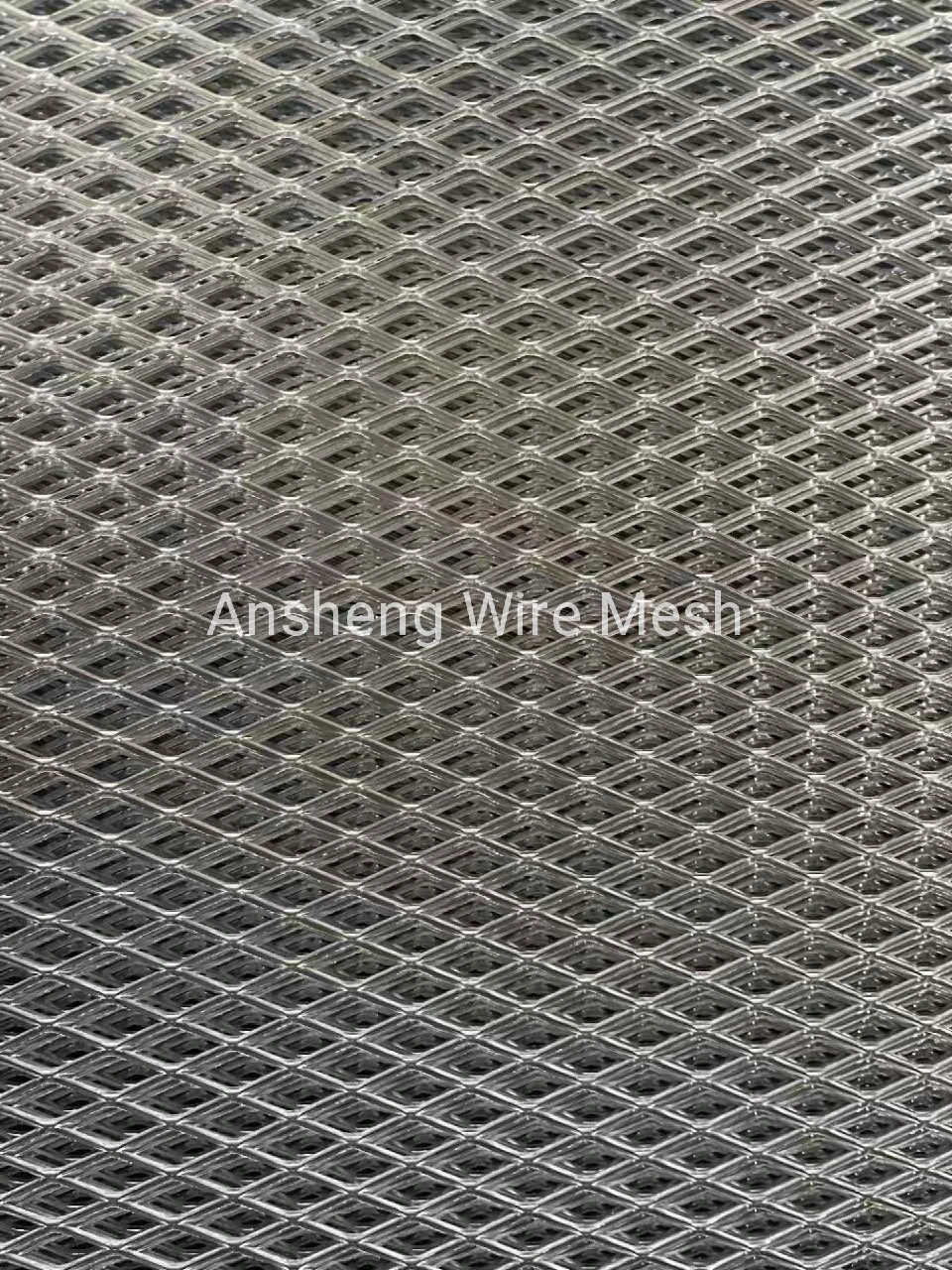

In the realm of advanced industrial filtration and separation, the choice of media is paramount. Stainless Steel dutch weave mesh stands out as a superior solution, particularly for applications demanding exceptional precision, mechanical strength, and chemical resistance. This specialized woven wire product, also widely known as dutch weave wire mesh or simply dutch mesh, is engineered with a unique weaving pattern that optimizes filtration efficiency by creating intricate, fine pore structures. Unlike standard square or plain weaves, the warp wires (running lengthwise) are typically heavier and fewer in number, while the shute wires (running crosswise) are significantly finer and packed tightly together, overlapping to form a dense, robust filter medium. This construction ensures precise filtration, excellent particle retention, and a robust structure capable of withstanding high-pressure differentials and harsh operating environments, making it indispensable across diverse industrial sectors.

The increasing complexity of industrial processes and the stringent requirements for product purity and environmental compliance have driven a steady rise in the demand for high-performance filtration solutions. According to market research, the global industrial filtration market is projected to reach over $40 billion by 2027, with wire mesh filters, including those utilizing dutch weave mesh, playing a crucial role in critical applications. Its distinct characteristics, such as controlled permeability and high tensile strength, position it as a preferred material for fluidization, hydraulic filtration, and gas purification, reflecting its vital contribution to operational efficiency and product quality.

The Precision Manufacturing Process of Dutch Weave Wire Mesh

The manufacturing of high-quality Stainless Steel dutch weave mesh is a sophisticated process that demands meticulous control over material selection, wire drawing, and weaving techniques. The journey begins with the selection of premium-grade stainless steel alloys, typically AISI 304 or AISI 316L, known for their exceptional corrosion resistance, high-temperature stability, and mechanical properties. These materials undergo a precise wire drawing process to achieve the exact diameters required for both warp and shute wires, which is critical for defining the mesh's filtration capabilities. Subsequent annealing processes are often employed to enhance wire ductility, preventing breakage during weaving and ensuring the final product's flexibility and durability.

