- Comprehensive overview of 4x4 welded wire panels

, wire mesh panels, and wire panels - Industry significance and technical advantages

- Comparative analysis of manufacturers with data table

- Customization options and process insights

- Real-world application examples in various sectors

- Maintenance, installation tips, and lifespan statistics

- Conclusion with future trends for 4x4 welded wire panels

(4x4 welded wire panels)

4x4 Welded Wire Panels: Fundamental Overview and Market Significance

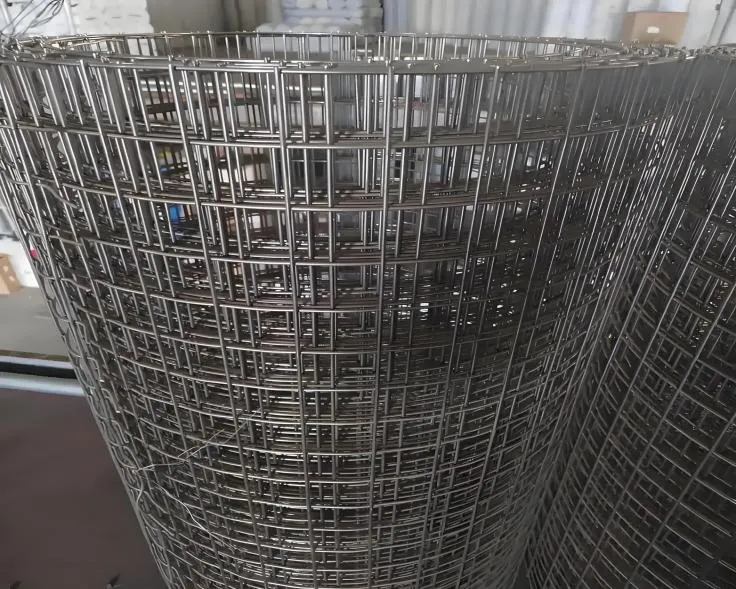

4x4 welded wire panels, along with closely related 4x4 welded wire mesh panels and 4x4 wire panels, have become essential components across construction, agricultural, industrial, and commercial applications. Characterized by their 4-inch by 4-inch mesh grid, these panels balance strength and open space, making them optimal for security fencing, animal enclosures, infrastructure reinforcement, and garden projects. Industry reports from 2022 show the global welded wire mesh market valued at $8.6 billion, with 4x4 panel variants comprising approximately 17% of total volume due to their unique balance between versatility and durability. Their widespread adoption is a testament to their cost-effectiveness and adaptability in a variety of demanding environments.

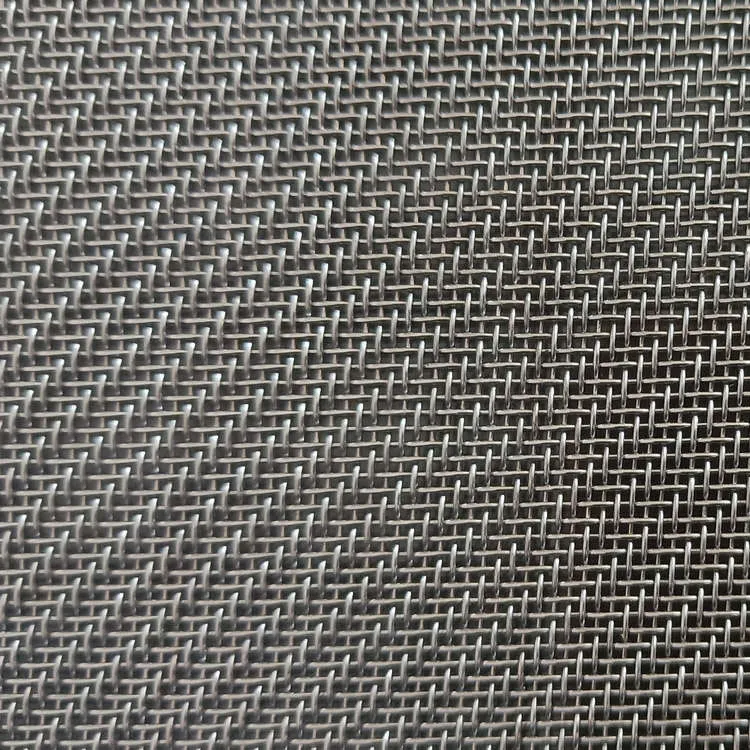

Technical Advantages: Engineered Performance and Design Excellence

Modern 4x4 welded wire mesh panels leverage advancements in metallurgy and welding to deliver exceptional strength-to-weight ratios. Typical panels use galvanized, stainless, or PVC-coated steel, providing resistance against rust, corrosion, and weathering, which extends lifespan by up to 35% over traditional wooden fencing alternatives. The welding process ensures consistent grid spacing and superior rigidity, ideal for load-bearing applications. With tensile strengths often exceeding 500 MPa and coatings conforming to ASTM A641/A641M standards, these panels require minimal maintenance during their 20-30 year average service life. Not only do these technologies reduce long-term costs, but they also deliver higher safety standards for high-traffic and high-security environments.

