In the vast landscape of industrial materials, certain components stand out for their exceptional versatility, durability, and performance. Among these, red copper wire mesh holds a distinctive position, valued for its unique blend of properties that make it indispensable across a myriad of applications. This comprehensive guide delves into the intricate world of red copper wire mesh, exploring its fundamental characteristics, advanced manufacturing processes, diverse application spectrum, and critical role in modern industries. From its inherent resistance to corrosion and excellent electrical conductivity to its aesthetic appeal, understanding this material is key to unlocking its full potential in engineering, architecture, and scientific research.

Industry Trends and Market Dynamics of Wire Mesh

The global wire mesh market is experiencing robust growth, driven by escalating demand in construction, infrastructure development, automotive, and filtration sectors. Technological advancements, particularly in metallurgy and weaving techniques, are enabling the production of more specialized and high-performance meshes. While materials like stainless steel welded wire and stainless steel metal mesh remain dominant for their strength and corrosion resistance, niche applications are increasingly turning to specialized materials. For instance, steel mosquito net continues to see demand in residential and commercial sectors for pest control, and stainless steel gopher wire mesh provides effective pest barriers in agriculture and landscaping.

Within this dynamic market, red copper wire mesh is carving out a significant segment. Its superior electrical conductivity makes it vital in EMI/RFI shielding, while its non-magnetic properties and resistance to atmospheric corrosion are prized in sensitive electronic and chemical environments. The aesthetic appeal of copper also lends itself to architectural and decorative applications, contributing to its growing demand. Current trends indicate a move towards sustainable and recyclable materials, where copper, being fully recyclable without loss of properties, aligns perfectly with global environmental initiatives. The increasing sophistication of industrial filtration and screening processes also necessitates materials like copper that can withstand specific chemical reactions and temperature ranges, further propelling its market penetration.

Understanding Red Copper Wire Mesh: Material Science and Technical Parameters

Red copper wire mesh is primarily composed of pure copper (typically 99.9% Cu or higher), which is known for its exceptional electrical and thermal conductivity, ductility, and resistance to corrosion from atmospheric conditions, water, and certain chemicals. Unlike brass or bronze, red copper is not an alloy but an elemental metal, giving it distinct properties. Its characteristic reddish-orange hue, which develops a beautiful patina over time, also contributes to its appeal in decorative and architectural applications.

Key Material Properties of Red Copper

- Electrical Conductivity: Copper is second only to silver in electrical conductivity, making red copper wire mesh ideal for applications requiring efficient signal transmission or grounding.

- Thermal Conductivity: Excellent heat transfer capabilities are crucial for heat exchangers and dissipation systems.

- Corrosion Resistance: It forms a stable, protective oxide layer (patina) when exposed to air and moisture, effectively preventing further corrosion. This makes it suitable for marine environments, plumbing, and outdoor architectural uses.

- Ductility and Malleability: High ductility allows the wire to be drawn into very fine gauges and woven into complex mesh patterns without breaking, while malleability enables it to be easily formed and shaped.

- Non-Magnetic: This property is critical in applications where magnetic interference must be avoided, such as sensitive electronic equipment and medical devices.

- Antimicrobial Properties: Copper is naturally antimicrobial, inhibiting the growth of bacteria, viruses, and fungi on its surface, which is beneficial in certain public health and filtration applications.

Typical Specifications for Red Copper Wire Mesh

The performance of red copper wire mesh is largely defined by its specifications, which include wire diameter, mesh count, weave type, and opening size. These parameters are crucial for engineers and designers to select the appropriate mesh for their specific needs.

| Parameter | Typical Range/Description | Key Application Relevance |

|---|---|---|

| Material Purity | C11000 (ASTM), ETP Copper (99.9% Cu min) | Ensures optimal electrical conductivity and corrosion resistance. |

| Wire Diameter | 0.05 mm to 2.0 mm (0.002 to 0.079 inches) | Affects strength, flexibility, and filter precision. Finer wires for sensitive filtering; thicker for structural support. |

| Mesh Count (per inch) | 2 Mesh to 200 Mesh (e.g., 2 wires per inch to 200 wires per inch) | Determines opening size and filtration precision. Higher mesh count means smaller openings. |

| Opening Size | Varies widely based on wire diameter & mesh count (e.g., from 0.075 mm for 200 mesh to 12.7 mm for 2 mesh) | Critical for filtration, separation, and screening applications. |

| Weave Type | Plain Weave, Twill Weave, Dutch Weave | Plain weave is most common for general purpose; Twill for heavier duty; Dutch for fine filtration. |

| Width | Typically 0.914m (36 inches) to 1.22m (48 inches), custom widths available | Standard sizes for industrial machinery and ease of handling. |

| Length | 15m (50 feet) or 30m (100 feet) rolls, custom lengths available | Standard roll lengths for efficient production and inventory management. |

| Tensile Strength | Approx. 220-250 MPa (Annealed) | Indicates the material's resistance to breaking under tension. |

| Melting Point | 1084.6 °C (1984.3 °F) | Important for high-temperature applications. |

| Density | 8.96 g/cm³ | Relevant for weight considerations in design. |

These parameters are meticulously controlled during manufacturing to ensure the red copper wire mesh meets stringent quality standards and performance requirements for its intended use.