The core of the process lies in the specialized weaving on high-precision looms. Unlike plain weave or twill weave, dutch twill weave involves interlacing two shute wires over and under two warp wires, with the shute wires packed extremely close together, forming a very tight mesh. This creates a tortuous path for particles, enhancing filtration accuracy down to very fine micron levels. Strict quality control protocols, adhering to international standards such as ISO 9001 and ASTM E2814, are integrated at every stage. This includes systematic checks on wire diameter, mesh count, and weave integrity. Post-weaving, the mesh typically undergoes cleaning, annealing, and tensioning processes to ensure uniformity, remove impurities, and enhance flatness. These rigorous steps guarantee that each roll of dutch weave wire mesh delivers consistent performance, extended service life, and compliance with the most demanding industrial specifications for petrochemical, metallurgical, and water treatment applications, where energy efficiency and corrosion resistance are key advantages.

Technical Specifications and Performance Metrics of Dutch Mesh

The performance of Stainless Steel dutch mesh is defined by a set of critical technical parameters that dictate its suitability for specific filtration and separation tasks. Key among these are the warp and weft mesh counts (wires per inch), wire diameters, and the resultant micron rating. Unlike square mesh, dutch weave screen's filtration rating is not simply the size of the square opening, but rather the smallest particle it can effectively block, often measured in microns. The distinct packing of the weft wires creates extremely fine and precise pore sizes, providing superior filtration efficiency compared to conventional weaves, even at lower nominal mesh counts.

The robust nature of dutch weave wire mesh, particularly in Stainless Steel 316L, provides exceptional corrosion resistance against acids, alkalis, and chlorides, making it ideal for highly aggressive chemical environments. Its high strength-to-weight ratio allows for the creation of compact, high-efficiency filters capable of handling significant operational pressures. This combination of fine filtration capability and mechanical resilience translates into a longer service life, reduced maintenance, and improved overall system performance, directly contributing to energy savings and operational safety in demanding industrial applications.

Diverse Applications of Stainless Steel Dutch Weave Mesh

The unique characteristics of Stainless Steel dutch weave wire mesh make it an indispensable component across a vast spectrum of industrial applications. Its ability to achieve precise micron ratings, coupled with its inherent mechanical strength and resistance to harsh environments, positions it as a preferred material for critical filtration and separation tasks.

