Understanding Plain Weave Mesh in Modern Industrial Applications

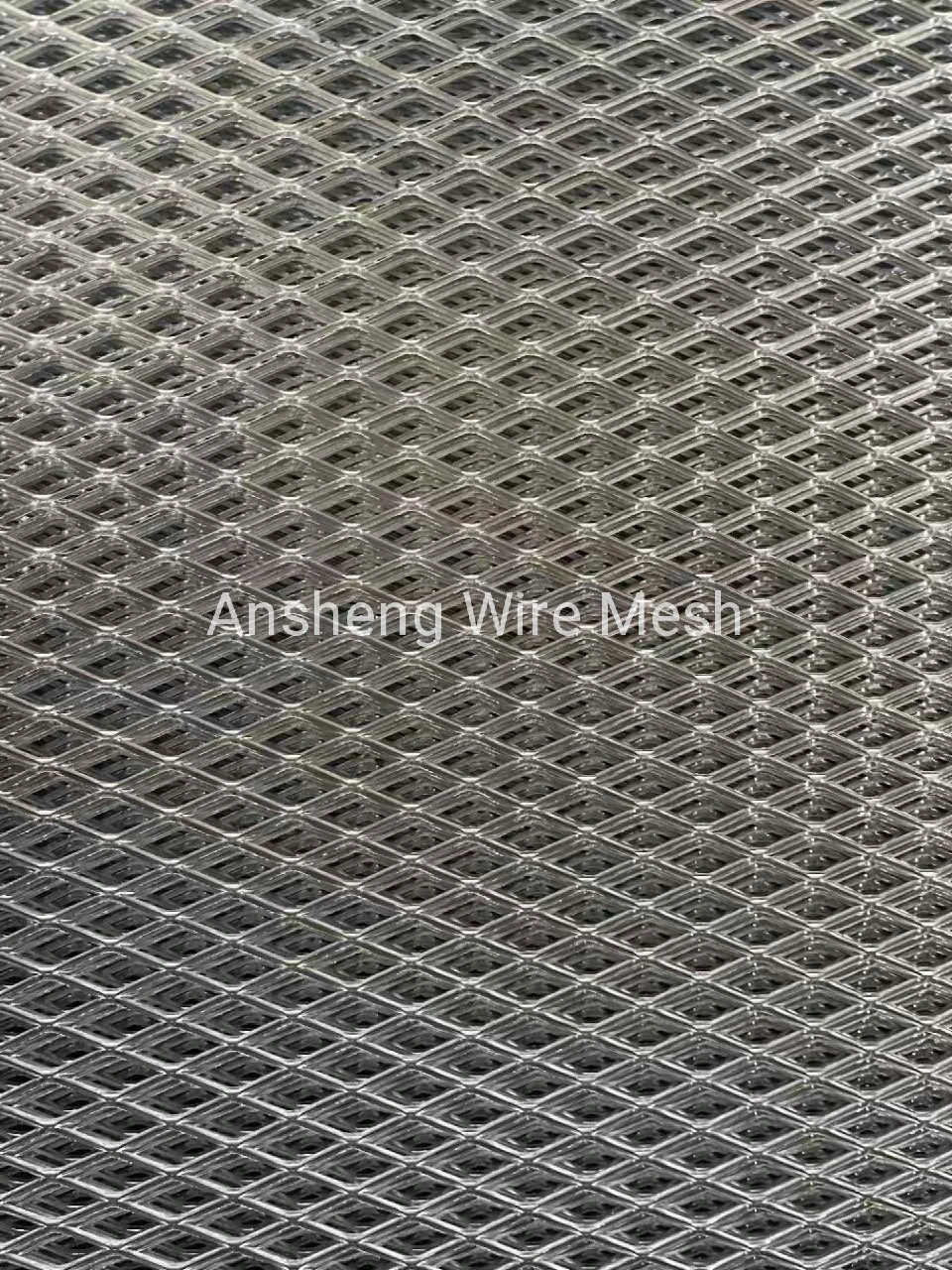

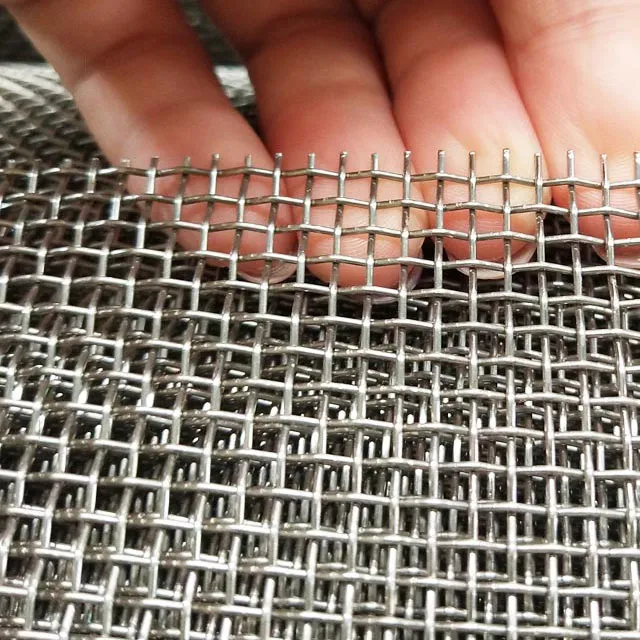

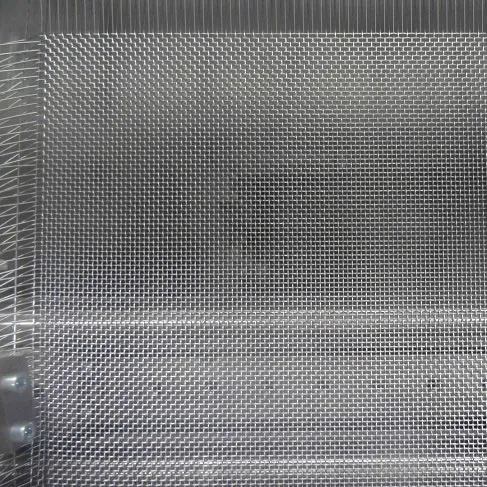

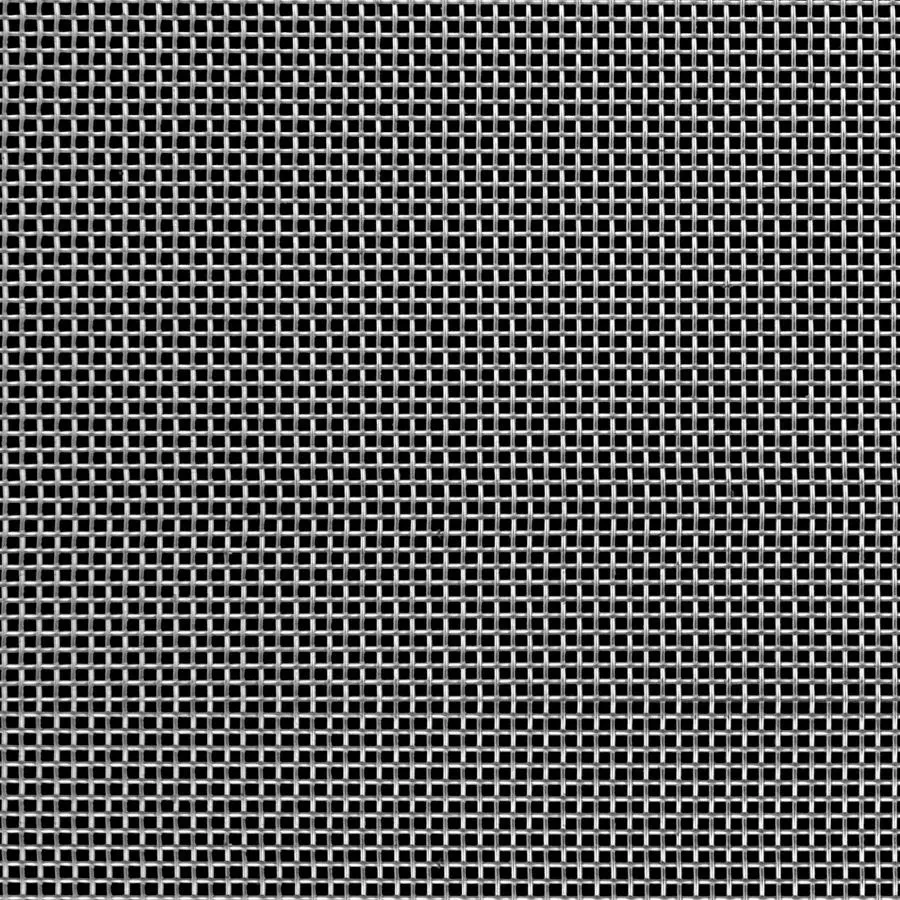

In the intricate landscape of industrial filtration, separation, and support, plain weave mesh stands as a cornerstone material, celebrated for its robust structural integrity and consistent aperture size. This fundamental weaving pattern, characterized by warp wires and weft wires passing alternately over and under each other, creates a square opening that is highly predictable and dimensionally stable, making it ideal for applications demanding precision and reliability. The global industrial sector's reliance on such precision elements has surged, driven by an escalating demand for high-efficiency filtration solutions across diverse sectors, including petrochemical, pharmaceutical, food and beverage, mining, and environmental engineering. Current trends