Introduction

The TPO waterproof membrane has emerged as a leading solution in the construction industry, offering superior protection against water infiltration, UV radiation, and environmental stress. This article delves into the product's features, advantages, technical specifications, applications, and the company behind it, Anping County Ansheng Wire Meshes Product Co., Ltd.

Product Overview

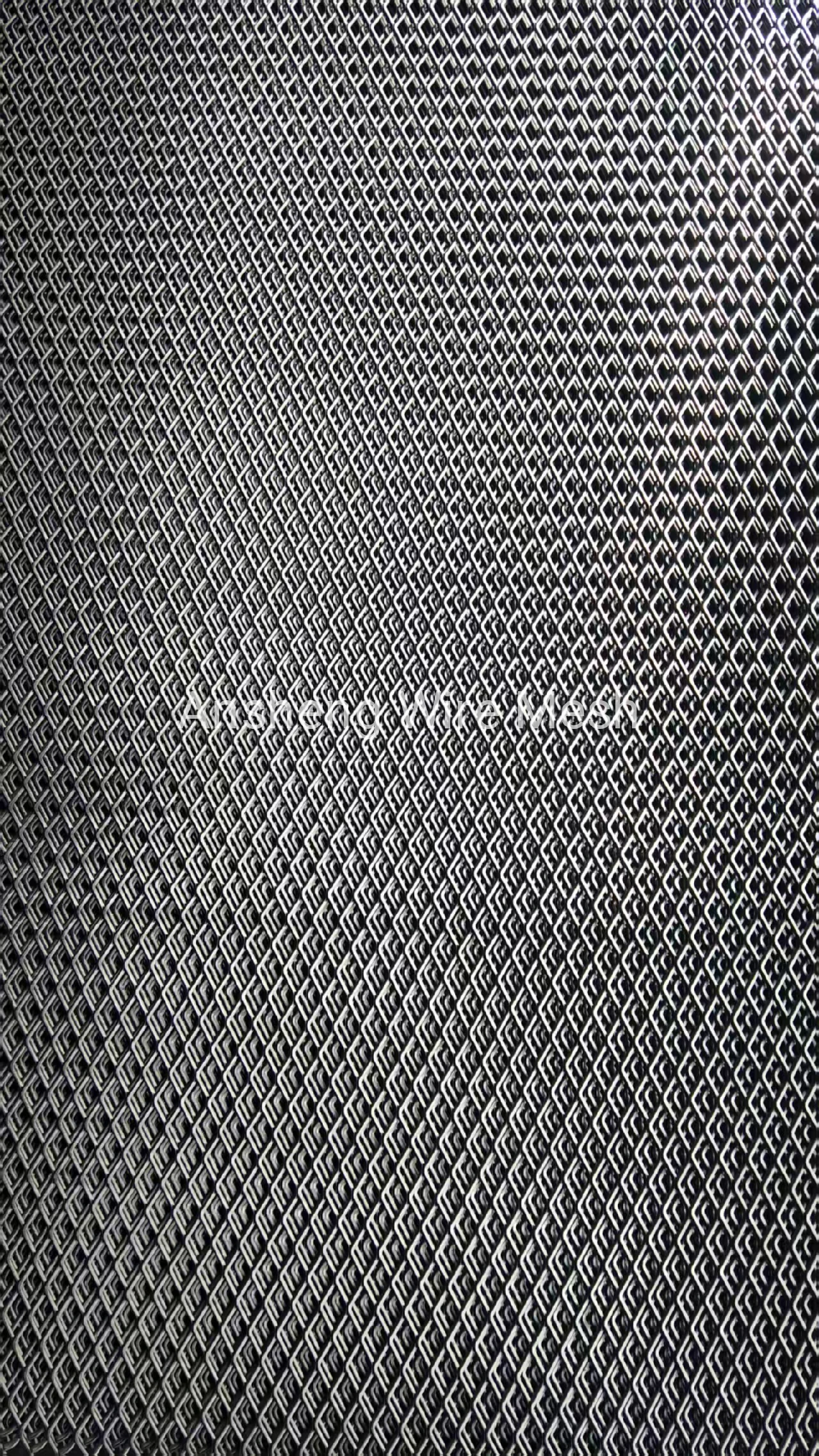

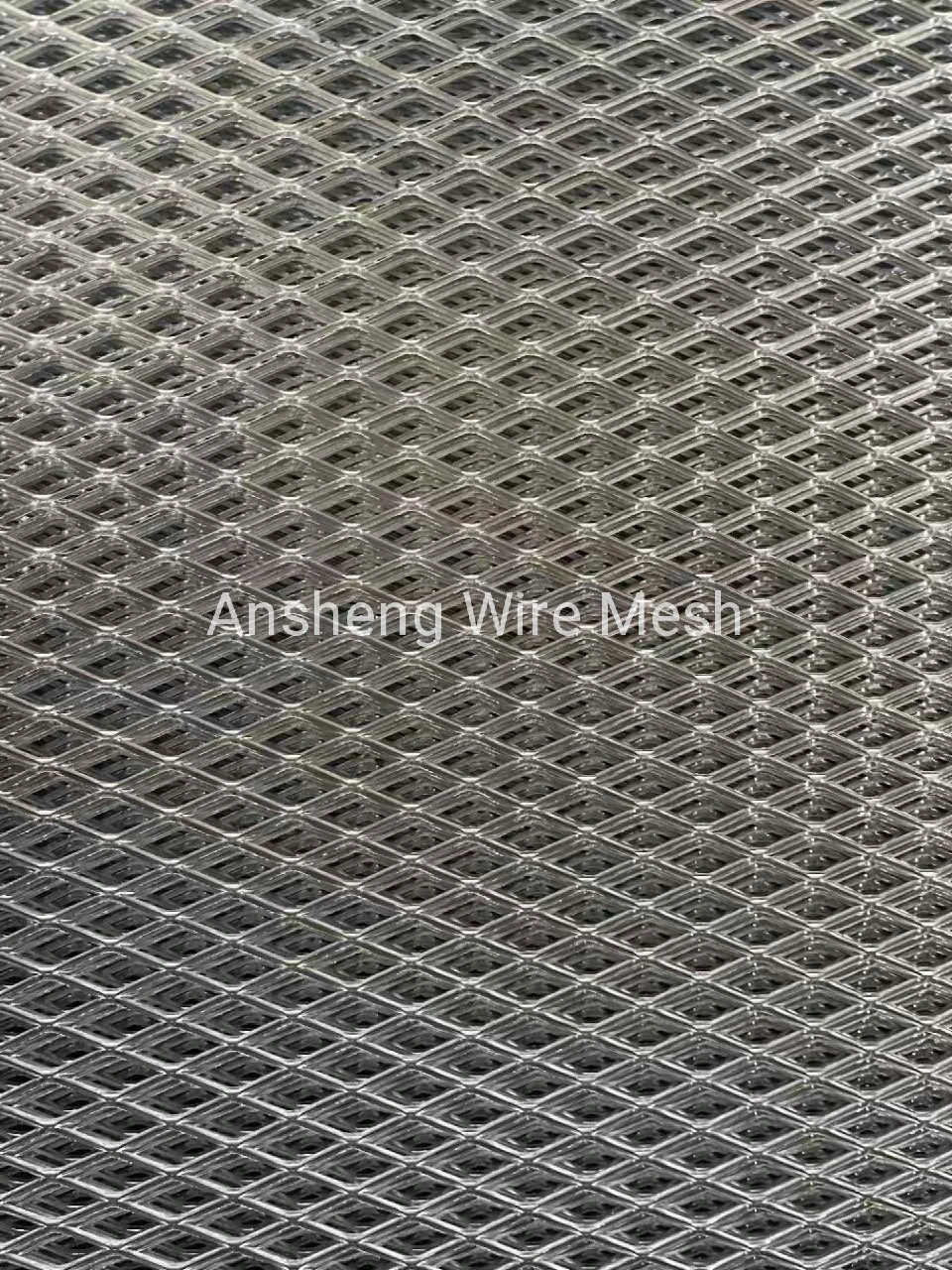

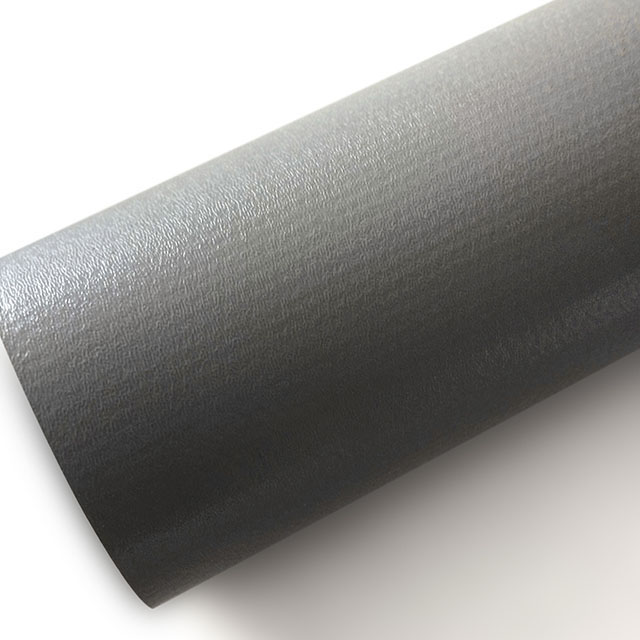

The TPO waterproof membrane is a high-performance, single-ply roofing and waterproofing material designed to provide long-lasting protection for both commercial and residential buildings. Manufactured using thermoplastic olefin (TPO) modified polyolefin, this membrane is reinforced with a polyester mesh, featuring a double-color white/black structure achieved through co-extrusion. The white upper layer is engineered for exceptional resistance to weather and UV rays, while the underlying black layer offers enhanced puncture resistance. Certified by NIST standards, this product ensures compliance with rigorous quality and environmental management systems.

Key Features of TPO Waterproof Membrane

