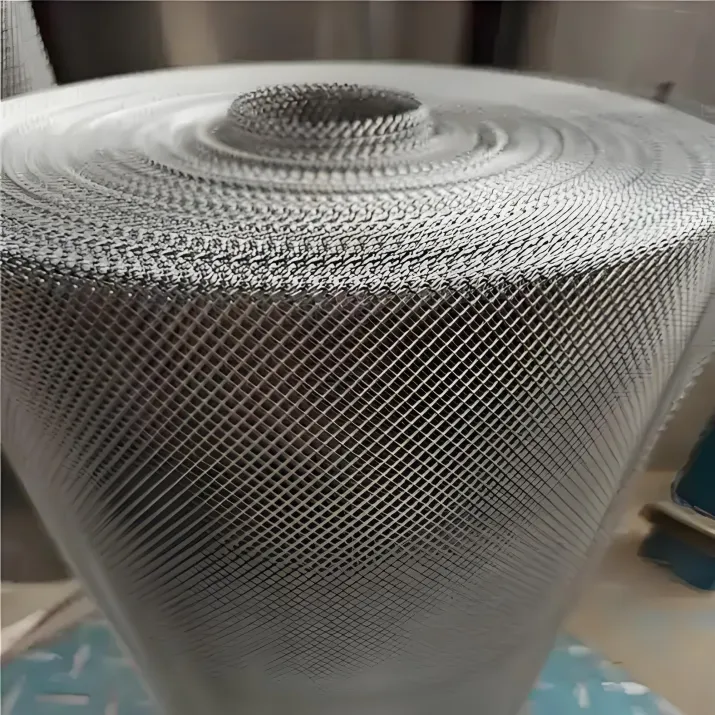

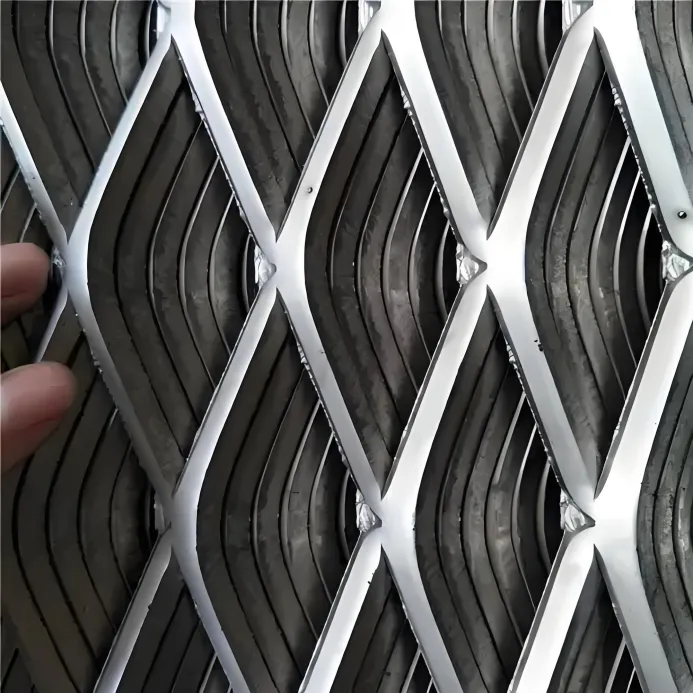

Expanded metal is a versatile sheet material created by cutting and stretching a single metal sheet (e.g., steel, aluminum, stainless steel) into a mesh-like pattern of different shapes of openings. This process retains structural integrity while minimizing waste, resulting in a lightweight, durable, and cost-effective product. Manufacturing: Sheets are slit and stretched under tension, forming interconnected strands and openings.