indicate a significant shift towards advanced materials, particularly stainless steel alloys like 304, 316, and 316L, to enhance resistance against corrosion, extreme temperatures, and mechanical stress, thereby extending operational lifespans and reducing maintenance overheads. This material evolution is critical as industries face increasingly aggressive processing conditions. Innovations in wire drawing and weaving technologies have further refined the consistency, surface finish, and overall quality of plain mesh products, allowing for significantly finer filtration capabilities, even down to micron levels, and broader applicability in areas such as gas purification and fine chemical processing. Moreover, the pervasive global push for sustainable industrial practices is propelling the adoption of durable, reusable, and easily cleanable filtration media, positioning plain weave wire mesh as an indispensable component in circular economy initiatives aimed at minimizing waste and maximizing resource utilization. Manufacturers are increasingly focusing on specialized surface treatments, such as electropolishing, and developing composite structures to optimize flow rates and particulate capture efficiency, addressing complex challenges in modern processing environments where both efficiency and environmental impact are paramount. This continuous evolution underscores the critical role of material science, precision engineering, and responsive manufacturing in meeting the rigorous demands of contemporary industrial operations, ensuring both performance reliability and economic viability for end-users worldwide. The unparalleled versatility of plain steel mesh, ranging from coarse screening of aggregates to fine particle separation in pharmaceutical compounds, makes it an essential tool for engineers, procurement specialists, and R&D departments seeking dependable, cost-effective, and long-lasting solutions for fluid and solid management across the industrial spectrum.

