The Indispensable Role of Extruder Screens in Modern Industrial Processes

In the intricate world of industrial manufacturing, precision and purity are paramount. Central to achieving these objectives, particularly in polymer processing, chemical filtration, and other high-demand applications, are extruder screens. These seemingly simple filtration components are engineered to remove contaminants, impurities, and un-melted plastics from molten polymers, ensuring the integrity and quality of the final product. Their role extends beyond mere filtration; they contribute significantly to process stability, equipment longevity, and overall operational efficiency. From fine mesh screens that filter out sub-micron particles to robust multi-layer designs capable of withstanding extreme pressures and temperatures, the right extruder screen is a critical determinant of manufacturing success. Understanding their design, application, and material science is essential for optimizing industrial output and maintaining competitive advantage in a demanding global market.

The demand for high-performance filtration solutions continues to grow, driven by stricter quality standards and the processing of more complex materials. Consequently, the technology behind extruder screens has evolved, incorporating advanced materials like stainless steel alloys, sophisticated weaving patterns, and specialized finishes to enhance durability and filtration efficiency. Industries ranging from plastics and rubber to food processing and pharmaceuticals rely heavily on these screens to maintain product consistency and prevent costly production disruptions. Our commitment to innovation ensures that our filtration solutions meet the rigorous demands of modern industrial processes, offering superior performance and reliability.

