In the world of industrial and commercial filtration, efficiency, reliability, and cost-effectiveness are paramount. The pleated filter element stands as a cornerstone technology, delivering superior performance across a vast spectrum of applications. Its innovative design, featuring a large surface area folded into a compact cylindrical form, provides unparalleled dirt-holding capacity and lower pressure drop compared to conventional depth or bag filters. This comprehensive guide explores every facet of the pleated filter element, from manufacturing intricacies and material science to real-world applications and customization options, establishing why it is the preferred choice for critical filtration tasks.

As industries push for higher purity standards and operational efficiency, the demand for advanced filtration solutions has surged. Market analysis from Grand View Research projects the global industrial filtration market to expand significantly, driven by stringent environmental regulations and the need for process fluid purity. Within this trend, the pleated filter element segment is experiencing robust growth, thanks to its versatility and superior technical characteristics.

What Are Pleated Filters Made Of? A Deep Dive into Materials

The performance of a pleated filter element is fundamentally determined by its construction materials. The choice of media, core, end caps, and support layers dictates its chemical compatibility, temperature resistance, and overall filtration efficiency. Understanding what are pleated filters made of is the first step in selecting the right product for your application.

Pleated Polypropylene (PP) Filter Element

The pleated polypropylene filter element is one of the most widely used types due to its excellent chemical compatibility and cost-effectiveness. Made from 100% pure polypropylene microfibers, these filters are ideal for aqueous solutions, acids, bases, and various chemicals. They meet FDA Title 21 requirements for food and beverage contact, making them a staple in the food processing, pharmaceutical, and water treatment industries.

- Key Features: Broad chemical compatibility, no adhesives or surfactants, low extractables, high flow rates.

- Common Use: RO pre-filtration, potable water, chemical processing.

