The Indispensable Role and Evolving Landscape of Red Copper Wire Mesh

In the vast realm of industrial filtration, shielding, and aesthetic applications, wire mesh stands as a foundational component. Among its diverse material compositions, red copper wire mesh distinguishes itself with a unique blend of conductivity, corrosion resistance, and malleability, making it invaluable across an array of sectors. While alternatives like steel mosquito net, stainless steel welded wire, stainless steel metal mesh, and stainless steel gopher wire mesh offer their own distinct advantages in terms of strength and specific chemical resistance, red copper brings properties that are often irreplaceable for specific high-performance applications.

The industry landscape for specialized wire meshes is experiencing dynamic shifts, driven by advancements in material science and increasing demands for efficient, durable, and environmentally conscious solutions. There's a growing trend towards materials that offer superior performance in niche applications, where the unique attributes of copper — such as its exceptional electrical and thermal conductivity, non-magnetic properties, and inherent anti-microbial characteristics — position red copper wire mesh at the forefront. As industries like electronics, architecture, and advanced filtration continue to evolve, the demand for high-quality, precisely manufactured copper mesh is set to expand significantly.

Technical Parameters and Specifications of Red Copper Wire Mesh

Understanding the technical specifications of red copper wire mesh is crucial for selecting the right product for specific applications. Pure copper (typically 99.9% pure, often C11000 grade) is the primary material, renowned for its superior electrical and thermal conductivity, excellent ductility, and good corrosion resistance in most environments. Unlike iron or steel-based meshes like stainless steel welded wire, copper does not rust, though it does form a protective patina (verdigris) over time when exposed to the elements, which can add to its aesthetic appeal in architectural contexts.

Key Material Properties:

- Electrical Conductivity: Extremely high, second only to silver, making it ideal for RFI/EMI shielding and grounding applications.

- Thermal Conductivity: Excellent heat transfer capabilities, useful in heat exchangers or thermal management systems.

- Corrosion Resistance: Resistant to atmospheric corrosion, saltwater, and many chemicals, though susceptible to strong acids and ammonia-based compounds.

- Non-Magnetic: Does not interfere with magnetic fields, crucial for sensitive electronic equipment.

- Ductility and Malleability: Highly workable, allowing for fine wire drawing and complex weaving patterns.

- Antimicrobial Properties: Naturally inhibits the growth of bacteria, viruses, and fungi on its surface, a significant advantage in certain environments.

Common Red Copper Wire Mesh Specifications Table:

| Parameter | Description | Typical Range for Red Copper Wire Mesh | Industry Standard Reference |

|---|---|---|---|

| Material Purity | Composition of copper alloy used. | 99.9% Pure Copper (C11000/CW004A) | ASTM B152 / EN 1652 |

| Mesh Count (Mesh/inch) | Number of openings per linear inch. Higher count means smaller openings. | 2 Mesh to 200 Mesh (or finer up to 400 mesh) | ISO 9044 / ASTM E2016 |

| Wire Diameter (mm/inch) | Diameter of individual wires before weaving. | 0.025mm to 1.6mm (0.001" to 0.063") | ASTM B1 / EN 12166 |

| Aperture/Opening Size (mm/inch) | Size of the square opening between adjacent wires. Calculated as (25.4/Mesh Count) - Wire Diameter. | 0.038mm to 12.5mm (0.0015" to 0.5") | ISO 3310-1 |

