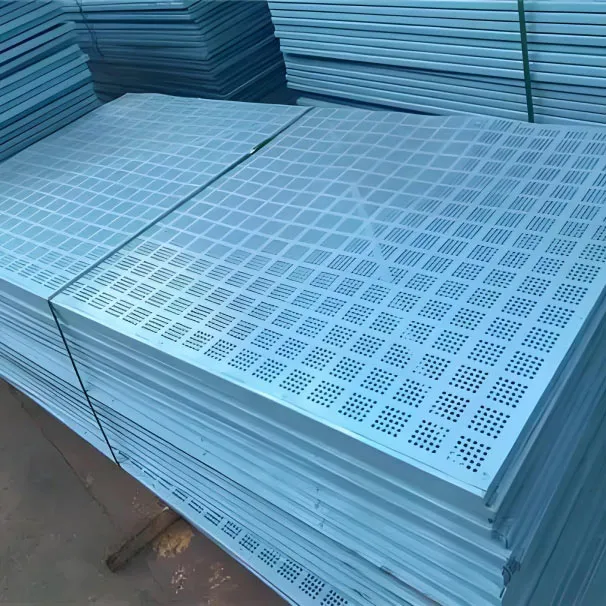

Perforated mesh (also called perforated metal or perforated sheet) is a versatile sheet material characterized by a pattern of precisely punched holes. These holes can vary in sizes, shapes, spacings, and arrangements, making the material adaptable to a wide range of industrial, architectural, and decorative applications.