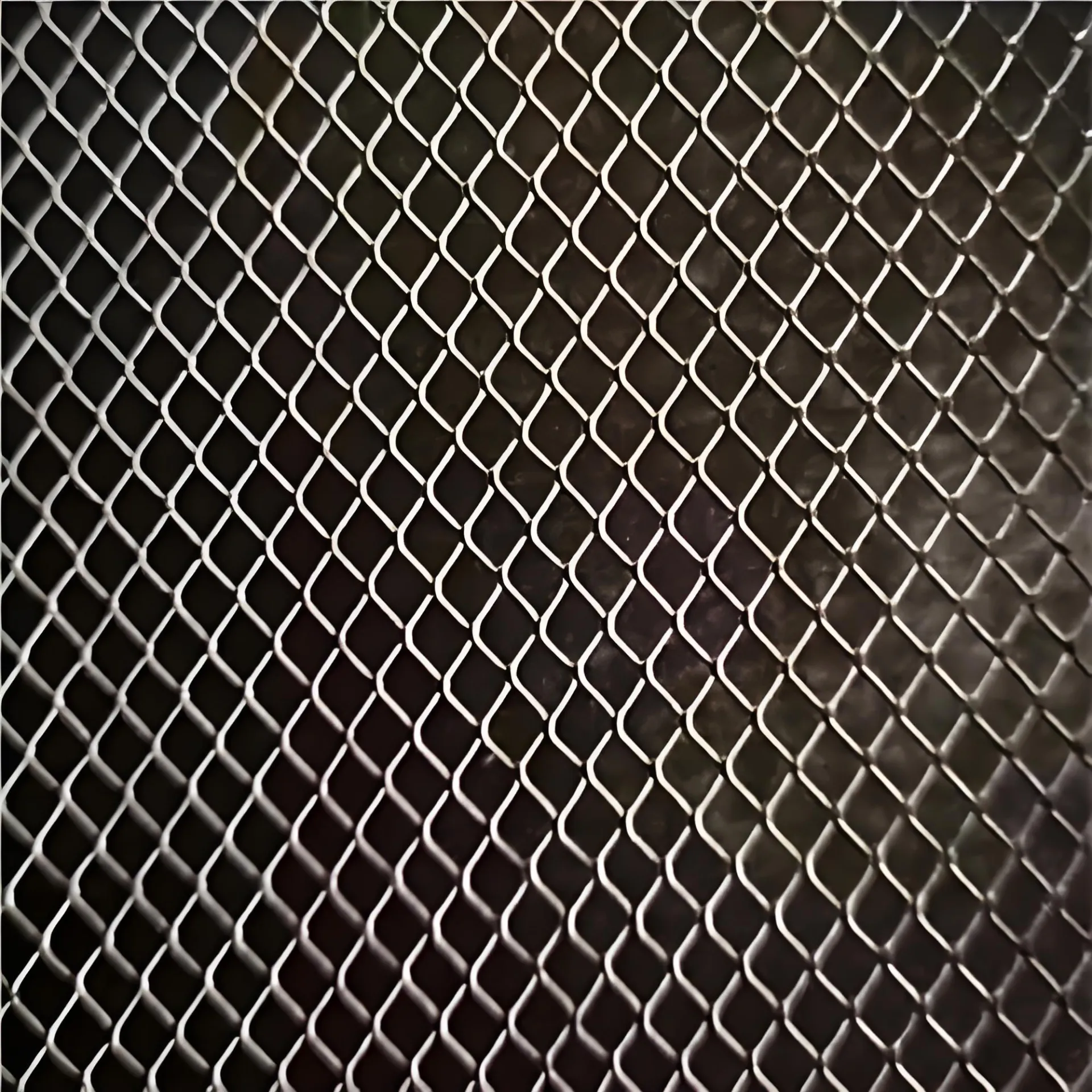

Pattern: different shapes of openingss-

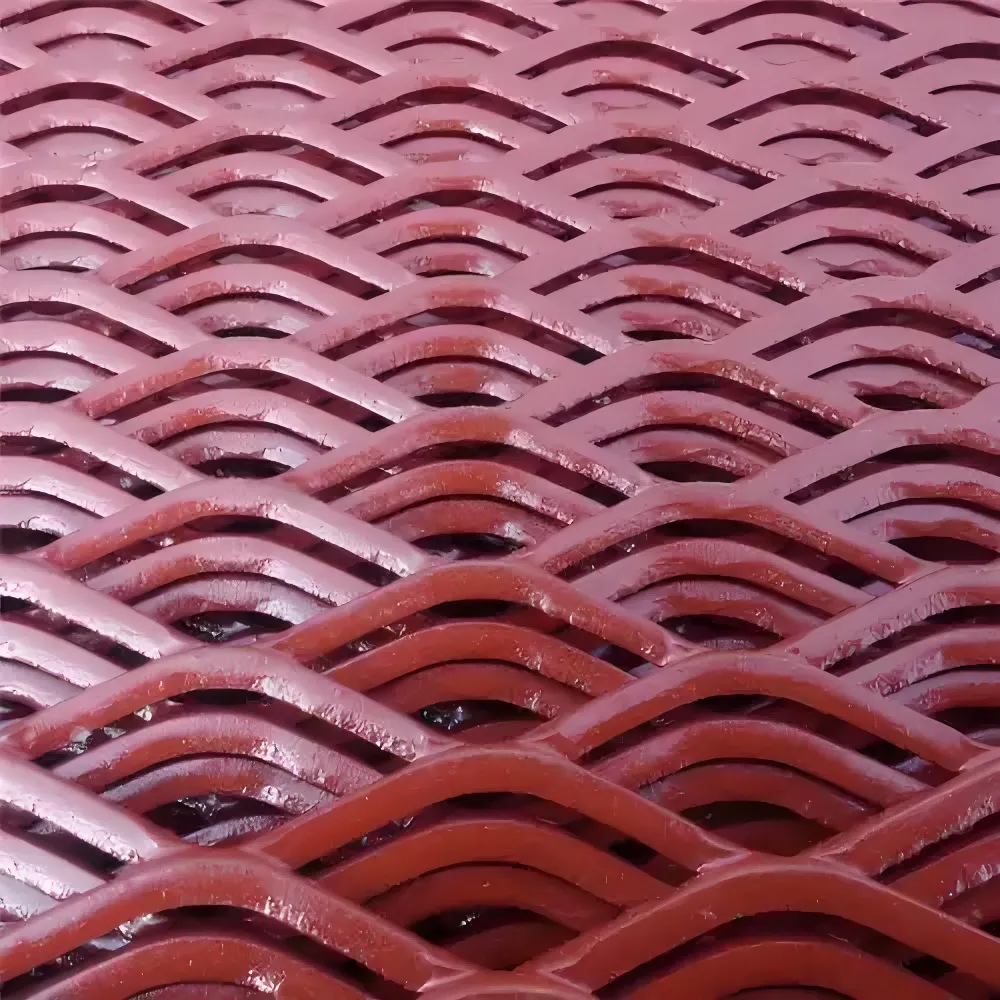

Type :Standar(Raised)/flattened

Textured surface for slip resistance (e.g., walkways).

Flattened: Smooth finish for architectural uses (e.g., façades).

Micro-Expanded: Fine mesh for filtration or screens.