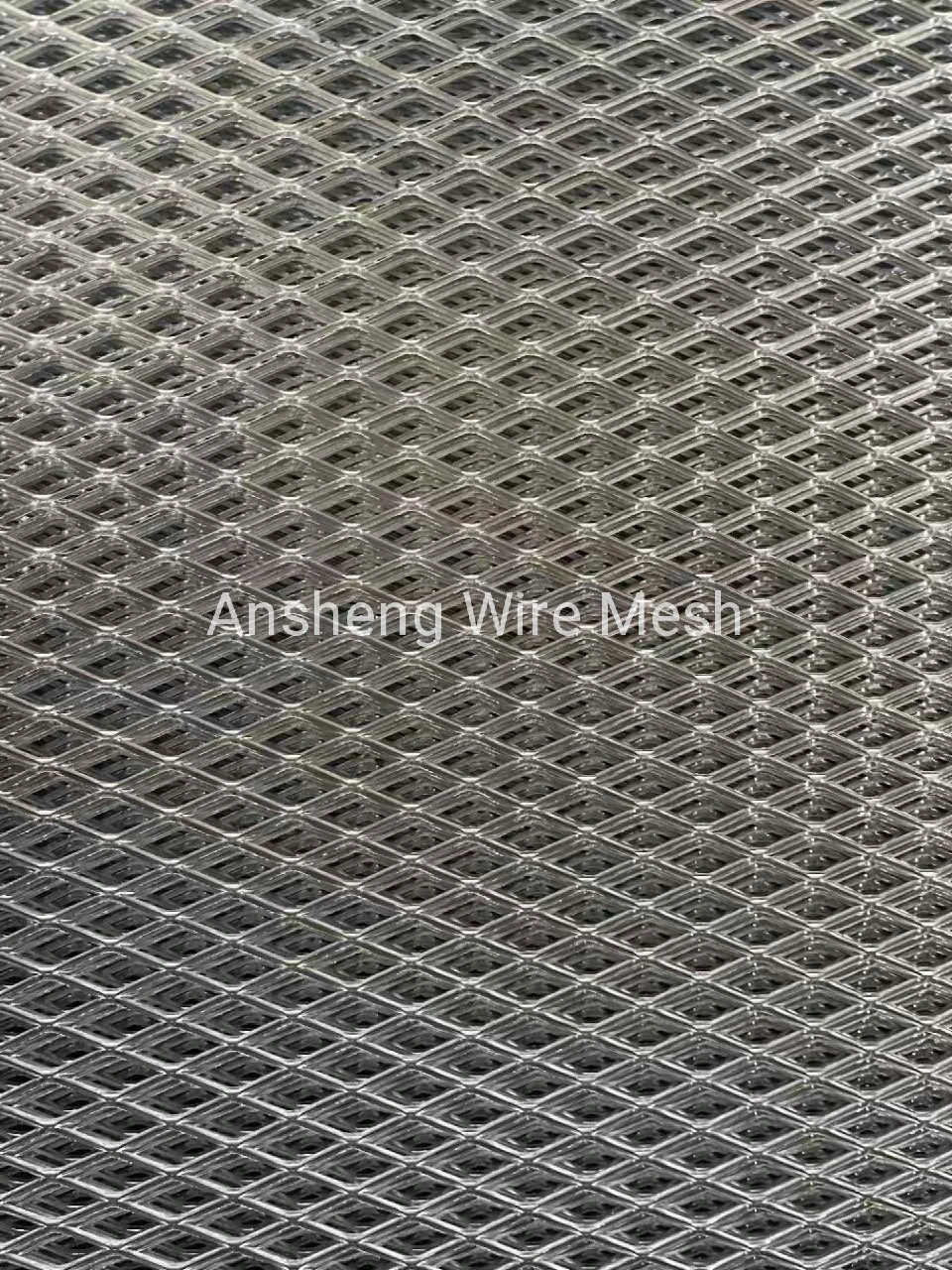

| Weave Type | Pattern in which wires are interlaced. | Plain Weave, Twilled Weave, Dutch Weave | Customary Industry Terms |

| Roll Width (m/ft) | Standard width of the mesh rolls. | 0.914m to 1.5m (3ft to 5ft) | Manufacturer Specific |

| Roll Length (m/ft) | Standard length of the mesh rolls. | 15m to 30m (50ft to 100ft) | Manufacturer Specific |

| Open Area (%) | Percentage of open space in the mesh, affecting flow rate and filtration efficiency. | Typically 25% to 80% | Calculated based on Mesh Count & Wire Diameter |

| Tensile Strength (MPa) | Resistance to breaking under tension. | Approx. 200-250 MPa (Annealed) | ASTM B224 |

These parameters allow engineers and designers to precisely specify the characteristics needed for optimal performance, whether for fine filtration, robust shielding, or decorative paneling.

