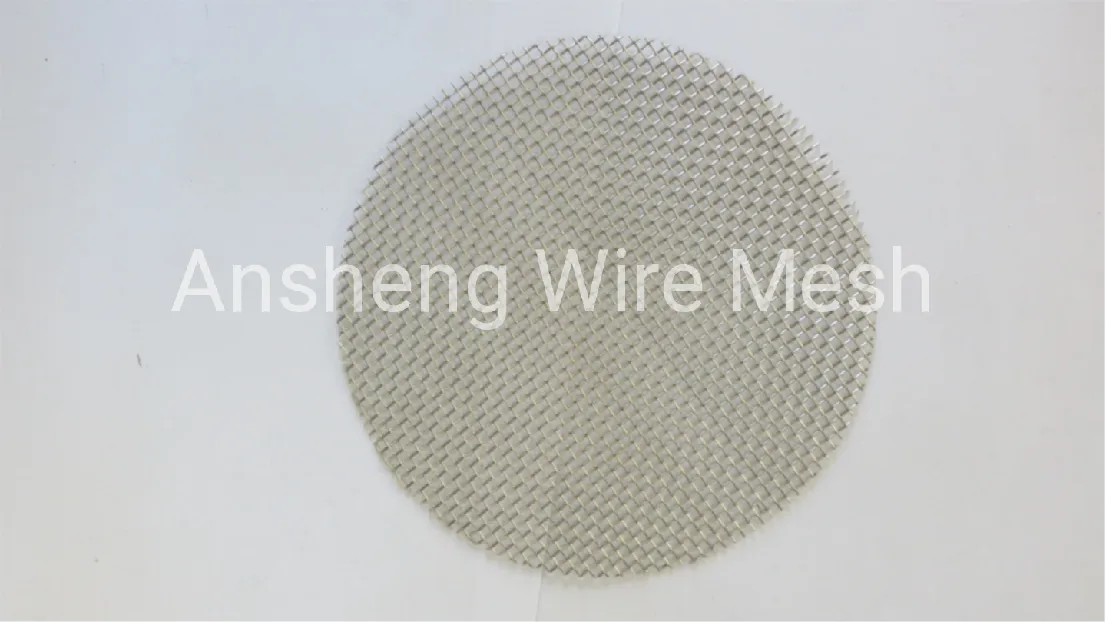

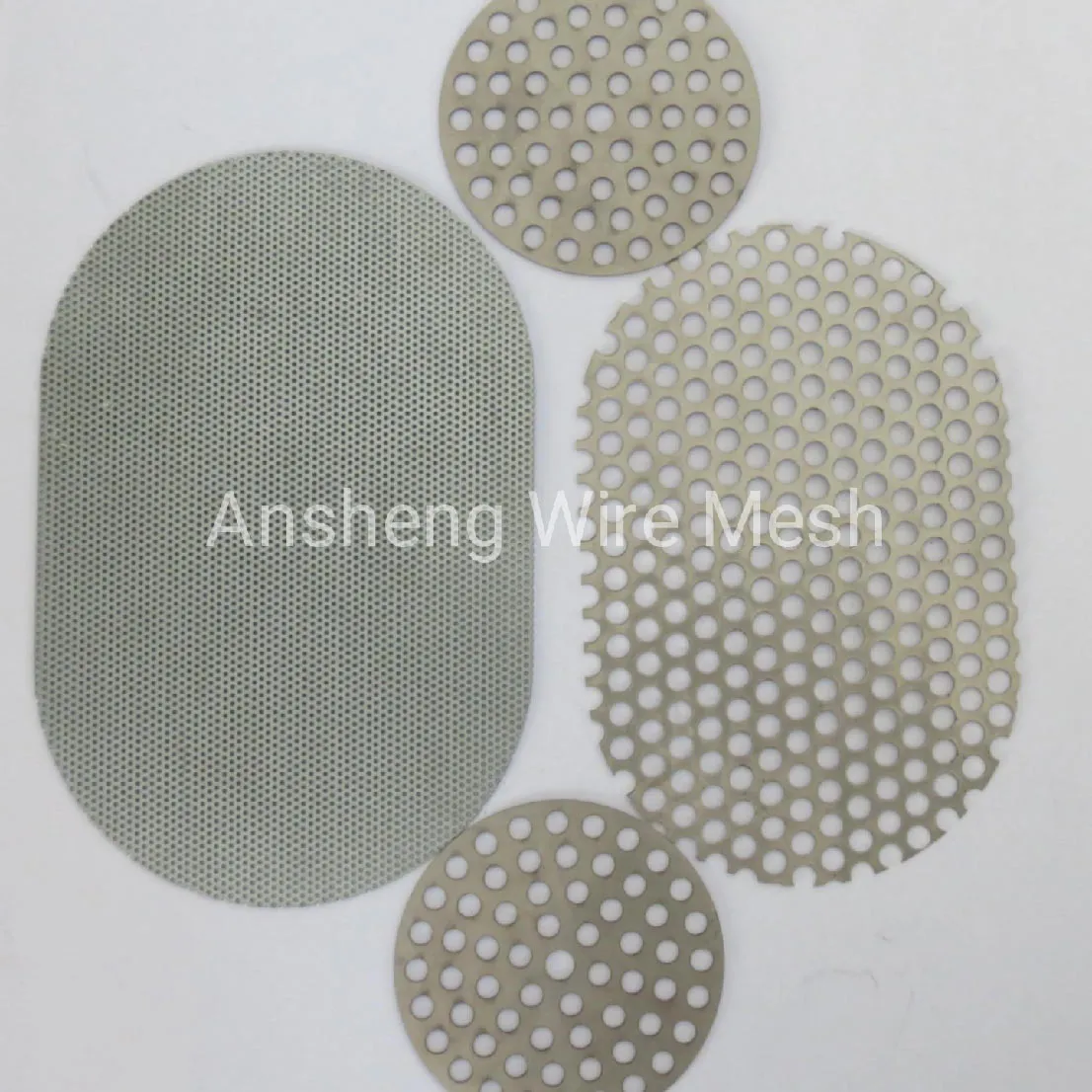

Discover the superior performance and reliability of **wire mesh discs from Anping County Ansheng Wire Meshes Product Co., Ltd. These precision-engineered discs are designed to meet the highest standards of accuracy, durability, and versatility, making them ideal for a wide range of industrial and commercial applications. This article explores the features, technical specifications, and benefits of these **mesh discs, while highlighting the company's commitment to excellence and innovation.

Why Choose Single Layer Wire Mesh Discs?

Single layer **wire mesh discs are engineered to deliver exceptional performance in demanding environments. Whether used for filtration, screening, or structural applications, these discs combine advanced manufacturing techniques with high-quality materials to ensure precision, durability, and cost-effectiveness. Let’s delve into the key features that set these **mesh sanding discs apart.

