Understanding Expanded Metal: An Industrial Essential

Expanded metal, a versatile and robust material, plays a critical role across numerous industrial applications. It is manufactured from a single piece of metal, slit and stretched into a diamond-shaped pattern, resulting in a mesh-like product that is lighter than solid metal, yet remarkably strong. This unique construction provides an exceptional strength-to-weight ratio, making it an ideal choice for safety, filtration, and architectural purposes. Its inherent properties, such as excellent light and air permeability, make it superior to solid sheets in many contexts. The growing demand for durable, cost-effective, and adaptable materials continues to drive innovation in the expanded metal industry, with particular focus on improved corrosion resistance, customizability, and sustainable manufacturing processes. Industry trends indicate a strong move towards specialized alloys and advanced coating technologies to meet the stringent requirements of extreme environments, pushing the boundaries of what expanded metal can achieve.

For businesses looking for reliable material solutions, investing in high-quality expanded metal for sale is a strategic decision. This material is not merely a component; it's an engineering solution that offers inherent advantages like slip resistance, effective light and air passage, and inherent anti-climb properties when properly installed. Its single-piece construction eliminates welds or interlocks, which are often points of failure in other mesh types, thus enhancing its structural integrity and longevity. This makes it a preferred material for applications requiring both high performance and minimal maintenance, from industrial walkways to protective enclosures in hazardous environments.