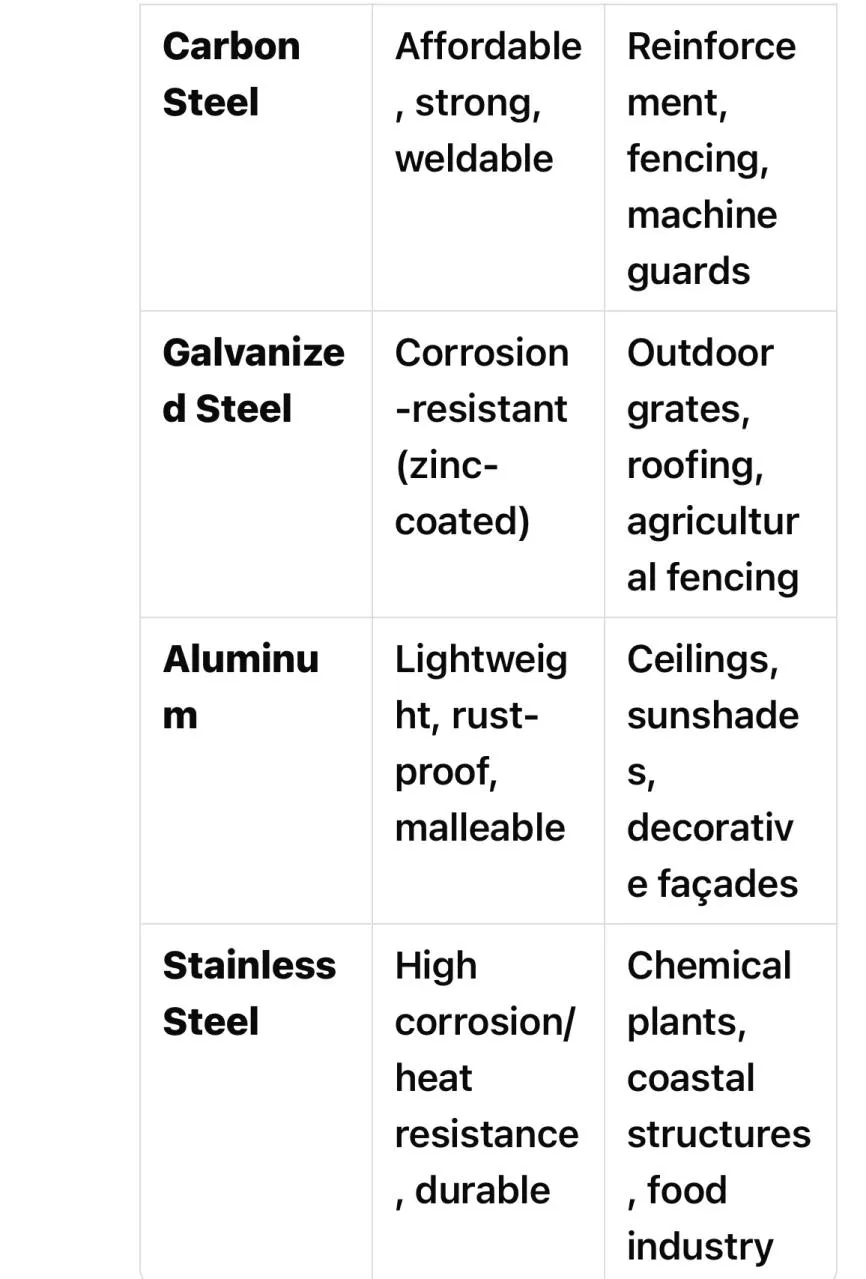

Materials

- Carbon steel: Affordable and strong.

-Galvanized steel: Rust-resistant for outdoor use.

- Aluminum: Light weight and corrosion-resistant.

- Stainless steel: Durable for harsh environments.

Advantages:

- High strength-to-weight ratio.

- Cost-effective (minimal material waste).

- Customizable patterns and finishes.

- Recyclable and sustainable.

Common Uses:

Construction: Grating, fencing, concrete reinforcement.

Architecture: Decorative panels, sunshades, ceilings.

-Industrial: Machine guards, safety barriers.

Limitations:

- Sharp edges (requires finishing in high-traffic areas).

- Limited load capacity compared to solid metal.

Expanded metal bridges functionality and design, making it ideal for projects requiring durability, airflow, or aesthetic flexibility.

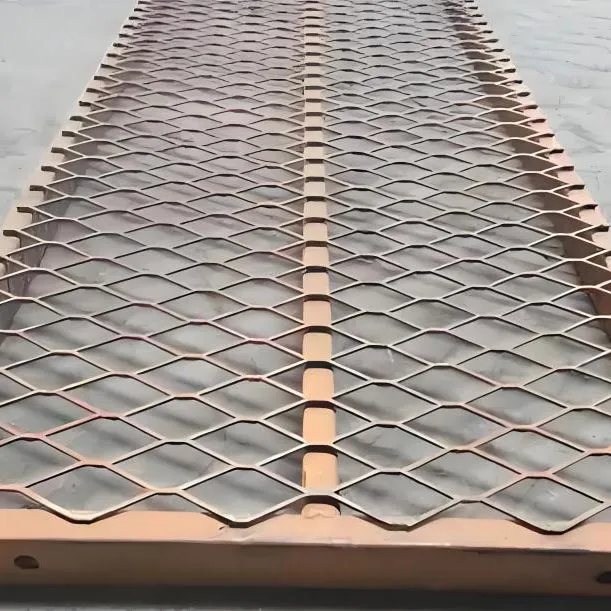

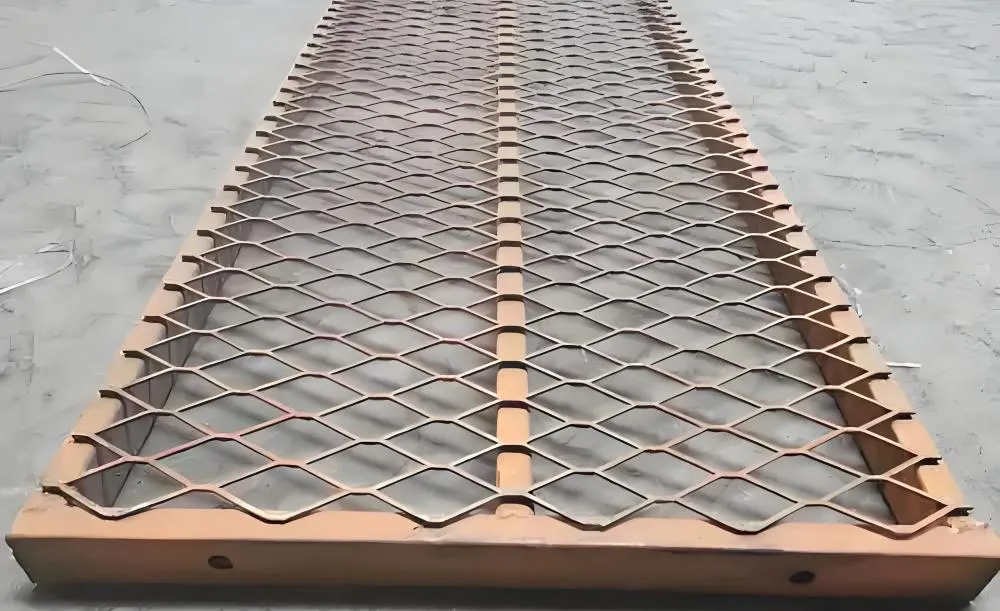

USED IN WALKWAYS

Expanded Metal grating provides a walking surface that is strong, durable, and lightweight .Expanded metal walkway grating is an extremely common application for expanded metal panels. The raised bonds and strands provide stronger supporting capacity than the original steel platform. With different weight per square meter and the shapes of the diamond pattern, expanded metal walkway grating yields different strength to weight ratio for various industrial and commercial situations.For the purpose of skid resistance and space saving, most of clients prefer expanded metal platform. General expanded metal platform consists of expanded metal panels, U-edges and posts.