Detailed Manufacturing Process of Red Copper Wire Mesh

The production of high-quality red copper wire mesh is a sophisticated process that begins with raw copper and culminates in a precisely engineered product. Unlike heavy industrial processes like casting or forging, wire mesh manufacturing primarily involves precision drawing and weaving. The meticulous control at each stage ensures the mesh meets stringent performance criteria for its intended applications, from sensitive electronics to durable architectural installations. This process highlights our expertise and commitment to quality.

Raw Material Sourcing & Quality Inspection

The journey begins with selecting high-purity copper rods, typically C11000 (ASTM B152 standard) or CW004A (EN 1652 standard), known for their excellent electrical and thermal conductivity, and malleability. Incoming materials undergo rigorous inspection to verify chemical composition, purity (minimum 99.9% copper), and absence of defects, ensuring a superior base for the final product.

Wire Drawing

Copper rods are drawn through a series of progressively smaller dies to reduce their diameter to the desired wire gauge. This cold-drawing process increases the wire's tensile strength and improves its surface finish. Multiple drawing stages are often required to achieve the fine wire diameters necessary for high-mesh-count screens, ensuring uniformity and precision.

Annealing (Heat Treatment)

After drawing, the copper wire can become work-hardened. Annealing is a heat treatment process where the wire is heated to a specific temperature and then slowly cooled. This restores the copper's ductility and flexibility, making it pliable enough for weaving without breaking. The annealing process is critical for producing wire that can withstand the stresses of the weaving loom and result in a durable, flexible mesh.

Weaving Preparation (Warp & Weft Setup)

The annealed copper wires are prepared for weaving. Longitudinal wires (warp) are precisely tensioned and loaded onto the loom. Transverse wires (weft) are loaded onto shuttles. The choice of weave pattern – plain, twilled, or Dutch – dictates how these wires interlace. Plain weave, where warp and weft wires pass over and under each other alternately, is common for general purpose mesh. Twilled weave, with each weft wire passing over two and under two warp wires, allows for heavier wires and finer meshes. Dutch weave creates a dense, strong mesh ideal for filtration.

Weaving Process

High-precision automatic looms weave the copper wires into mesh. The looms are meticulously calibrated to ensure consistent mesh count, aperture size, and tension across the entire roll. Advanced sensor systems monitor the weaving process, detecting and correcting any irregularities in real-time. This stage is where the raw copper wire transforms into the desired red copper wire mesh product, characterized by its uniform openings and structural integrity.

Cleaning & Finishing

After weaving, the mesh undergoes a thorough cleaning process to remove any residues from the manufacturing process, such as lubricants or surface contaminants. This ensures a clean, bright finish and prepares the mesh for any further processing or application. Depending on the end-use, additional finishing treatments might be applied, though copper's natural aesthetic often requires minimal enhancement.

Final Quality Control & Inspection

Each roll of red copper wire mesh undergoes stringent final quality control. This includes visual inspection for defects, precise measurement of mesh count and wire diameter using calibrated instruments (in accordance with ISO 9044 or ASTM E2016 standards), and verification of dimensional accuracy (width, length). Tensile strength tests (ASTM B224) may also be performed on samples to ensure the mesh meets specified mechanical properties. Only mesh that passes all these checks is approved for packaging.

Packaging & Shipping

The finished red copper wire mesh is carefully rolled and packaged, often in protective film and sturdy cardboard tubes or wooden crates, to prevent damage during transit. Proper labeling ensures traceability and identifies product specifications, guaranteeing that the mesh arrives at the customer's site in perfect condition, ready for immediate use. Our meticulous packaging reflects our commitment to delivering excellence from our factory to your application.

