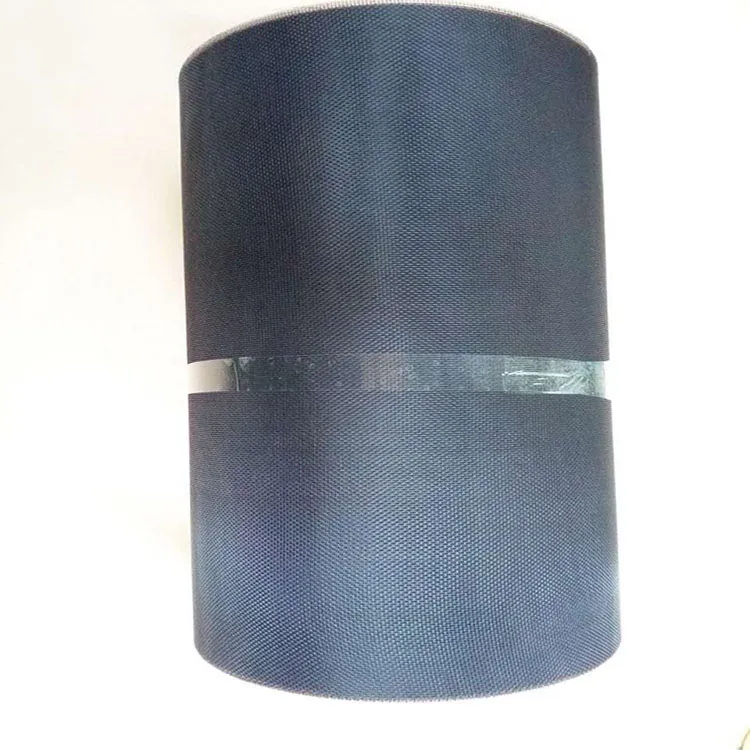

Epoxy Coated Wire Mesh

The epoxy coated wire mesh produced by Ansheng Wire Mesh plays a crucial role in both industrial and civil applications. In the industrial field, it is mainly used as the supporting layer for hydraulic or air filters, serving as a core component to ensure the stable operation of the filtration system. In the civil aspect, it is often used as a safety protection mesh for high-end apartments and office buildings, providing a reliable safety guarantee for living and working environments.