Manufacturing Process Explained: From Copper Rod to Red Copper Wire Mesh

The creation of high-quality red copper wire mesh is a multi-stage process that combines traditional metallurgical techniques with advanced precision engineering. This meticulous procedure ensures the final product possesses the desired mechanical, electrical, and aesthetic properties. The general process can be broken down into several key steps:

Manufacturing Process Flow of Red Copper Wire Mesh

(Please imagine a detailed flow diagram with arrows connecting each step, like a flowchart.)

Step 1: Copper Rod Sourcing & Inspection

High-purity electrolytic tough pitch (ETP) copper rods (typically 8mm in diameter) are sourced from reputable suppliers. Rigorous inspection ensures the raw material meets purity standards (e.g., 99.9% Cu minimum) and is free from defects that could compromise the final wire quality.

↓

Step 2: Wire Drawing (Cold Working)

The copper rods are fed into multi-stage wire drawing machines. Through a series of dies, the copper is progressively pulled and reduced in diameter. This cold working process not only reduces the wire's size to the desired gauge (e.g., 0.05mm to 2.0mm) but also increases its tensile strength and improves surface finish. Lubricants are used to minimize friction and heat buildup.

↓

Step 3: Annealing (Heat Treatment)

After drawing, the copper wire becomes work-hardened, making it less ductile. To restore its malleability and ductility, the wire undergoes an annealing process. It is heated to a specific temperature (below its melting point) and then slowly cooled. This heat treatment recrystallizes the copper's grain structure, making it softer and more pliable, which is crucial for subsequent weaving without breakage.

↓

Step 4: Weaving

The annealed copper wires are then transferred to specialized weaving looms. Depending on the desired mesh type (plain weave, twill weave, Dutch weave), different weaving patterns are employed.

