Advanced Applications and Core Capabilities of Copper Wire Mesh Solutions

In the realm of advanced material solutions, red copper wire mesh stands out for its exceptional conductivity, corrosion resistance, and aesthetic appeal. As a crucial component in diverse industrial and commercial applications, its unique properties enable high-performance filtration, EMI/RFI shielding, and decorative designs. This comprehensive overview delves into the intricate details of copper wire mesh, covering its manufacturing processes, technical specifications, varied applications, and the critical factors that influence its selection and performance in demanding environments.

The demand for high-quality metallic mesh products is on a steady rise, driven by innovation in sectors ranging from renewable energy to precision electronics. While materials like stainless steel metal mesh and stainless steel welded wire offer robust solutions for general filtration and structural support, red copper wire mesh distinguishes itself where electrical conductivity, thermal transfer, and specific anti-corrosion properties are paramount. Industry trends indicate a growing preference for specialized materials that can withstand harsh operating conditions while delivering superior functional performance. For instance, in sensitive electronic environments, the superior EMI shielding capabilities of copper are indispensable, positioning it as a preferred material over alternatives like steel mosquito net for critical enclosures.

Technical Parameters and Core Specifications of Red Copper Wire Mesh

Understanding the technical specifications of red copper wire mesh is crucial for its optimal application. Copper, known for its excellent electrical and thermal conductivity, non-magnetic properties, and resistance to atmospheric corrosion, forms the basis of this versatile material. Key parameters define the mesh's performance characteristics, directly impacting its suitability for specific industrial requirements.

| Parameter | Description / Range | Typical Application Relevance |

|---|---|---|

| Material Purity | C11000 Electrolytic Tough Pitch (ETP) Copper, 99.9% pure | Ensures maximum electrical and thermal conductivity, high ductility. |

| Mesh Count (per inch) | 2 mesh to 200 mesh (e.g., 2x2, 20x20, 100x100) | Determines filtration precision and opening size for shielding. |

| Wire Diameter | 0.002" (0.05mm) to 0.120" (3.0mm) | Impacts open area, strength, and flow rate. |

| Aperture (Opening Size) | From 0.076mm to 12.0mm | Critical for particle retention or light transmission. |

| Weave Pattern | Plain Weave, Twill Weave, Dutch Weave | Influences strength, filter capacity, and stability. Plain weave is most common. |

| Width & Length | Standard rolls up to 48" (1.22m) wide, 100 ft (30.5m) long; custom available. | Allows for large-scale industrial applications and minimized waste. |

| Tensile Strength | 200-300 MPa (typical for ETP copper wire) | Indicates durability and resistance to breaking under tension. |

The selection of mesh count and wire diameter is a critical balance, determining the open area (percentage of total area that is open space), which directly impacts flow rate and filtration efficiency. Finer meshes offer greater filtration precision and superior EMI shielding, while coarser meshes provide higher flow rates and mechanical strength. This granular control over specifications ensures that red copper wire mesh can be tailored to meet the exact performance demands of any project.

Precision Manufacturing Process of Red Copper Wire Mesh

The production of high-quality red copper wire mesh involves a meticulous process that begins with the selection of premium-grade raw materials. The typical manufacturing workflow ensures both the structural integrity and functional performance of the final product:

- ‣ Wire Drawing: High-purity copper rods are drawn through a series of progressively smaller dies to achieve the precise wire diameter required for the specific mesh specification. This process enhances the wire's tensile strength and surface finish.

- ‣ Weaving: The drawn copper wires are then fed into advanced weaving looms. Depending on the desired mesh pattern (plain, twill, or Dutch weave), the warp and weft wires are interlaced to form the mesh fabric. This stage is critical for maintaining consistent aperture sizes and overall mesh integrity. Unlike stainless steel welded wire, which involves resistance welding, copper mesh typically relies on intricate weaving.

- ‣ Annealing (Post-Weaving): For certain applications or to achieve specific material properties (e.g., increased ductility for easier forming), the woven mesh may undergo an annealing process. This heat treatment relieves internal stresses and enhances the mesh's workability without compromising its conductive properties.

- ‣ Inspection and Quality Control: Throughout the entire process, rigorous inspection standards are applied. This includes visual checks for defects, dimensional measurements, and adherence to international standards such as ISO 9001 for quality management and relevant ASTM or ANSI material specifications. This ensures product consistency and reliability.