- ✓ Petrochemical and Chemical Processing: Used extensively in catalyst recovery, fluid bed filtration, and fine particle separation in highly corrosive chemical streams. Its robust construction ensures longevity and reliability in high-temperature and high-pressure reactors.

- ✓ Food and Beverage Industry: Critical for precision filtration of edible oils, syrups, juices, and brewing liquids, ensuring product purity and compliance with stringent food safety standards (e.g., FDA requirements for material contact).

- ✓ Pharmaceutical Applications: Employed in sterile filtration, solvent recovery, and purification processes where absolute particle retention and material inertness are paramount to prevent contamination.

- ✓ Water Treatment and Wastewater Management: Utilized in micro-filtration systems, pre-filters for reverse osmosis, and dewatering processes where efficient solid-liquid separation is essential for environmental compliance and resource recovery.

- ✓ Hydraulic and Lubrication Systems: Essential for protecting sensitive hydraulic components from abrasive particles, extending equipment lifespan and ensuring smooth operation in heavy machinery and industrial automation.

A key advantage of dutch weave wire mesh in these high-stakes environments is its exceptional durability and resistance to clogging. The unique structure allows for efficient backwashing or cleaning, significantly extending filter lifespan and reducing operational downtime. For example, in a major petrochemical plant in Texas, transitioning from conventional filter cloth to custom-fabricated dutch mesh filters for catalyst recovery resulted in a 30% increase in filter element lifespan and a 15% reduction in overall maintenance costs within the first year, underscoring its tangible benefits in terms of operational efficiency and cost-effectiveness. This demonstrates the superior performance and economic benefits derived from deploying high-quality dutch weave screen in critical industrial processes.

Competitive Advantages and Customization Solutions of Dutch Wire Mesh

When evaluating filtration media, the advantages of Stainless Steel dutch weave mesh become clear, especially when compared to other common weaves. Its distinct structure offers superior filtration precision and mechanical stability, making it ideal for high-pressure and critical applications where a very fine and robust filter is needed. While plain weave offers a high open area and is cost-effective for general sifting, and twill weave provides good strength for finer filtration, neither can match the ultimate filtration precision and dirt-holding capacity of dutch weave wire mesh under pressure.