1. TPO waterproof membrane provides an effective, continuous barrier against water penetration. Its durable surface ensures roofs remain protected from leaks, moisture infiltration, and environmental damage, making it ideal for flat and low-slope roofing systems.

2. The membrane exhibits excellent resistance to UV rays, ozone, and weathering, maintaining its flexibility and waterproofing performance even under prolonged exposure to sunlight and extreme weather conditions.

3. The reflective surface of TPO significantly reduces heat absorption, contributing to energy efficiency by lowering cooling costs. This eco-friendly feature aligns with sustainable construction practices.

4. TPO is highly resistant to punctures, tears, and abrasions, offering a durable solution for both commercial and residential applications. It can withstand foot traffic and physical stress, ensuring long-term reliability.

5. Lightweight and easy to install, TPO membranes require less labor and reduce installation time. They can be applied using heat welding, adhesive, or mechanical fasteners, ensuring a secure and lasting bond.

Applications of TPO Waterproof Membrane

- TPO waterproof membrane is widely used for flat and low-slope roofing systems in commercial and residential buildings. Its waterproofing and UV resistance ensure reliable protection against water damage.

- Due to its energy-efficient reflective properties, TPO is often employed in green roofing systems, contributing to sustainable construction by reducing energy consumption and enhancing a building's environmental performance.

- Industrial settings such as warehouses, manufacturing facilities, and parking garages benefit from TPO's durability and waterproofing capabilities.

- The membrane is also suitable for foundations and below-grade applications, preventing water infiltration and moisture damage.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Thermoplastic Olefin (TPO) with polyester reinforcement |

| Color | Double-color (White/Black) |

| Thickness | Varies (typically 1.2mm to 2.0mm) |

| UV Resistance | High resistance to UV degradation |

| Temperature Range | Flexible at low temperatures (down to -30°C) |

| Installation Methods | Heat welding, adhesive, or mechanical fasteners |

| Weight | Lightweight, reducing structural load |

| Environmental Certifications | UNI EN ISO 9001 (Quality Management) and UNI EN ISO 14001 (Environmental Management) |

Company Background: Anping County Ansheng Wire Meshes Product Co., Ltd.