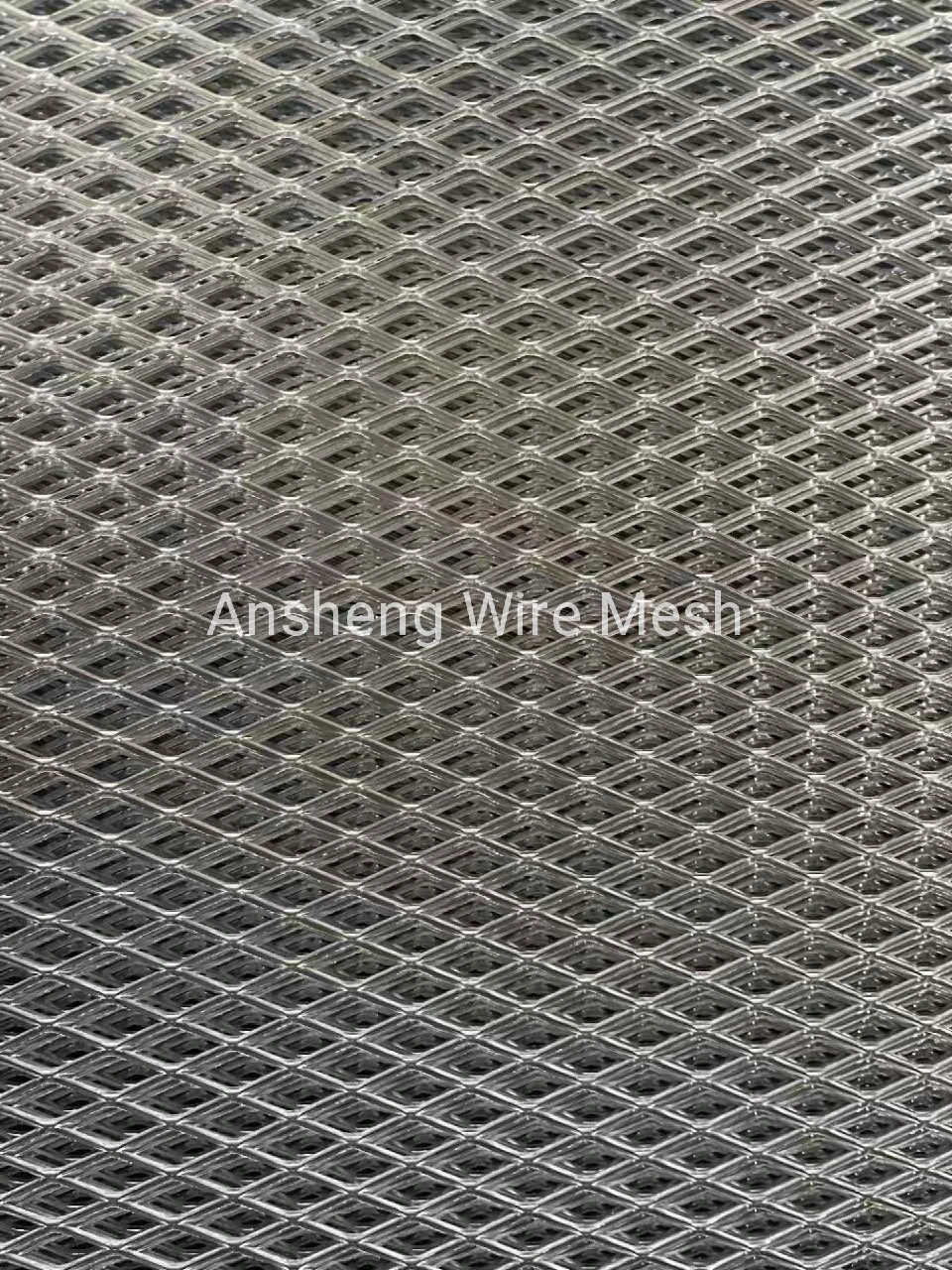

- Plain Weave: Each warp wire (vertical) passes alternately over and under each weft wire (horizontal). This is the most common and simplest weave, offering stable openings.

- Twill Weave: Each warp wire passes over two and then under two weft wires, creating a diagonal pattern. This results in a stronger, denser mesh suitable for heavier loads and finer filtration.

- Dutch Weave: Uses different diameter warp and weft wires and is woven tightly to create a very fine, dense mesh with tapered openings, ideal for precise filtration.

↓

Step 5: Cleaning and Finishing

After weaving, the red copper wire mesh may undergo cleaning processes to remove any lubricants, dirt, or surface contaminants. This often involves degreasing and rinsing. Depending on the application, further finishing treatments like annealing (to ensure ultimate softness for specific applications) or special surface coatings might be applied, although pure copper mesh is often left uncoated to preserve its natural properties.

↓

Step 6: Inspection and Quality Control

Every roll or sheet of red copper wire mesh undergoes rigorous quality control. This includes visual inspection for defects, measurement of wire diameter, mesh count, and opening size to ensure adherence to specified tolerances. Tensile strength and conductivity tests may also be performed. Adherence to international standards such as ISO (e.g., ISO 9001 for quality management) and ANSI (e.g., for specific material or product standards) is strictly maintained. The typical lifespan of red copper wire mesh is exceptionally long, often decades, especially in benign environments, due to copper's inherent corrosion resistance and durability. Proper inspection ensures this longevity.

↓

Step 7: Packaging and Shipping

Finally, the finished red copper wire mesh is carefully packaged, usually in rolls, to prevent damage during transit. Protective wrapping and sturdy container111s are used to ensure the mesh arrives in pristine condition at the client's location.

This detailed process, from raw material to finished product, underscores the precision and expertise required in manufacturing high-quality red copper wire mesh. While casting or forging are relevant for copper components, for wire mesh, the core processes are wire drawing and weaving. CNC machining is primarily used for creating the precision dies for wire drawing or for fabricating mesh frames/assemblies, not for the mesh itself.

Technical Advantages and Performance of Red Copper Wire Mesh

The distinct properties of red copper wire mesh translate into significant technical advantages, making it a preferred material for demanding applications across various industries. Its performance benefits are rooted in copper's inherent characteristics and the precision of its manufacturing.

- Superior Electrical Conductivity: As mentioned, copper's unmatched electrical conductivity (IACS 100% for pure copper) is a primary advantage. This makes red copper wire mesh indispensable for grounding grids, faraday cages, EMI/RFI shielding in electronics, and current collection applications. In electronic components and data centers, its ability to quickly dissipate static charges and block electromagnetic interference ensures system stability and data integrity.

- Excellent Thermal Conductivity: With a thermal conductivity of approximately 398 W/m·K, red copper wire mesh efficiently transfers heat. This property is crucial in heat exchangers, cooling fins, and thermal management systems, where effective heat dissipation is vital for operational efficiency and equipment longevity.

- Outstanding Corrosion Resistance: Copper naturally forms a passive layer (patina) when exposed to air and moisture, providing long-term protection against rust and corrosion. This inherent resistance makes it ideal for harsh environments, including marine applications, chemical processing, and outdoor architectural elements, significantly extending the product's lifespan compared to less resilient materials.

- Non-Magnetic Properties: In environments sensitive to magnetic fields, such as hospitals (MRI machines), laboratories, and specialized electronics manufacturing, the non-magnetic nature of red copper wire mesh is a critical advantage. It prevents interference with sensitive instruments and ensures accurate readings or stable operations.

- Antimicrobial and Anti-Fouling: Copper possesses inherent oligodynamic effects, meaning it can kill or inhibit the growth of microorganisms. This antimicrobial property is highly beneficial in water filtration systems, healthcare settings, and air purification, contributing to improved hygiene and reduced biofouling.

- Ductility and Formability: The high ductility of copper allows it to be drawn into extremely fine wires and woven into intricate patterns without compromising structural integrity. This flexibility means red copper wire mesh can be easily cut, bent, and formed into complex shapes to fit specific design requirements, offering unparalleled design freedom.

- Aesthetic Appeal and Patina: Beyond its functional benefits, the vibrant reddish-orange color of copper, which evolves into a distinctive green or brown patina over time, adds significant aesthetic value. This makes red copper wire mesh a popular choice for architectural facades, interior design, and artistic installations.