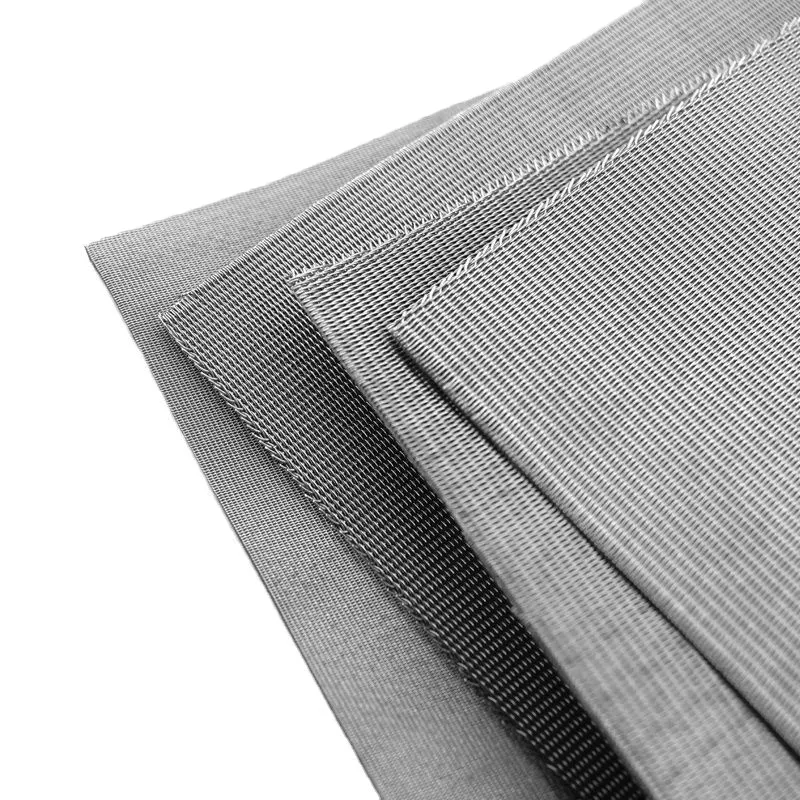

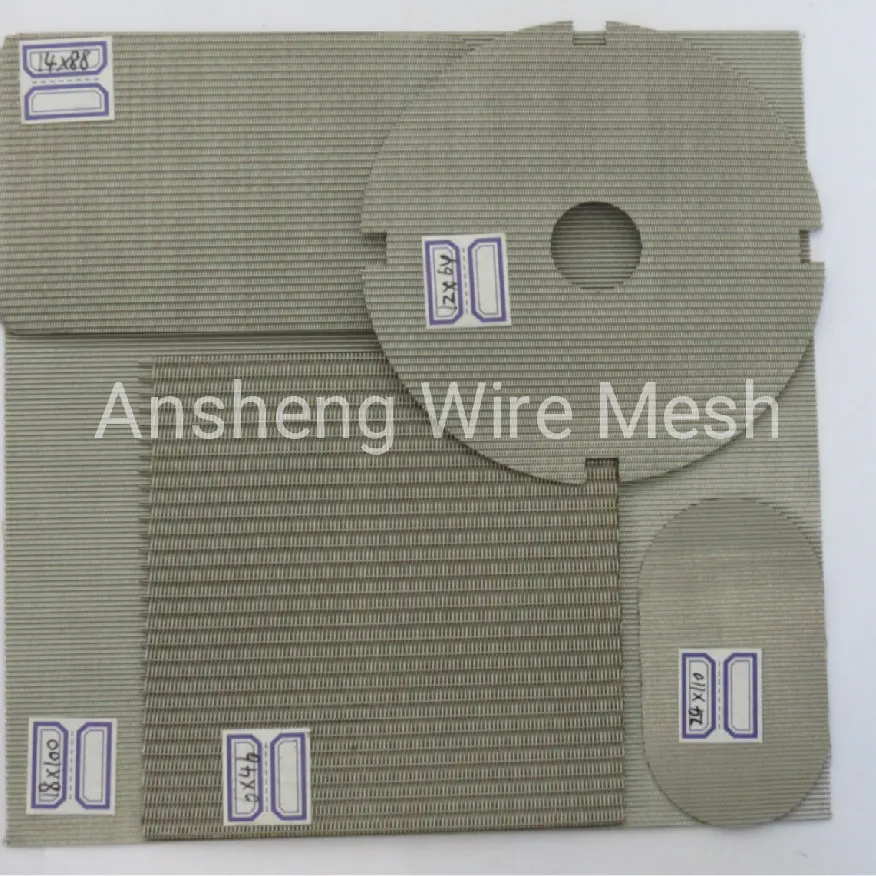

Our expertise extends to providing comprehensive customization solutions for dutch weave screen to meet the exact requirements of any industrial application. Whether it's selecting specific stainless steel grades (e.g., 304, 316, 904L, Duplex), tailoring dimensions from rolls to custom cut pieces, or implementing specialized edge treatments and fabrication into filter elements (e.g., filter discs, cylinders, cones), our engineering team collaborates closely with clients. We leverage advanced manufacturing capabilities to deliver bespoke solutions that optimize performance, ensuring seamless integration into existing systems and maximizing operational efficiency.

This commitment to precision and customization is backed by decades of industry experience. Our portfolio includes successful projects supplying tailored dutch twill weave solutions to leading companies in the petrochemical, pharmaceutical, and aerospace sectors across North America, Europe, and Asia, affirming our position as an authoritative supplier in complex filtration applications.

Ensuring Trust and Reliability: FAQs, Warranty, and Support of Dutch Woven Wire Mesh

Building and maintaining trust with our B2B partners is at the core of our operations. We understand that investing in specialized industrial components like Stainless Steel dutch woven wire mesh requires confidence in both product quality and supplier reliability. To foster this trust, we provide clear information, comprehensive support, and robust quality assurances.

