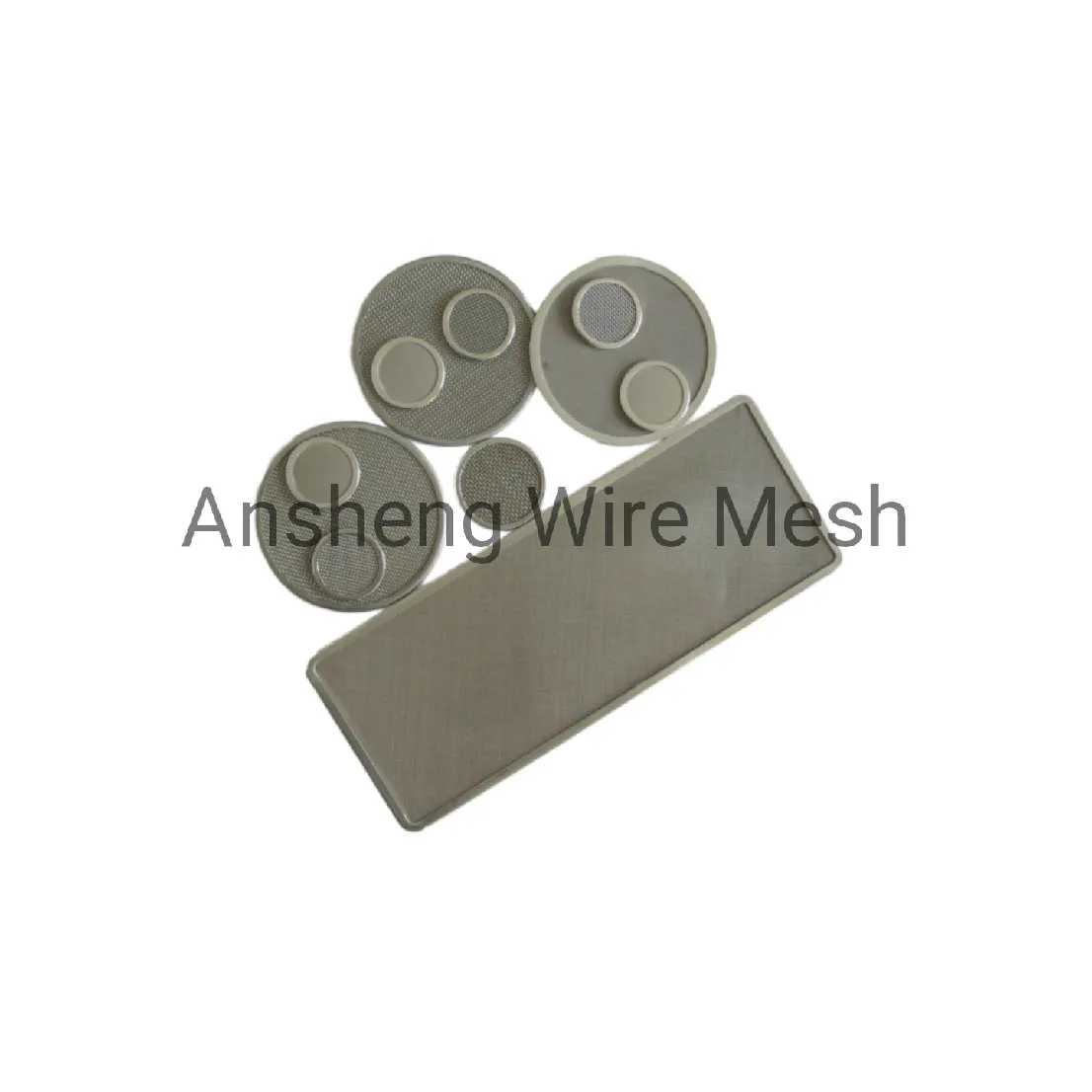

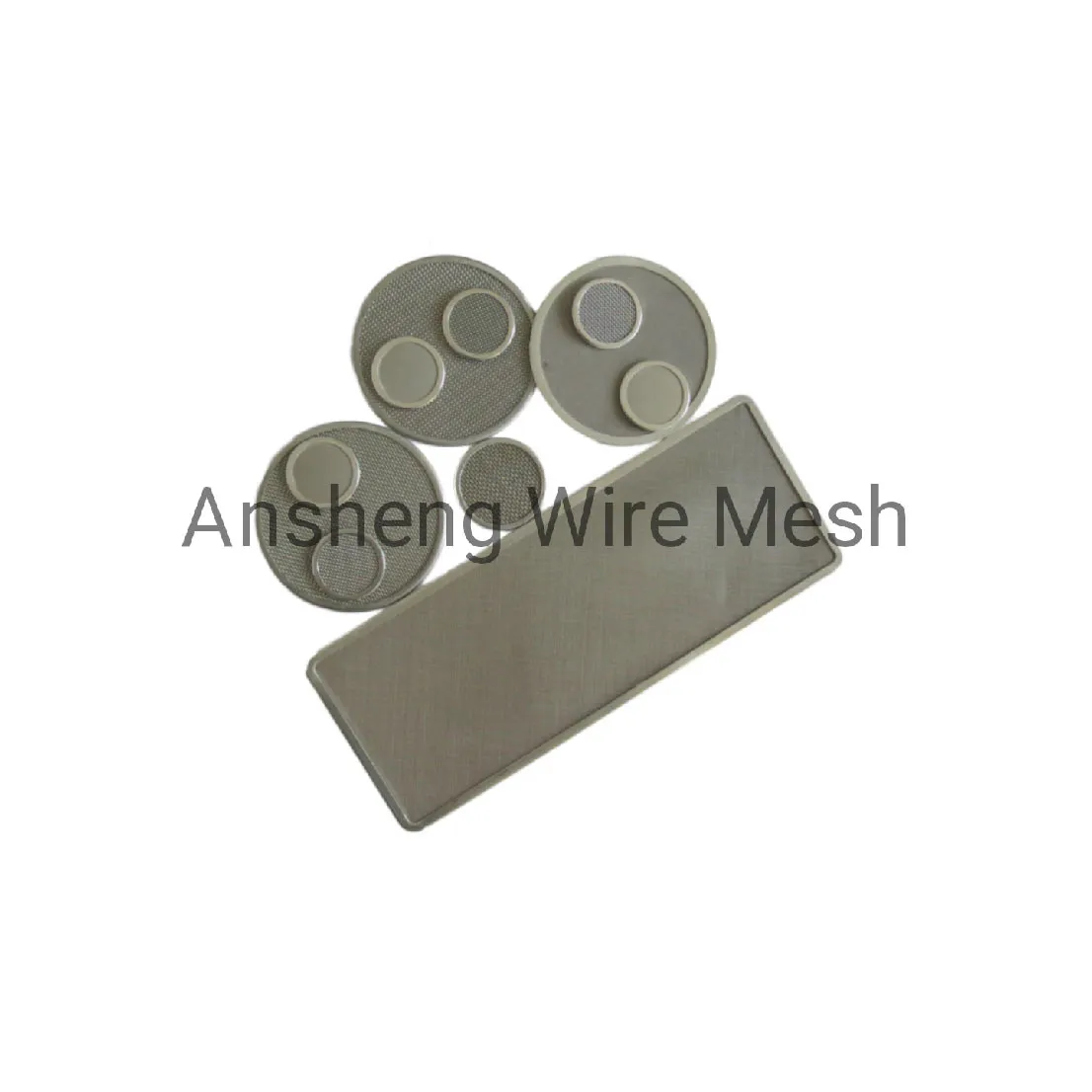

Our high-quality mesh with rim

-High quality material selection: Using high-purity and high-quality raw materials, such as high-grade stainless steel , high-quality galvanized iron , etc., to ensure that the mesh and rim has good corrosion resistance, strength, and toughness.