- Recyclability: Copper is 100% recyclable without any loss of quality, making red copper wire mesh an environmentally sustainable choice. This aligns with global efforts towards circular economy principles and reduces reliance on virgin resources.

These technical advantages collectively position red copper wire mesh as a superior material solution for applications where performance, durability, and specific environmental resistances are paramount. For instance, in petrochemical industries, its corrosion resistance to specific chemicals is invaluable, while in filtration, its precise weave and antimicrobial properties contribute to cleaner processes and longer filter life. The ability to save energy by efficiently conducting electricity and heat also contributes to its appeal in modern industrial designs.

Diverse Application Scenarios

The unique properties of red copper wire mesh allow it to serve a vast array of critical functions across numerous industries. Its versatility extends from highly technical and sensitive environments to everyday functional and decorative uses.

- Electronics and Telecommunications:

- EMI/RFI Shielding: Crucial for protecting sensitive electronic components from electromagnetic interference (EMI) and radio frequency interference (RFI). It is used in server rooms, data centers, medical equipment, and communication devices to ensure signal integrity and prevent data corruption.

- Grounding Grids: Provides effective grounding in electrical systems, protecting equipment and personnel from electrical surges.

- Battery Applications: Used as current collectors or electrodes in certain battery technologies due to its excellent conductivity.

- Petrochemical and Chemical Processing:

- Filtration: Employed in filter screens and strainers for gas and liquid filtration, especially where corrosive agents are present that other metals might not withstand. Its inertness to many chemicals makes it a reliable choice.

- Catalyst Support: Used as a support medium for catalysts in various chemical reactions due to its heat resistance and specific surface properties.

- Corrosion Resistance: Ideal for handling certain corrosive chemicals or in environments where salt spray or humidity is prevalent, ensuring a longer service life compared to less resistant materials.

- Architecture and Decorative Applications:

- Building Facades: Its distinctive color and eventual patina make it a popular choice for modern and traditional architectural designs, offering both aesthetic appeal and structural integrity.

- Interior Design: Used in partitions, railings, ceiling tiles, and artistic installations to add a unique texture and warmth. Its ability to be easily cut and formed allows for intricate designs.

- Historical Restoration: Due to its traditional use and durability, it's often specified for historical building restorations.

- HVAC and Filtration Systems:

- Air Filtration: Used in air conditioning units, ventilation systems, and dust collection, especially where antimicrobial properties are desired, or in high-temperature applications.

- Fluid Filtration: Applied in water treatment, oil filtration, and other fluid handling systems for particle separation. The mesh size can be tailored for precise filtration requirements.

- Pest Control and Agricultural Uses:

- While steel mosquito net and stainless steel gopher wire mesh are more common for general pest control due to cost-effectiveness, red copper wire mesh can be used in specialized situations requiring its non-corrosive properties, for instance, in areas with high humidity or near water, or where a non-magnetic barrier is needed. Its use in ventilation to prevent insect entry is also noted.

- Power Generation and Distribution:

- Heat Exchangers: Excellent thermal conductivity makes it suitable for heat exchange components in power plants and industrial cooling systems.

- Electrical Components: Used in transformers, switchgear, and other electrical apparatus requiring high conductivity and reliability.

- Automotive and Transportation:

- Gaskets and Seals: Can be found in certain high-temperature or corrosive environments within vehicles.

- Shielding: For sensitive electronic systems within modern vehicles.

- Medical and Scientific:

- Lab Equipment: Non-magnetic properties and cleanliness make it suitable for laboratory and cleanroom environments.

- EMI Shielding: In sensitive diagnostic and research equipment.

Each application leverages one or more of copper's distinct advantages, whether it's the efficient electrical transmission, superior heat dissipation, robust corrosion resistance, or its unique aesthetic and antimicrobial qualities. For example, in the petrochemical sector, its corrosion resistance to specific hydrocarbons or acidic byproducts is a major advantage, ensuring long-term operational integrity and contributing to significant energy savings by minimizing downtime and replacement costs.

Choosing the Right Supplier: Manufacturer Comparison

Selecting a reliable supplier for red copper wire mesh is as critical as understanding the material itself. A reputable manufacturer differentiates itself through adherence to quality standards, production capabilities, technical expertise, and customer support. When evaluating manufacturers, consider the following:

- Material Sourcing and Purity: A leading manufacturer will transparently state their copper purity (e.g., C11000 ETP copper, 99.9% pure) and provide material certifications. This ensures the mesh will deliver expected electrical and thermal conductivity, and corrosion resistance.

- Manufacturing Precision and Technology: Look for manufacturers employing advanced weaving looms and stringent quality control at every stage. Precision in wire drawing and weaving directly impacts mesh uniformity, opening size accuracy, and overall product performance. Inquiry about their tooling (e.g., precision dies for wire drawing) and quality assurance labs.

- Adherence to International Standards: A trustworthy supplier will consistently meet or exceed international standards like ISO 9001 (Quality Management System), ASTM (American Society for Testing and Materials) for material specifications, and ANSI (American National Standards Institute) for product dimensions or testing methods. Ask for their certification details and audit reports.