This comprehensive manufacturing process, coupled with adherence to international standards like ISO 9001 for quality management systems and specific ASTM/ANSI standards for material and mesh properties, ensures that our red copper wire mesh products deliver exceptional performance and reliability throughout their extensive service life.

Application Scenarios & Technical Advantages

Red copper wire mesh boasts a spectrum of technical advantages that make it indispensable in particular applications, often outperforming other materials like stainless steel metal mesh or steel mosquito net where electrical conductivity, thermal performance, or non-magnetic properties are paramount. Its service life can range from 10-20 years or more, depending on environmental conditions and specific application stresses, thanks to its inherent corrosion resistance and robust construction.

Key Advantages of Red Copper Wire Mesh:

- Superior Electrical and Thermal Conductivity: Crucial for applications requiring efficient heat dissipation or electrical grounding, such as in electronics or power generation.

- Excellent RFI/EMI Shielding: Its high conductivity makes it an ideal material for creating Faraday cages and shielding sensitive electronic equipment from electromagnetic interference.

- Corrosion Resistance: Naturally resistant to rust and many corrosive agents, making it suitable for outdoor use, marine environments, and certain chemical processing applications. It can form a protective patina, enhancing durability.

- Non-Magnetic Properties: Essential for environments where magnetic interference must be avoided, such as in medical imaging facilities (MRI rooms) or specialized research laboratories.

- Anti-sparking: Copper does not generate sparks when struck, making it a safe choice in volatile environments (e.g., petrochemical facilities) where flammable gases or liquids are present. This provides a critical safety advantage over many steel-based meshes.

- Aesthetic Appeal: The distinctive reddish-brown hue and the way it patinates over time make it highly desirable for architectural and decorative purposes, adding warmth and character.

- Antimicrobial Characteristics: Naturally inhibits microbial growth, making it suitable for applications in healthcare, water treatment (e.g., certain stages of municipal water supply/drainage systems), and food processing where hygiene is paramount.

Typical Application Scenarios:

- Petrochemical Industry: Used in filters, strainers, and safety screens where non-sparking properties and corrosion resistance to specific chemicals are vital. Its durability contributes to long-term energy efficiency by maintaining clean flow paths.

- Electronics and Electrical Engineering: Extensive use in RFI/EMI shielding in server rooms, shielded enclosures, data centers, and telecommunications equipment. It protects sensitive components from external electromagnetic noise and prevents internal emissions.

- Architectural and Decorative Applications: Utilized for façade cladding, interior design elements, balustrades, and artistic installations. Its unique color and ability to age gracefully add significant aesthetic value.

- HVAC and Air Filtration: Employed in certain air filters, especially where antimicrobial properties are desired, contributing to cleaner air quality in commercial and residential buildings.

- Power Generation: Found in grounding systems, busbar insulation, and certain cooling applications due to its high electrical and thermal conductivity.

- Research & Development: Integral in laboratory settings for experimental setups requiring precise shielding or specific conductive properties.

- Pest Control (Alternative to Stainless Steel Gopher Wire Mesh): While stainless steel is common for gopher mesh due to its strength, copper mesh can be used for smaller pest exclusion (e.g., mice, insects) where its malleability allows for easier sealing of irregular openings, and its non-corrosive nature in some environments is preferred. For applications like steel mosquito net, copper offers similar barrier protection with the added benefit of antimicrobial properties.

- Water Supply and Drainage (Specific Applications): Used in certain filtration steps for sediment removal or where inherent antimicrobial properties are beneficial to prevent biofilm buildup in specific water handling components.

For example, in a critical RFI shielding application for a sensitive medical device manufacturing facility, the use of red copper wire mesh ensured compliance with strict electromagnetic compatibility (EMC) standards, preventing external signal interference that could compromise equipment performance and product quality. This direct experience underscores its practical value and how it enables reliable operation in demanding environments.

Choosing the Right Manufacturer: Expertise, Authority, and Trust

When investing in red copper wire mesh, selecting a manufacturer that demonstrates true expertise, industry authority, and unwavering trustworthiness is paramount. A reputable manufacturer doesn't just supply a product; they provide a solution built on deep understanding, stringent quality control, and reliable customer support.