Applications (for platform):

Billboard platform./Sign platforms./Machinery platforms./Conveyor walkway./ower platforms./Interior/exterior catwalks./Work platforms./Bridge decks./Storeroom floors./Stair treads and ladder rungs

Stair treads made of expanded metal suits for temporary use in construction sites and permanent use for a long time. By thick, raised and small-opening-holes expanded metal panels. As a metal product with finish coating, our stair treads are corrosion resistant, water resistant, long-lasting compared with wooden stairs, more stable and suitable for various shoes than stairs made of bar grating.

Applications (indoors and out):

Stairway./Ladders./Vehicle steps.

Specifications (for stair treads and ladder rungs):

Material: stainless steel, low carbon steel, copper, brass, bronze, aluminum, etc.

Hole shape: diamond, square, hexagon, fan-shape, etc.

LWD: 1.0–4.0 inches.

SWD: 0.25–1.50 inches.

Overall thickness (standard): 0.100–0.450 inches.

Panel sizes: customization.

Surface treatment: galvanized, power coated, painting, etc.

Color: primary metallic color, other colors also available under request.

Accessories (for stair treads and ladder rungs):

Installation procedures (for platform, stair treads and ladder rungs):

For maximum load, position long way of design parallel to the clear span. LWD must be installed parallel to span. Butt or overlap one half of design. No increase in overall thickness.

Bolt or welded every 6 inches or every fourth design to rigid supports.

Install with straight edge up (top-straight edge, bottom-rounded edge). Bonds of adjoining should shape in same direction and align with adjoining pieces.

Key Benefits for Walkways

1. Slip Resistance: The textured surface and raised strands provide excellent traction, crucial in wet or oily conditions.

2. Drainage and Debris Management: Openings allow water and debris to pass through, reducing puddles and maintenance.

3. Strength and Durability: High load-bearing capacity, especially with thicker gauges, supports heavy machinery in industrial settings.

4. Lightweight: Easier to install compared to solid surfaces, reducing structural support needs.

5. Corrosion Resistance: Materials like galvanized steel or stainless steel cater to harsh environments, including marine areas.

Applications

- Industrial: Catwalks, platforms, and stair treads in factories.

- Public Infrastructure: Pedestrian bridges, park walkways, and transportation hubs.

- Specialized Environments: Chemical plants (using corrosion-resistant alloys) and fire escapes (non-combustible materials).

Considerations

- Material Selection: Choose based on environment (e.g., stainless steel for corrosion resistance, aluminum for lightweight needs).

- Safety Standards: Compliance with OSHA slip-resistance guidelines and ASTM load-bearing standards.

- Installation: Welded or bolted to robust frameworks; edge finishing prevents sharp protrusions.

- Maintenance: Regular inspections for corrosion, with treatments like powder coating enhancing longevity.

Disadvantages

- Noise: Can be noisy underfoot; mitigated with rubber coatings.

- Thermal Conductivity: Metal may become hot in direct sunlight; consider coatings or shaded installations.

- Comfort: Less comfortable for prolonged use compared to cushioned surfaces, but safety prioritizes traction.

Conclusion

Expanded metal walkways are a cost-effective, durable solution tailored to diverse environments. By selecting appropriate materials and designs, they meet stringent safety standards while ensuring long-term performance and minimal maintenance.