Advanced Manufacturing Processes and Quality Assurance for Extrusion Screens

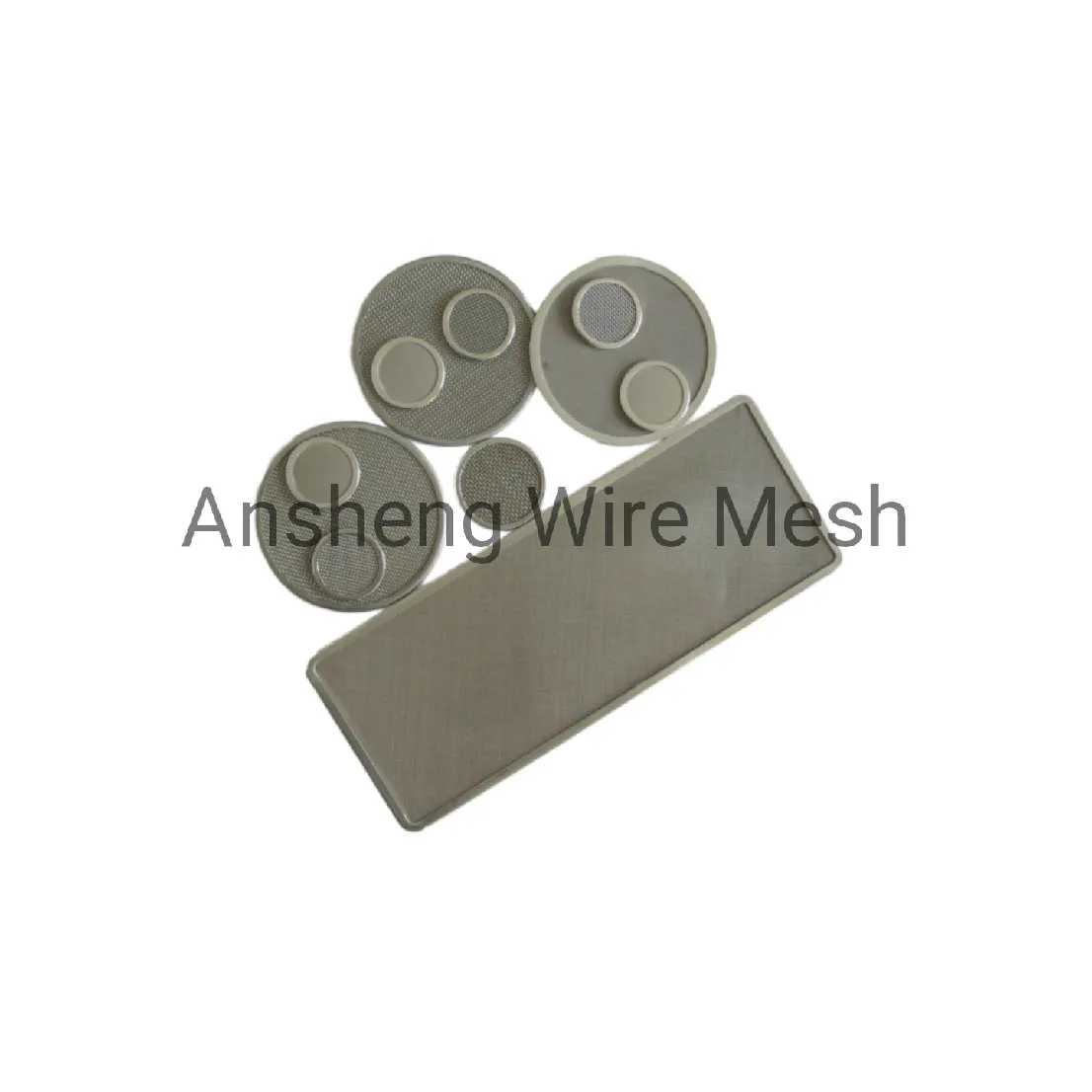

The production of high-quality extruder screens, particularly for demanding applications like screen extrusion, involves a meticulous manufacturing process that prioritizes precision, material integrity, and structural robustness. Our manufacturing journey begins with the selection of premium-grade materials, primarily stainless steel (SS304, SS316, SS316L for corrosion resistance and high-temperature stability) and sometimes nickel alloys, chosen for their chemical inertness, mechanical strength, and thermal properties. The core process involves advanced weaving or sintering techniques to create uniform mesh structures with precise micron ratings, crucial for consistent filtration. For products like Multi-Layer Mesh With Rim, multiple layers of mesh are precisely cut and then integrated, often through a robust rimming or welding process, to create a composite structure that offers enhanced filtration capacity and durability under high differential pressures.

Post-manufacturing, each extrusion screen undergoes stringent quality control procedures. These include visual inspections for defects, dimensional checks to ensure adherence to specifications (e.g., thickness, diameter, rim integrity), and functional testing where applicable. Our testing protocols align with international standards such as ISO 9001 for quality management and ANSI standards for product performance and measurement. We employ advanced optical microscopy to verify mesh uniformity and pore size distribution, ensuring optimal filtration efficiency. The result is a product with an extended service life, capable of performing reliably in harsh industrial environments. These screens are widely applied in petrochemical, plastics, rubber, metallurgy, and water treatment industries, offering significant advantages such as improved energy efficiency due to reduced backpressure, superior anti-corrosion properties, and enhanced purity of the processed medium.