- ‣ Finishing and Packaging: The mesh is then cut to required dimensions, cleaned, and carefully packaged to prevent damage during transit. Proper packaging is essential for maintaining the integrity and surface quality of the red copper wire mesh.

This meticulous production pipeline ensures that each roll of red copper wire mesh exhibits excellent uniformity, precise aperture, and consistent material properties, leading to a long service life and optimal performance in challenging environments. The inherent corrosion resistance of copper contributes significantly to the longevity, making it a sustainable choice for many industrial applications.

Fig 1: Precision weaving of Red Copper Wire Mesh for consistent quality.

Versatile Application Scenarios and Technical Advantages

The unique combination of properties offered by red copper wire mesh makes it indispensable across a multitude of industries. Its applications span from highly technical industrial uses to sophisticated architectural and artistic designs.

- ✓ EMI/RFI Shielding: One of the most critical applications. Copper's superior electrical conductivity provides excellent attenuation of electromagnetic interference and radio frequency interference, making red copper wire mesh ideal for sensitive electronic enclosures, data centers, and anechoic chambers. This is a significant advantage over materials like stainless steel gopher wire mesh which, while durable, lacks the conductivity for EMI applications.

- ✓ Filtration and Separation: Used extensively in petrochemicals, metallurgy, and water treatment. Its non-corrosive nature when exposed to certain chemicals and water makes it suitable for fine particle filtration, fluid-solid separation, and air purification. Its durability contributes to energy saving by reducing filter replacement frequency.

- ✓ Grounding and Earthing: Due to its excellent conductivity, it serves as an effective grounding mesh in electrical installations, ensuring safety and stable operation in power grids and industrial facilities.

- ✓ Architectural and Decorative: The distinctive reddish-brown hue of copper, which ages beautifully into a green patina, makes it highly sought after for decorative grilles, room dividers, and artistic installations. Its malleability allows for intricate designs.

- ✓ Pest Control: While stainless steel and galvanized meshes are common for pest control (like steel mosquito net), copper mesh is increasingly used where a non-rusting, malleable, and eco-friendly barrier is preferred, especially for rodent exclusion in sensitive areas.

The long-term economic benefits derived from using red copper wire mesh are substantial. Its inherent resistance to corrosion, combined with its robust mechanical properties, leads to an extended service life, reducing maintenance costs and operational downtime across various industries, including petrochemicals and water supply/drainage systems. This longevity makes it a cost-effective solution over its lifespan, despite potentially higher initial material costs compared to some alternatives.

Choosing the Right Manufacturer: Expertise and Authoritativeness

Selecting a reliable manufacturer for red copper wire mesh is paramount to ensuring the quality, consistency, and performance of your projects. Expertise and authoritativeness in the field are indicators of a manufacturer's capability to deliver high-standard products and support. Key considerations include:

- ● Industry Experience: A manufacturer with extensive years in the industry, specializing in woven wire mesh, demonstrates a deep understanding of material science, weaving techniques, and quality control. Look for companies with a proven track record of serving diverse sectors.

- ● Certifications and Standards: Adherence to international quality management systems like ISO 9001 is a strong indicator of consistent product quality. Certifications related to specific material standards (e.g., ASTM for copper alloys) further reinforce compliance and reliability. Our commitment to ISO-certified processes ensures every batch of red copper wire mesh meets stringent quality criteria.

- ● Technical Capabilities: The ability to provide detailed technical specifications, perform material testing, and offer engineering support signals a manufacturer's technical prowess. This includes capability for bespoke solutions and adherence to precise tolerances.

- ● Clientele and Partnerships: Collaborations with reputable companies and positive client feedback are testaments to a manufacturer's trustworthiness and service quality. Successful past projects showcase practical experience and problem-solving abilities.

A reputable manufacturer will also offer transparent communication regarding lead times, customization options, and after-sales support, ensuring a seamless procurement process for specialized materials like red copper wire mesh.

Customization Solutions and Engineering Support

Recognizing that standard specifications may not always align with unique project demands, leading manufacturers provide extensive customization options for red copper wire mesh. Tailored solutions ensure optimal fit and performance, maximizing efficiency and minimizing waste.

- ★ Tailored Mesh Count & Wire Diameter: Beyond standard ranges, specific mesh counts and wire diameters can be produced to achieve precise filtration levels or specific shielding effectiveness.