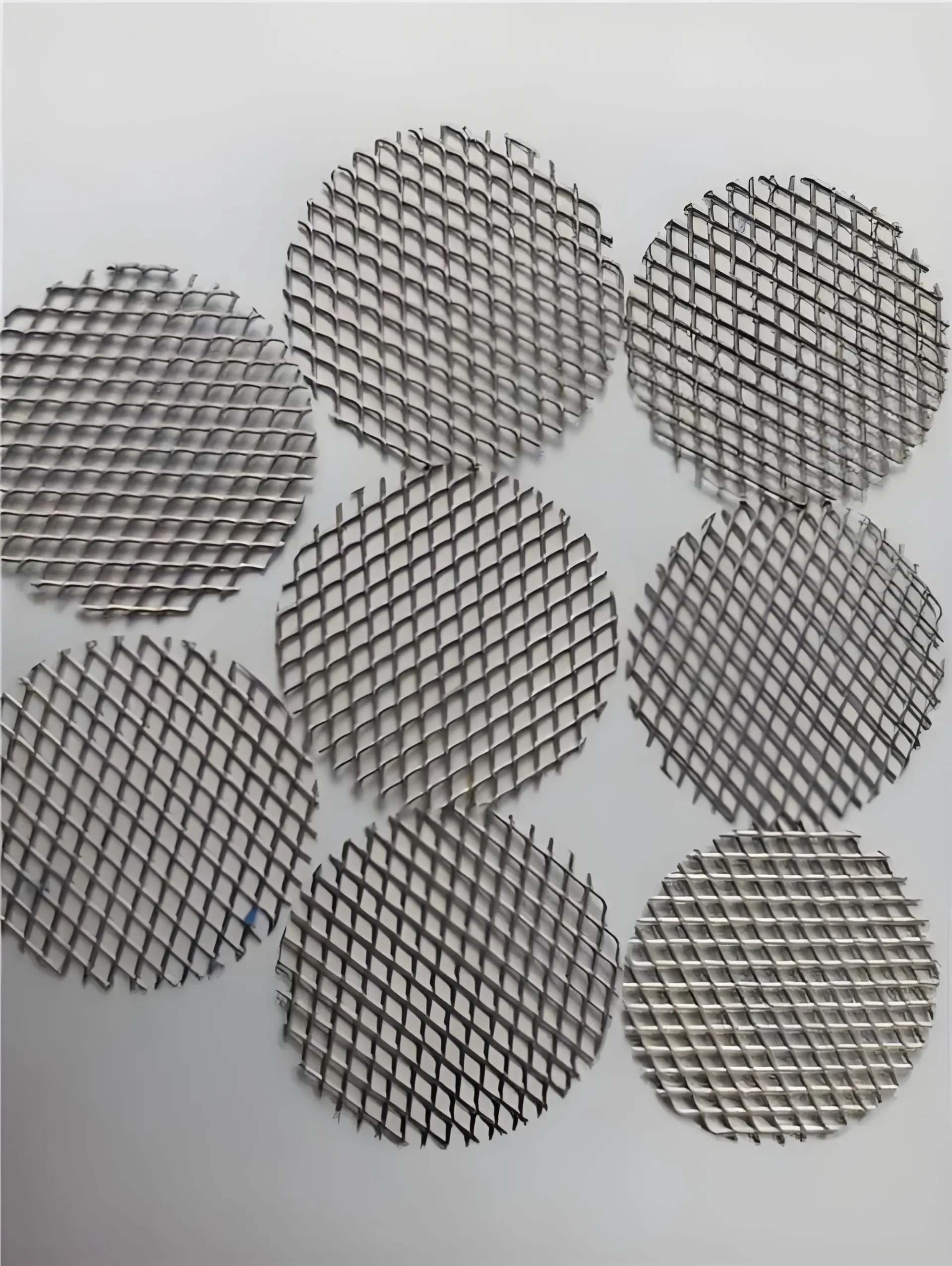

Battery

Introduction

Expanded metal, a material formed by slitting and stretching metal sheets into a mesh-like pattern, is widely used in battery technology. Its unique properties, such as high conductivity, structural integrity, and customizable design, make it an essential component in various battery types, including lead-acid, lithium-ion, and fuel cells.

Role of Expanded Metal in Batteries

Expanded metal is primarily used in battery electrodes and current collectors due to its:

1. High Electrical Conductivity: Ensures efficient electron transfer.

2. Lightweight: Reduces overall battery weight, enhancing energy density.

3. Structural Strength: Provides mechanical support to active materials.

4. Customizable Design: Mesh size and thickness can be tailored for specific battery requirements.

Applications in Battery Technology

1. Lead-Acid Batteries:

- Used as grids for electrodes, providing a framework for active materials like lead dioxide (positive electrode) and sponge lead (negative electrode).

- Enhances conductivity and durability while reducing weight.

2. Lithium-Ion Batteries:

- Serves as a current collector for cathodes and anodes.

- Commonly made from aluminum (cathode) and copper (anode) due to their excellent conductivity and corrosion resistance.

3. Fuel Cells:

- Used as bipolar plates or flow field plates to distribute reactants and collect current.

- Materials like stainless steel or titanium are chosen for their corrosion resistance in harsh environments.

4. Nickel-Based Batteries:

- Acts as a substrate for nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) batteries.

Provides a robust structure for active materials.

Advantages of Expanded Metal in Batteries

1. Enhanced Conductivity: Facilitates efficient electron flow, improving battery performance.

2. Improved Durability: Withstands mechanical stress during charge-discharge cycles.

3. Cost-Effectiveness: Lightweight and easy to manufacture, reducing production costs.

4. Customizability: Mesh size, thickness, and material can be tailored for specific applications.

5. Thermal Management: Open mesh design aids in heat dissipation, preventing overheating.

Materials Used

1. Aluminum: Lightweight and corrosion-resistant, ideal for lithium-ion cathodes.

2. Copper: High conductivity, used in lithium-ion anodes.

3. Stainless Steel: Durable and corrosion-resistant, suitable for fuel cells.

4. Titanium: Used in specialized applications requiring high strength and corrosion resistance.

Challenges and Considerations

1. Corrosion: In harsh environments, material selection is critical to prevent degradation.

2. Weight: While lightweight, expanded metal must balance strength and mass for optimal energy density.

3. Manufacturing Precision: Consistent mesh size and thickness are crucial for uniform performance.

4. Cost: High-performance materials like titanium can increase production costs.

Conclusion

Expanded metal plays a critical role in battery technology, offering a balance of conductivity, strength, and lightweight properties. Its versatility and adaptability make it a key component in advancing battery performance and efficiency across various applications. By addressing challenges like corrosion and cost, expanded metal will continue to be a vital material in the evolution of energy storage systems.

It works as current collector and also provides the electrical connection point for the external circuit. It is mainly used in batteries, like Ni-MH battery, Ni-Cd battery and lithium ion cells, etc.

Applications:

Battery Current Collector/Battery Support Structure

Our Advantages:

We provide wide range of alloys available in the industry, such as nickel, copper, aluminum, nickel coated stainless steel plate, Tin, Zinc, Titanium and silver, etc.

We provide custom slitting, blanking, heat treatment and edge treatment options.

We control the quality precisely: we control the mesh’s area density, thickness, opening, strength; our product does not have black spot, oil stains, wrinkle, connected hole and breaking stick. It is flat and clear diamond.

Specifications:

Mesh size starting at TL1mm x TB2mm/Base material thickness down to 0.04mm/Widths to 400mm

Factors need to be considered when you choose the expanded metal mesh for battery electrode:

Resistivity./Surface Area/Open Area/Weight/Overall Thickness/Material Type/Battery Life

Expanded metal technology is exploited to confer excellent mechanical strength and precision to the positive and negative grids, and is particularly suited to large series, high volume productions.

The use of lead-calcium alloys is a solution ensuring maintenance-free durability to the battery.

The self-discharging process of the battery is very short during storage and if the vehicle is left standing for a longer time.

Furthermore, low water consumption means that the electrolyte is sufficient for the entire lifecycle of the battery and no maintenance is needed.

Expanded metal provides high mechanical stability to hold the electrodes in place while allowing free movement of ions within the battery. This enables an effective reaction of the electrode materials and improves the performance of the battery

In addition, the expanded metal can also act as a current conductor and help to distribute the current over the surface of the electrode. This helps to reduce the internal resistance of the battery and increase the discharge and charging efficiency.

Used in filter elements

Expanded metal, is widely used in filtration systems. Its structural integrity, customizable design, and permeability make it ideal for applications ranging from industrial air filtration to liquid processing. Below, we explore its roles, benefits, and challenges in filter technology.

Key Roles in Filtration Systems

1. Support Structure:

- Acts as a rigid frame to hold delicate filter media (e.g., fabric, paper, or foam) in place, preventing collapse under pressure.