Anping County Ansheng Wire Meshes Product Co., Ltd. is a leading manufacturer of high-quality waterproofing solutions, specializing in TPO membranes and related products. With a commitment to innovation and sustainability, the company adheres to international standards such as NIST guidelines, ensuring that its products meet the highest quality and environmental benchmarks. Their expertise in manufacturing TPO membranes, combined with advanced production techniques, positions them as a trusted partner for construction professionals worldwide.

Why Choose TPO Waterproof Membrane?

The TPO waterproof membrane stands out due to its unique combination of durability, energy efficiency, and ease of installation. Unlike traditional roofing materials, TPO offers a lightweight solution that reduces the load on structures while providing long-term protection. Its reflective surface not only lowers energy costs but also contributes to a cooler indoor environment, aligning with global efforts to reduce carbon footprints. Additionally, the membrane's resistance to punctures and abrasions ensures it can withstand harsh conditions, making it a cost-effective choice for both new constructions and retrofit projects.

Comparative Advantages

Compared to other waterproofing materials like PVC or EPDM, TPO membranes offer superior UV resistance and energy efficiency. While PVC may degrade over time under prolonged sunlight, TPO maintains its integrity and performance. EPDM, though durable, lacks the reflective properties of TPO, leading to higher cooling costs. Furthermore, TPO's lightweight nature and ease of installation reduce labor costs and time, making it a more economical option for large-scale projects.

Installation and Maintenance

Proper installation is critical to maximizing the performance of TPO waterproof membrane. The process typically involves preparing the substrate, applying the membrane using heat welding or adhesives, and ensuring seamless joints. Regular maintenance, such as inspecting for damage and cleaning the surface, is essential to prolong the membrane's lifespan. The company provides detailed installation guidelines and support to ensure optimal results.

Environmental Impact and Sustainability

As a sustainable building material, TPO contributes to green construction practices. Its energy-efficient properties reduce the need for air conditioning, lowering energy consumption and greenhouse gas emissions. Additionally, TPO membranes are recyclable, aligning with the industry's push toward circular economy principles. Anping County Ansheng Wire Meshes Product Co., Ltd. is committed to minimizing its environmental footprint through eco-friendly production processes and adherence to international environmental standards.

Case Studies and Real-World Applications

Several projects have successfully utilized TPO waterproof membrane to address complex waterproofing challenges. For instance, a large warehouse in [Location] implemented TPO membranes to protect its flat roof from extreme weather conditions, resulting in a 30% reduction in cooling costs. Similarly, a residential complex in [Location] adopted TPO for its green roof system, enhancing energy efficiency while complying with local sustainability regulations.

Future Trends and Innovations

The demand for high-performance waterproofing solutions is expected to grow as construction projects increasingly prioritize sustainability and resilience. Innovations in TPO technology, such as enhanced UV resistance and improved thermal properties, will further solidify its position in the market. Anping County Ansheng Wire Meshes Product Co., Ltd. is actively researching and developing next-generation TPO membranes to meet evolving industry needs and regulatory requirements.

Conclusion

The TPO waterproof membrane represents a significant advancement in roofing and waterproofing technology. Its combination of durability, energy efficiency, and environmental benefits makes it an ideal choice for modern construction projects. With the support of Anping County Ansheng Wire Meshes Product Co., Ltd., this product continues to set new standards in the industry, offering reliable solutions for a wide range of applications.

Product Images

References

1. NIST (National Institute of Standards and Technology). "Driving Innovation." Retrieved from https://www.nist.gov/.

2. Anping County Ansheng Wire Meshes Product Co., Ltd.. "TPO Waterproof Membrane Specifications." Retrieved from https://www.gardepota.com/tpo-waterproof-membrane.html.

Post time: Aug . 12, 2025 11:10