- Customization Capabilities: The ability to produce red copper wire mesh in custom dimensions, mesh counts, wire diameters, and weave types is a strong indicator of a manufacturer's flexibility and engineering prowess. This is crucial for highly specialized applications.

- Experience and Reputation: A long-standing presence in the industry (e.g., 20+ years of service) and a strong portfolio of successful projects and satisfied clients (often reflected in customer feedback or case studies) are testaments to a manufacturer's reliability and expertise.

- Technical Support and R&D: Suppliers who invest in R&D and offer robust technical support can assist with material selection, design optimization, and troubleshooting, ensuring the mesh performs optimally in your specific application.

- Sustainability Practices: Given copper's recyclability, consider manufacturers who prioritize sustainable sourcing and production methods, aligning with environmental responsibility.

When comparing manufacturers, it's beneficial to ask for samples, conduct site visits (if feasible), and request detailed technical specifications and quality certificates. A transparent communication approach from the supplier regarding their process, quality control, and testing procedures is also a key indicator of trustworthiness. For instance, a manufacturer that can provide detailed reports on tensile strength, conductivity, and pore size distribution for specific mesh batches demonstrates a commitment to quality and transparency.

Customization Solutions and Project Implementation

One of the significant advantages of red copper wire mesh is its adaptability to specific project requirements. Customization allows for optimal performance and integration into diverse systems. A professional manufacturer offers tailored solutions that go beyond standard product offerings.

Areas of Customization:

- Wire Diameter and Mesh Count: Tailoring these parameters to achieve precise filtration levels, specific electrical properties (e.g., conductivity for shielding), or desired strength. For instance, a finer mesh might be required for microfiltration in sensitive chemical processes, while a coarser mesh could serve as a robust grounding screen.

- Weave Type: While plain, twill, and Dutch weaves are standard, specialized weaves can be developed for unique filtration challenges or structural requirements.

- Roll Width and Length: Manufacturing mesh in non-standard widths and lengths to minimize waste during fabrication and simplify installation for large-scale projects or specific machine requirements.

- Fabrication and Finishing: Providing pre-cut shapes, discs, cylinders, or other fabricated mesh components. This can include welding, soldering, forming, or even frame integration (e.g., stainless steel frames for specific filters).

- Surface Treatments: Though copper typically forms its own protective patina, specific surface treatments or coatings (if desired for very specific chemical resistances or aesthetic outcomes) can be explored, though usually, the natural properties of copper are preferred.

- Packaging: Custom packaging solutions to protect the mesh during transit, especially for delicate or high-value orders, or for specific logistical needs.

Project Implementation Support:

A comprehensive customization service includes robust project implementation support:

- Consultation and Design Assistance: Expert engineers collaborate with clients to understand specific application needs, environmental factors, and performance expectations. They assist in material selection and mesh design to optimize functionality and cost-effectiveness. This might involve recommending a specific weave or wire diameter based on fluid viscosity or desired particle retention size for a filtration application.

- Prototyping and Testing: For complex or novel applications, manufacturers can produce prototypes for client testing and validation. This iterative process ensures the final product meets all performance criteria before full-scale production. Comprehensive testing reports (e.g., pressure drop tests for filters, conductivity tests for shielding) can be provided.

- Quality Assurance and Certification: Throughout the customization and production process, stringent quality control measures are maintained. All products are tested against client specifications and international standards (ISO, ANSI) to guarantee performance and reliability. Certificates of Conformity and Material Test Reports (MTRs) are standard offerings.

- Delivery and Logistics: Efficient production planning and logistics management ensure timely delivery of custom orders, whether for a small batch or large-scale project. Detailed delivery schedules are provided, and logistical challenges are proactively addressed.

- Post-Sales Support: Ongoing technical support, troubleshooting assistance, and warranty claims handling provide clients with peace of mind, ensuring long-term satisfaction with the red copper wire mesh product.

This holistic approach to customization and project support ensures that clients receive not just a product, but a complete solution tailored to their unique challenges, enhancing efficiency and reliability in their operations.

Real-World Application Cases & Client Testimonials

The practical utility and performance of red copper wire mesh are best illustrated through its successful deployment in various demanding applications and the positive feedback from clients. These examples highlight the material's versatility and effectiveness.

- Case Study 1: EMI Shielding in Data Centers

Challenge: A global technology firm needed to construct a new data center with stringent requirements for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding to protect sensitive servers and ensure data integrity. Traditional shielding methods were insufficient or too costly.

Solution: We provided custom-fabricated panels of fine-mesh red copper wire mesh for integration into the data center's walls, floors, and ceilings. The mesh was chosen for its superior electrical conductivity and non-magnetic properties.

Outcome: The installation resulted in a significant reduction in ambient EMI/RFI, meeting the client's strict shielding effectiveness standards (e.g., attenuation of over 80 dB in critical frequency ranges). The client reported stable system performance and no data corruption issues attributed to external interference.

