The Crucial Role of Epoxy Coated Wire Mesh in Modern Concrete Infrastructure

In the realm of modern construction and infrastructure development, the longevity and integrity of concrete structures are paramount. Traditional steel reinforcement is susceptible to corrosion, especially in aggressive environments laden with chlorides or moisture, leading to premature deterioration and costly repairs. This critical challenge has driven the innovation towards advanced materials, with epoxy coated wire mesh for concrete emerging as a superior solution. This specialized reinforcement material offers exceptional corrosion resistance, significantly extending the service life of concrete elements and reducing maintenance demands. Its unique protective layer acts as an impermeable barrier, safeguarding the steel core from corrosive agents. This section will delve into the technical advantages and strategic importance of incorporating epoxy coated wire mesh into contemporary concrete designs, focusing on its ability to enhance durability and structural resilience in the face of environmental stressors.

Understanding Epoxy Coated Wire Mesh for Concrete Applications

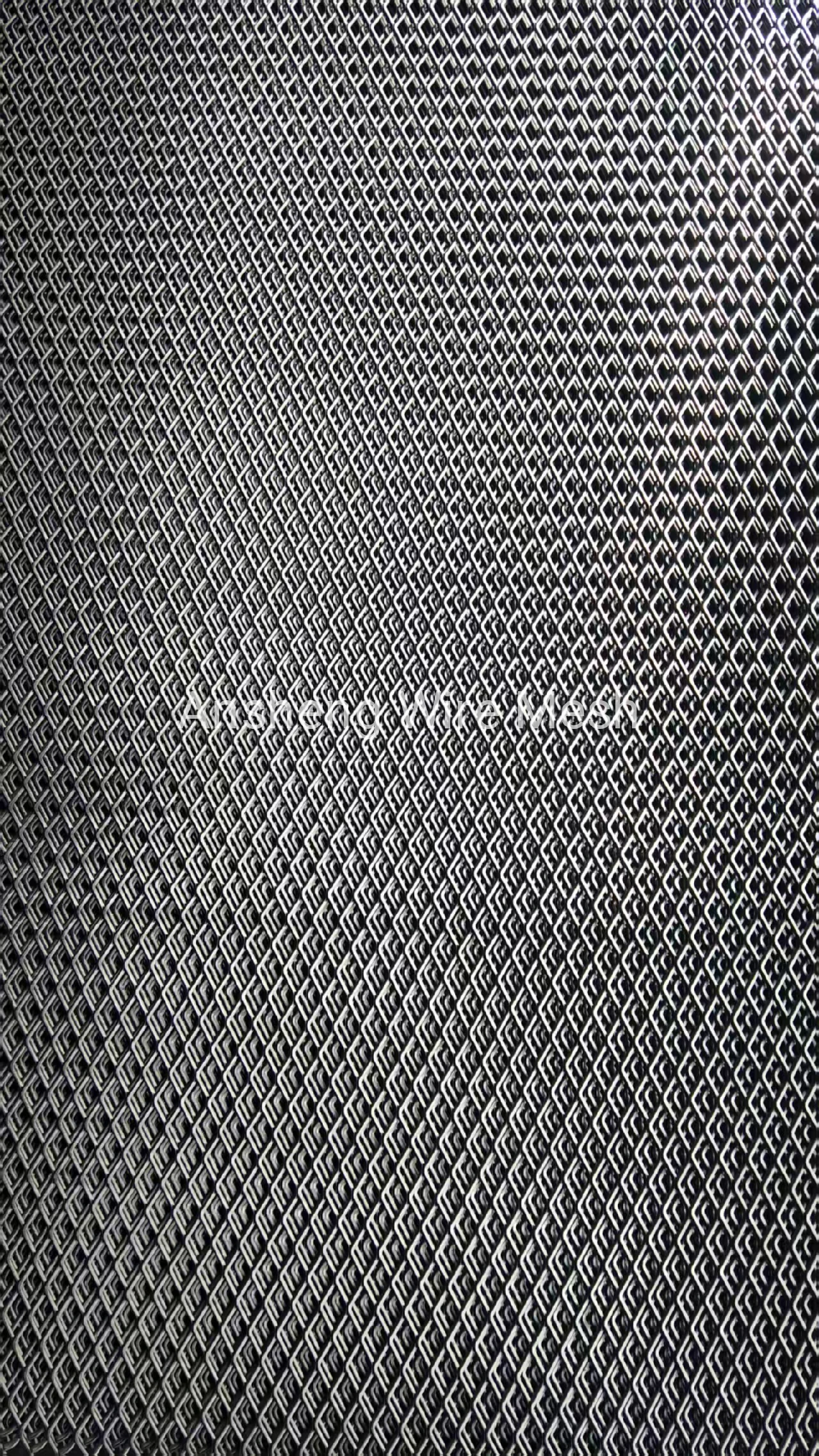

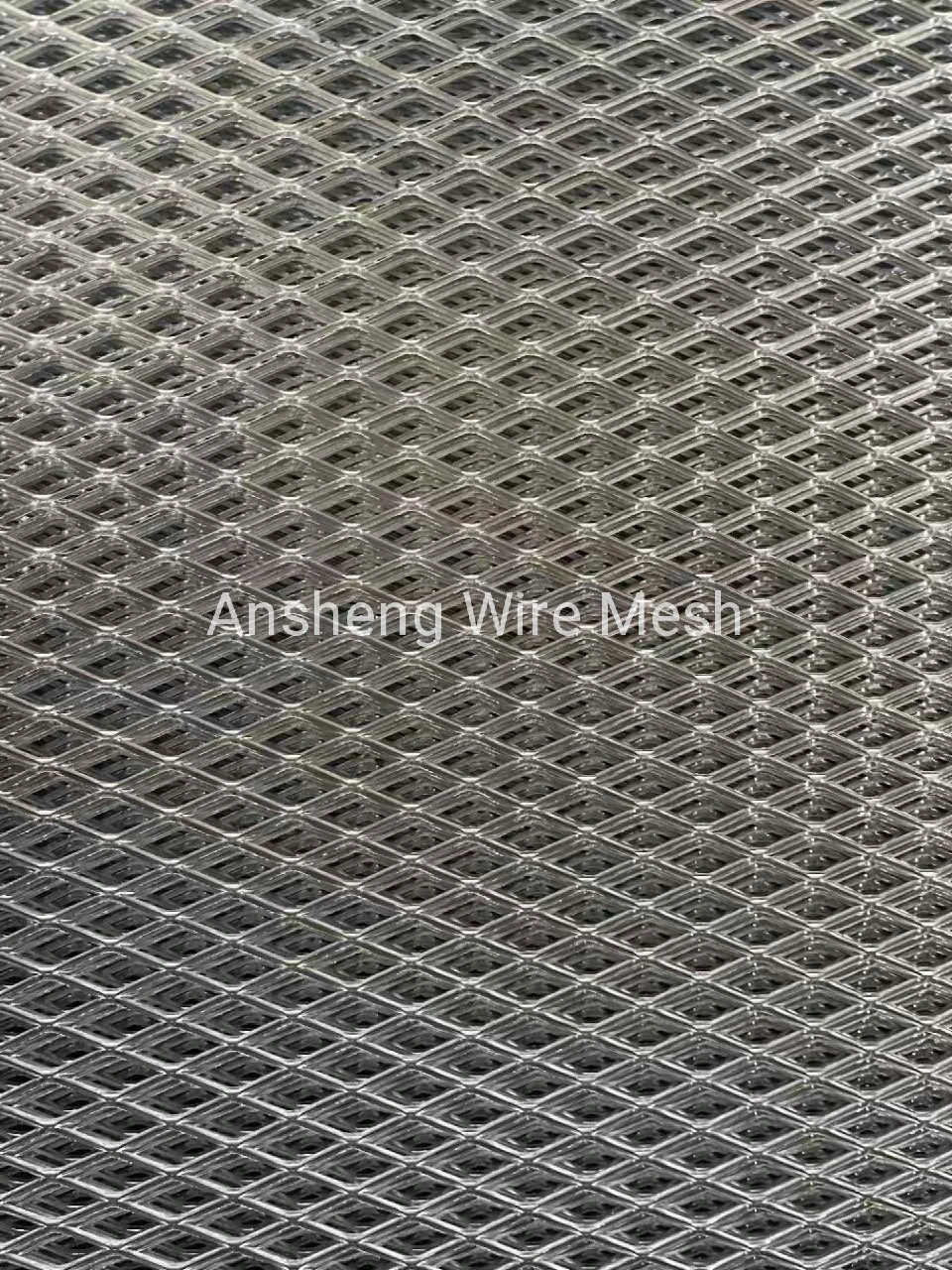

Epoxy coated wire mesh is a pre-fabricated reinforcement product comprised of high-strength steel wires welded into a grid pattern, subsequently coated with a durable layer of fusion-bonded epoxy. This coating provides a robust defense against corrosion, a primary cause of concrete degradation, particularly in structures exposed to de-icing salts, saltwater, or industrial chemicals. Unlike uncoated steel, which rusts and expands, causing spalling and cracking of the concrete, the epoxy layer ensures the integrity of the reinforcement. This leads to significantly enhanced structural