Key Features of Single Layer Wire Mesh Discs

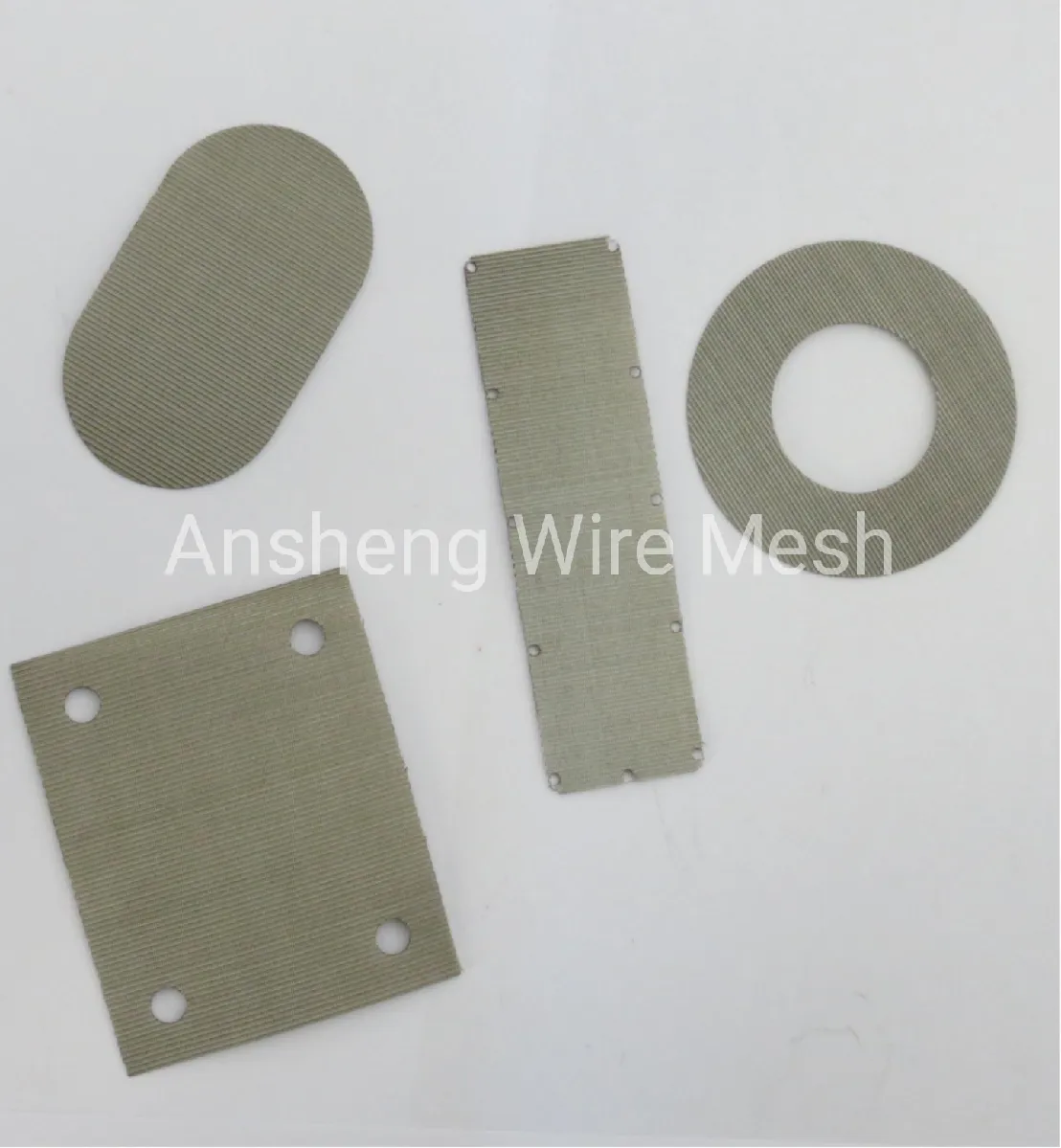

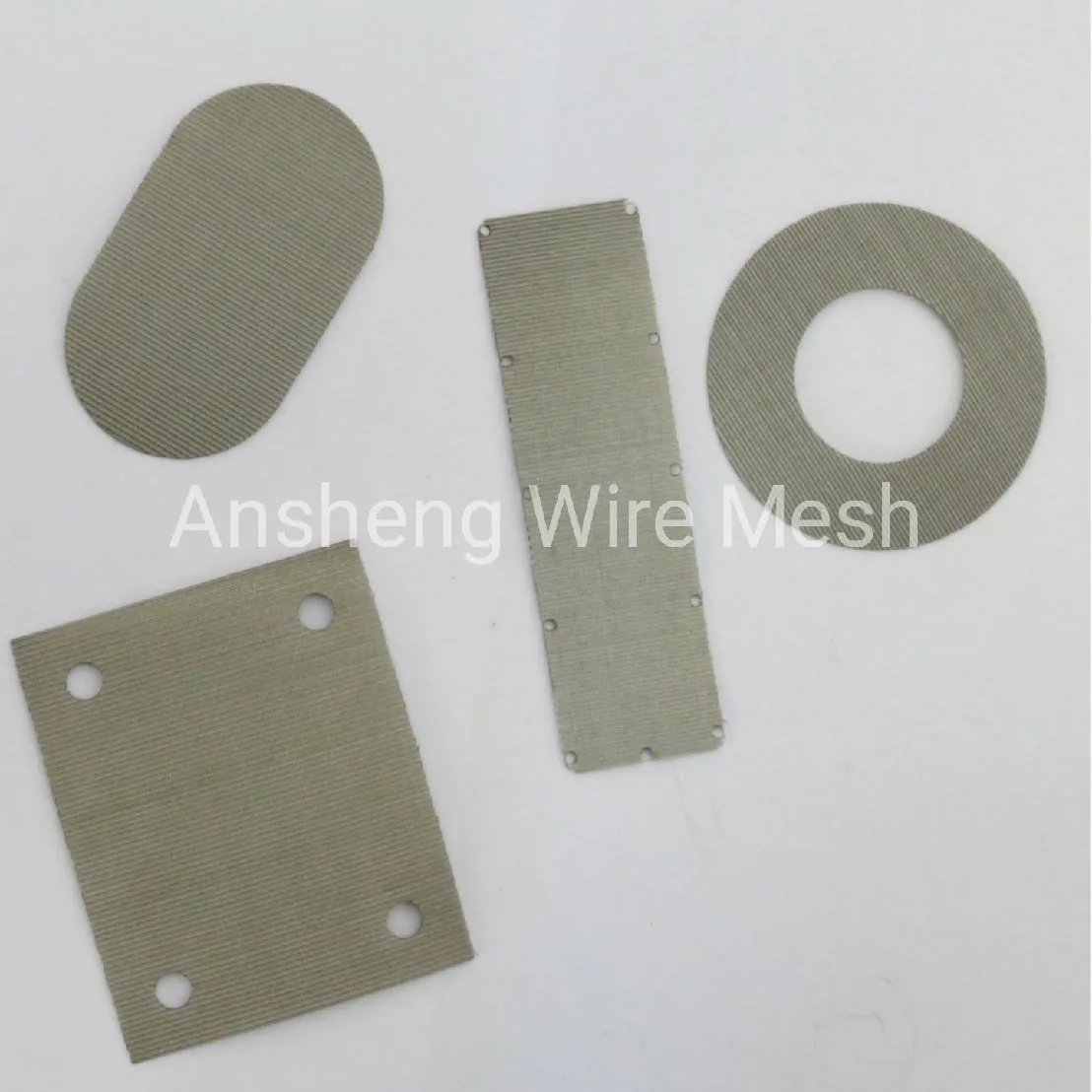

1. Shape Regularity for Seamless Integration

The **wire mesh discs are designed with meticulously crafted edges that maintain a regular shape, ensuring no distortion or deformation. This precision allows for easy installation and stable performance during operation. The uniformity of the discs ensures they integrate seamlessly with other components, minimizing the risk of misalignment or failure.

2. High-Quality Materials for Longevity

Constructed from premium materials such as **stainless steel 304, **stainless steel 201, **stainless steel 316, and **galvanized steel, these discs offer outstanding corrosion resistance, strength, and toughness. The use of high-purity raw materials ensures the discs can withstand harsh conditions, making them suitable for both industrial and outdoor applications.

3. Fine Weaving for Optimal Filtration

The **mesh discs are tightly woven with consistent mesh sizes, eliminating defects such as skipped threads or gaps. This precision ensures accurate filtration and a visually appealing finish. The fine weaving also enhances the structural integrity of the discs, preventing deformation under pressure or load.

4. Accurate Specifications for Precision Applications

Every **wire mesh disc is manufactured to meet strict dimensional tolerances. The length, width, and aperture are precisely controlled to ensure compatibility with existing equipment. This accuracy is critical for applications requiring exact fit and performance, such as in the pharmaceutical, food processing, and chemical industries.