The Precision Manufacturing Process of Expanded Metal

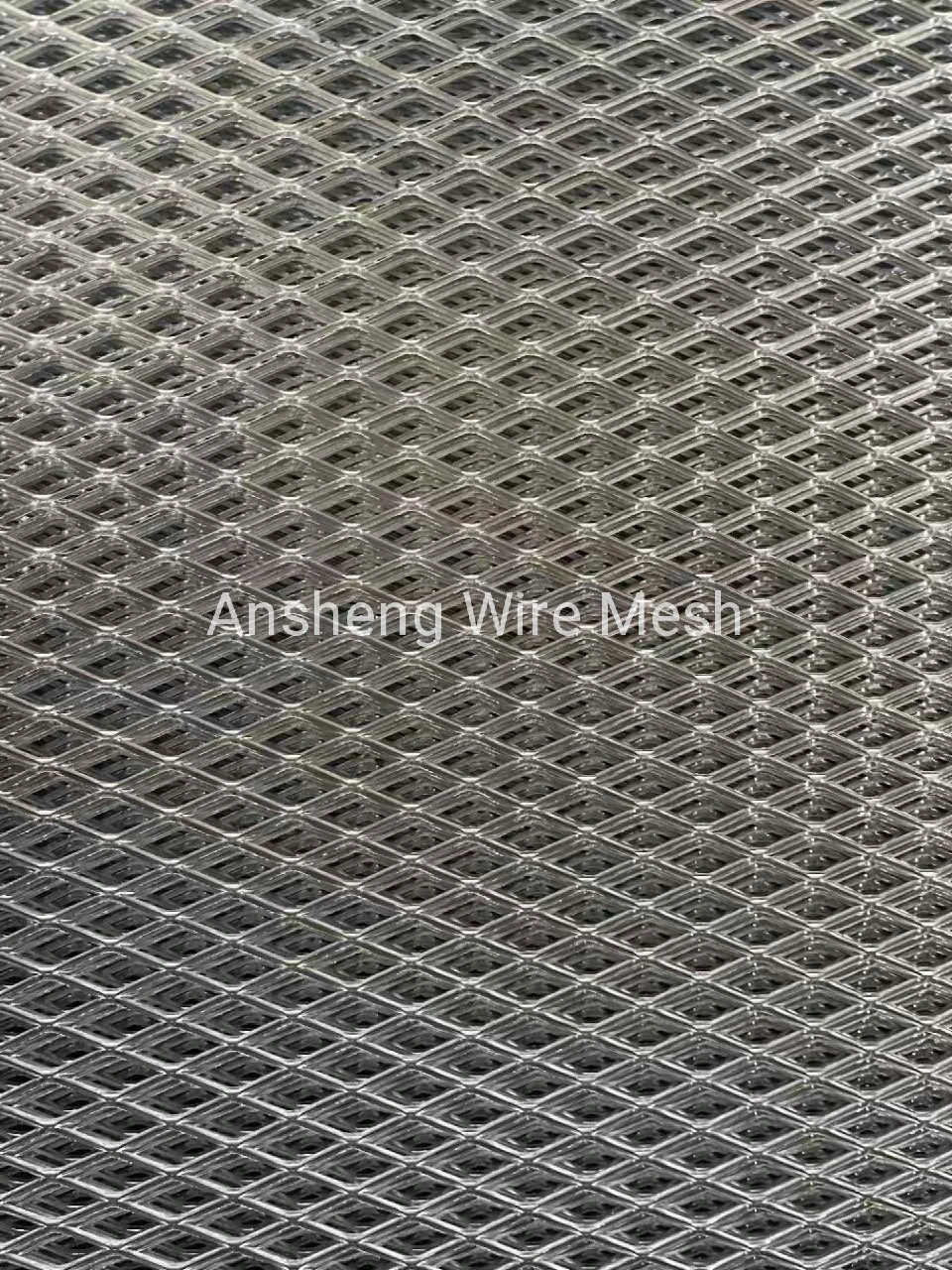

The production of expanded metal involves a highly specialized cold-forming process that transforms a solid sheet of material into a sturdy, open mesh without any waste. This process begins with selecting high-grade raw materials, typically carbon steel, stainless steel (e.g., SS304, SS316), aluminum, or galvanized steel, chosen for their specific properties like corrosion resistance, strength, and weldability. Unlike casting or forging, which involve melting or shaping molten metal, expanded metal is produced by simultaneously slitting and stretching the metal sheet. This creates uniform diamond-shaped openings, known as the mesh pattern. The two primary dimensions defining the mesh are the Long Way of the Diamond (LWD) and the Short Way of the Diamond (SWD). The strand is the side of the diamond opening, and the bond is where the strands intersect.

The manufacturing process adheres to strict international standards such as ISO 9001 for quality management and relevant ANSI (American National Standards Institute) specifications for material dimensions and tolerances. This ensures that every sheet of expanded metal for sale meets precise specifications for industries demanding high reliability. Quality control involves meticulous checks on mesh dimensions, strand thickness, overall sheet flatness, and material integrity. The resulting product is characterized by its high strength-to-weight ratio, excellent energy absorption properties, and a unique anti-slip surface. The life span of expanded metal can vary significantly, ranging from 15 to 50+ years, depending on the material, protective coatings (like galvanization or powder coating), and the specific environmental conditions of its application, especially in corrosive environments like those found in petrochemical or marine industries.

Technical Parameters and Specifications

When sourcing expanded metal for sale, understanding its key technical parameters is crucial for optimal application. These parameters define the mesh's performance characteristics and suitability for specific tasks. Key dimensions include the SWD (Short Way of Diamond), LWD (Long Way of Diamond), strand thickness (the thickness of the original sheet before expanding), and strand width (the amount of metal fed under the die). The selection of material (carbon steel, stainless steel, aluminum), and finishes (galvanized, PVC coated, painted) also greatly influences performance. For instance, in applications like security fencing, a smaller SWD and LWD with a thicker strand provides higher rigidity and anti-climb properties.

Common Expanded Metal Specifications Table

| Parameter | Typical Range / Value | Notes |

|---|---|---|

| Material | Carbon Steel, SS304/316, Aluminum, Galvanized Steel | Selected based on corrosion resistance & strength needs |

| SWD (Short Way of Diamond) | 4 mm - 76 mm | Determines aperture size |

| LWD (Long Way of Diamond) | 8 mm - 200 mm | Determines aperture size |

| Strand Thickness | 0.5 mm - 8.0 mm | Affects weight and rigidity |

| Strand Width | 0.5 mm - 8.0 mm | Contributes to strength and open area |

| Sheet Size | Standard 4x8 ft, 1x2m, Custom up to 3m x 15m | Available in sheets or rolls |

| Open Area Percentage | As high as 80% | Important for air/light flow, filtration |