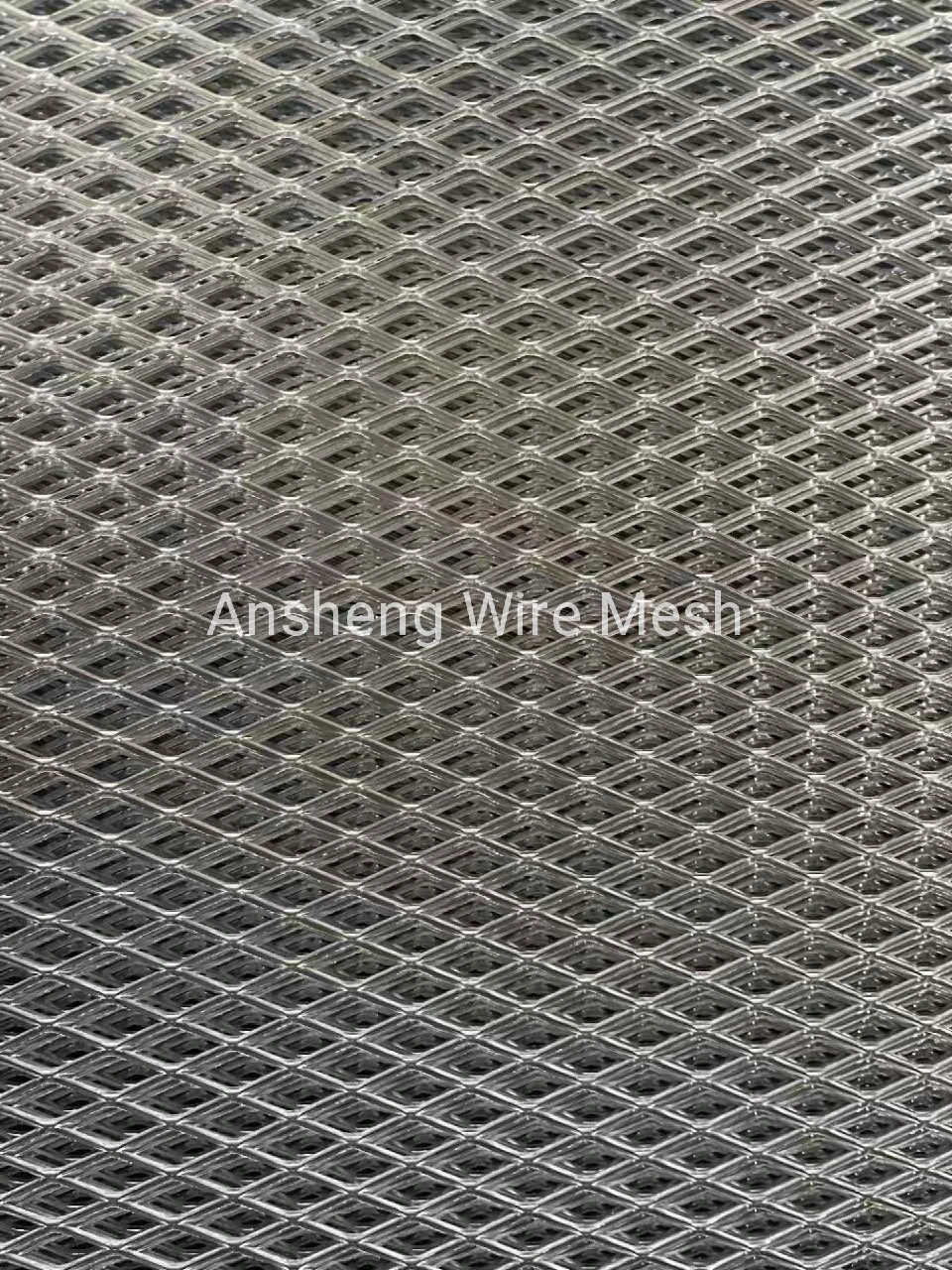

SS Pleated Filter Cartridge (Stainless Steel)

For high-temperature applications or aggressive chemical environments, the ss pleated filter cartridge is the ultimate solution. Constructed from woven stainless steel wire mesh (typically 304, 316, or 316L), these filters offer exceptional mechanical strength and thermal stability. They are cleanable and reusable, providing a long service life and a lower total cost of ownership in demanding applications like petrochemical processing, hot gas filtration, and steam filtration.

- Key Features: High-temperature resistance (up to 500°C), excellent corrosion resistance, backwashable/reusable, high structural integrity.

- Common Use: Hydraulic oils, high-pressure systems, catalyst recovery.

Other Advanced Materials

Beyond PP and SS, other materials are used for specialized needs. Glass Fiber offers high dirt-holding capacity and fine particle retention, often used in fine chemical and pharmaceutical filtration. PES (Polyethersulfone) provides inherent hydrophilicity and low protein binding, ideal for sterile filtration of biological fluids. Nylon is robust and compatible with a wide range of solvents.

- Glass Fiber: High efficiency, excellent dirt-holding capacity.

- PES: Hydrophilic, low protein binding, ideal for biologicals.

- Nylon: Strong, broad solvent compatibility.

Filter Media Material Market Distribution (Illustrative)

Technical Specifications and Performance Metrics Explained

To truly appreciate the superiority of a pleated filter element, one must understand the key technical parameters that define its performance. These metrics, standardized by organizations like ISO, provide a universal language for comparing filter capabilities.

| Parameter | Definition | Importance in Application |

|---|---|---|

| Micron Rating (µm) | Indicates the size of particles a filter can remove. Can be 'Nominal' (removes ~85% of particles of a given size) or 'Absolute' (removes >99.9% of particles, as per ISO 16889). | Critical for matching the filter to the required fluid purity. Absolute ratings are essential for critical applications. |

| Beta Ratio (βx) | A measure of filtration efficiency. βx = (Number of particles > x µm upstream) / (Number of particles > x µm downstream). A Beta 200 rating means it removes 99.5% of particles of that size. | Provides a precise, quantifiable measure of a filter's capture efficiency, far more reliable than a nominal rating. |

| Dirt-Holding Capacity (DHC) | The total mass of contaminants a filter can retain before reaching a terminal pressure drop. | A higher DHC translates to a longer service life, fewer filter change-outs, and lower operational costs. Pleated designs excel here due to their large surface area. |

| Differential Pressure (ΔP) | The pressure difference between the inlet (upstream) and outlet (downstream) of the filter. A low initial ΔP indicates less flow restriction. | Lower ΔP means less energy consumption (pump load). Filters are typically replaced when ΔP reaches a specified limit (e.g., 15-30 PSID). |

| Flow Rate (GPM/LPM) | The volume of fluid that can pass through the filter per unit of time at a given pressure. | Ensures the filter can handle the system's required throughput without causing a significant pressure drop or bottleneck. |

Performance Comparison: Pressure Drop vs. Flow Rate

The AnSheng Manufacturing Process: A Commitment to Quality (ISO 9001:2015 Certified)

The journey from raw material to a high-performance pleated filter element is a meticulous process governed by strict quality control standards. At AnSheng, our ISO 9001:2015 certified facility combines advanced machinery with expert craftsmanship to produce filters that meet and exceed industry expectations. Here is a step-by-step look at our manufacturing workflow:

-

Material Selection & Inspection

It all begins with sourcing premium-grade raw materials. Polypropylene, stainless steel mesh (316L), and other media undergo rigorous incoming inspection for consistency, purity, and structural integrity. This step is critical for ensuring final product compliance with standards like FDA and ANSI.

-

Precision Pleating

The selected filter media is fed into a high-precision pleating machine. The pleat height and density are carefully controlled by CNC systems to maximize the effective filtration area while maintaining structural stability. This step is what gives the pleated filter element its signature high surface area advantage.