Key Considerations for Manufacturer Comparison:

- Expertise & Specialization: Look for manufacturers with years of specialized experience in wire mesh production, particularly with copper alloys. Their team should possess profound knowledge of material properties, weaving techniques, and application requirements. They should be able to speak confidently about different mesh types, industry standards (like ISO and ASTM), and optimal solutions for complex challenges.

- Quality Certifications & Compliance: A highly authoritative manufacturer will hold relevant certifications such as ISO 9001 for quality management systems. This indicates a commitment to consistent quality control and continuous improvement throughout their processes. Adherence to international standards (e.g., ASTM, ANSI, DIN) for material composition, mesh dimensions, and testing procedures is also critical.

- Track Record & Client Testimonials: Proven experience through successful projects and positive client feedback are strong indicators of reliability. A long history of service (e.g., 20+ years in the industry) and partnerships with well-known companies in petrochemical, electronics, or architectural sectors solidify their authority. We pride ourselves on a consistent record of satisfied customers who rely on our red copper wire mesh for critical applications.

- Customization Capabilities: The ability to provide bespoke solutions (e.g., specific mesh counts, wire diameters, roll sizes, or fabricated components) demonstrates flexibility and a deep understanding of diverse client needs. This is crucial for niche applications where standard products may not suffice.

- After-Sales Support & Warranty: A trustworthy manufacturer stands behind its products. This includes clear warranty policies, responsive customer support, and technical assistance post-purchase. This commitment provides peace of mind and ensures long-term satisfaction.

Customization Solutions and Services

Recognizing that every application has unique requirements, we offer extensive customization options for our red copper wire mesh. Our team of experts collaborates closely with clients to develop tailored solutions that meet precise specifications and performance demands, enhancing the overall value and effectiveness of the mesh in your system.

- Tailored Specifications: We can produce red copper wire mesh with specific mesh counts (e.g., fine 200 mesh for advanced filtration or coarser 4 mesh for security), precise wire diameters, and custom aperture sizes.

- Weave Patterns: Beyond standard plain and twilled weaves, we can explore specialized weave patterns (like reverse Dutch weave) for particular filtration efficiencies or strength requirements.

- Roll Dimensions & Fabricated Components: Whether you need custom roll widths and lengths or pre-cut pieces, discs, cylinders, or other fabricated mesh components, our capabilities ensure exact fit and ready-to-install solutions.

- Surface Treatments & Finishes: While natural copper is often preferred, specific surface treatments can be explored for enhanced properties or aesthetic considerations, though care must be taken not to compromise conductivity.

- Prototyping & Testing: For complex applications, we can provide prototypes and conduct rigorous testing to validate performance against your specific criteria before full-scale production, ensuring optimal results.

Our commitment to partnership means we work with you from concept to delivery, ensuring the red copper wire mesh solution perfectly integrates with your project. Our extensive service history, spanning over two decades, demonstrates our ability to deliver reliable, high-quality, customized products to a diverse global clientele.

Ensuring Trustworthiness: FAQ, Delivery & Warranty

Building trust is at the core of our operations. We strive to provide complete transparency and support throughout your experience, from initial inquiry to long-term use of our red copper wire mesh products. Our commitment is reflected in our robust customer support, clear communication on delivery, and comprehensive warranty offerings.

Frequently Asked Questions (FAQ) about Red Copper Wire Mesh:

A1: Our red copper wire mesh is primarily manufactured from C11000 (CDA 110) Electrolytic Tough Pitch (ETP) Copper, which is at least 99.9% pure copper. This ensures optimal electrical and thermal conductivity, as well as excellent ductility.

A2: While stainless steel offers strength, red copper wire mesh provides significantly superior electrical and thermal conductivity, making it ideal for high-performance RFI/EMI shielding. It is also non-magnetic and naturally antimicrobial, which are critical advantages in certain specialized environments where stainless steel metal mesh might not suffice.