Technical Specifications and Performance Parameters of Extruder Screens

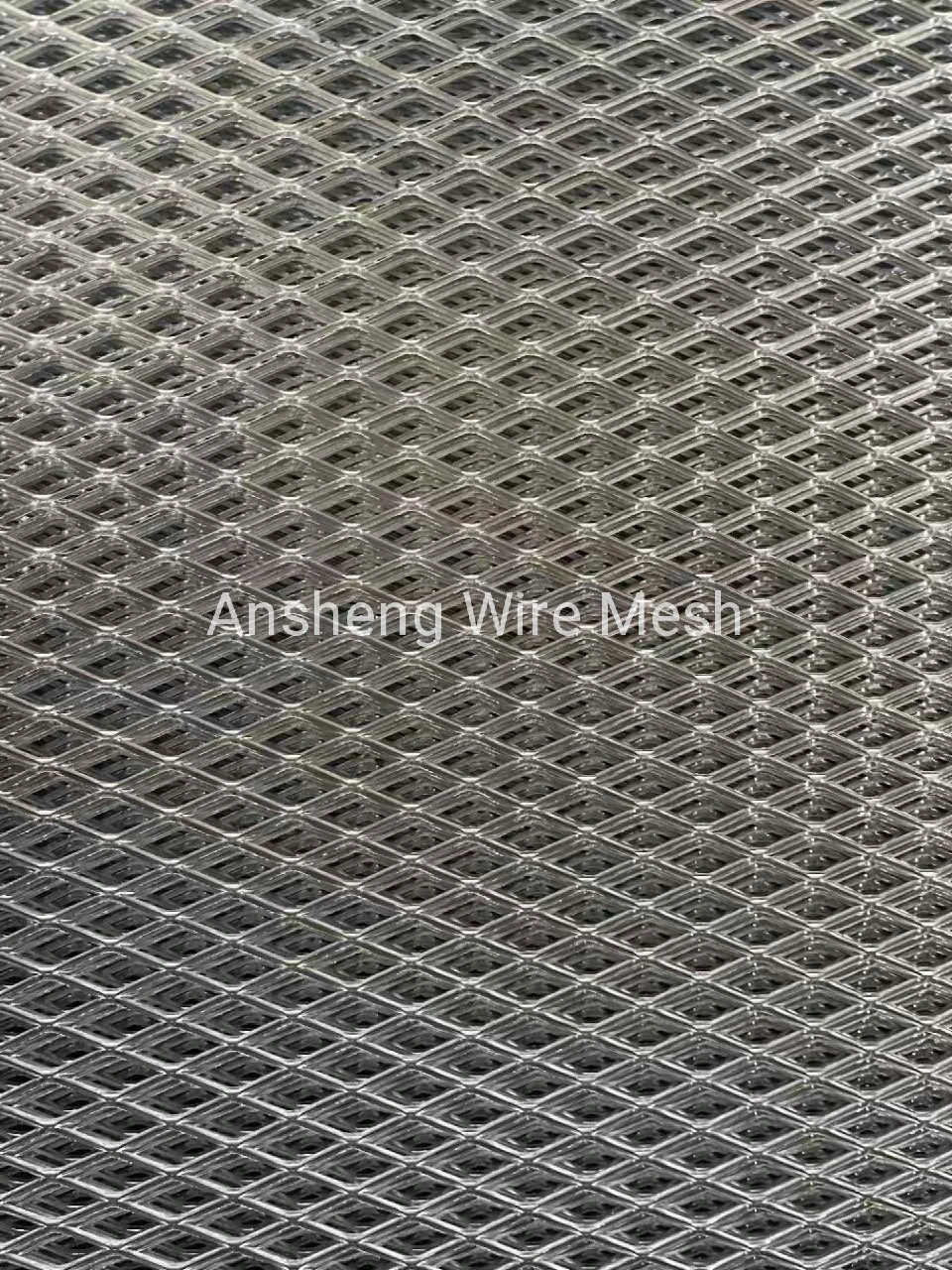

Selecting the appropriate extruder screen requires a detailed understanding of its technical specifications and how these parameters influence performance. Key metrics include mesh count (wires per inch), wire diameter, pore size (micron rating), open area percentage, and material composition. These factors directly impact filtration efficiency, flow rate, and the screen's resistance to clogging and degradation. For instance, a higher mesh count typically signifies finer filtration, while specific wire diameters contribute to overall screen strength and rigidity. Our screens are designed to offer optimal balance between these parameters, ensuring high throughput with effective particle retention.

| Parameter | Description | Typical Range/Value | Impact on Performance |

|---|---|---|---|

| Material | Common alloys used for durability and corrosion resistance. | SS304, SS316, SS316L, Nickel Alloys | Corrosion resistance, temperature limit, longevity. |

| Mesh Count | Number of wires per linear inch. | 10 to 600 mesh | Determines filtration fineness; higher count means finer filtration. |

| Micron Rating | Size of particles the screen can filter out effectively. | 5 to 2000 microns | Directly impacts product purity and flow rate. |

| Open Area (%) | Percentage of total screen area that is open for flow. | 25% to 60% | Higher open area facilitates higher flow rates, lower pressure drop. |

| Configuration | Shape and structure of the screen. | Circles, rectangles, discs, multi-layer, rimmed. | Compatibility with specific extruder designs, ease of installation. |

The performance of extrusion screens is also influenced by operational parameters such as processing temperature, pressure, and the viscosity of the material being filtered. Our engineers work closely with clients to recommend solutions that are precisely matched to their specific process requirements, ensuring optimal filtration performance and longevity. This tailored approach minimizes downtime and maximizes the purity of the end product, from plastic granules to high-grade chemical compounds.