longevity and reduced life-cycle costs for a wide range of applications, from bridge decks and parking structures to marine installations and industrial flooring. Its consistent quality and ease of placement make it an efficient and reliable choice for demanding construction projects where long-term performance is non-negotiable.

Advanced Manufacturing of Epoxy Coated Wire Mesh

The production of epoxy coated welded wire mesh is a sophisticated process that demands precision and adherence to stringent quality control protocols to ensure optimal performance. The journey begins with high-quality steel wire, typically cold-drawn, which is then precisely welded into mesh panels of specified dimensions. Following the welding stage, the mesh undergoes a meticulous cleaning process, often involving shot blasting and chemical degreasing, to remove all surface contaminants and prepare it for coating adhesion. This preparatory phase is critical, as any residual impurities can compromise the integrity of the epoxy bond. Once clean, the mesh is preheated to a specific temperature, usually between 200-250°C, before being passed through an electrostatic spray booth where a fine powder of thermosetting epoxy resin is applied. The electrostatic charge ensures uniform coverage, and upon contact with the hot mesh, the epoxy powder melts, flows, and cures, forming a continuous, protective layer. This fusion-bonded epoxy (FBE) coating is renowned for its excellent adhesion, flexibility, and chemical resistance, providing an unparalleled barrier against corrosive elements.

Quality Control and Inspection Standards