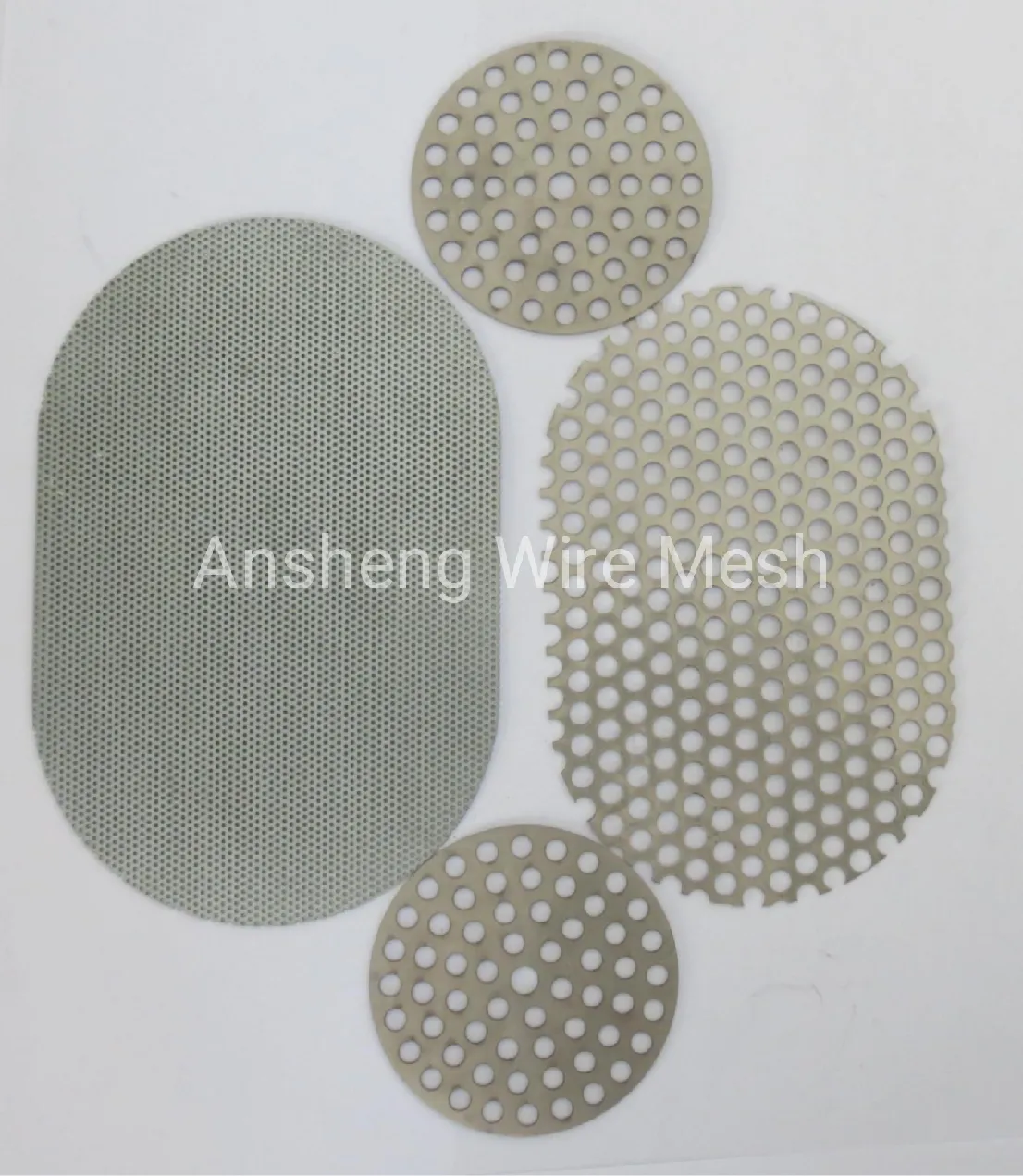

Technical Specifications of Single Layer Wire Mesh Discs

| Parameter | Details |

|---|---|

| Materials | Stainless steel 304, 201, 316, 316L, nickel N6, nickel200, nickel N4, low-carbon steel, galvanized steel, and others. |

| Mesh Size Range | 1 to 635 mesh |

| Dimensions | 1mm to 1m in length and width |

| Shapes | Circle, square, oval, kidney-shaped, rectangle, and irregular shapes. |

| Types | Woven wire mesh, perforated mesh, expanded metal mesh. |

| Surface Finish | Smooth edges, burr-free, and uniform texture. |

Applications Across Industries

The versatility of **wire mesh discs makes them indispensable in various sectors. Here are some key applications:

- Industrial Filtration: Used in chemical processing, oil and gas, and water treatment to remove impurities and ensure product purity.

- Food and Beverage: Ideal for sieving, grading, and separating ingredients in food production facilities.

- Pharmaceuticals: Ensures precise particle size control during drug formulation and packaging.

- Automotive and Manufacturing: Employed in dust collection systems, ventilation, and structural components.

- Construction: Used in scaffolding, safety barriers, and decorative elements.

Why Anping County Ansheng Wire Meshes Product Co., Ltd.?

As a leading manufacturer in the **wire mesh industry, Anping County Ansheng Wire Meshes Product Co., Ltd. combines advanced technology, experienced expertise, and rigorous quality control to deliver exceptional products. Their commitment to innovation and customer satisfaction is evident in every **mesh disc they produce.

Advanced Manufacturing Process