Precision Manufacturing and Technical Specifications of Plain Weave Wire Mesh

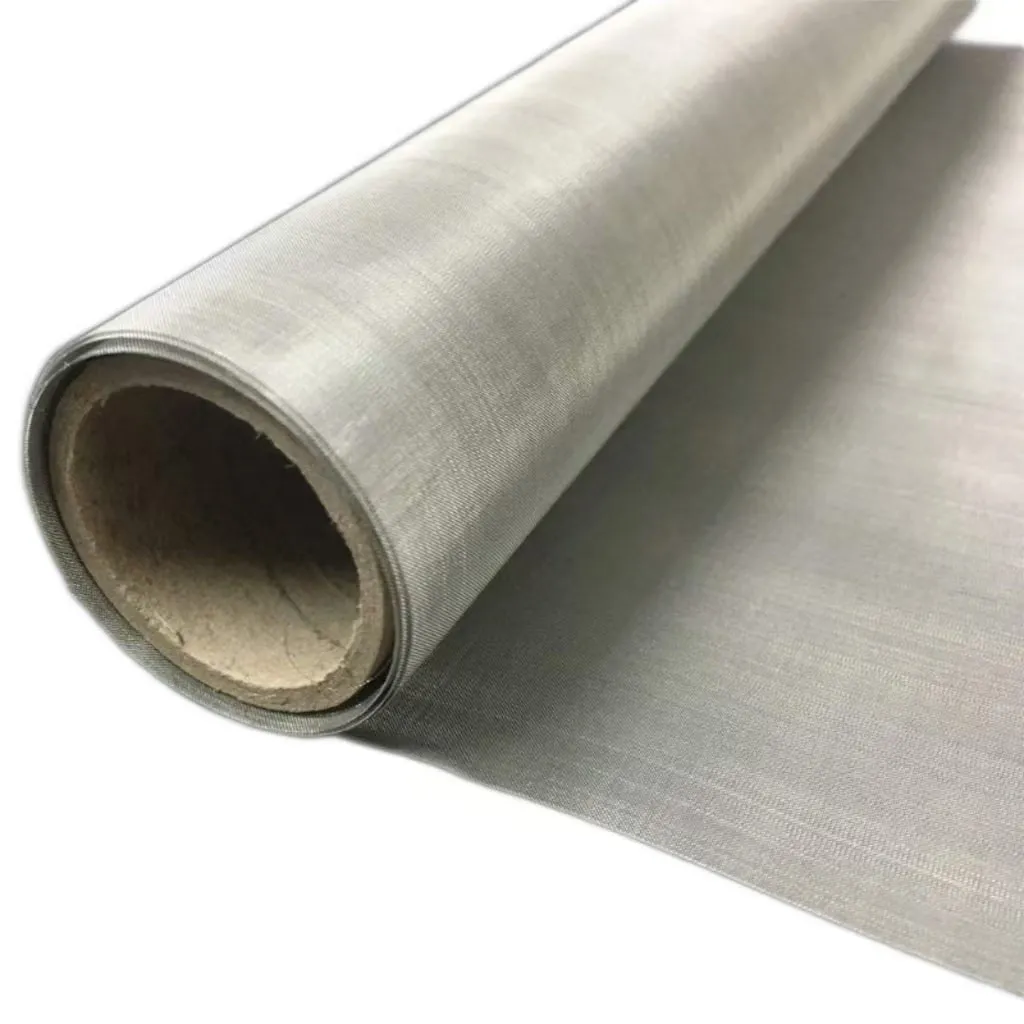

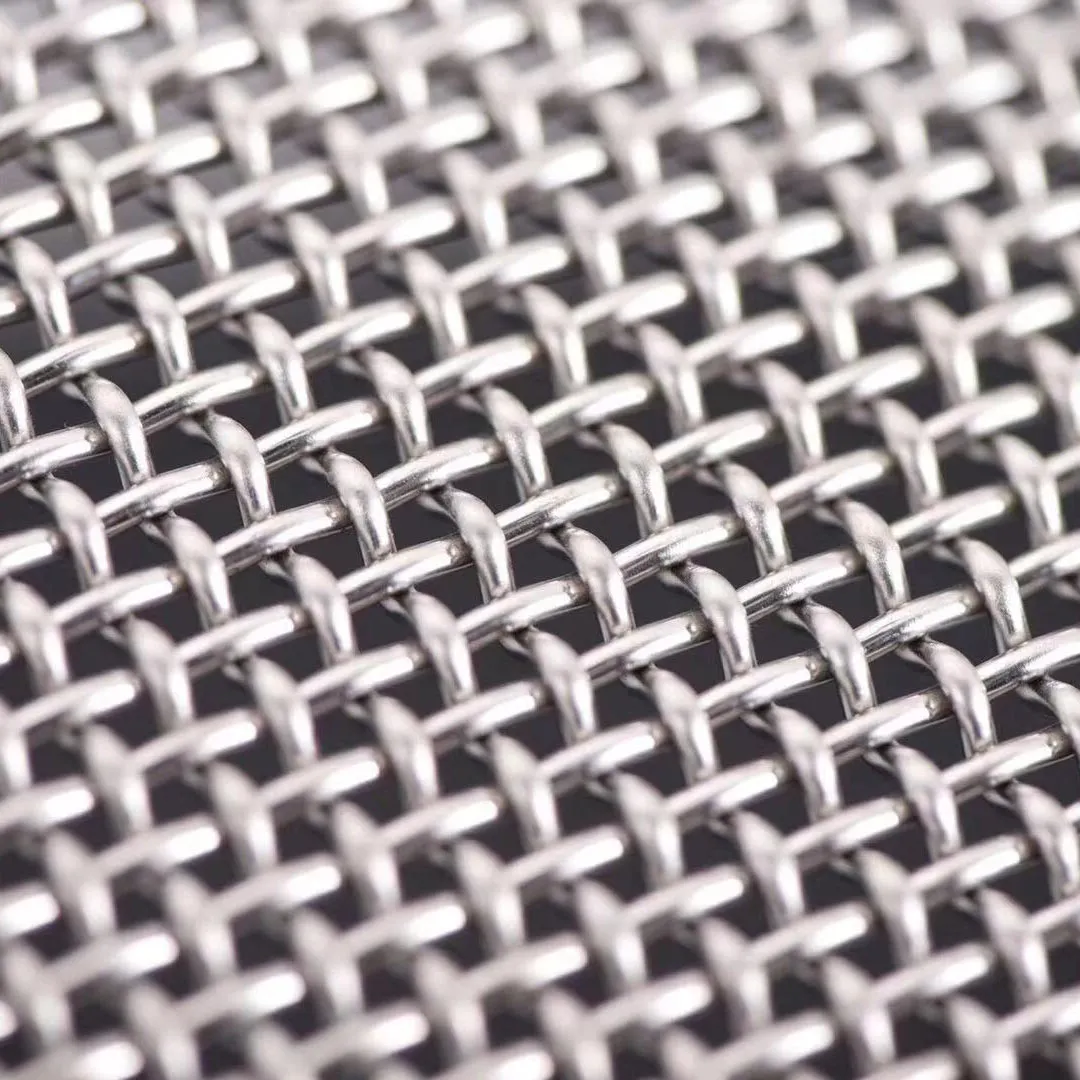

The production of high-quality plain weave wire mesh, particularly when crafted from stainless steel, involves a meticulously controlled sequence of processes to ensure unparalleled performance and longevity. It begins with the selection of premium-grade stainless steel wire, typically AISI 304, 316, or 316L, chosen for its superior corrosion resistance, tensile strength, and heat resistance. These wires undergo a precise drawing process to achieve the desired diameter, followed by annealing to enhance ductility and prepare them for weaving. The core manufacturing process is the weaving itself, executed on advanced automatic looms that interlace warp (longitudinal) and weft (transverse) wires at right angles. Each weft wire passes over one warp wire and under the next, creating the characteristic plain weave mesh pattern. This method ensures uniform mesh openings and high stability, crucial for consistent filtration and screening results. Post-weaving, the mesh undergoes rigorous inspection, including visual checks for defects, dimensional accuracy verification (mesh count per inch/cm, wire diameter, aperture size), and material composition analysis using X-ray fluorescence (XRF) or spectrography to confirm adherence to international standards like ASTM A240 for stainless steel and ISO 9001 for quality management systems. Specialized testing may include tensile strength tests, burst pressure tests for filter media, and corrosion resistance tests (e.g., salt spray tests) to validate performance under demanding operational conditions. The lifespan of stainless steel plain mesh is significantly extended by its inherent material properties and the precision of its manufacture, making it a reliable choice for applications requiring resistance to aggressive chemicals, high temperatures, and abrasive media in petrochemical refining, metallurgy, water treatment, and food processing industries. The stringent quality control measures at each stage guarantee that the final product offers optimal filtration efficiency, minimal pressure drop, and exceptional durability, contributing significantly to the operational success and cost-efficiency of industrial systems.

Typical Specifications for Stainless Steel Plain Weave Mesh

| Mesh Count (per inch) | Wire Diameter (mm) | Aperture Size (mm) | Open Area (%) | Material Grade |