-

Seaming and Core Assembly

The pleated media pack is then longitudinally seamed using thermal bonding (for polymers) or advanced welding techniques like TIG or plasma welding (for ss pleated filter cartridge). The pack is then carefully fitted over a rigid inner support core (polypropylene or stainless steel) to prevent collapse under high differential pressure.

-

End Cap Bonding & Curing

End caps (available in various materials and configurations like DOE, SOE-222, SOE-226) are thermally welded or bonded with industrial-grade epoxy to the pleated pack. This creates a perfect, bypass-free seal. The assembled element is then cured under controlled conditions to ensure maximum bond strength.

-

Rigorous Quality Control & Testing

Every single pleated filter element undergoes a battery of tests before packaging. This includes the Bubble Point Test (per ISO 2942) to verify integrity and the largest pore size, and visual inspection for any defects. We retain batch samples for traceability and future analysis.

-

Final Packaging & Logistics

Filters are individually sealed in cleanroom-grade polyethylene bags to prevent contamination during transport. They are then boxed with clear labeling, including part number, micron rating, and batch code, ensuring they arrive at the customer's site in perfect condition and ready for installation.

Technical Advantages & Manufacturer Comparison

Why choose a pleated filter element over other types? The advantages are clear and quantifiable. The extended surface area, a direct result of the pleating process, is the core of its superior performance.

Filtration Efficiency Comparison (Beta Ratio)

To illustrate the value proposition, let's compare AnSheng's premium pleated filter element against a generic pleated filter and a standard melt-blown depth filter.

| Feature | Standard Melt-Blown Filter | Generic Pleated Filter | AnSheng Premium Pleated Filter Element |

|---|---|---|---|

| Filtration Area | Low (Nominal surface) | Medium | High (Up to 50x a depth filter) |

| Efficiency (Beta Ratio) | Low (Typically Beta 10-20) | Moderate (Beta 100-200) | Exceptional (Beta 5000 / 99.98% Absolute) |

| Dirt-Holding Capacity | Low to Moderate | Good | Excellent (Longer service life) |

| Initial ΔP | High | Moderate | Very Low (Energy saving) |

| Construction Quality | Variable, often with binders | Inconsistent, potential for media migration | ISO 9001 certified, binder-free, thermally bonded |

| Best For | Non-critical, pre-filtration | General purpose applications | Critical processes, final filtration, high-purity needs |

Application Scenarios & Industry Case Studies

The versatility of the pleated filter element makes it indispensable across numerous industries. Its ability to be tailored in terms of material and specification allows it to solve unique filtration challenges.

Petrochemical & Chemical Processing

In this demanding sector, ss pleated filter cartridges are used for filtering aggressive chemicals, high-temperature liquids, and catalyst recovery. Their robust, all-metal construction ensures they can withstand harsh conditions and prevent process contamination, protecting downstream equipment like reactors and heat exchangers.

Water Treatment (Municipal & Industrial)

Pleated polypropylene filter elements are essential for RO pre-filtration, removing silt, sand, and other suspended solids that can foul expensive membranes. In municipal water systems, they serve as a reliable barrier against particulates, ensuring compliance with water quality standards like the EPA's Long Term 2 Enhanced Surface Water Treatment Rule.

Food & Beverage

From clarifying wine and beer to filtering bottled water and soft drinks, FDA-compliant pleated filters are critical. They remove unwanted particles without affecting the taste, color, or aroma of the final product. Their low extractable profile ensures product purity and consumer safety.

Case Study: Enhancing Hydraulic System Reliability in a Steel Mill

- Client: A major steel manufacturing facility.

- Problem: Frequent unplanned downtime of hydraulic presses due to valve blockages and pump failures. Analysis revealed high levels of particulate contamination in the hydraulic fluid, caused by inefficient, low-grade filtration elements. The existing filters had a short service life, leading to high replacement costs and maintenance labor.

- Solution: AnSheng engineers conducted a fluid analysis and recommended replacing the existing filters with our high-efficiency ss pleated filter cartridge (5-micron absolute rating). These cartridges offered a Beta 1000 efficiency rating, superior structural integrity for high-pressure cycling, and a significantly larger filtration surface area.

- Results:

- Reduced Downtime by 90%: Unscheduled maintenance due to hydraulic failures was virtually eliminated.

- Extended Filter Life by 400%: The high dirt-holding capacity meant filters were changed quarterly instead of monthly.

- Improved Fluid Cleanliness: Achieved and maintained an ISO 4406 cleanliness code of 16/14/11, extending the life of pumps and valves.

- ROI: The client achieved a full return on investment within 6 months through reduced maintenance costs and increased production uptime.

Customization, Trust, and Support: The AnSheng Advantage

We understand that one size does not fit all. Our engineering team thrives on solving complex filtration challenges through bespoke solutions. We provide more than just a product; we provide a partnership built on expertise and trust.