Diverse Applications and Customization Solutions

The versatility of extruder screens allows for their deployment across a broad spectrum of industries, each with unique filtration challenges. In the plastics industry, they are fundamental for producing high-quality films, sheets, pipes, and profiles by removing gels, black specks, and other contaminants from polymer melts. For rubber processing, screens ensure the consistency and purity of compounds. The chemical sector relies on them for critical separation and filtration steps, safeguarding product integrity and preventing equipment damage from particulates. Beyond these, industries such as food and beverage, pharmaceuticals, and even wastewater treatment utilize specialized variants, including those used in aluminum extrusion screen frame applications and even advanced fly screen extrusion for specialized air filtration systems.

Our flagship product, the Multi-Layer Mesh With Rim, exemplifies our commitment to tailored solutions. This product is specifically designed for applications demanding superior strength, precise filtration, and extended operational cycles. By combining multiple mesh layers of varying fineness and reinforcing them with a durable rim, it offers exceptional resistance to deformation under high pressure and significantly extends service life compared to single-layer screens. This design is particularly advantageous in processes involving high-viscosity polymers or abrasive materials, where maintaining consistent flow and preventing screen breakage is critical. We offer extensive customization options, including specific dimensions, mesh configurations, material combinations, and rim materials (e.g., aluminum, stainless steel), ensuring a perfect fit for any existing extrusion system or new project requirement. Our technical team works collaboratively with clients to analyze process conditions and material properties, delivering solutions that are not just filters, but performance enhancers.

Comparative Analysis: Choosing the Right Extruder Screen

The market offers a variety of extruder screens, each with distinct features and benefits. Understanding these differences is crucial for making an informed decision that aligns with your operational goals and budget. Below is a comparative overview of common extruder screen types, highlighting their unique attributes and ideal applications. This analysis considers factors such as filtration precision, durability, cost-effectiveness, and ease of replacement.

| Screen Type | Key Characteristics | Advantages | Disadvantages | Ideal Application |

|---|---|---|---|---|

| Single-Layer Mesh | One layer of woven wire mesh. | Cost-effective, simple to use. | Limited strength, prone to breakage under high pressure. | Basic filtration, low-pressure applications. |

| Multi-Layer Mesh (e.g., Multi-Layer Mesh With Rim) | Multiple layers of different mesh sizes, often reinforced with a rim. | Superior strength, high filtration efficiency, extended life. | Higher initial cost. | High-pressure extrusion, fine filtration, demanding polymers. |

| Sintered Mesh | Layers of woven wire mesh bonded together through a sintering process. | Exceptional rigidity, precise pore size, cleanable. | Most expensive, specialized manufacturing. | Ultra-fine filtration, critical applications (e.g., pharmaceutical). |

| Punched Plate/Perforated Metal | Metal sheet with precisely punched holes. | Very robust, excellent mechanical strength. | Limited fineness, lower open area for finer filtration. | Coarse filtration, support for finer mesh layers. |

Our expertise lies in guiding clients through this selection process, ensuring they choose a solution that optimizes filtration performance while considering factors such as total cost of ownership, including screen lifespan and potential energy savings. We consistently recommend multi-layer solutions, such as our Multi-Layer Mesh With Rim, for their superior performance and long-term value in most industrial extrusion applications.

Ensuring Reliability: Quality Control, Certification, and Client Success

Our commitment to quality is unwavering, serving as the bedrock of our operations and client relationships. Each extruder screen we produce adheres to rigorous quality control protocols, from raw material inspection to final product verification. We maintain ISO 9001 certification, underscoring our dedication to consistent quality management systems and continuous improvement. Our screens also comply with relevant industry standards for material purity and filtration performance, ensuring they meet the stringent requirements of diverse applications, including those necessitating FDA compliance for food contact materials where applicable. Our extensive experience spanning over 15 years in the filtration industry has allowed us to refine our processes, building a reputation for reliability and excellence.