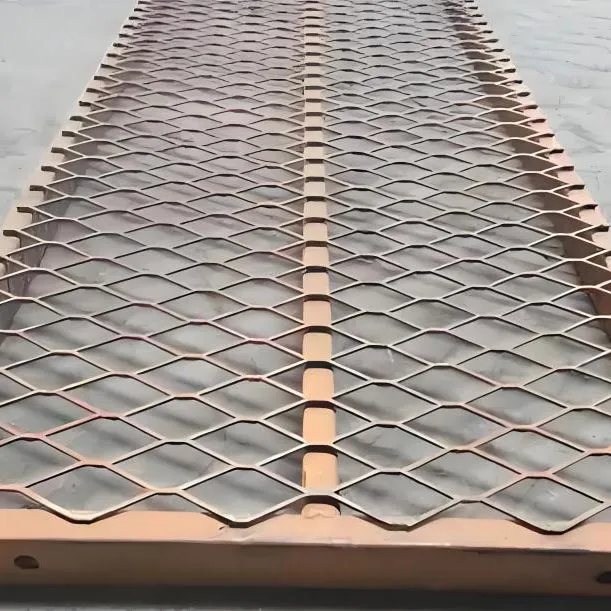

The `4x8 expanded metal` sheet is a particularly common size due to its versatility and ease of handling in various construction and manufacturing environments. This standardized dimension facilitates easier planning and integration into large-scale projects, reducing waste and fabrication time. Beyond standard sizes, custom solutions are frequently required to meet unique project specifications, involving specific mesh patterns, material grades, or complex forming. Manufacturers often work closely with clients to develop bespoke expanded metal products, ensuring precise fit and optimal performance for specialized applications, from industrial machine guards to sophisticated architectural facades.

Versatile Applications and Key Advantages

The adaptability of expanded metal makes it indispensable across a vast array of industries. In the petrochemical sector, it is widely used for catwalks, stair treads, and safety barriers on offshore platforms and refineries, where its anti-slip properties and excellent drainage capabilities are critical for safety and operational efficiency. Its open mesh design facilitates proper ventilation, preventing the accumulation of hazardous gases, and its single-piece construction resists vibrations, enhancing structural integrity in dynamic environments. For metallurgical plants, expanded steel mesh serves as robust screening material for classifying raw materials, and as guards for heavy machinery, protecting personnel from moving parts while allowing for visual inspection.

In water treatment and drainage systems, expanded mesh is employed for filter screens, grates, and security enclosures due to its superior flow-through characteristics and corrosion resistance, especially when made from stainless steel or galvanized materials. Its open structure prevents clogging and allows for efficient fluid management, contributing to energy savings by reducing pumping loads. Beyond these heavy industries, expanded metal finds use in architectural design for facades, sunscreens, and decorative elements; in automotive for grilles and filters; and in construction for reinforcement and security fencing. The inherent advantage of no welds means higher structural integrity, and its formability allows for diverse design possibilities.

Expanded Metal vs. Other Mesh Types

| Feature | Expanded Metal | Woven Wire Mesh | Perforated Sheet |

|---|---|---|---|

| Manufacturing | Slit & stretched from single sheet (no waste) | Wires interwoven (labor intensive) | Holes punched out of solid sheet (material waste) |

| Strength/Rigidity | High, especially perpendicular to sheet | Moderate, can unravel if cut | Lower than expanded, holes reduce structural integrity |

| Weight | Lighter than solid sheet, efficient material use | Generally lighter, but less robust | Heavier than expanded for same open area |

| Open Area Uniformity | Uniform throughout | Uniform, but can deform under stress | Uniform pattern, but limited by hole size/spacing |

| Cost Efficiency | Highly efficient, minimal material waste | Higher due to weaving process | Material waste increases cost |

The clear advantages in structural integrity, material efficiency, and versatility solidify the position of expanded metal for sale as a superior choice for a multitude of demanding industrial and commercial applications. Its ability to provide both ventilation and structural support simultaneously, without the material loss associated with punching, results in a more economical and environmentally friendly product.