The company utilizes state-of-the-art **CNC machining equipment and employs a skilled technical team to ensure precision and consistency. Every **wire mesh disc undergoes strict testing to meet industry standards, guaranteeing reliability and performance.

Cost-Effective Solutions

By offering customized cutting and precise logistics planning, Anping County Ansheng eliminates the need for customers to purchase and cut entire rolls, reducing material waste and shipping costs. This approach not only saves time and money but also ensures that every **mesh sanding disc is tailored to the customer’s specific requirements.

Industry Standards and Certifications

The **wire mesh discs produced by Anping County Ansheng adhere to international standards for quality and performance. The company’s adherence to **NIST (National Institute of Standards and Technology) guidelines ensures that their products meet the highest levels of accuracy and reliability. According to NIST, "Precision measurements and standards are critical for advancing technology and ensuring consistency across industries" (NIST). This alignment with industry benchmarks underscores the company’s commitment to excellence.

Conclusion

Anping County Ansheng Wire Meshes Product Co., Ltd. offers **wire mesh discs that combine precision, durability, and versatility to meet the demands of modern industries. With their advanced manufacturing processes, high-quality materials, and customer-centric approach, the company has established itself as a trusted leader in the **wire mesh industry. Whether you need **mesh sanding discs for filtration, structural support, or decorative purposes, Anping County Ansheng delivers solutions that exceed expectations.

References

National Institute of Standards and Technology (NIST). "Driving Innovation." Retrieved from https://www.nist.gov/.

Post time: Aug . 05, 2025 12:05