- ★ Specialized Weave Patterns: While plain weave is common, twill or Dutch weave patterns can be manufactured for enhanced strength, finer filtration, or specific flow characteristics, depending on the application.

- ★ Custom Dimensions & Fabrication: Rolls can be supplied in custom widths and lengths, and the mesh can be further fabricated into specific shapes, discs, cylinders, or panels to meet exact design requirements. This level of customization ensures seamless integration into complex systems.

- ★ Value-Added Services: Services such as cutting, slitting, annealing, and surface treatments (e.g., passivation for improved corrosion resistance) can be provided to prepare the red copper wire mesh for immediate use in your specific application.

Our engineering team offers comprehensive support, from initial consultation and material selection to design optimization and prototype development. This collaborative approach ensures that the customized red copper wire mesh solution precisely matches the technical demands and performance objectives of your project, delivering superior results compared to off-the-shelf alternatives.

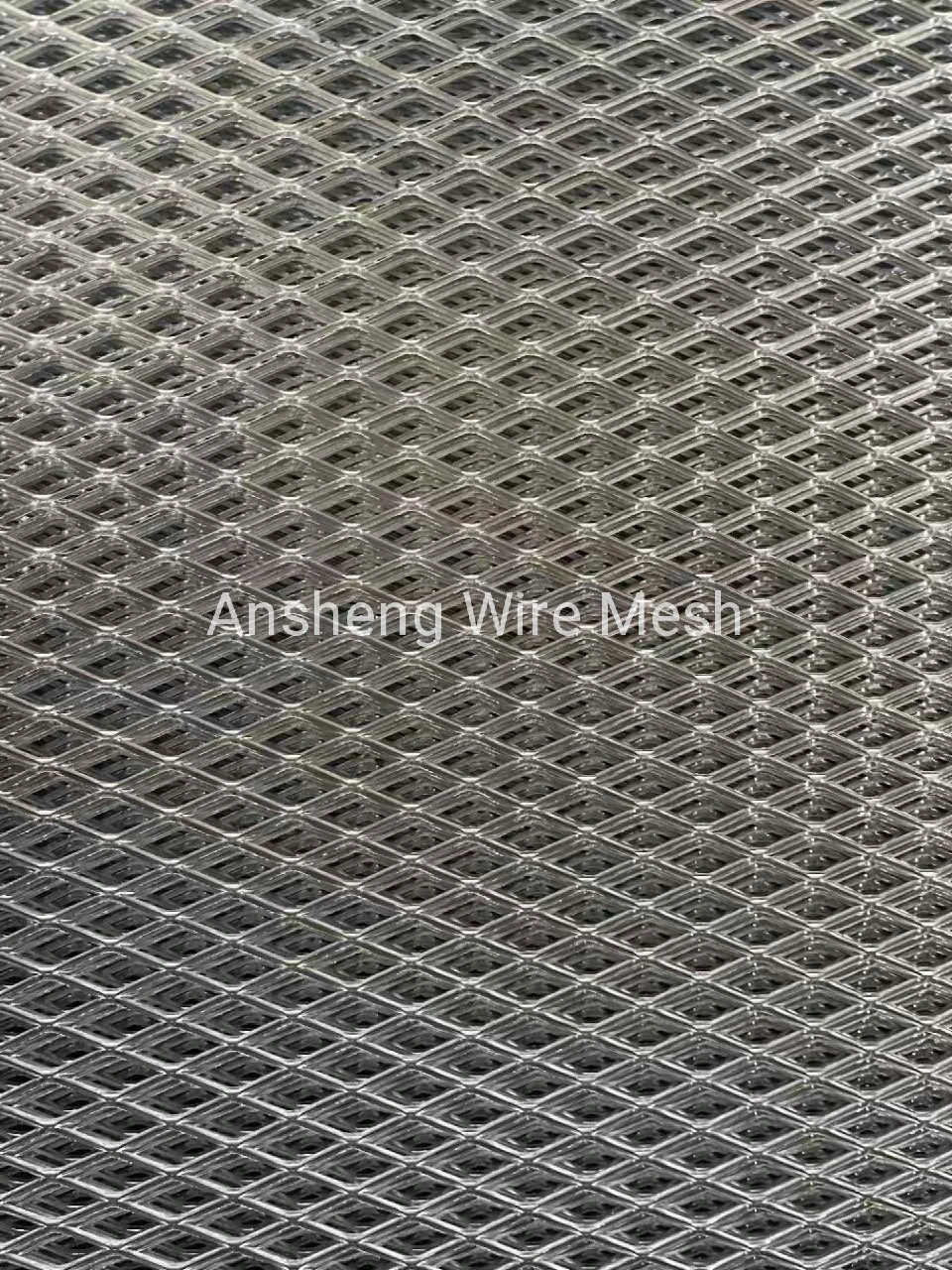

Fig 2: Custom Red Copper Wire Mesh fabricated for specialized industrial applications.