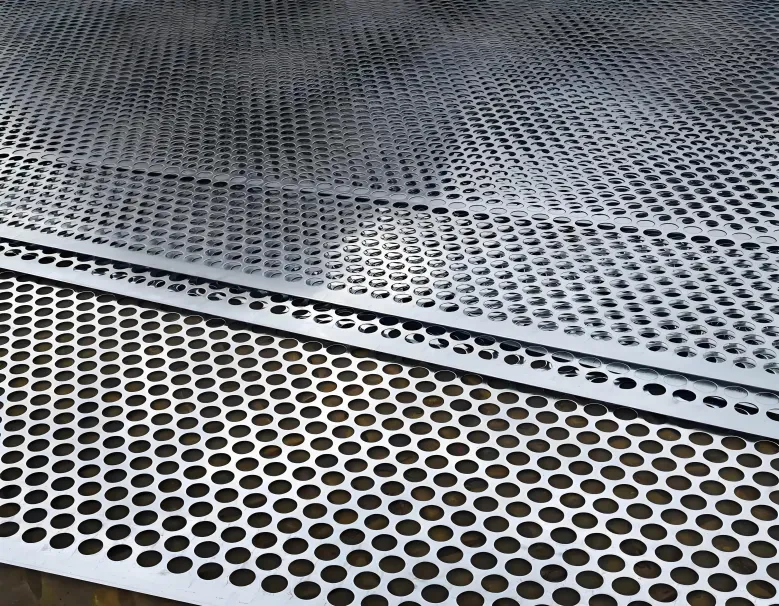

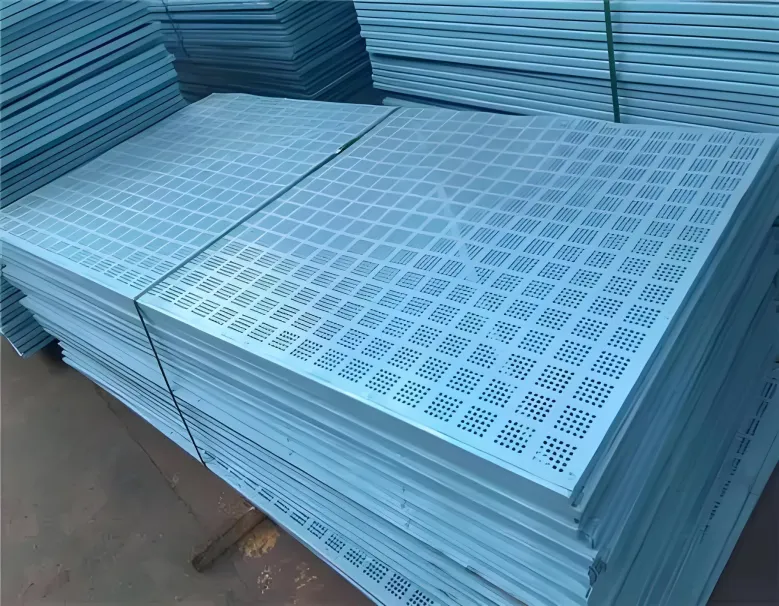

Perforated metal is one of the most versatile and popular metal products on the market today. Perforated sheet can range from light to heavy gauge thickness and any type of material can be perforated, such as perforated carbon steel. Perforated metal is versatile, in the way that it can have either small or large aesthetically appealing openings. We offer perforated metal with round, square, slotted, and hexagonal holes. This makes perforated sheet metal ideal for many architectural metal and decorative metal uses. Perforated metal is also an economical choice for your project. Our perforated metal filters out solids, diffuses light, air, and sound. It also has a high strength-to-weight ratio.

Key Features

Material Options:

Metals: Stainless steel, aluminum, galvanized steel, copper.

Plastics: PVC, acrylic, or polycarbonate.

Specialty Alloys: Titanium, brass, or corten steel (for outdoor/artistic use).

- Hole Patterns:

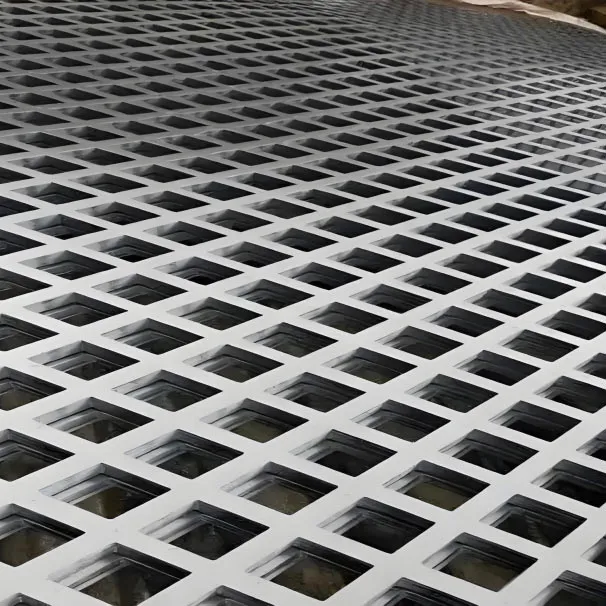

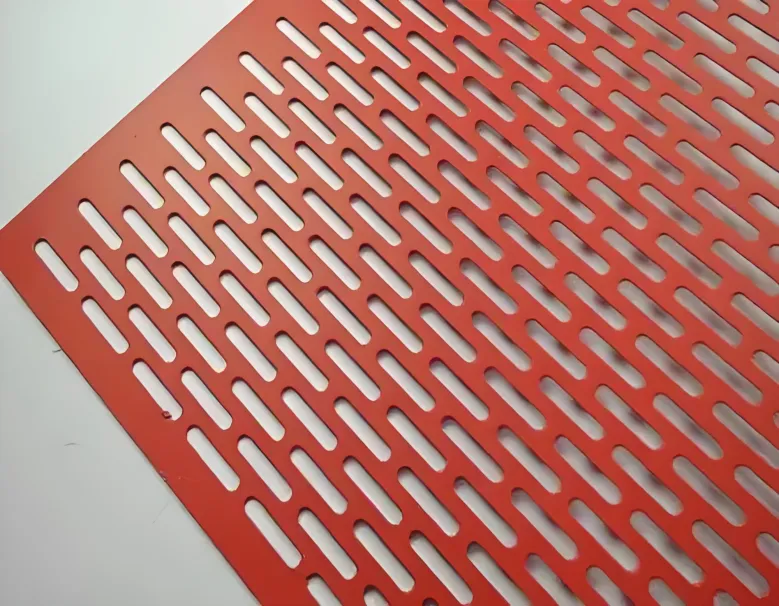

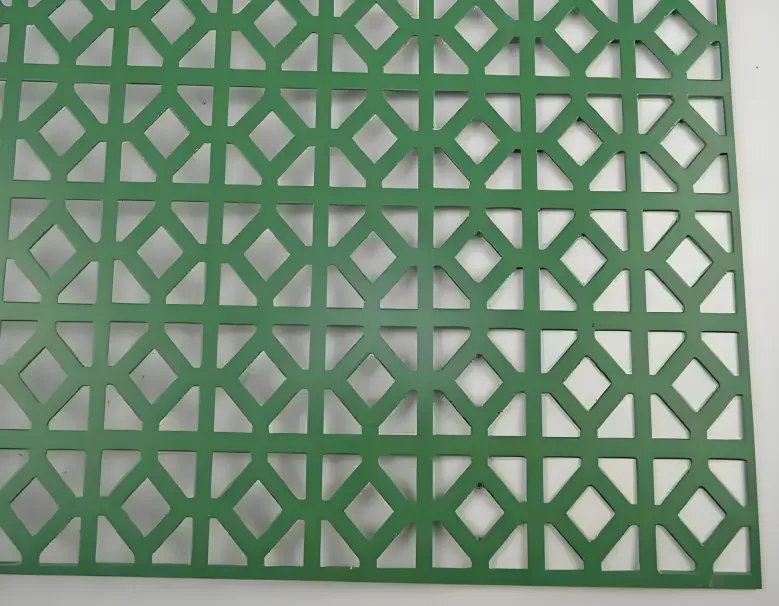

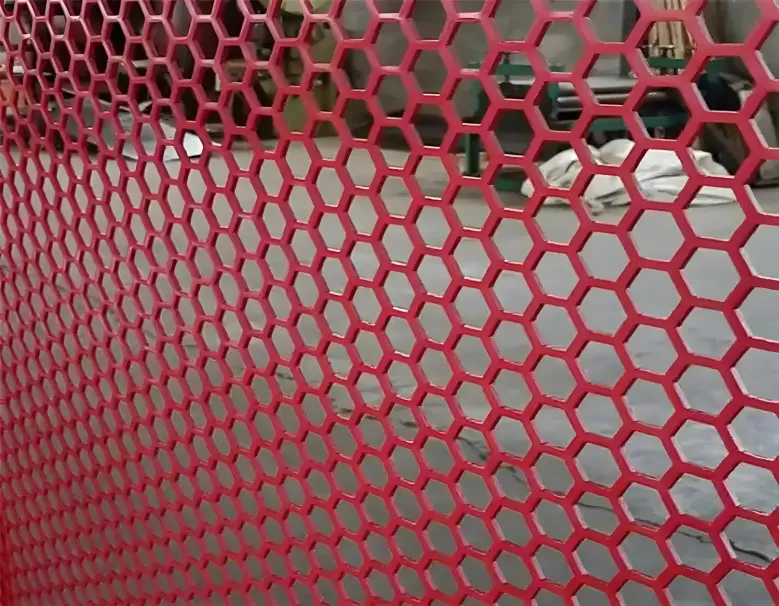

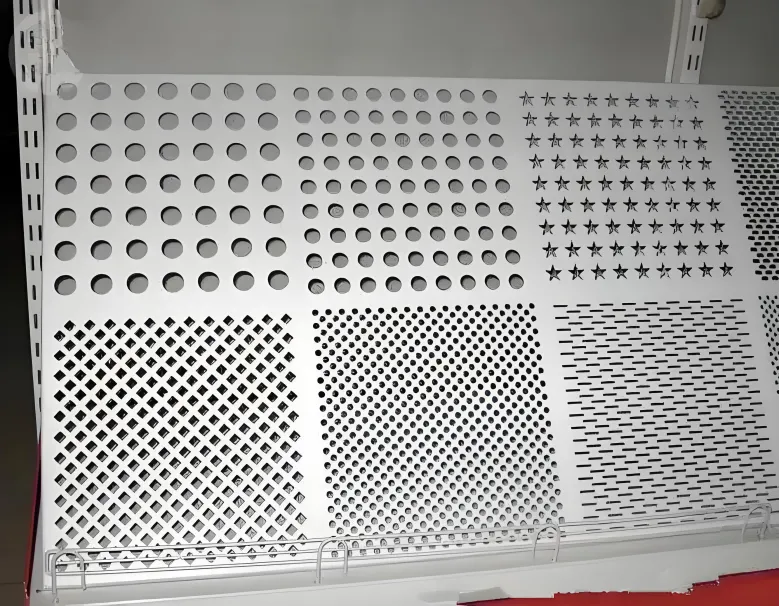