|---|---|---|---|---|

| 2 | 1.60 | 11.10 | 74.7 | 304, 316L |

| 10 | 0.45 | 2.09 | 70.4 | 304, 316L |

| 30 | 0.28 | 0.56 | 46.7 | 304, 316L |

| 60 | 0.19 | 0.23 | 30.0 | 304, 316L |

| 100 | 0.10 | 0.15 | 36.0 | 304, 316L |

| 200 | 0.05 | 0.077 | 36.9 | 304, 316L |

Versatile Applications and Core Advantages of Stainless Steel Plain Mesh

The inherent durability and precision of plain weave mesh render it indispensable across a multitude of industrial application scenarios, delivering significant technical advantages that translate into operational efficiency and cost savings. In the petrochemical industry, plain mesh is extensively utilized for catalyst support grids, molecular sieve retention, and the filtration of crude oil and refined products, where its high corrosion resistance to hydrocarbons and elevated temperatures ensures long-term integrity and prevents costly downtime. For metallurgical processes, it serves as crucial screening media for ore classification, molten metal filtration, and the separation of slag from valuable metals, contributing to enhanced product purity and process optimization. In the water treatment and wastewater management sectors, stainless steel plain mesh excels as pre-filtration screens, fine particulate filters for potable water, and media retention screens in sand filters or activated carbon beds, effectively reducing suspended solids and protecting downstream equipment from fouling, thereby contributing to energy saving by reducing pump strain and improving overall system efficiency. Its non-reactive nature makes it ideal for the food and beverage industry, where it is used in sifting, straining, and drying processes for various consumables, adhering to strict hygiene standards. The principal technical advantages include its exceptional resistance to oxidation, acids, alkalis, and salts, which guarantees extended service life even in highly corrosive environments. Furthermore, the uniform aperture size of plain steel mesh ensures consistent and precise filtration or separation, critical for product quality and process control. Its high open area percentage allows for excellent flow rates with minimal pressure drop, which significantly contributes to energy efficiency in pumping and filtration systems. This combination of material strength, chemical inertness, and precise structural integrity makes it a superior choice over less durable alternatives, offering a robust and cost-effective solution for demanding industrial filtration and separation needs globally. The adaptability of plain weave wire mesh to various fabrication methods, such as welding, cutting, and forming, further enhances its utility in creating custom components like filter baskets, strainers, and decorative panels, extending its value proposition beyond basic filtration to a wide range of structural and aesthetic applications.

Choosing the Right Partner: Manufacturer Comparison and Tailored Plain Weave Mesh Solutions

Selecting a reputable manufacturer for plain weave mesh is paramount for ensuring product quality, performance consistency, and long-term reliability in critical industrial applications. When evaluating potential suppliers, discerning B2B decision-makers and technical personnel should prioritize several key factors beyond mere cost. A leading manufacturer distinguishes itself through extensive experience, often boasting service tenures exceeding two decades, demonstrating deep industry knowledge and a proven track record of successful projects across diverse and demanding sectors. Their unwavering commitment to quality is underscored by strict adherence to international certifications such as ISO 9001:2015 for comprehensive quality management, and potentially industry-specific certifications or compliance with standards like ASTM for materials composition and ANSI for dimensional accuracy, ensuring every batch of plain steel wire mesh meets stringent global benchmarks for performance and safety. Furthermore, a top-tier provider offers comprehensive customization capabilities, understanding that off-the-shelf solutions rarely fit all unique operational requirements precisely. This includes the ability to fabricate plain mesh in diverse wire diameters, mesh counts, material alloys (e.g., Duplex stainless steels, Monel for extreme conditions, or even specialized nickel alloys), and even specific roll widths or meticulously cut-to-size sheets with custom edge finishes and perforations tailored to exact client specifications. They should also demonstrate profound technical expertise through dedicated engineering support, assisting clients in optimizing mesh specifications for specific pressure drops, flow rates, and particulate removal efficiencies to achieve peak system performance. Transparency in their manufacturing processes, alongside a robust quality control protocol encompassing full material traceability and rigorous performance testing, builds significant trust. Established partnerships with leading industrial firms, alongside verifiable positive client feedback and detailed case studies, serve as strong indicators of a manufacturer's reliability, technical prowess, and proven expertise. The ability to offer tailored delivery schedules and comprehensive after-sales support, including detailed installation guidance and efficient troubleshooting, further differentiates a superior supplier. This holistic approach ensures clients receive not only a high-quality product but also a strategic partnership that supports their operational success and long-term objectives.