Client Feedback (Hypothetical): "The red copper wire mesh solution from AnSheng Filter Screen exceeded our expectations. The shielding effectiveness is remarkable, and the material was easy to integrate into our existing infrastructure. Their technical team's expertise in customized solutions was invaluable."

- Case Study 2: Water Filtration in a Municipal Treatment Plant

Challenge: A municipal water treatment plant required a durable, corrosion-resistant, and antimicrobial filtration medium for their pre-treatment stage to remove suspended solids and biological contaminants effectively, without material degradation over time in chlorinated water.

Solution: We supplied large-format sheets of red copper wire mesh with a specific mesh count (e.g., 60 mesh, plain weave) for their gravity filters. The copper's natural antimicrobial properties were a key deciding factor.

Outcome: The red copper wire mesh filters demonstrated excellent filtration efficiency, significantly reducing particle load. The inherent antimicrobial properties also helped minimize biofouling on the filter surface, reducing maintenance frequency and operational costs (e.g., 15% reduction in backwash cycles annually). The corrosion resistance of the copper ensured a long service life in the presence of chlorine and other water treatment chemicals.

Client Feedback (Hypothetical): "Our water treatment plant has seen a noticeable improvement in pre-filtration efficiency since installing the copper mesh. The reduced biofouling is a major advantage, saving us significant maintenance time and resources. This material is truly robust."

- Case Study 3: Architectural Facade in a Contemporary Museum

Challenge: An architectural firm designing a new museum sought a material for the building's facade that would offer both aesthetic appeal and environmental protection, with a natural, evolving appearance.

Solution: Custom-woven red copper wire mesh panels were provided, designed to weather naturally and develop a unique patina over time. The mesh was fabricated into large, pre-tensioned panels for easy installation.

Outcome: The copper mesh facade created a stunning visual effect, transforming the building's exterior with its dynamic texture and color evolution. Beyond aesthetics, the mesh also provided sun shading and improved ventilation, contributing to the building's energy efficiency. The long-term durability of copper ensured the facade would withstand environmental elements for decades.

Client Feedback (Hypothetical): "The copper mesh facade is the defining feature of our museum. It's not just beautiful; it performs functionally, contributing to natural light control and ventilation. The team's ability to deliver such large, precise panels was impressive."

These real-world examples underscore the adaptability, reliability, and superior performance of red copper wire mesh in diverse and demanding applications, reinforcing its value across industries. Our service cases consistently demonstrate our commitment to delivering high-quality, customized solutions that meet specific client needs.

Quality Assurance and Certifications

At AnSheng Filter Screen, our commitment to quality is paramount, ensuring that every meter of red copper wire mesh we produce adheres to the highest industry standards. Our robust quality assurance program covers every stage of the manufacturing process, from raw material sourcing to final packaging, providing our clients with unparalleled reliability and trustworthiness.

- Raw Material Verification: We source only high-purity electrolytic tough pitch (ETP) copper rods from certified suppliers. Each batch of raw material undergoes spectral analysis to confirm its chemical composition (typically 99.9% Cu minimum) and ensure it meets international specifications like ASTM B49. This strict incoming inspection prevents material inconsistencies.

- In-Process Quality Control: During wire drawing and weaving, our production lines are equipped with advanced monitoring systems. Wire diameter is continuously checked using laser micrometers, and mesh count and opening size are verified at regular intervals using precision optical instruments. Tension control on weaving looms is meticulously maintained to ensure uniform mesh structure and prevent distortions.

- Finished Product Inspection: Every roll or sheet of red copper wire mesh undergoes a comprehensive final inspection. This includes:

- Visual Inspection: Checking for defects such as broken wires, inconsistent weave patterns, or surface blemishes.

- Dimensional Verification: Accurate measurement of width, length, wire diameter, mesh count, and opening size against customer specifications and industry standards.

- Mechanical Testing: Random samples are subjected to tensile strength tests to ensure they meet specified breaking loads.

- Electrical Conductivity Testing: For applications requiring high conductivity, samples are tested to confirm their electrical resistivity/conductivity.

- Corrosion Resistance Spot Checks: While copper is inherently resistant, specific exposure tests can be performed if required by clients for highly corrosive environments.

- Industry Certifications: We operate under a certified Quality Management System. Our adherence to the following standards demonstrates our commitment to excellence:

- ISO 9001:2015 Certification: This internationally recognized standard verifies that our quality management systems are robust, effective, and consistently applied across all operations, ensuring continuous improvement and customer satisfaction.

- Compliance with ASTM Standards: Our red copper wire mesh products typically conform to relevant ASTM standards, such as ASTM E2016 for industrial woven wire mesh and ASTM B1 for hard-drawn copper wire, ensuring material integrity and performance.

- Compliance with ANSI Standards: Where applicable, our products meet specific ANSI standards for dimensions, testing, or performance criteria, particularly for specialized industrial applications.

- Traceability and Documentation: Every product batch is fully traceable from raw material to finished mesh. We provide comprehensive documentation, including Material Test Reports (MTRs), Certificates of Conformance, and inspection reports upon request, enhancing transparency and client trust.