Frequently Asked Questions (FAQs) about Dutch Woven Wire Mesh

-

Q: What is the primary advantage of dutch weave wire mesh for critical filtration?

A: The primary advantage stems from its unique design, which features a higher density of fine shute wires packed tightly together, creating a tortuous path and extremely precise, sub-micron pore openings. This allows for superior filtration efficiency and particle retention, especially crucial for high-pressure, fine filtration, and dewatering applications. Its robust structure also provides excellent mechanical strength and resistance to blinding, leading to longer filter life.

-

Q: How do you ensure the quality and consistency of your dutch weave mesh products?

A: Our manufacturing processes are rigorously aligned with ISO 9001:2015 quality management systems. We implement multi-stage quality control, including raw material inspection, in-process monitoring of weaving parameters, and comprehensive final product testing. This includes visual inspections for weave integrity, precise measurement of mesh dimensions, and verification of material composition via XRF analysis, ensuring every batch of dutch mesh meets specified technical and performance criteria.

-

Q: Can dutch twill weave be customized for unique industrial requirements?

A: Absolutely. We specialize in providing highly customized Stainless Steel Dutch Weave Wire Mesh solutions. Our engineering team works closely with clients to tailor mesh specifications including specific alloy types (e.g., SS304, 316L, Duplex, Inconel), precise dimensions (from rolls to custom-fabricated filter elements like discs, cones, or cylinders), and specific edge treatments or coatings. Our ability to deliver bespoke solutions is a significant advantage for complex and specialized applications, ensuring optimal performance and system compatibility.

Delivery Timelines and Quality Assurance of Anping County Ansheng Wire Meshes Product Co., Ltd.

We understand the importance of timely delivery in industrial operations. Our advanced production planning and efficient logistics network enable us to offer competitive lead times, even for customized dutch weave screen orders. Typical lead times range from 2-4 weeks for standard products, with expedited options available for urgent requirements. Each shipment comes with comprehensive documentation, including material certifications and quality inspection reports, ensuring complete transparency and traceability.

Comprehensive Warranty and After-Sales Support

All our Stainless Steel Dutch Weave Wire Mesh products are backed by a comprehensive warranty against manufacturing defects and material failures, reflecting our confidence in their quality and durability. Our dedicated technical support team is available to assist with product selection, application guidance, troubleshooting, and post-sales inquiries. We are committed to providing continuous support throughout the product lifecycle, ensuring our clients derive maximum value and optimal performance from their investment in our high-quality filtration solutions.

Industry Trends and Future Outlook for Dutch Weave Screen

The industrial filtration landscape is continuously evolving, driven by increasingly stringent environmental regulations, the demand for higher product purity, and the pursuit of greater operational efficiency. Current trends indicate a significant shift towards micro-filtration and ultra-filtration technologies, where the precise and robust nature of Stainless Steel dutch weave mesh is becoming ever more critical. There's a growing emphasis on sustainable manufacturing processes, requiring filtration media that offer longer service life, are easier to clean, and can withstand aggressive recycling or regeneration cycles.

The future outlook for dutch weave wire mesh remains exceptionally strong. Its inherent advantages in terms of precise pore size control, mechanical strength, and chemical inertness position it as a foundational material for emerging filtration challenges. As industries move towards zero-liquid discharge systems, advanced material recovery, and more complex chemical syntheses, the demand for specialized media like dutch mesh that can perform reliably under extreme conditions will only intensify. Continued innovation in alloy development and weaving technologies promises even finer filtration capabilities and enhanced durability, ensuring that dutch weave screen will remain a pivotal component in the advanced filtration solutions of tomorrow.

References

- ASTM E2814/E2814M-11(2017), Standard Guide for the Development and Use of Industrial Woven Wire Filter Cloth.

- ISO 9044:2013, Industrial woven wire cloth — Technical requirements and tests.

- P. Cheremisinoff, "Filtration and Separation Handbook," Butterworth-Heinemann, 2011.

- S. P. Shard, "Practical Handbook of Materials Science and Technology," Woodhead Publishing, 2017.

- Market Research Reports, Global Industrial Filtration Market Analysis, 2020-2027.

Post time: Aug . 12, 2025 05:20