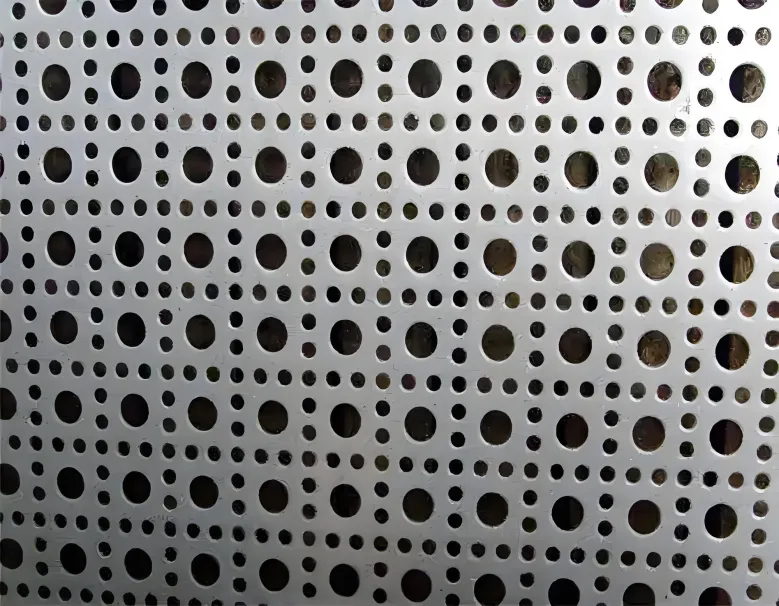

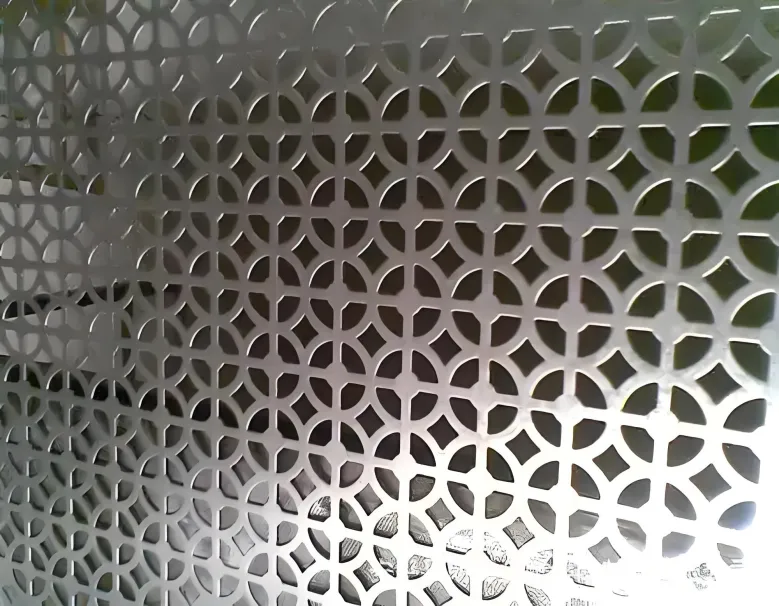

Shapes: Round, square, hexagonal, slotted, or custom designs (e.g., decorative floral patterns).