Real-World Impact: Application Cases and Unwavering Customer Support for Plain Mesh

The practical utility and efficacy of plain weave wire mesh are best demonstrated through its successful deployment in challenging industrial environments, providing concrete evidence of its reliability and performance. Consider a major petrochemical refinery that required a highly robust and corrosion-resistant filtering medium for its distillation columns to prevent catalyst bed fouling and improve product purity. By implementing custom-fabricated plain weave mesh panels made from 316L stainless steel with precise 20-mesh specifications, the refinery reported a remarkable 15% improvement in process uptime, a significant reduction in maintenance costs associated with frequent filter replacement, and enhanced catalyst lifespan, showcasing the material's superior chemical inertness and mechanical strength under extreme operating conditions. Another compelling case involves a large-scale municipal wastewater treatment plant facing escalating issues with microplastic contamination in their effluent discharge. The strategic integration of fine plain mesh screens (specifically, 100-mesh stainless steel) as a tertiary filtration stage effectively captured over 90% of particulate matter down to 150 microns, substantially enhancing the quality of water discharged into natural ecosystems and demonstrating the mesh's exceptional capacity for high-efficiency environmental protection and regulatory compliance. In the food processing sector, a leading dairy producer successfully utilized plain steel mesh in their milk pasteurization units to ensure the complete removal of any potential contaminants or unwanted solids, benefiting from its inherently hygienic properties, ease of cleaning, and resistance to bacterial growth, all of which are absolutely critical for stringent FDA compliance and ensuring utmost consumer safety. These diverse examples underscore the unparalleled versatility, critical performance, and substantial economic benefits derived from deploying high-quality plain steel mesh in varied, high-stakes industrial scenarios. Beyond delivering product excellence, a steadfast commitment to exceptional customer service forms the bedrock of a trusted and enduring supplier relationship. This comprehensive support includes rapid response to all inquiries, proactive and comprehensive technical assistance during product selection, seamless integration, and post-installation support, alongside flexible delivery options meticulously tailored to align with critical project timelines. A clear and robust quality assurance protocol, typically backed by a substantial product warranty (e.g., a 5-year warranty against manufacturing defects) and a transparent policy on prompt defect resolution, instills profound confidence in the supplier. Furthermore, dedicated after-sales support, encompassing detailed maintenance guidelines, optimal cleaning procedures, and expert operational troubleshooting, ensures that clients maximize their long-term investment in plain mesh solutions and achieve sustained operational efficiency.

Frequently Asked Questions (FAQ) about Plain Weave Mesh and Our Commitment

Q1: What are the primary advantages of Stainless Steel Plain Weave Wire Mesh over other materials?

Stainless Steel plain weave mesh offers unparalleled advantages, making it a superior choice for a wide array of industrial applications compared to meshes made from other materials like carbon steel, brass, or plastic, especially for demanding environments. Primarily, its exceptional corrosion resistance, particularly for alloys such as 304 and 316L, allows it to withstand prolonged exposure to aggressive chemicals, acids, alkalis, and saline environments without degrading, rusting, or contaminating the process stream. This is absolutely critical in sectors like chemical processing, marine applications, wastewater treatment, and pharmaceutical manufacturing, where material integrity and purity are paramount. Furthermore, stainless steel boasts inherently high tensile strength and excellent ductility, ensuring that the plain mesh maintains its structural integrity, precise aperture size, and overall dimensional stability even under significant operational pressures, mechanical stress, or constant vibration, which directly translates to consistent filtration efficiency and an extended service life. It also exhibits excellent heat resistance, allowing it to perform reliably and without compromise in elevated temperature applications that would cause other materials to deform, melt, or lose their crucial mechanical properties. Beyond its robust mechanical and chemical attributes, stainless steel is inherently hygienic, non-reactive, and remarkably easy to clean, actively preventing bacterial growth and material contamination, thus making it the material of choice for the food and beverage, pharmaceutical, and medical industries where cleanliness and safety are non-negotiable. The synergistic combination of these superior attributes contributes to significantly lower overall lifecycle costs due to reduced maintenance requirements, fewer replacements, and consistently reliable operational performance, presenting a robust, versatile, and highly economical choice for any demanding industrial application requiring long-term reliability and adherence to stringent quality and performance standards.