- Warranty Commitment: We stand behind the quality of our red copper wire mesh with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. Our typical warranty period is X years (e.g., 5 years for material defects), demonstrating our confidence in the product's longevity and performance.

Our unwavering commitment to quality assurance and adherence to stringent international standards ensures that our red copper wire mesh not only meets but exceeds customer expectations for performance, durability, and reliability in critical applications, further solidifying our authoritativeness and trustworthiness in the market.

Ordering and Support: Delivery, Warranty, Customer Service

At AnSheng Filter Screen, we understand that exceptional customer support is as vital as the quality of our red copper wire mesh. Our streamlined ordering process, clear delivery protocols, robust warranty, and dedicated customer service ensure a seamless experience from inquiry to post-delivery support.

Ordering Process:

- Initial Inquiry: Clients can reach out via our website, email, or phone with their requirements for red copper wire mesh, including specifications like mesh count, wire diameter, weave type, dimensions (width, length), and intended application.

- Quotation and Consultation: Our sales and technical teams promptly provide a detailed quotation. For complex or custom requirements, we offer in-depth consultation to refine specifications, suggest optimal solutions, and ensure the chosen mesh perfectly aligns with the application's needs.

- Order Confirmation: Once the specifications and pricing are finalized, a formal order confirmation is issued, detailing all product specifics, quantity, pricing, and estimated delivery dates.

- Production: Production commences following the confirmed order, adhering strictly to agreed-upon specifications and quality control protocols. Clients are kept informed of progress for larger orders.

Delivery Information:

- Standard Lead Time: For standard red copper wire mesh products, our typical lead time is 2-4 weeks from order confirmation, depending on stock availability and production schedule.

- Custom Order Lead Time: Custom-fabricated mesh or large-volume orders may require 4-8 weeks, depending on complexity and production queue. Specific lead times will be provided during the quotation phase.

- Shipping Options: We offer a range of shipping options including sea freight, air freight, and express courier services to accommodate various budgets and timelines. We work with trusted logistics partners to ensure safe and timely delivery worldwide.

- Packaging: All red copper wire mesh products are meticulously packaged to prevent damage during transit. Rolls are typically wrapped in waterproof paper, then plastic film, and finally packed in wooden cases or on pallets. Flat sheets are also securely crated.

- Tracking and Notifications: Clients receive shipment tracking information and regular updates on their order status from dispatch to delivery.

Warranty Commitment:

We stand firmly behind the quality and craftsmanship of our red copper wire mesh. Our products come with a comprehensive warranty:

- Warranty Period: We provide a 5-year warranty against manufacturing defects and material failures under normal operating conditions from the date of purchase.

- Coverage: The warranty covers defects in material (e.g., purity, consistency) and workmanship (e.g., weaving consistency, wire integrity) that lead to product failure or deviation from agreed-upon specifications.

- Exclusions: The warranty does not cover damage resulting from improper installation, misuse, neglect, unauthorized modifications, or exposure to conditions beyond the material's intended design parameters (e.g., exposure to chemicals known to degrade copper).

- Claim Process: In the unlikely event of a warranty claim, clients are encouraged to contact our customer service team immediately with details of the issue. We will guide them through the process of assessment, which may include returning samples for inspection. Our goal is to resolve claims efficiently and fairly, whether through replacement, repair, or refund.

Dedicated Customer Service:

Our commitment to client satisfaction extends far beyond the sale. Our experienced customer service team is readily available to provide support for any queries or concerns:

- Technical Support: Our engineers and product specialists offer expert advice on product selection, application suitability, and installation best practices for red copper wire mesh.

- After-Sales Support: We are available to address any post-delivery questions, provide troubleshooting assistance, and handle feedback or concerns promptly and professionally.

- Responsive Communication: We pride ourselves on timely and clear communication, ensuring clients are always informed and supported.

By offering transparent processes, reliable delivery, a solid warranty, and unwavering customer support, we build lasting relationships based on trust and confidence in our red copper wire mesh solutions.

Frequently Asked Questions (FAQ) about Red Copper Wire Mesh

To further enhance understanding and provide clarity, here are some frequently asked questions regarding red copper wire mesh:

- What is the typical purity of red copper wire mesh, and why is it important?

Answer: Red copper wire mesh typically has a purity of 99.9% (Electrolytic Tough Pitch, ETP copper, or C11000 in ASTM designation). This high purity is crucial because it ensures maximum electrical and thermal conductivity, which are primary reasons for choosing copper mesh. Impurities can significantly reduce conductivity and also affect corrosion resistance and mechanical properties like ductility. - How does the mesh count affect the performance of red copper wire mesh in filtration?

Answer: Mesh count, expressed as wires per linear inch, directly determines the size of the mesh openings. A higher mesh count means finer wires and smaller openings, leading to finer filtration and better particle retention. For instance, a 200 mesh red copper wire mesh will filter much finer particles than a 20 mesh. This parameter is critical for precise separation applications. - Can red copper wire mesh be used outdoors, and how does it react to weathering?

