Production method

It is made of multiple layers of woven mesh connected by spot welding. The mesh can be woven in various ways, such as plain weave, twill weave, dutch weave, etc. The mesh size and wire diameter of each layer of mesh can be selected and combined according to usage needs. Spot welding firmly binds the layers of mesh together, forming a composite mesh structure that retains the flexibility of the woven mesh while increasing its strength and stability through the multi-layered structure.

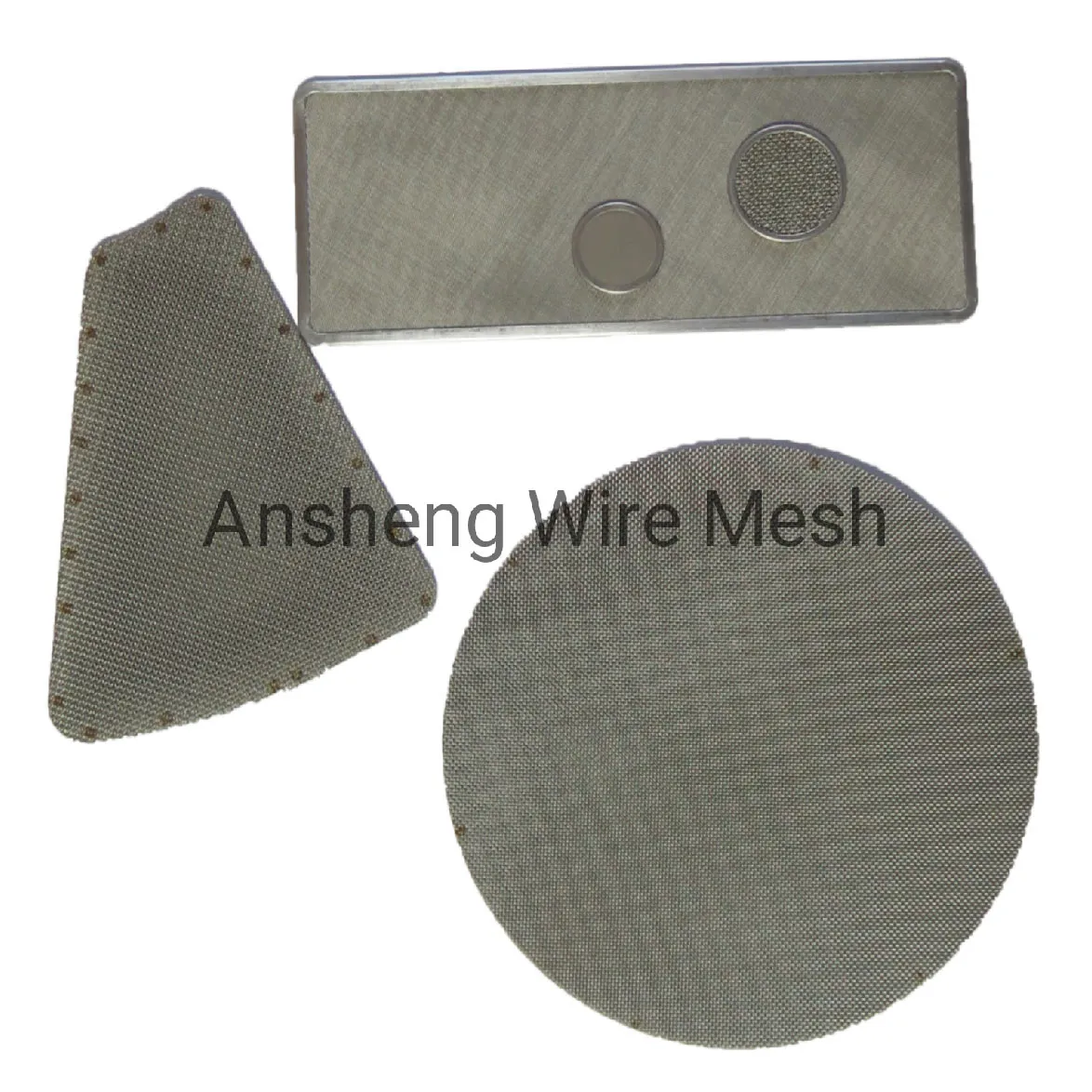

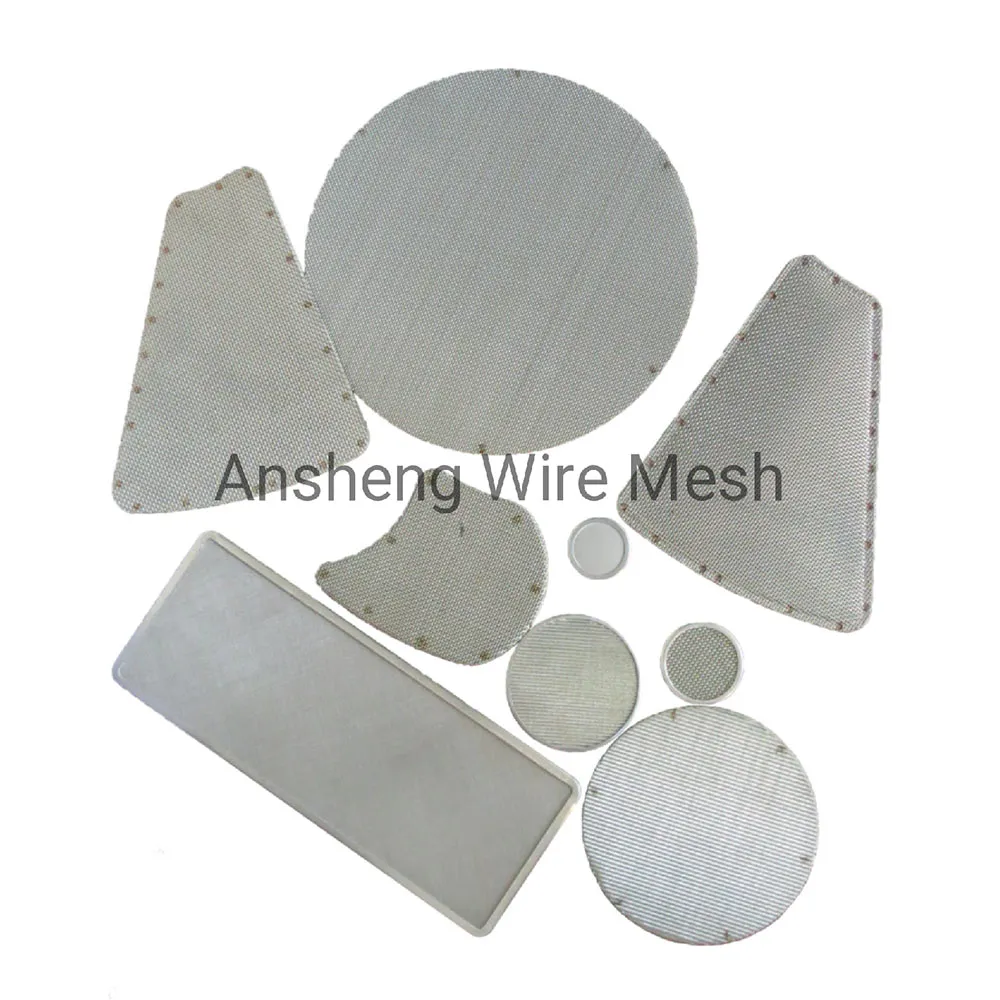

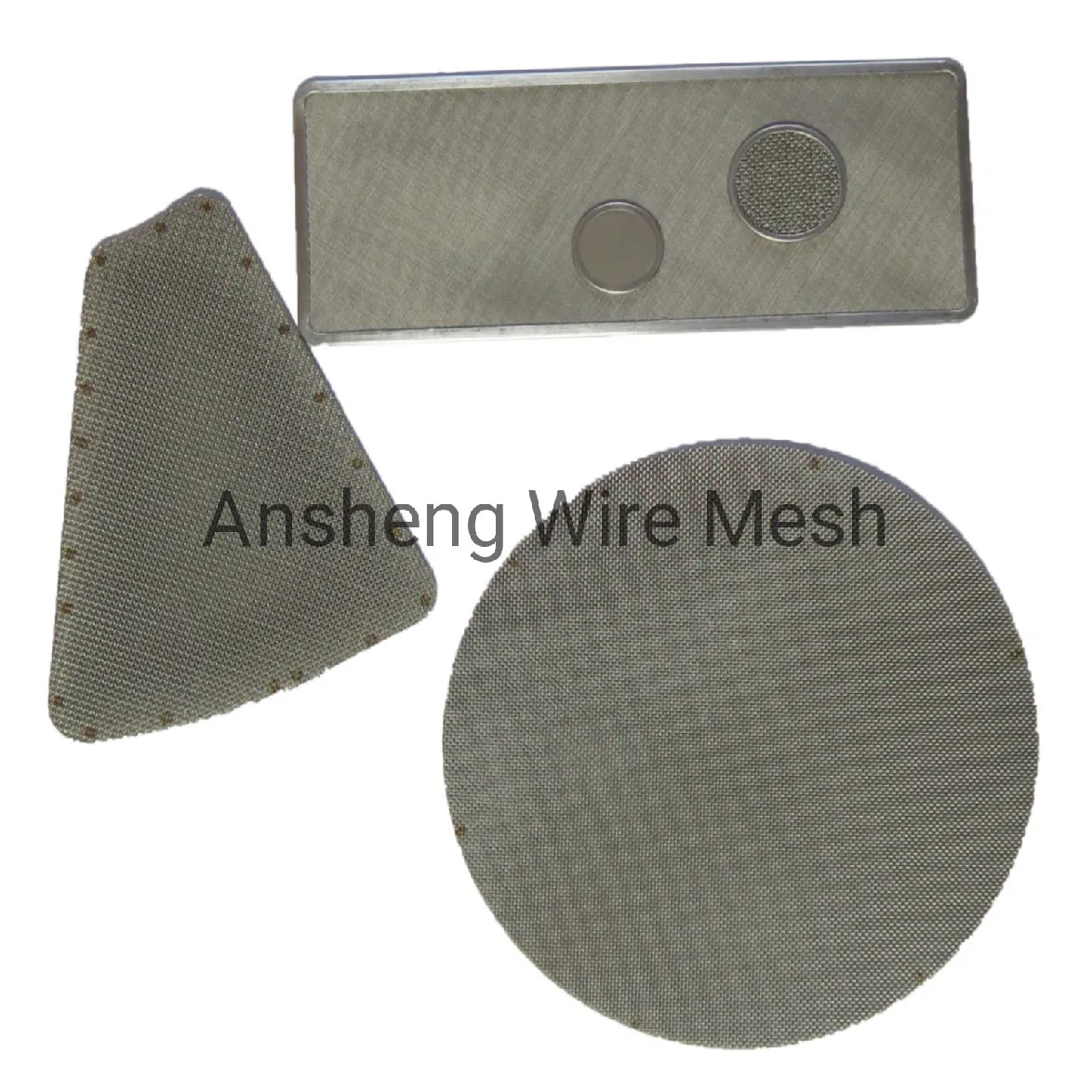

Our high-quality spot welding mesh

solder joint quality

-Firm and reliable: The solder joints are firm enough to withstand certain tensile and shear forces, and are not easily detached during use.

-Uniform and consistent: The size and shape of the solder joints are uniform, and the distribution spacing meets the design requirements. This can ensure uniform force distribution on the mesh and avoid weak local strength caused by uneven solder joints.

-No obvious defects: The surface of the solder joint is smooth, without defects such as pores, slag inclusions, cracks, etc., to avoid affecting the strength and corrosion resistance of the solder joint.

Mesh size accuracy

