for each lot.

- Customer Support: Pre-sale engineering advice, 24/7 chat/email support, site video tours for large orders, and after-sales technical bulletins.

- Certifications: ISO, SGS, CE, Factory QA/Laboratory test available for each batch on request.

- Global Clients: Projects in 76+ countries; top-rated supplier for filter/engineering OEM Tier 1, utilities, and contractors.

- Reputation: 98.5% client repeat rate; rated 4.85/5 on major B2B platforms.

X. Client Case Studies & Industry Endorsements

- Petrochemical Refinery, Middle East (2023): Perforated filter pipe installations, with perforated metal mesh exceeding API/ISO pressure drop specs and doubling cleaning cycle frequency. ROI improvement: 18% per annum.

- Municipal Water Treatment, Europe (2022): Intake screening system. Reduced blockages by 67% and operation cost by 23%; 40,000h field-tested lifespan.

- Architectural Landmark, Australia (2024): Custom facade; passed salt-spray and wind pressure tests, conforming to AS/NZS 4284. Client feedback: “Unparalleled durability and aesthetics.”

Customer Testimonials

- “Their technical team’s expertise in optimizing open area made a real difference for our filtration efficiency. Highly recommended!” — Senior Engineer, Fortune 500 Energy

- “On-time delivery, strict QA, and competitive warranties. Faultless.” — Municipal Project Manager, EU

- “Seamless solution from design to installation. Our first choice for perforated metal for sale.” — Architect, Award-winning Firm

- Mordor Intelligence. "Global Perforated Sheet Metal Market Outlook 2024". Read report

- IndustryARC. "Perforated Metal Mesh Trends & Forecasts". source

- Materials Science Forum (2023), Corrosion Resistance Testing in SS Mesh, journal article

- ISO/TC 155, ISO 900

Post time: Aug . 05, 2025 13:00