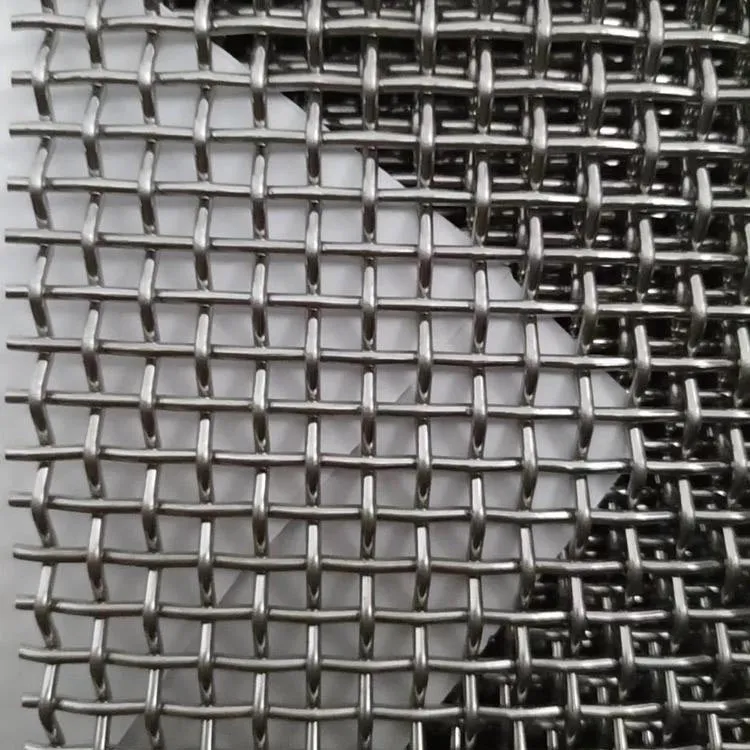

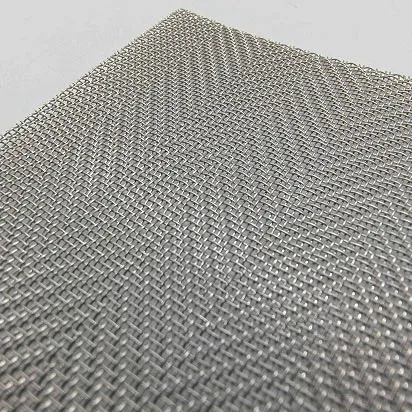

-Fine weaving of mesh: The mesh is tightly and evenly woven, with consistent mesh sizes and no defects such as skipping or leaking, ensuring the filtration accuracy and overall aesthetics of the mesh.

-Secure and flat edge wrapping: The edge wrapping is tightly combined with the mesh, using advanced welding, riveting, or bonding processes to ensure that there are no gaps or looseness between the edge wrapping and the mesh, and the edge wrapping surface is flat and smooth, without obvious bumps, wrinkles, or burrs.

-Accurate specifications: The length, width, aperture and other dimensions of the mesh meet the design requirements, with deviations controlled within the allowable range, ensuring that the mesh can be accurately installed in the predetermined position and well coordinated with other equipment or components.

Advantages

High safety

-Smooth edge: The edge wrapping treatment ensures that the edges of the mesh are free of sharp burrs and edges, effectively avoiding injuries such as scratches and cuts to personnel during use. Especially in situations where personnel frequently come into contact, it can significantly improve safety.

-Preventing the shedding of mesh: The edge wrapping can fix the edge of the mesh, preventing the mesh from loosening or falling off due to external pulling, friction, etc., reducing the safety hazards that may be caused by the shedding of mesh. For example, in food processing workshops, it avoids the mixing of mesh into food, ensuring food safety.

strong stability

-Enhance overall structure: Edge wrapping is equivalent to adding a sturdy frame to the mesh, making the overall structure of the mesh more stable and able to withstand greater external forces. In some applications that require significant pressure or tension, edge wrapping mesh can better maintain its shape, prevent deformation, and provide reliable protection.

-Reduce mesh deformation: During use, the mesh may be deformed by various external forces. Edge wrapping can limit the deformation range of the mesh, allowing it to more evenly distribute stress when subjected to external forces, reducing excessive local deformation, and extending the service life of the mesh.

Good adaptability

-Easy to install: The edges of the edge wrapped mesh are neat and regular, making it easier to connect and fix with other components during installation. The installation process is more convenient and efficient, which can improve construction efficiency and reduce installation costs.

-Tight fitting with equipment: In filtering, screening and other equipment, the edge wrapping mesh can be tightly fitted with the interface or frame of the equipment, ensuring no gaps or loopholes, thereby ensuring the effectiveness of filtering and screening, preventing material leakage from the edges, and improving the efficiency and product quality of the equipment.

Good durability

-Improved corrosion resistance: The edge wrapping material is made of corrosion-resistant metals such as stainless steel, which not only protects the edges of the mesh from corrosion, but also enhances the overall corrosion resistance of the mesh to a certain extent, allowing it to maintain good performance and extend its service life in harsh environmental conditions such as humidity, acid and alkali corrosive environments.

-Enhanced wear resistance: Edge wrapping can provide additional protection for the edges of the mesh, reducing wear caused by friction and collision with other objects during use. Especially in situations where frequent use or severe wear occurs, the wear resistance advantage of edge wrapped mesh is more obvious, which can reduce the frequency of mesh replacement and save costs.