- Common in oil filters, HVAC systems, and industrial dust collectors.

2. Pre-Filter Layer:

- Captures large debris (e.g., leaves, dirt) before finer filtration stages.

- Used in automotive air intakes, water treatment screens, and agricultural machinery.

3. Primary Filter Element:

- In applications requiring coarse filtration, expanded metal itself serves as the filtering medium.

- Examples: Grating for stormwater drains, gravel screens in mining, or particle separators.

4. Flow Distribution:

- Ensures even distribution of fluids or gases across the filter media, enhancing efficiency.

Critical in chemical processing and fuel filtration.

Advantages of Expanded Metal in Filters

1. Durability:

- Withstands high pressure, temperature, and mechanical stress (e.g., stainless steel in harsh environments).

2. Customizable Design:

- Mesh size, strand thickness, and material (aluminum, galvanized steel, titanium) can be tailored to specific needs.

3. Permeability:

- Open-area ratio (40–80%) balances airflow/liquid flow with particle retention.

4. Corrosion Resistance:

- Materials like stainless steel or coated metals excel in wet or chemically aggressive environments.

5. Cost-Effectiveness:

Lightweight and produced with minimal material waste, reducing manufacturing costs.

Common Applications

1. Air Filtration:

- HVAC systems, engine air filters, and industrial dust collectors (e.g., capturing sawdust in woodworking).

2. Liquid Filtration:

- Water treatment screens, oil filters in machinery, and food/beverage processing (e.g., straining solids).

3. Industrial Processes:

- Separating aggregates in mining, filtering molten metals, or protecting sensors in chemical plants.

1. Hybrid Filters:

- Combining expanded metal with activated carbon or nanofiber layers for multi-stage filtration.

2. Anti-Clog Coatings:

- Hydrophobic or non-stick surfaces to reduce maintenance.

3. 3D-Printed Designs:

- Custom geometries for specialized industrial or medical applications.

Air filters for cars and stationary engines

Tractors

Construction equipment

Residential and commercial exhaust fans

Small mesh expanded metal not only serves to protect and support non-woven fabrics, filter papers, and other filter media but also functions as the main filter material to remove foreign substances. It's an ideal choice for the filtration industry and widely used in air filtration, process water purification, paint filtration, oil filtration, and other areas.

Expanded metal for filtration is typically made from small mesh expanded metal. Through advanced shaping processes, it can be formed into conical, curved, cylindrical, and other shapes to meet the demands of various filtration applications.

Features:

Economical and eco-friendly: Expanded metal is made through slitting and stretching, resulting in no material waste during production, making it an excellent alternative to perforated metal.

Strong and durable: When air or liquid passes through filter elements under high operating pressure, the support layer remains robust and resistant to loosening.

Precise filtration: The aperture sizes of expanded metal can be customized according to the desired filtration grade to effectively remove specified solid particles.

Corrosion resistance: Hot-dip galvanized expanded metal surfaces do not facilitate rusting in acid and alkali filtration environments.

Perforated filters are utilized in various systems and by different consumer types. These metal structures are an ideal solution for keeping filter media clean and preventing unwanted contaminants from affecting light, liquid, and composite filtration systems.

Features:

Air systems, household systems utilize perforated metal filters to clean airflow from dust and particle pollutants in industrial environments to safeguard against potential harmful contaminants.

Liquid filtration systems employ perforated metal to filter water or other liquids through high-pressure mechanisms or vibrations while maintaining a stable structure. Perforated metal patterns ensure the filter remains stable while remaining efficient.

Filters can also be utilized in solid waste filtration. Perforated metal is resilient against damages that may arise from usage, making it suitable for devices and systems encountering solid debris particles, such as in the automotive and agricultural machinery industries.

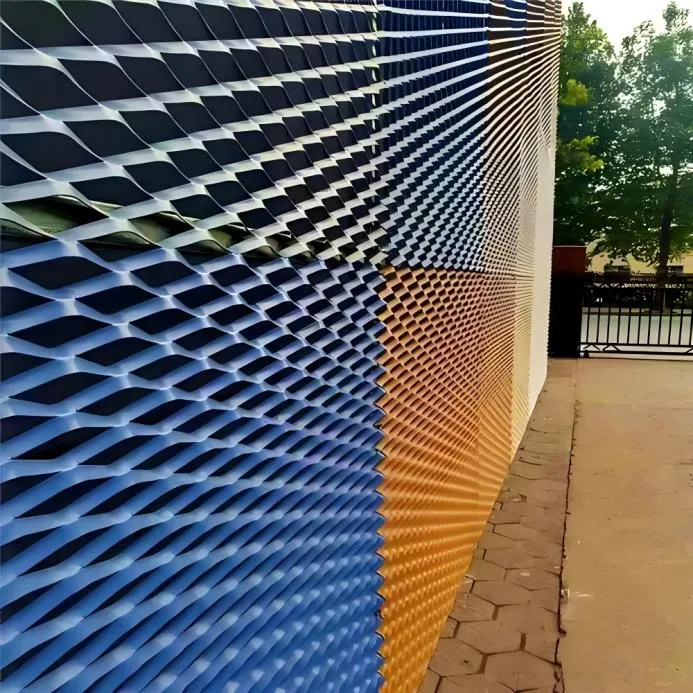

DECORATION

Expanded metal is a versatile material widely used in various decorative applications due to its unique texture, durability, and aesthetic appeal. Here are some common uses of expanded metal in decoration:

1. Architectural Facades

- Expanded metal sheets are often used as cladding for building exteriors. They provide a modern, industrial look while allowing airflow and natural light to pass through.

- Used in sunscreens or shading systems to reduce heat buildup while maintaining visibility and ventilation.

2. Interior Design

- Room Dividers: Expanded metal panels can be used to create stylish and functional room dividers, offering a semi-transparent barrier that doesn’t completely block light or airflow.

- Wall Art: The unique patterns of expanded metal can be used to create decorative wall panels or sculptures.

- Ceiling Panels: Used in suspended ceilings to add texture and visual interest.

3. Furniture Design

- Expanded metal is often incorporated into furniture design, such as chair backs, table bases, or cabinet doors, adding a modern and industrial aesthetic.

- It can also be used for shelving or storage units, providing a lightweight yet sturdy solution.