-Accurate specifications: The length, width, and mesh size of the mesh comply with the design specifications, and the size deviation is within the allowable range.

-Neat edges: The edges of the mesh are cut neatly, without burrs or flying edges, to avoid injury to personnel or damage to other items during use.

Material quality

-Material meets requirements: The metal wire material used complies with relevant standards and has the specified strength, toughness, and corrosion resistance properties. If stainless steel wire is used, its proportion of elements such as nickel and chromium should comply with the corresponding grade standards.

-Good surface quality: The surface of the metal wire is smooth, without obvious scratches, rust, oil stains, etc., to ensure the quality of the solder joints and the appearance quality of the mesh.

Overall performance of mesh

-High flatness: The mesh is flat without obvious warping or deformation, making it easy to install and use. It can fit well with the contact surface when placed or laid.

-Strength and stiffness meet the requirements: The mesh has sufficient strength and stiffness to withstand various external forces that may occur during use, such as the pressure during construction processes such as concrete pouring when used as a building mesh.

Advantages

-Enhanced strength and load-bearing capacity: By stacking multiple layers of mesh and connecting them through spot welding, the strength of the mesh in all directions can be significantly improved, and it can withstand greater tensile, compressive, and impact forces.

-Improving stability and deformation resistance: Spot welding fixes the relative position of each layer of mesh, making the overall structure of the mesh more stable, less prone to local deformation or displacement, and better able to maintain its shape and function under external forces. It can be used in some components or structures that require precise shape maintenance.

-Realize multifunctional combination: combining mesh sheets of different materials, mesh sizes, and weaving methods together can achieve multiple properties. For example, the outer layer uses coarse wire diameter and large mesh mesh to provide high strength and protection, while the inner layer uses fine wire diameter and small mesh mesh for filtration or fine protection, thus meeting complex usage requirements.

-Improving filtration performance: In filtration applications, multi-layer mesh can achieve gradient filtration, which is a gradual filtration process from coarse filtration to fine filtration. The combination of mesh sheets with different mesh sizes can more effectively intercept particles of different sizes, improve filtration efficiency and accuracy, reduce impurity leakage, and is widely used in filtration systems in industries such as chemical, petroleum, and water treatment.