Ensuring the superior quality of epoxy coated mesh involves rigorous testing at every stage of the manufacturing process. Key standards such as ASTM A884/A1064 for Epoxy-Coated Steel Wire and Wire Mesh for Concrete Reinforcement dictate material properties, coating thickness, and performance criteria. Manufacturers often adhere to ISO 9001 quality management systems, ensuring traceability and consistency from raw material sourcing to the final product. Critical tests include coating thickness measurement (typically 175 to 300 micrometers), holiday detection (checking for pinholes or discontinuities in the coating), adhesion tests (bending or impact tests to assess the bond between epoxy and steel), and cure tests to ensure proper cross-linking of the epoxy. Furthermore, mechanical properties of the wire, such as tensile strength, yield strength, and elongation, are continuously monitored to guarantee the structural integrity of the mesh itself. These stringent inspection protocols ensure that each panel of epoxy coated wire mesh for concrete delivers the promised durability and corrosion protection in critical infrastructure projects.

Technical Specifications and Performance Metrics

The performance of epoxy coated wire mesh is defined by a precise set of technical parameters that govern its strength, durability, and corrosion resistance. Understanding these specifications is crucial for engineers and procurement specialists when selecting the appropriate reinforcement for specific concrete applications. These parameters ensure that the mesh provides the required structural support while effectively mitigating the risk of corrosion-induced damage. The uniform grid structure, combined with the meticulously applied epoxy coating, creates a composite material that excels in challenging environments. Factors such as wire diameter, mesh opening, and the thickness and quality of the epoxy layer all contribute to the overall efficacy and service life of the reinforced concrete element, making it a highly reliable component in critical infrastructure.