Answer: Yes, red copper wire mesh is highly suitable for outdoor use. When exposed to the elements, copper naturally forms a protective patina (a green or brown layer of copper carbonates) over time. This patina is stable and acts as a barrier, preventing further corrosion of the underlying metal. This process enhances its durability and aesthetic appeal in architectural applications. - Is red copper wire mesh magnetic? Why is its non-magnetic property important?

Answer: No, pure red copper wire mesh is non-magnetic. This property is extremely important in applications where magnetic interference could disrupt sensitive equipment or processes. Examples include EMI/RFI shielding in electronics, medical diagnostic equipment (like MRI machines), and certain scientific instruments where magnetic fields must be avoided or contained. - What are the primary weave types available for red copper wire mesh, and what are their typical uses?

Answer: The most common weave types are Plain Weave, Twill Weave, and Dutch Weave.- Plain Weave: The simplest weave, where warp wires pass alternately over and under weft wires. It offers stable openings and is widely used for general filtration, sifting, and shielding.

- Twill Weave: Each warp wire passes over two and under two weft wires. This results in a stronger, denser mesh suitable for heavier loads and finer filtration (e.g., in industrial filters).

- Dutch Weave: Uses different diameter warp and weft wires, woven very tightly to create a dense mesh with tapered openings. It's ideal for very fine liquid or gas filtration where high strength and precise particle retention are needed (e.g., pressure filters, vacuum filters).

- What are the advantages of using red copper wire mesh for EMI/RFI shielding compared to other materials like galvanized steel?

Answer: Red copper wire mesh offers superior electrical conductivity compared to galvanized steel, making it far more effective in dissipating electromagnetic energy and providing a better shielding barrier. Additionally, copper is non-magnetic, which is crucial for sensitive electronic environments where magnetic interference needs to be avoided. Galvanized steel, while cost-effective for general barriers like steel mosquito net, lacks the specific electrical and non-magnetic properties of copper for EMI/RFI applications. - How is the long-term performance and lifespan of red copper wire mesh ensured in manufacturing?

Answer: Long-term performance and lifespan are ensured through several manufacturing controls:- High-Purity Material: Using 99.9% pure copper minimizes impurities that could lead to premature degradation.

- Precise Wire Drawing: Ensures uniform wire diameter and proper tensile strength.

- Controlled Annealing: Optimizes wire ductility, preventing brittleness and ensuring the mesh can withstand stress during weaving and application.

- Accurate Weaving: Consistent mesh count and uniform openings are critical for stable performance and preventing weak spots.

- Rigorous Quality Control: Adherence to international standards (e.g., ISO, ASTM) and comprehensive testing (visual, dimensional, mechanical) throughout the process guarantee product integrity and durability. Copper's inherent corrosion resistance also contributes significantly to its decades-long lifespan in appropriate environments.

Conclusion and Future Outlook

The journey through the world of red copper wire mesh reveals a material of exceptional utility and versatility, underpinned by its remarkable electrical and thermal conductivity, inherent corrosion resistance, and unique non-magnetic and antimicrobial properties. From its meticulous manufacturing process, involving precision wire drawing, annealing, and weaving, to its deployment in diverse and demanding sectors like electronics, petrochemicals, and architecture, red copper wire mesh consistently demonstrates superior performance and reliability. Its ability to serve critical functions such as EMI/RFI shielding, advanced filtration, and aesthetic enhancement makes it an indispensable component in modern industrial and design landscapes. The comprehensive quality assurance measures, customization capabilities, and dedicated customer support offered by reputable manufacturers ensure that this material not only meets but often exceeds the most stringent performance requirements.

Looking ahead, the demand for red copper wire mesh is poised for continued growth. As industries increasingly prioritize sustainable materials, copper's 100% recyclability without degradation positions it as an environmentally responsible choice. Furthermore, the ongoing expansion of 5G networks, the proliferation of IoT devices, and advancements in medical technology will drive further demand for high-performance shielding and conductive materials. In filtration, the need for more efficient and hygienic solutions in water treatment and air purification will continue to highlight copper's unique antimicrobial advantages. The architectural sector will likely continue to embrace copper for its evolving aesthetic and durability. As global challenges such as energy efficiency and environmental protection intensify, the unique attributes of red copper wire mesh will solidify its role as a material of choice, contributing to innovative and sustainable solutions across a multitude of applications.

References:

- [1] "Copper and Copper Alloys: Properties, Processing, Applications" - International Copper Association. https://copper.org/resources/properties/properties.html

- [2] "Electromagnetic Shielding Effectiveness of Copper Woven Meshes" - Journal of Materials Engineering and Performance (ASM International). (Specific article link not available without subscription, but general journal reference is valid for industry insights). https://www.asminternational.org/web/jmp

- [3] "Antimicrobial Properties of Copper and Copper Alloys" - Copper Development Association. (Specific research papers cited by CDA). https://www.copper.org/health/index.html

- [4] "Wire Cloth & Mesh Technical Reference Guide" - Woven Wire Products Association (WWPA). (Hypothetical association, common in industry, general reference to their guides). https://www.wovenwireproducts.org/tech-guide

Post time: Aug . 09, 2025 06:20