4. Lighting Fixtures

- Expanded metal is used in lampshades, pendant lights, and other lighting fixtures to create interesting light patterns and shadows.

- Its open structure allows light to diffuse beautifully, making it ideal for decorative lighting.

5. Staircases and Balustrades

- Expanded metal is a popular choice for stair treads, risers, and balustrades, offering a sleek and contemporary look while ensuring safety and durability.

6. Garden and Landscape Design

- Used as decorative screens or trellises in gardens to support climbing plants or create privacy.

- Can be incorporated into outdoor furniture, gates, or fences for a modern aesthetic.

7. Retail and Exhibition Displays

- Expanded metal is often used in retail displays, trade show booths, and exhibition stands due to its lightweight yet sturdy nature and visually appealing texture.

8. Custom Art Installations

- Artists and designers use expanded metal to create custom art pieces, sculptures, or installations, taking advantage of its flexibility and unique patterns.

Advantages of Expanded Metal in Decoration:

- Durability: Resistant to corrosion, especially when made from materials like stainless steel or aluminum.

- Lightweight: Easy to handle and install, making it ideal for large-scale projects.

- Versatility: Available in various materials, thicknesses, and patterns to suit different design needs.

Cost-Effective: Provides an affordable yet stylish solution for decorative applications.

Expanded metal’s combination of functionality and aesthetics makes it a popular choice for both interior and exterior decorative projects.

Decorative Expanded items are popular in shelving, signage, and ceiling tile applications. Expanded Metal is supplied in a Standard (Raised) diamond pattern or a Flattened variety, and materials include Aluminum, Carbon Steel, Galvanized Steel, and Stainless Steel.

Its unique combination of durability, aesthetic appeal, and functionality makes it a preferred choice for architects, interior designers, and engineers alike.

Whether you’re looking to enhance the visual appeal of a building facade, improve airflow in an industrial setting, or add a touch of sophistication to your interiors, decorative expanded metal offers endless possibilities.

What is decorative expanded metal?

Decorative expanded metal is a sheet of metal that has been simultaneously cut and stretched to form a mesh with a unique pattern. This process creates an open network of diamond-shaped or custom-designed holes, giving the material its distinctive appearance. Unlike welded or woven mesh, expanded metal is made from a single piece of metal, ensuring seamless strength and integrity.

The most common materials used for the production of expanded metal mesh include:

aluminum (lightweight, corrosion-resistant, and ideal for architectural purposes);

stainless steel (durable, strong, and resistant to rust, making it suitable for both indoor and outdoor use);

galvanized steel (economical and corrosion-resistant, perfect for industrial and commercial applications);

Corten and copper (used for decorative purposes to add a luxurious touch).

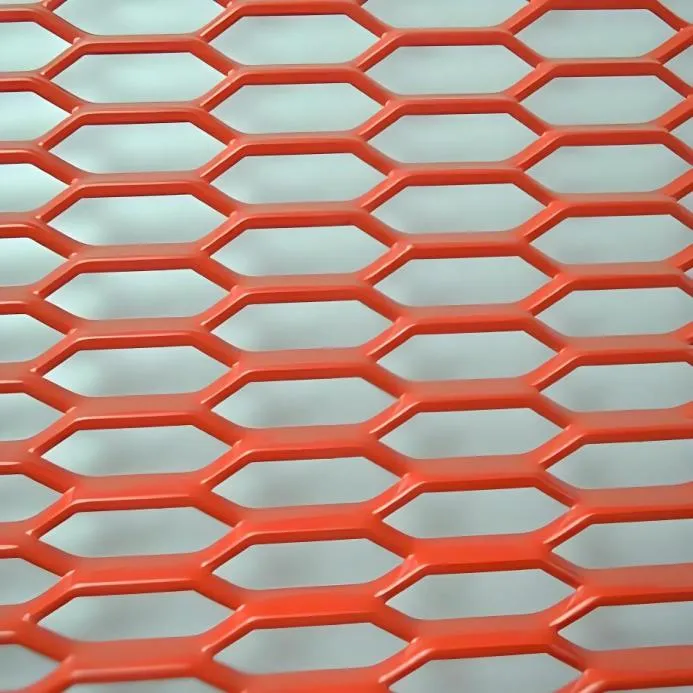

Decorative expanded metal comes in a variety of patterns, finishes, and colours. You can choose from different hole shapes (diamond, hexagonal, circular), strand widths, and coatings (anodized, powder-coated, or painted) to match your specific requirements.

Expanded metal is an incredibly versatile material that combines functionality with aesthetic appeal, making it a popular choice for decorative applications. Whether in architecture, interior design, or industrial projects, expanded metal offers unique benefits that elevate both form and function.

What are the elements that make it so special? The variety of patterns and the treatments contribute play a key role.

Patterns

Diamond: the classic pattern with various sizes to suit different applications.

Hexagonal: a modern option that adds a unique aesthetic.

Custom shapes: manufacturers can create bespoke patterns that align with the project vision.

Finishes

Raw metal: it retains the natural look for an industrial feel.

Powder-coated: it is available in a variety of colors for a durable, vibrant finish.

Anodized: it is ideal for aluminum, offering increased corrosion resistance and color options.

Painted or plated: the treatment adds color or a protective layer to the surface.

DISCOVER OUR SERVICES

The importance of professional consultations

When it comes to selecting the best expanded metal for a project, the choices can be overwhelming. With so many materials, patterns, finishes, and applications available, finding the perfect solution requires careful consideration. Professional consultation can make all the difference, ensuring that the final choice meets both functional and aesthetic requirements while staying within budget.

An expert company, with its skilled staff, can analyze these factors and recommend the solution that aligns with the required goals, whether it is durability, visual appeal, or both.

Choosing the right material is one of the most important decisions in using expanded metal. The options include aluminum, stainless steel, galvanized steel, copper, and brass, each with its own strengths and limitations.

Experts can guide you to materials that are resistant to environmental factors like rust, corrosion.

They can suggest lightweight options for easy handling or heavy-duty metals for high-stress applications.

For decorative purposes, consultants can suggest visually appealing materials like brass or coated aluminum.

Expanded metal comes in a variety of patterns, such as diamond, hexagonal, or custom shapes. Each pattern serves different purposes:

smaller openings for security applications;

larger openings for maximum airflow and light;

decorative patterns for architectural appeal.