Manufacturer Comparison: Performance and Pricing Data Table

When sourcing 4x4 welded wire panels, key decision factors include material quality, production precision, availability of customizations, warranty, and after-sales support. The table below compares leading manufacturers to highlight product specifications, warranties, and delivered value:

| Manufacturer | Panel Size | Material | Coating | Tensile Strength (MPa) | Warranty | Avg. Price per Panel (USD) |

|---|---|---|---|---|---|---|

| MeshGuard Industries | 4'x8' | Galvanized Steel | Hot-Dip Galv. | 550 | 20 Years | $48 |

| WirePro Solutions | 4'x10' | Stainless Steel 304 | None | 600 | 25 Years | $82 |

| SteelNet Corp | 4'x6' | PVC-Coated Steel | Green PVC | 510 | 15 Years | $44 |

| Eagle Mesh Works | 4'x8' | Galvanized Steel | Electro-Galv. | 530 | 18 Years | $52 |

Note how custom sizing and advanced coatings impact both longevity and investment cost, with stainless steel panels commanding higher prices due to superior corrosion resistance. Regular product certifications and adherence to ISO 9001:2015 standards further differentiate major manufacturers.

Customization Solutions: Tailored Options for Diverse Industries

As project requirements grow ever more specific, manufacturers now offer bespoke 4x4 welded wire mesh panels tailored for unique loads, environments, and security ratings. Custom parameters include wire gauge (from 8 to 14), panel dimensions, mesh opening tolerances, and finishing options such as powder coating or specialized galvanization. For industrial automation or agriculture, custom cutouts and reinforced frames cater to mounting equipment or protecting livestock. Logistic companies often specify panels with integrated brackets or quick-assembly modular clips to accelerate installation in dynamic warehouse layouts. Over 60% of corporate clients now request customized solutions, seeking maximum efficiency and regulatory compliance. Streamlined digital ordering platforms now allow real-time CAD integration, reducing lead times and ensuring precise fit-to-purpose solutions.

Application Cases: Real-World Deployment in Core Sectors

The impact of 4x4 welded wire panels can be seen in transformative case studies across several industries. In transportation, large-scale infrastructure projects utilize these panels for bridge reinforcement and highway barriers, contributing to a 25% reduction in annual maintenance costs according to DOT statistics. Agricultural operators deploy customized panels in feedlots and aviaries, reporting improved animal welfare and biosecurity. In commercial settings, retail chains have transitioned to wire mesh partitioning for stockroom security, decreasing inventory shrinkage by 18% after implementation. Parks and recreation departments leverage the panels for playground and sports field enclosures, benefiting from extended lifecycles and lower repair frequency. These successes underline the panels’ adaptability and measurable value in both operational and financial metrics.

Installation Insights and Maintenance Strategies

Proper installation and maintenance are critical to unlocking the full lifespan and security performance of 4x4 welded wire panels. Data from field tests show that panels anchored with galvanized steel posts and anti-tamper fasteners withstand lateral loads of over 850 Newtons without deformation, ideal for high-security contexts. It's recommended to inspect panel joints and coating integrity annually—studies reveal diligent maintenance can extend operative lifespan by as much as 12%. For cleaning, using low-pressure water and non-abrasive detergents helps preserve coatings, while modular panel designs allow for rapid replacement in high-traffic or vandal-prone areas. Detailed installation manuals and QR-coded instructional resources have reduced field installation times by up to 22%, boosting contractor efficiency and reducing project downtime.

Future Trends and Innovations in 4x4 Welded Wire Panels

Looking ahead, the 4x4 welded wire panels market is anticipated to grow at a CAGR of 5.5% through 2030, propelled by innovations in composite materials, smart coating technologies, and digital supply chain integration. Emerging trends include self-healing polymer overlays, IoT-enabled security monitoring with embedded sensors, and environmentally sustainable manufacturing techniques that lower total lifecycle emissions by up to 30%. As regulatory emphasis on safety and resilience increases, these panels are evolving beyond mere enclosures, becoming integral to intelligent infrastructure. Stakeholders investing in high-quality, customizable welded wire panel solutions will continue to benefit from unmatched versatility, durability, and cutting-edge features, further cementing these products as industry mainstays.

(4x4 welded wire panels)

FAQS on 4x4 welded wire panels

Q: What are 4x4 welded wire panels?

A: 4x4 welded wire panels are metal mesh sheets with a 4x4 inch grid, commonly used for fencing and enclosures. They are formed by welding intersecting wires together. This construction ensures strength and stability.Q: What materials are 4x4 welded wire mesh panels made from?

A: 4x4 welded wire mesh panels are usually made from galvanized or stainless steel. These materials offer rust resistance and durability. They are suitable for both indoor and outdoor applications.Q: How can I use 4x4 wire panels?

A: 4x4 wire panels can be used for fencing, animal cages, garden trellises, and shelving. Their sturdy design makes them versatile for various construction projects. They are easy to install and cut to size.Q: Are 4x4 welded wire panels suitable for outdoor use?

A: Yes, most 4x4 welded wire panels are designed for outdoor use, especially when galvanized or coated. They can withstand weather and moisture. Regular maintenance extends their lifespan.Q: Can I cut 4x4 welded wire panels to fit specific dimensions?

A: Yes, you can easily cut 4x4 welded wire mesh panels with bolt cutters or wire snips. This allows for customized sizing according to your project needs. Always use safety gloves when cutting.Post time: Jul . 04, 2025 12:37