A3: Mesh count refers to the number of openings per linear inch. A higher mesh count means smaller openings and finer filtration capabilities, but also a lower open area, which can affect flow rate. Conversely, a lower mesh count has larger openings, greater open area, and higher flow rates, but less effective fine particle separation or shielding.

A4: Red copper wire mesh does not rust in the way iron or steel does. It is highly resistant to atmospheric corrosion and saltwater. Over time, when exposed to air and moisture, it forms a protective greenish-blue patina (verdigris) which is a stable layer that actually enhances its corrosion resistance and is often valued for its aesthetic appeal.

A5: Yes, due to its excellent atmospheric and saltwater corrosion resistance, red copper wire mesh is highly suitable for outdoor and marine applications, including architectural facades, security screens, and specific marine filters. Its patination process is a natural protective mechanism.

A6: We adhere to international quality management systems, primarily ISO 9001. Our production and inspection processes follow industry-specific standards such as ASTM B152 for copper material, ASTM E2016 for industrial woven wire mesh, and ISO 9044 for industrial wire screens, ensuring consistent quality and performance.

A7: Lead times vary based on the specific mesh specifications, order quantity, and current production schedule. For standard items, it typically ranges from 2-4 weeks. For custom or large-volume orders, we provide an estimated delivery timeline upon quotation, and we strive to meet or exceed agreed-upon deadlines. Expedited options may be available upon request.

Delivery Cycle and Customer Support:

Our sophisticated logistics network ensures efficient and timely delivery of your red copper wire mesh orders worldwide. We communicate transparently about lead times and shipping schedules, providing tracking information to keep you informed. Our dedicated customer support team is available to assist with any inquiries, from technical specifications to order status, ensuring a seamless experience. We believe that exceptional support is as vital as the quality of the product itself.

Quality Assurance and Warranty Commitment:

We stand by the quality of our red copper wire mesh products. Each batch undergoes rigorous quality control inspections, adhering to international standards such as ISO 9001, ASTM E2016, and relevant material specifications (e.g., ASTM B152 for copper). We provide a comprehensive warranty against manufacturing defects and material flaws, demonstrating our confidence in the durability and performance of our mesh. Our commitment to quality is a cornerstone of our long-standing reputation as a trusted supplier.

Conclusion: The Enduring Value of Red Copper Wire Mesh

In a world increasingly reliant on advanced materials for complex applications, red copper wire mesh stands out as a material of enduring value. Its exceptional electrical and thermal conductivity, coupled with inherent corrosion resistance, non-magnetic properties, and aesthetic appeal, position it uniquely across diverse industries. From critical RFI shielding in electronics to durable architectural elements and specialized filtration in petrochemical processes, copper mesh delivers performance where other materials, including common stainless steel welded wire or steel mosquito net, fall short.

As technological demands escalate, the role of materials like red copper wire mesh becomes even more pronounced. Its capacity for precise fabrication, long service life, and natural antimicrobial characteristics contribute to both functional superiority and sustainable solutions. Our commitment to meticulous manufacturing processes, adherence to global quality standards, and dedicated customer support ensures that our red copper wire mesh products are not merely components but integral solutions that empower innovation and enhance reliability across your operations. Choosing red copper wire mesh means investing in a material that offers unparalleled benefits, supported by expertise and a commitment to excellence.

References & Further Reading:

- For detailed copper properties: "Copper and Copper Alloys: Properties, Uses, Applications" by the Copper Development Association Inc. (CDA). https://www.copper.org/applications/

- On electromagnetic shielding effectiveness of mesh materials: Research published in IEEE Transactions on Electromagnetic Compatibility, often discussing various mesh types and their shielding capabilities. https://ieeexplore.ieee.org/XPLORE/home.jsp (Requires subscription for full access, but abstracts often available).

- For general wire mesh standards: ISO 9044:2016 - Industrial wire screens and woven wire cloth — Technical requirements and testing. https://www.iso.org/standard/66840.html

Post time: Aug . 08, 2025 07:20