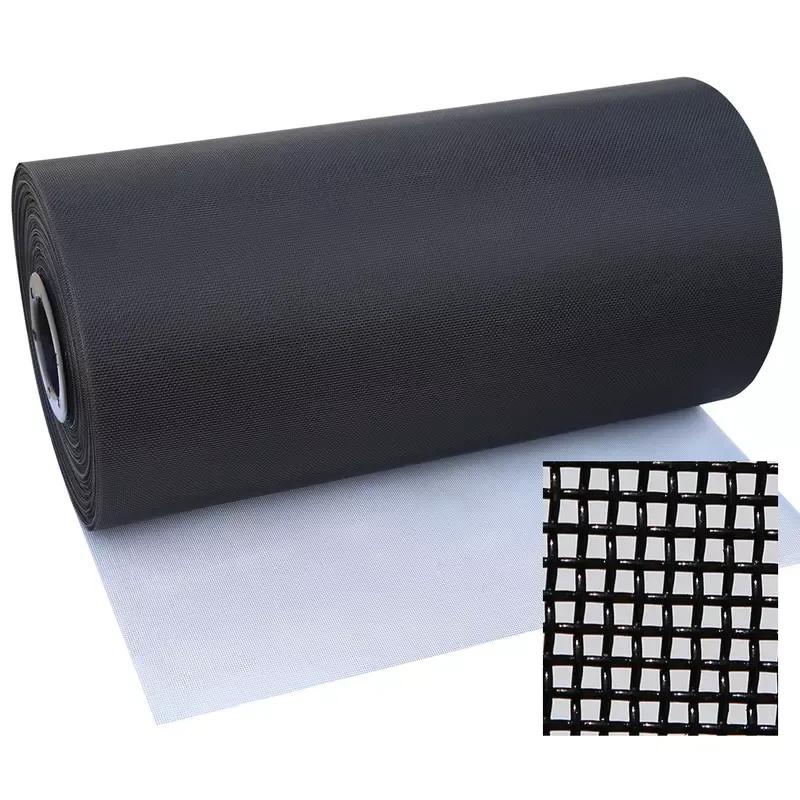

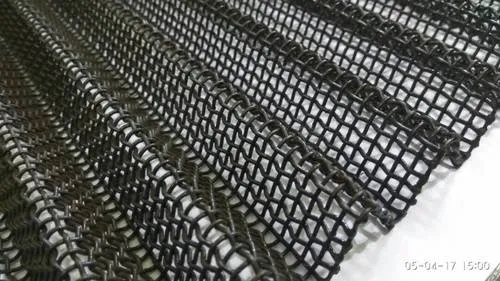

Its manufacturing process is elaborate and complex. Different types of metal wires are first woven into a mesh, and then through the electrostatic spraying process, the specially made epoxy powder is evenly attached to the surface of the mesh. Under specific time and temperature conditions, the epoxy powder melts and closely covers the mesh surface, forming a dense and sturdy protective layer. Commonly used base mesh materials include stainless steel mesh, aluminum mesh, and low-carbon steel mesh to meet the requirements for strength, corrosion resistance, etc., in different scenarios. The epoxy powder is also divided into indoor and outdoor types to adapt to different usage environments. In addition, Ansheng Wire Mesh can also conduct customized research and development according to customers' special needs, providing personalized solutions.

Characteristics of Epoxy Coated Welded Wire Mesh

Stable Structure: After surface treatment, the interlacing points of the mesh are firmly fixed. The mesh holes are uniform and regular, in a square shape, and the warp and weft wires are perpendicular to each other. The overall structure is stable, not prone to looseness or deformation, which greatly enhances the supporting force and ensures reliable performance in various application scenarios.

Convenient Processing: The mesh surface is soft, making it convenient for various shaping and forming processes, and it can easily meet the design requirements of different projects. Whether it is a complex shape or a special installation requirement, it can be flexibly handled.

Rich in Colors: According to customers' preferences and actual needs, epoxy powders of different colors can be sprayed, and the colors are uniform and consistent. This not only improves the aesthetic appeal of the product but also allows it to blend perfectly with the surrounding environment, adding a unique decorative effect to buildings and facilities.

Advantages of Ansheng Epoxy Coated Welded Wire Mesh

1. Strict Inspection: Ansheng Wire Mesh has a professional performance simulation laboratory, equipped with advanced testing equipment and professional technicians. The laboratory conducts a variety of strict tests,

2. Advanced Production: It owns two self-developed large-scale surface treatment production lines, representing the leading level in the industry. The production adopts far-infrared and natural gas hot air circulation processes, with the characteristics of stable and uniform heat dissipation. This not only ensures the consistency of product quality but also makes the operation more convenient and efficient. At the same time, the production process pays attention to environmental protection and meets the requirements of sustainable development.

Epoxy coated wire mesh Specifications

|

No. |

Substrate material |

coating |

specification |

(mm)width |

Applied industry |

|

1 |

Q195 |

black color &Oil resistance |

18x14/0.18 |

20mm-1300mm |

hydraulics |

|

2 |

Q195 |

black color &oil resistance |

18x14/T0.18 |

20mm-1300mm |

hydraulics |

|

3 |

Q195 |

black color &Oil resistance |

12x10/0.254 |

50mm-1300mm |

hydraulics |

|

4 |

Q195 |

black color &Oil resistance |

22x20/0.18 |

20mm-1300mm |

hydraulics |

|

5 |

Q195 |

white color &Oil resistance |

18x14/0.18 |

20mm-1300mm |

hydraulics |