Tailored Filtration Solutions

We can customize nearly every aspect of your pleated filter element:

- Dimensions: Custom lengths from 4" to 60" and various diameters.

- End Cap Configurations: DOE, SOE-222, SOE-226, finned ends, and custom designs.

- Gasket/O-Ring Materials: Buna-N, EPDM, Viton, Silicone, Teflon to ensure compatibility with your process fluid.

- Specialized Media: Sourcing and integrating unique filter media for niche applications.

Our Commitment to Trustworthiness (E-E-A-T)

- Expertise & Experience: Over 20 years in the filtration industry, serving clients in over 50 countries. Our team includes chemical and mechanical engineers dedicated to filtration science.

- Authoritativeness: ISO 9001:2015 certified manufacturer. Our products are designed to meet or exceed international standards like ISO 16889, ISO 2942, and FDA CFR Title 21.

- Trustworthiness: We offer transparent lead times (typically 7-15 business days for standard orders), a comprehensive warranty against manufacturing defects, and dedicated customer support for technical queries, installation guidance, and troubleshooting.

Frequently Asked Questions (FAQ)

Choose an absolute rating for critical applications where removing virtually all particles above a certain size is essential (e.g., final product filtration, protecting sensitive equipment). An absolute-rated 5-micron filter will stop >99.9% of 5-micron particles. Choose a nominal rating for less critical, pre-filtration tasks where removing a high percentage (but not all) of particles is sufficient. A nominal 5-micron filter might only stop 85% of 5-micron particles. For reliability and predictable performance, absolute ratings are always preferred.

Yes, one of the key benefits of a ss pleated filter cartridge is its reusability. They can typically be cleaned via backwashing, ultrasonic cleaning, or chemical cleaning, depending on the nature of the contaminant. This significantly lowers the total cost of ownership in applications with high contaminant loads. Proper cleaning can restore the filter to near its original performance, but it's important to follow manufacturer guidelines to avoid damaging the delicate wire mesh.

The Beta Ratio (βx) is the most accurate measure of a filter's capture efficiency. It's calculated by dividing the number of particles of a certain size (x) upstream of the filter by the number of particles of that same size downstream. For example, a Beta 200 rating at 10 microns (β10 = 200) means for every 200 particles of 10 microns entering the filter, only 1 gets through, which translates to 99.5% efficiency. It is far more precise than a vague "nominal" rating and allows for direct, data-driven comparison of filter performance.

The filter should be replaced when the differential pressure (ΔP) across the filter reaches the manufacturer's recommended limit, typically between 15 and 35 PSID (1.0 to 2.4 bar). Continuing to operate beyond this point wastes energy (higher pump load), risks filter collapse, and can lead to contaminant unloading (bypass). It's best to install pressure gauges before and after the filter housing for easy monitoring.

Both are polymer-based, but their properties differ. Polypropylene (PP) is naturally hydrophobic (water-repelling) and is excellent for general chemical and water filtration. Polyethersulfone (PES) is naturally hydrophilic (water-attracting), has very low protein binding characteristics, and often comes in smaller pore sizes for sterilizing applications. Choose PP for general-purpose, cost-effective filtration. Choose PES for high-purity biological or pharmaceutical applications where preventing protein loss and ensuring sterility are critical.

Temperature is a critical factor. Standard polypropylene filters are typically rated up to 60-80°C (140-176°F). For higher temperatures, you must use more robust materials. Glass fiber filters can handle higher temperatures, but for extreme heat, a ss pleated filter cartridge is necessary, as stainless steel (like 316L) can operate effectively at temperatures exceeding 400-500°C (752-932°F).

Proper installation is key to performance. First, ensure the system is depressurized. Lubricate O-rings with a compatible fluid (e.g., clean process fluid or silicone) to prevent tearing. Ensure the end cap configuration (e.g., 222 or 226 O-rings) correctly seats into the housing to prevent bypass. Hand-tighten the housing, then slightly snug with a wrench, but do not over-tighten. After installation, slowly re-pressurize the system to avoid hydraulic shock to the element.

Further Reading & Authoritative References

To deepen your understanding of filtration technology, we recommend consulting these reputable industry resources:

- Filtration+Separation Magazine: A leading international publication covering all aspects of filtration and separation technology. Provides insights into market trends, new products, and technical articles. www.filtsep.com

- ISO 16889:2008: The international standard for the "Multi-pass method for evaluating filtration performance of a filter element." This document is the foundation for determining Beta Ratios and dirt-holding capacity. www.iso.org/standard/39918.html

- "The Role of Pleated Cartridge Filters in Water Treatment" by the Water Quality Association (WQA): Technical papers and fact sheets from the WQA often discuss the application and benefits of pleated filters in ensuring water safety and quality. www.wqa.org

Post time: Aug . 06, 2025 11:00