Stainless Steel Wire Mesh Filters: Tailored Solutions for Diverse Needs

We specialize in the production of custom - made filters, pressings, and filter elements, meticulously crafted to meet our customers' exact specifications. Our state - of - the - art facilities are equipped to handle various manufacturing processes, including welding, spot welding, seam welding, and press forming, ensuring the highest quality and precision in every product.

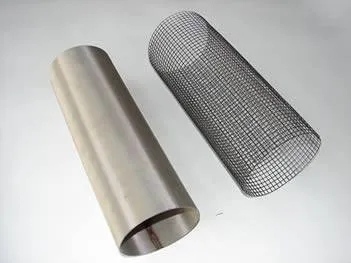

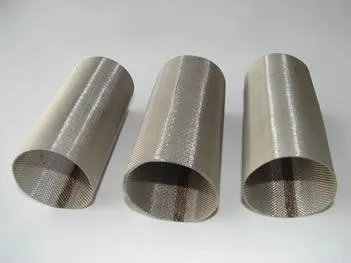

Filter Tubes, Filter Cylinders, and Filter Elements

Our range of wire cloth processed welded filter tubes, cylinders, and other filter elements is designed to provide efficient filtration solutions. We understand that different applications require different dimensions, which is why we offer the flexibility of customizing the width and length of these products according to your specific needs. Whether you need a small filter tube for a laboratory experiment or a large filter cylinder for industrial use, we've got you covered.

Additional Facilities and Products

In addition to our core filter products, we also offer high - speed cutting of stainless steel or plain discs. This, combined with our production of a variety of shaped screens, allows us to provide a comprehensive range of filtration components. These components can be supplied as individual parts or integrated in different combinations. We can create multi - layer screen packs by spot welding different meshes together or bind them with aluminium or stainless steel rims. Our spinneret filters, made with the same attention to detail and quality, are also available for specific applications that require fine filtration.

At our company, we are committed to delivering stainless steel wire mesh filter products that not only meet but exceed your expectations. With our advanced manufacturing capabilities and dedication to customization, we are your reliable partner for all your filtration needs. Whether you are in the chemical, pharmaceutical, food and beverage, or any other industry that requires high - quality filtration solutions, feel free to contact us to discuss your requirements and let us provide you with the perfect product.