Q2: How do you ensure the quality and consistency of your plain mesh products?

Our commitment to ensuring the highest quality and unwavering consistency for every roll of plain weave mesh we produce is paramount, underpinned by a comprehensive, multi-stage, and rigorous quality control protocol that spans the entire manufacturing process, from initial material procurement to final product packaging. It commences with the meticulous selection of premium-grade raw materials, specifically stainless steel wires, which are sourced exclusively from certified and reputable mills globally; each incoming batch arrives with comprehensive material certificates confirming its precise chemical composition and critical mechanical properties. During the manufacturing phase, we deploy advanced automated looms equipped with state-of-the-art precision controls, ensuring uniform wire tension, consistent weave patterns, and absolutely precise mesh count, which are fundamental to achieving accurate aperture sizes, exceptional structural stability, and consistent filtration performance. Post-production, every single batch of plain mesh undergoes rigorous and detailed inspection processes. This includes thorough visual checks for any surface defects, optical microscopy for precise aperture size verification, accurate wire diameter measurement using calibrated digital calipers, and comprehensive tensile strength testing performed strictly according to internationally recognized industry standards to confirm mechanical robustness and durability. We strictly adhere to and are certified under the ISO 9001:2015 quality management system, ensuring that all our operational processes, from raw material procurement and production planning to manufacturing and final packaging, are systematically managed for optimal quality outcomes. Products can be supplied with comprehensive material test reports and certificates of conformity upon request, providing full traceability and transparency. This comprehensive approach, combined with our extensive experience in producing plain mesh for over two decades and a dedication to continuous improvement, guarantees that every product leaving our facility not only meets but often significantly exceeds the most exacting industrial specifications and customer expectations, thereby fostering enduring trust and long-term reliability in our solutions.

Q3: What is the typical lead time for custom plain steel wire mesh orders?

The typical lead time for custom plain steel wire mesh orders is carefully determined and influenced by several critical factors, including the inherent complexity of the required specifications, the immediate availability of specialized material alloys, and the overall volume of the order. For most standard custom orders, where materials are readily accessible in our inventory and specifications are within common industry parameters, our typical lead time ranges efficiently from 2 to 4 weeks, covering the entire period from confirmed order placement to final dispatch from our facility. However, for highly specialized configurations, such as ultra-fine mesh counts, unique or extremely precise wire diameters, or orders requiring rare or exotic material alloys like Duplex stainless steels, Monel, or other specialized nickel alloys, the lead time may necessarily extend, potentially up to 6-8 weeks, to account for specialized material procurement, intricate production scheduling, and additional quality assurance checks. To effectively mitigate potential delays and provide maximum flexibility for our valued recurrent clients, we strategically maintain a substantial and diverse inventory of common stainless steel wire grades (e.g., 304, 316L) and frequently requested plain mesh counts. Our sophisticated production planning system, coupled with a highly responsive and dedicated customer support team, works in close collaboration with clients throughout the entire process. This collaboration ensures accurate lead time estimates are provided at the initial quoting stage, and regular, transparent updates keep clients thoroughly informed throughout every phase of the manufacturing process, from material preparation and weaving to final inspection and shipment. We also recognize that urgent requirements can arise unexpectedly and, subject to current material availability and real-time production capacity, we are pleased to offer expedited production options for time-sensitive projects. Our overarching goal is to minimize any potential project downtime for our clients by ensuring timely delivery of superior quality, precisely customized plain weave mesh solutions, all underpinned by transparent communication, reliable logistics management, and an unwavering commitment to meeting critical deadlines.

Authoritative References and Industry Standards

- ASTM International. ASTM A240/A240M, Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications.

- International Organization for Standardization. ISO 9001:2015, Quality management systems — Requirements.

- Perry, R. H., & Green, D. W. (Eds.). (2008). Perry's Chemical Engineers' Handbook (8th ed.). McGraw-Hill.

- Lide, D. R. (Ed.). (2004). CRC Handbook of Chemistry and Physics (85th ed.). CRC Press.

- Tiller, F. M., & Leu, W. C. (2012). Solid-liquid Separation. In Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons.

Post time: Aug . 17, 2025 05:40