Professionals can assess the project and recommend the best pattern that balances functionality and style. For unique designs, they can also help coordinate custom pattern creation to align with architects and designers’ vision.

The finish of expanded metal not only affects its appearance but also its durability. Common finishes include:

anodizing for corrosion resistance and color options;

powder coating for vibrant, durable colors;

galvanization for rust resistance in outdoor applications.

A professional consultation ensures that the choice is the appropriate finish to enhance the longevity and look of the material, especially in challenging environments.

Certain projects, especially in industrial or public spaces, require materials that meet safety regulations. Expanded metal used for walkways, fences, or machinery guards may need to comply with:

anti-slip standards;

fire resistance codes;

structural safety regulations.

Consultants are familiar with these requirements and can guide you to solutions that meet all necessary standards, avoiding costly mistakes or legal issues.

How you install and care for expanded metal affects how long it lasts and how well it works. Experts can provide:

installation tips (advice on using frames, fasteners, or mounting methods to set it up securely);

maintenance advice (simple ways to clean and protect the metal to keep it in good condition).

This guidance ensures your expanded metal works perfectly and stays durable for years.

Every project is different and can come with challenges, like tough environmental conditions or unique design needs. Professional consultants have the experience to find smart solutions for even the most complicated projects, helping you achieve your goals.

Sustainability is becoming more important in design and construction. Experts can recommend expanded metal that is recyclable or made with processes that create less waste. This helps you make environmentally responsible choices while meeting modern standards.

USED IN CONSTRUCTION

It is commonly used for fences and grates, and as metallic lath to support plaster or stucco.

Expanded metal, also known as mesh, is one of the main building materials in the construction sector. The raw material of the product is cut and expanded with the help of special devices. Thus, the expanded metal product appears. Expanded metal mesh is a strong material with low maintenance.Flexible and formable. Especially the use of metal mesh in exterior facades and space design shows that these products are reliable.

Because of its safe structure, it is durable and offers strong impact resistance.Provides sound insulation. In addition, it is designed in one piece without welding or additions and provides effective durability. Expanded metal is easily assembled at the weight point due to its lightness according to its dimensions.

Durability is an important term in the use of metals. This is especially true in construction, shipping, heavy industry and tool construction. Because these areas are of great importance to us. Metal alloys are generally stronger than a metal in their pure form. The size of the product can be extended to a certain point thanks to its flexible structure. This makes the product more economically advantageous.

Expanded metal can be produced from different materials, such as steel, aluminum, galvaniz, copper. Pattern and eye range size can be preferred according to request and need. Easy to rust, strong enough to be used for many years. Metal sheets, which are designed by processing coil sheets with presses over the hot state, can differ in their weight by taking different factors. This varies depending on the area to be used.

Expanded Metal in Construction: A Comprehensive Guide

Expanded metal is a versatile and cost-effective material widely used in construction for its unique combination of strength, flexibility, and aesthetic appeal. Below is a detailed exploration of its applications, benefits, and considerations

What is Expanded Metal?

Expanded metal is created by cutting and stretching a single sheet of metal (e.g., steel, aluminum, stainless steel) to form a mesh-like pattern of diamond-shaped openings. This process retains material integrity while minimizing waste, making it both lightweight and durable.

Types of Expanded Metal

1. Standard/Raised Expanded Metal:

- Features raised strands for rigidity.

- Ideal for walkways, platforms, and grating due to its slip-resistant surface.

2. Flattened Expanded Metal:

- Rolled smooth after expansion.

- Used in façades, partitions, and decorative panels where a flat surface is preferred.

3. Micro-Expanded Metal:

- Fine mesh with small openings.

- Suitable for filtration, screens, or lightweight cladding.

4. Heavy-Duty Expanded Metal:

- Thicker gauges for structural reinforcement.

- Common in industrial flooring or trench covers.

Materials :

Advantages

- Cost Efficiency: Minimal material waste during production.

- Strength-to-Weight Ratio: Lightweight yet robust for structural uses.

- Versatility: Allows airflow, light penetration, and visibility.

- Customization: Available in various patterns, thicknesses, and coatings.

- Non-Slip Surface: Raised strands enhance safety in walkways.

Limitations

- Sharp Edges: Raised strands may require finishing for safety.

- Corrosion Risk: Uncoated metals (e.g., carbon steel) degrade in moisture.

- Load Limits: Not ideal for heavy structural loads without reinforcement.

Applications in Construction

1. Reinforcement

- Concrete & Plaster: Acts as lath for stucco or lightweight concrete slabs.

- Roadways: Reinforces asphalt to reduce cracking.

2. Safety & Infrastructure

- Trench Covers: Temporary protection for excavations.

- Safety Barriers: Secure construction sites while allowing visibility.

3. Architectural Design

- Solar Screens: Reduces glare/heat while maintaining airflow.

- Decorative Panels: Adds texture to façades, ceilings, or partitions.

4. Industrial Uses

- Machine Guards: Protects equipment while enabling ventilation.

- Catwalks: Durable, slip-resistant platforms in factories.

5. Landscaping & Agriculture

- Greenhouse Frames: Rust-resistant support for plants.

- Tree Guards: Shields saplings from animals.

Sustainability & Innovation

- Recyclability: Most expanded metals (e.g., steel, aluminum) are fully recyclable.

- Green Building: Used in LEED-certified projects for energy-efficient façades.

- Coatings: Eco-friendly options (e.g., powder coating) enhance lifespan and reduce waste.

Installation Tips

- Edge Trimming: Use flattened expanded metal in high-traffic areas to avoid injuries.

- Corrosion Protection: Opt for galvanized or powder-coated finishes in humid climates.

- Anchoring: Secure panels with bolts or welds for heavy-duty applications.

When to Choose Expanded Metal

- For lightweight reinforcement (e.g., plaster walls).

- When airflow, visibility, or aesthetics are priorities (e.g., sunshades).

- In cost-sensitive projects requiring minimal material waste.

Expanded metal bridges functionality and design, making it indispensable in modern construction. Its adaptability ensures relevance in everything from industrial safety to cutting-edge architecture. Always consult engineering guidelines for load-bearing applications!