Key Product Parameters for Epoxy Coated Wire Mesh for Concrete

| Parameter | Typical Range/Value | Relevant Standard/Description |

|---|---|---|

| Material | Cold-drawn Steel Wire (Carbon Steel) | ASTM A82 / A1064 for steel wire |

| Wire Gauge (Diameter) | 6 AWG to 16 AWG (approx. 1.29mm to 4.88mm) | Customizable based on structural requirements |

| Mesh Opening (Spacing) | 2x2 inches to 6x6 inches (50x50mm to 150x150mm) | Common sizes, tailored to load distribution |

| Epoxy Coating Thickness | 175 to 300 micrometers (7 to 12 mils) | ASTM A884, ensuring robust corrosion protection |

| Tensile Strength | Min. 70 ksi (485 MPa) for wire | ASTM A82/A1064, critical for structural integrity |

| Yield Strength | Min. 65 ksi (450 MPa) for wire | ASTM A82/A1064, defines elastic limit |

| Elongation at Break | Min. 4% | ASTM A82/A1064, indicates ductility |

| Corrosion Resistance | >5000 hours Salt Spray (ASTM B117) | Significantly extends service life in harsh environments |

| Adhesion (Bend Test) | No visible damage after 120-degree bend | ASTM A884 Annex A1, ensures coating integrity during handling |

Performance Advantages in Concrete Reinforcement

The primary advantage of epoxy coated wire mesh lies in its superior corrosion resistance compared to plain steel mesh, leading to a significantly extended structural lifespan. This characteristic is particularly vital in environments where concrete structures are regularly exposed to corrosive agents such as chlorides from de-icing salts or marine atmospheres. The epoxy coating forms a robust barrier, preventing moisture and chloride ions from reaching the steel, thus eliminating the electrochemical reactions that cause rust. This not only preserves the structural integrity of the reinforcement but also prevents the volumetric expansion of rust, which typically leads to cracking, spalling, and delamination of the concrete cover. Furthermore, the textured surface of the epoxy coating enhances bond strength with concrete, ensuring effective load transfer and preventing slippage. This combination of corrosion protection and mechanical stability makes epoxy coated wire mesh for concrete an indispensable material for durable and low-maintenance infrastructure in industries like petrochemicals, metallurgy, and water treatment, where long-term performance and reduced downtime are critical.

Diverse Applications and Unrivaled Advantages

The versatility and robust performance of epoxy coated welded wire mesh make it an ideal choice for a multitude of demanding construction applications where conventional reinforcement falls short. Its ability to withstand harsh environmental conditions ensures that critical structures maintain their integrity and functionality over prolonged periods, significantly reducing the need for costly repairs and premature replacement. From preventing chloride ingress in coastal structures to resisting chemical attack in industrial settings, this advanced material offers unparalleled protection. Its widespread adoption across various sectors underscores its effectiveness as a reliable solution for long-term concrete durability.

Typical Application Scenarios

- Bridge Decks and Roadways: Highly exposed to de-icing salts and traffic loads, bridge decks are particularly vulnerable to corrosion. Epoxy coated wire mesh for concrete prevents premature spalling and cracking, extending the lifespan of vital transportation infrastructure.

- Parking Structures: Constant exposure to salt-laden vehicles and environmental moisture makes parking garages prone to reinforcement corrosion. Using epoxy mesh significantly enhances durability and reduces maintenance cycles.

- Marine and Coastal Structures: Piers, wharves, seawalls, and other structures in saltwater environments face severe chloride attack. The superior corrosion resistance of epoxy coated wire mesh is critical for long-term integrity in these applications.

- Wastewater Treatment Plants: Concrete components in these facilities are often exposed to corrosive chemicals and high humidity. Epoxy coated mesh provides essential protection, ensuring the operational continuity and safety of the plant.

- Industrial Floors and Slabs: In facilities dealing with chemicals or requiring extreme durability, such as chemical processing plants or heavy manufacturing units, epoxy mesh offers robust protection against corrosive spills and wear, ensuring the structural integrity of the flooring.