Arrangement: Staggered, straight-line, or radial layouts.

- Customization:

- Hole diameter (from <1 mm to 50+ mm).

- Open area percentage (ratio of holes to solid material).

- Sheet thickness (gauge) and overall dimensions.

Perforated mesh is created by punching holes into flat sheets using:

Mechanical presses (for standard patterns).

Laser/CNC cutting (for precision or intricate designs).

Perforated mesh is utilized across various industries due to its versatile design, which combines functionality with efficiency. Here are the key reasons for its use, organized by application:

- Airflow and Ventilation:

- Allows air circulation while blocking debris, ideal for HVAC systems, engine covers, and industrial vents.

- Filtration and Screening:

- Acts as a sieve or filter in food processing, water treatment, and agricultural settings, with hole sizes tailored to particle separation.

- Weight Reduction and Structural Integrity:

- Maintains strength while reducing weight, beneficial in aerospace and automotive industries for fuel efficiency and load management.

- Drainage and Liquid Management:

- Facilitates liquid passage in drainage systems, sinks, and agricultural irrigation, preventing water accumulation.

- Acoustic Control:

- Used in soundproofing panels and acoustic tiles to absorb sound waves, targeting specific frequencies through strategic hole patterns.

- Aesthetic and Architectural Design:

- Serves decorative purposes in façades, screens, and lighting fixtures, offering visual appeal with functional light and air penetration.

- Safety Applications:

- Provides visibility and airflow in machine guards and safety barriers, while preventing access to hazardous areas.

- Industrial and Manufacturing Efficiency:

- Customizable patterns (round, square, slotted) cater to specific needs, such as conveyor belts in manufacturing or shielding in electronics.

- Material and Environmental Adaptability:

- Available in materials like stainless steel for corrosion resistance or plastics for lightweight applications, ensuring suitability across environments.

Considerations: While perforated mesh offers numerous benefits, potential drawbacks include clogging in filtration contexts and the need for precise engineering to maintain structural strength. Regular maintenance and thoughtful design mitigate these issues, making perforated mesh a highly adaptable solution.

Common Applications

- Industrial:

Filtration/Screening: Sieves, oil filters, mining screens.

Ventilation: Machine guards, HVAC panels, conveyor belts.

Acoustic Control: Sound-dampening panels in studios or factories.

- Architectural:

Facades: Decorative building cladding or sunshades.

Flooring: Anti-slip walkways, stair treads, or drainage grates.

Safety: Guardrails, fencing, or protective barriers.

- Automotive:

- Grilles, radiator covers, or exhaust shields.

- Consumer/DIY:

Home Decor: Furniture, lampshades, room dividers.

Gardening: Compost bins, trellises, animal enclosures.

Art: Sculptures, signage, or outdoor installations.

Advantages :

Functionality: Combines strength with airflow, light diffusion, or filtration.

Durability: Resists corrosion, heat, and wear (depending on material).

Aesthetics: Modern, industrial, or decorative appeal.

Lightweight: Ideal for projects requiring strength without bulk.

Whether you’re building a machine guard, designing a facade, or crafting a DIY project, perforated mesh offers a blend of practicality and creativity.

Advantages

Functionality: Combines strength with airflow, light diffusion, or filtration.

Durability: Resists corrosion, heat, and wear (depending on material).

Aesthetics: Modern, industrial, or decorative appeal.

Lightweight: Ideal for projects requiring strength without bulk.

Choosing the Right Perforated Mesh

Environment: Use stainless steel or PVC for humid/outdoor settings.

Load Requirements: Thicker gauges (e.g., 10–14 gauge) for heavy-duty structural uses.

Aesthetic Needs: custom patterns or colored coatings for visual projects.

-

图片文字描述1

-

图片文字描述1

-

图片文字描述1