Custom Solutions and Manufacturer Expertise

While standard sizes like `4x8 expanded metal` are readily available, many complex industrial projects require highly customized expanded metal for sale solutions. Reputable manufacturers distinguish themselves through their ability to provide bespoke services, ranging from specific mesh patterns and strand dimensions to specialized materials and finishes. This includes the production of flattened expanded metal, which involves a cold rolling process to create a smooth, level surface, ideal for applications requiring a less aggressive texture. Precision cutting, welding, and forming capabilities are essential for delivering tailor-made solutions that seamlessly integrate into existing systems or new designs.

Choosing the right manufacturer is paramount. A provider with extensive experience and a proven track record demonstrates not only technical proficiency but also a deep understanding of industry-specific challenges. For example, a company specializing in `expanded steel mesh` for demanding filtration systems would possess the expertise in material selection (e.g., specific stainless steel grades for corrosive media) and precision manufacturing to ensure optimal pore size and flow characteristics. Look for certifications (e.g., ISO 9001), consistent quality control processes, and a willingness to provide detailed technical data and material certifications. Our company, with over 15 years of dedicated service in the wire mesh and expanded metal industry, prides itself on delivering certified, high-performance solutions tailored to exact client specifications, backed by rigorous testing and a commitment to customer satisfaction.

Client Success Spotlight: Energy Sector

A leading energy company approached us for a durable, non-slip flooring solution for their new power plant's elevated walkways. They required a material that could withstand extreme temperatures, heavy foot traffic, and potential chemical spills, while also allowing for efficient light and air circulation. We recommended our heavy-duty galvanized `expanded metal` with a specific strand configuration to maximize strength and slip resistance. Our engineering team worked closely with their procurement and safety departments to customize the panel sizes, ensuring minimal waste and easy installation. The project was completed on time and within budget, with the client reporting significantly improved safety conditions and reduced maintenance needs compared to their previous solutions. This case exemplifies how specialized expanded mesh can optimize operational safety and efficiency in critical industrial environments.

FAQs, Delivery, and Support

Frequently Asked Questions (FAQs) about Expanded Metal

-

Q: What is the difference between standard and flattened expanded metal?

A: Standard expanded metal has a raised, textured surface (the strands are set at an angle to the plane of the sheet). Flattened expanded metal is produced by cold rolling standard expanded metal, resulting in a smooth, flat surface. Flattened types are preferred for applications requiring a uniform, non-aggressive surface, while standard types offer superior anti-slip properties.

-

Q: Can expanded metal be used outdoors, and what finishes are best for corrosion resistance?

A: Yes, it is widely used outdoors. For enhanced corrosion resistance, galvanized steel expanded metal is a common choice, offering zinc coating protection. Stainless steel (e.g., 304 or 316) is ideal for highly corrosive environments, like marine or chemical processing. Powder coating provides an additional layer of protection and allows for aesthetic customization.

-

Q: What is the typical lead time for an order of expanded metal for sale?

A: Standard orders of common sizes like 4x8 expanded metal can typically be dispatched within 5-7 business days, depending on stock availability. Custom or large-volume orders may require 2-4 weeks for production and quality assurance. We maintain efficient supply chain management to minimize lead times and ensure timely delivery globally.

Delivery and Quality Assurance

We understand the critical importance of timely delivery and unwavering quality in B2B transactions. Our streamlined logistics ensure efficient dispatch and secure transit of your `expanded mesh` orders. Each shipment undergoes a final rigorous quality check to confirm compliance with all specified parameters and international standards. We provide comprehensive documentation, including material test certificates (MTCs) and certificates of conformity (CoCs), ensuring full traceability and peace of mind.

Our commitment extends beyond delivery. We offer robust after-sales support, including technical assistance for installation and maintenance. All our `expanded steel mesh` products come with a minimum 10-year structural integrity warranty under normal operating conditions, underscoring our confidence in the durability and performance of our materials. For any inquiries or support, our dedicated customer service team is readily available.

References

- ASTM F1267 - 07(2021) Standard Specification for Metal, Expanded, Steel, for Fencing and Other Security Applications.

- ISO 9001:2015 - Quality Management Systems - Requirements.

- The Engineering Handbook of Perforated and Expanded Metals, 3rd Edition.

- Corrosion Resistance of Steel and Other Alloys, NACE International Journal, Vol. 55, Issue 2.

Post time: Aug . 14, 2025 05:40