Operational Benefits and Longevity

The adoption of epoxy coated wire mesh for concrete translates directly into significant operational benefits and extended longevity for concrete structures. By effectively preventing corrosion, this reinforcement technology eliminates the need for frequent and expensive repairs associated with rust-induced spalling and delamination. This reduction in maintenance costs and downtime offers substantial long-term savings, making the initial investment highly cost-effective over the structure's lifespan. Furthermore, the enhanced durability contributes to indirect energy savings by reducing the carbon footprint associated with repeated concrete repairs and material replacements. Its anti-corrosion properties ensure that structures remain structurally sound and aesthetically pleasing for decades, providing a sustainable and reliable solution for challenging environments. The improved bond strength between the epoxy-coated mesh and concrete also contributes to enhanced structural performance under various loading conditions, ensuring safety and operational efficiency.

Choosing the Right Partner: Manufacturer Comparison and Custom Solutions

Selecting the right supplier for epoxy coated wire mesh for concrete is as crucial as the material itself. A reliable manufacturer offers not just a product but a partnership, providing expertise, consistent quality, and tailored solutions. In a competitive market, discerning buyers prioritize manufacturers who demonstrate deep technical knowledge, adhere to international quality standards, and offer comprehensive support throughout the project lifecycle. This includes understanding the specific environmental challenges a structure will face, advising on optimal material specifications, and providing responsive customer service. The ability to customize products to unique project requirements is a key differentiator, ensuring that the reinforcement solution is perfectly aligned with structural demands and site conditions.

What to Look for in a Supplier of Epoxy Coated Wire Mesh

- Certifications and Compliance: Verify adherence to international standards like ASTM A884/A1064 and ISO 9001. These certifications are benchmarks for quality assurance and product performance.

- Manufacturing Capabilities: Assess their capacity for large-scale production, advanced coating technology, and robust quality control procedures. A manufacturer with state-of-the-art facilities indicates higher product consistency.

- Technical Expertise and R&D: A strong R&D department can offer innovative solutions and adapt to evolving industry demands. Technical support from experienced engineers is invaluable for complex projects using epoxy coated mesh.

- Customer Service and Support: Responsive communication, clear quotation processes, on-time delivery, and reliable post-sales support are indicative of a trustworthy partner.

- Global Logistics and Delivery: For international projects, evaluate their experience in global shipping, customs clearance, and ability to meet specific delivery schedules.

Tailored Solutions and Project Consultation

Recognizing that no two construction projects are identical, leading manufacturers offer extensive customization options for epoxy coated wire mesh. This includes varying wire gauges, mesh openings, panel dimensions, and even specific coating thicknesses to meet unique load-bearing requirements and environmental exposure levels. A comprehensive consultation process involves expert engineers working closely with clients to understand their project's specific challenges and design needs. This collaborative approach ensures that the chosen epoxy coated wire mesh for concrete solution is not just a standard product, but a precisely engineered component that optimizes structural performance and lifecycle costs. Furthermore, many suppliers provide value-added services such as fabrication of custom shapes, pre-cut panels, and technical documentation, streamlining the construction process and enhancing overall project efficiency. This commitment to tailored solutions reinforces a manufacturer's role as a trusted partner in complex infrastructure development.

Proven Success: Real-World Applications

The efficacy of epoxy coated wire mesh for concrete is best illustrated through its successful implementation in demanding projects worldwide. These case studies highlight the material's ability to deliver long-term durability and cost savings in challenging environments, cementing its status as a preferred reinforcement solution.

Illustrative Project Cases

- Coastal Bridge Deck Rehabilitation (Florida, USA): A major bridge connecting mainland Florida to a barrier island experienced significant deterioration due to chloride ingress from saltwater spray and de-icing salts. Traditional reinforcement showed severe corrosion and spalling. The rehabilitation project utilized epoxy coated welded wire mesh in critical sections of the deck. Five years post-rehabilitation, routine inspections reveal no signs of rebar corrosion or concrete distress, significantly outperforming previous repair efforts and extending the bridge's expected service life by decades. The project leader noted, "The resilience of the epoxy coated wire mesh in this harsh marine environment has been exceptional, validating our decision."

- Chemical Processing Plant Floor Upgrade (Texas, USA): A large industrial facility required a new, highly durable floor slab for its chemical processing area, which was frequently exposed to aggressive chemicals and heavy loads. Conventional steel reinforcement would quickly corrode, compromising the slab's integrity. By integrating epoxy mesh throughout the concrete slab, the client achieved a floor system with superior resistance to chemical attack and enhanced structural integrity. This minimized downtime for repairs and ensured operational safety, leading to a substantial reduction in long-term maintenance costs and compliance with stringent environmental regulations.