Client success stories serve as powerful testaments to the efficacy of our extrusion screens. For instance, a major North American plastics manufacturer experienced a 25% reduction in screen changeover frequency and a significant improvement in product quality (measured by reduced gel count) after switching to our Multi-Layer Mesh With Rim solutions. This resulted in a 10% increase in production uptime and substantial cost savings annually. Another example involves a European chemical company that significantly improved the purity of their specialty polymers, achieving stringent specifications previously unattainable with conventional screens. These outcomes highlight our ability to deliver measurable benefits and demonstrate our deep understanding of complex industrial filtration challenges. We pride ourselves on fostering long-term partnerships, providing not just products, but comprehensive filtration solutions and expert technical support.

Frequently Asked Questions (FAQ)

Q1: How do I determine the correct mesh size for my extruder?

A1: The ideal mesh size depends on several factors, including the type of polymer or material being processed, the desired level of filtration, and the extruder's melt flow rate. Finer mesh (higher mesh count, smaller micron rating) provides better filtration but can lead to higher backpressure. Our technical experts can assist you in selecting the optimal mesh size by analyzing your specific process parameters and product quality requirements to ensure efficient and effective filtration.

Q2: What is the typical service life of an extruder screen?

A2: The service life of an extruder screen varies significantly based on factors such as the abrasiveness and cleanliness of the polymer, processing temperatures and pressures, and the frequency of screen changes. Our Multi-Layer Mesh With Rim screens are designed for extended life, often lasting significantly longer than single-layer screens due to their robust construction and enhanced filtration capacity. Regular monitoring of pressure differential across the screen is a good indicator for replacement.

Q3: Can your extruder screens be customized for specific dimensions or materials?

A3: Absolutely. We specialize in providing customized filtration solutions. Whether you require specific diameters, unique shapes (e.g., rings, rectangles), particular material combinations (e.g., different stainless steel grades, nickel alloys), or specialized rimming materials for your extrusion screens, our engineering team is equipped to design and manufacture screens precisely to your specifications. We pride ourselves on our flexibility and ability to meet diverse industrial demands.

Q4: What is your typical delivery lead time for orders?

A4: Our standard delivery lead time for common extruder screens is typically 7-14 business days, depending on order volume and stock availability. For custom orders, the lead time may vary based on complexity and material sourcing, usually ranging from 3 to 5 weeks. We maintain a robust supply chain and efficient production processes to ensure timely delivery and minimize disruption to your operations. We can also accommodate expedited requests when feasible.

Q5: Do you offer a warranty or customer support for your products?

A5: Yes, all our extruder screens come with a standard 12-month warranty against manufacturing defects, ensuring your peace of mind. Our dedicated customer support team is available to assist with product selection, technical inquiries, order tracking, and any post-purchase support you may require. We are committed to providing exceptional service and building lasting relationships with our clients, offering expert advice and prompt assistance whenever needed.

Conclusion and Authoritative References

The performance of extruder screens is undeniably a critical factor in the success of numerous industrial filtration and extrusion processes. From enhancing product purity and extending equipment lifespan to optimizing operational efficiency, their impact is far-reaching. Our specialized Multi-Layer Mesh With Rim products are a testament to advanced engineering, offering unparalleled durability, filtration precision, and adaptability to the most challenging industrial environments. By adhering to stringent quality standards, offering extensive customization, and providing comprehensive technical support, we empower our clients to achieve superior production outcomes. Partner with us to elevate your filtration capabilities and secure a competitive edge in your industry.

References:

- Smith, J. A. (2022). "Advances in Polymer Filtration Technologies for Extrusion Processes." Journal of Plastics Engineering.

- Davis, M. R. (2021). "Impact of Screen Pack Design on Melt Pressure and Polymer Degradation in Extruders." Chemical Engineering Transactions.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems – Requirements.

- American National Standards Institute. (Various Years). Standards for Wire Cloth and Woven Wire Products.

Post time: Aug . 15, 2025 05:20