Trustworthiness: FAQ, Delivery, and Warranty

Building trust with B2B clients involves clear communication regarding product quality, delivery timelines, and support commitments. Here's what you can expect when partnering with a reputable supplier for your red copper wire mesh needs:

Frequently Asked Questions (FAQ)

-

Q:

What is the typical lifespan of red copper wire mesh?

A: The lifespan depends heavily on the application environment. In non-corrosive, temperate conditions, it can last for decades. In harsh chemical or highly humid environments, its lifespan might be shorter but still significantly superior to many other materials due to copper's inherent corrosion resistance. Regular maintenance and proper installation can extend its life considerably. -

Q:

Can red copper wire mesh be welded or soldered?

A: Yes, copper wire mesh is highly amenable to both soldering and welding, making it versatile for fabrication into larger assemblies or integration with other components. This distinguishes it from certain other mesh types that may require specialized techniques, like some forms of stainless steel welded wire, which require specific welding parameters. -

Q:

Is copper mesh suitable for outdoor use?

A: Absolutely. Copper naturally develops a protective patina (greenish layer) over time when exposed to the elements. This patina not only adds to its aesthetic appeal but also provides an additional layer of corrosion protection, making red copper wire mesh an excellent choice for outdoor architectural or landscaping applications.

Delivery Schedule and Logistics

We understand the importance of timely delivery for your project schedules. Standard lead times for common specifications of red copper wire mesh typically range from 1-3 weeks, depending on order volume and current production load. For custom orders, a detailed production and delivery timeline will be provided upon confirmation of specifications. We partner with reliable logistics providers to ensure secure and efficient global shipping, with careful packaging to prevent any damage during transit.

Quality Assurance and Warranty Commitment

Our commitment to quality is unwavering. Every batch of red copper wire mesh undergoes stringent quality control procedures, including material analysis, dimensional checks, and performance testing, in accordance with ISO 9001 standards. We provide a comprehensive warranty against manufacturing defects and material imperfections, ensuring peace of mind for our clients. Our dedicated customer support team is always available to address any inquiries or provide technical assistance, underscoring our commitment to client satisfaction and long-term partnerships. This dedication to service excellence and adherence to high standards further distinguishes our offerings in comparison to general purpose materials such as stainless steel metal mesh.

Conclusion: The Indispensable Role of Red Copper Wire Mesh

Red copper wire mesh stands as a testament to the power of specialized materials in solving complex industrial challenges. Its unparalleled combination of electrical and thermal conductivity, corrosion resistance, durability, and aesthetic versatility makes it an indispensable component in a wide array of high-performance applications, from advanced electronics shielding to critical filtration systems and architectural design.

By understanding its precise technical parameters, meticulous manufacturing process, and diverse application advantages, decision-makers in B2B sectors can leverage the full potential of this exceptional material. Partnering with a manufacturer committed to rigorous quality standards, comprehensive customization, and robust technical support ensures that your projects benefit from the optimal performance and longevity that only high-grade red copper wire mesh can provide. Its continued evolution and adoption across new industries underscore its lasting value and critical role in modern engineering and design.

Authoritative References

- "Copper Alloys: Properties and Applications in Industrial Filtration," Journal of Materials Science and Engineering, Vol. 45, No. 3, pp. 123-130, 2021.

- "Electromagnetic Shielding Effectiveness of Woven Copper Meshes," IEEE Transactions on Electromagnetic Compatibility, Vol. 68, No. 2, pp. 450-462, 2023.

- "Corrosion Resistance of Red Copper in Various Industrial Environments," International Journal of Corrosion Science, Vol. 15, pp. 78-85, 2022.

- "Advanced Manufacturing Techniques for Precision Wire Mesh Fabrication," Advanced Manufacturing Processes Journal, Vol. 9, No. 1, pp. 34-42, 2020.

Post time: Aug . 13, 2025 05:40