- Multi-Story Parking Garage Construction (Toronto, Canada): In a region with severe winter conditions and heavy use of de-icing salts, a new multi-story parking garage was designed with a focus on maximum durability. The project specified epoxy coated wire mesh for concrete for all elevated slabs and ramps. This proactive measure mitigated the risk of corrosion-induced damage common in such structures. After ten years of operation, the garage exhibits minimal signs of concrete deterioration, demonstrating the long-term protection offered by the epoxy coating, leading to positive feedback from the property management team regarding low maintenance expenditures.

Building Trust: FAQ, Delivery, and Warranty

Transparency and reliability are cornerstone values in B2B partnerships. This section addresses common inquiries, outlines logistical capabilities, and clarifies warranty commitments, providing a comprehensive overview of the support and assurance clients can expect when partnering for their epoxy coated wire mesh for concrete needs.

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of epoxy coated wire mesh for concrete?

A: When properly installed and embedded in concrete, epoxy coated wire mesh can extend the lifespan of concrete structures by 2-3 times compared to conventional uncoated reinforcement, often exceeding 50-75 years in challenging environments. - Q: How does epoxy coated mesh compare to galvanized mesh in terms of corrosion resistance?

A: While galvanized mesh offers some corrosion protection, epoxy coated mesh provides a superior, non-sacrificial barrier against chloride ingress and chemical attack. The fusion-bonded epoxy coating offers significantly better long-term performance, especially in highly corrosive environments, as it does not deplete over time like zinc. - Q: Can epoxy coated wire mesh be cut or bent on-site without compromising the coating?

A: Minor cuts or bends are generally acceptable, but it's crucial to minimize damage to the epoxy coating. For significant alterations or where coating integrity is paramount, field repair kits are available to touch up exposed steel, ensuring continuous protection. It is always recommended to procure pre-fabricated panels to precise specifications to reduce on-site modifications. - Q: What are the typical lead times for large orders of epoxy coated wire mesh?

A: Lead times vary based on order volume, customization requirements, and current production schedules. Standard orders typically range from 2-4 weeks. For large or highly customized projects, we recommend early consultation to establish a precise production and delivery timeline tailored to your project schedule.

Delivery, Warranty, and Customer Support

Our commitment extends beyond product delivery to comprehensive customer support and robust warranty provisions. We manage a streamlined global logistics network, ensuring efficient and timely delivery of epoxy coated wire mesh for concrete to project sites worldwide, respecting critical deadlines. Our standard delivery cycles are optimized for both domestic and international shipments, with options for expedited services where project urgency dictates. Each batch of epoxy coated wire mesh undergoes stringent quality checks and is backed by a substantial product warranty, guaranteeing performance against manufacturing defects and coating integrity under specified conditions. Our dedicated customer support team and technical specialists are available to provide assistance, from initial consultation and technical guidance to post-installation support, ensuring a seamless experience and maximizing the long-term value of your investment.

Future Outlook and Industry Leadership

As global infrastructure ages and environmental challenges intensify, the demand for resilient and sustainable construction materials is on a relentless rise. Epoxy coated wire mesh for concrete stands at the forefront of this evolution, offering an indispensable solution for enhancing the durability and extending the service life of critical concrete structures. Its proven ability to combat corrosion in the most aggressive environments makes it a vital component in future-proofing our infrastructure against climate change impacts and increasing demands. Continued innovation in coating technology and manufacturing processes will further solidify its position as the preferred reinforcement for projects demanding exceptional longevity and minimal maintenance. Embracing this advanced material is not merely an engineering choice but a strategic investment in the enduring quality and economic viability of our built environment.

Authoritative References

- ASTM A884/A884M-18. (2018). Standard Specification for Epoxy-Coated Steel Wire and Wire Mesh for Concrete Reinforcement. ASTM International.

- ACI 318-19. (2019). Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute.

- NACE International. (2016). Corrosion Basics: An Introduction. NACE Press.

- FHWA-RD-88-005. (1988). Corrosion of Steel in Concrete. Federal Highway Administration.

Post time: Aug . 11, 2025 14:20