- Overview and Introduction to Screen Mesh Stainless Steel

- Technical Advantages of Stainless Steel Screen Mesh

- Manufacturer Comparison: Quality, Pricing, and Features

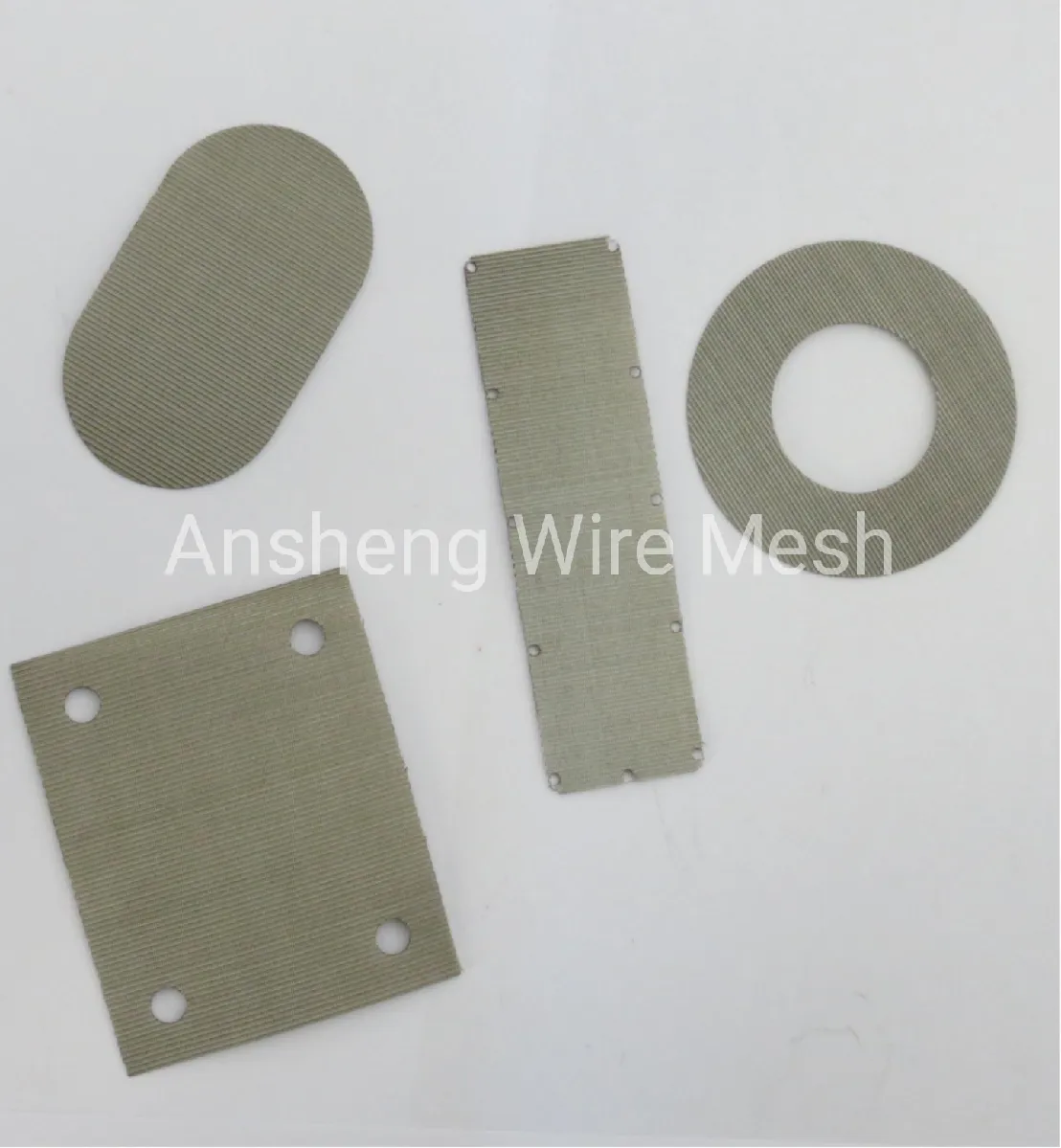

- Customization Solutions for Diverse Applications

- Real-World Applications and Case Studies

- Installation and Maintenance Guidelines

- Conclusion: Why Screen Mesh Stainless Steel Remains the Leading Choice

(screen mesh stainless steel)

Comprehensive Overview of Screen Mesh Stainless Steel

Screen mesh stainless steel, renowned for its exceptional durability and high-performance capabilities, is extensively utilized across residential, commercial, and industrial sectors. This product is engineered with precision to offer optimal protection, filtration, and visibility in varying environments.

The mesh is designed from high-grade stainless steel, which imparts outstanding corrosion resistance, making it the preferred choice for harsh weather conditions and demanding filtration tasks. Whether referred to as screen stainless steel mesh, fly screen stainless steel mesh, or fine screen mesh stainless steel

, the key benefits often overlap, encompassing strength, longevity, and minimal maintenance.

Among its broad range of applications, the mesh is found in security screens, window and door filters, pest control systems, industrial filtration, and ventilation projects. Its growing adoption arises from a rising consumer demand for resilient and safe screening solutions that maintain airflow and clarity of vision. Below, each aspect—from technical enhancements to real-world application—is examined to highlight its value proposition.

Technical Advantages of Stainless Steel Screen Mesh

The value of stainless steel mesh screens lies in their superior technical characteristics.

- Material Composition: Typically crafted from grade 304 or 316 stainless steel, these meshes exhibit advanced resistance to rust and chemical corrosion, even when exposed to marine or polluted environments.

- Strength Metrics: Stainless steel wire retains tensile strength exceeding 500 MPa, ensuring protection against cutting, puncturing, or deformation.

- Mesh Aperture Variability: Mesh counts range from 6–200 mesh per inch, with the finer mesh blocking insects and particles down to 0.1 mm in diameter without compromising air passage.

- Thermal and UV Stability: Unlike polymer alternatives, stainless mesh withstands thermal cycling and UV exposure, preserving structural integrity and clarity.

| Property | Stainless Steel Mesh | Polymer Mesh |

|---|---|---|

| Breaking Strength (MPa) | 500–700 | 70–120 |

| Operating Temperature (°C) | -100 to +600 | -30 to +80 |

| UV Resistance | Excellent (No Degradation) | Moderate (Degrades in Sunlight) |

| Corrosion Resistance (Salt Spray Hours) | > 2000 | < 100 |

| Mesh Aperture Consistency | ±2% | ±8% |

The data underlines the mesh’s efficacy in securing, filtering, and maintaining enduring performance. As a result, many industries classify stainless steel mesh as a "fit-and-forget" solution with a lifecycle exceeding 20 years under normal usage.

Comparative Analysis of Leading Manufacturers

When sourcing fine screen mesh stainless steel or heavy-duty variants, evaluating manufacturers is pivotal for ensuring quality, value, and after-sales support. Major global producers include Locker Group (Australia), Boegger Industrial Limited (China), and TWP Inc. (USA). Below is a detailed comparison:

| Manufacturer | Country | Material Grades | Mesh Range | Pricing (USD/m2) | Lead Time (Days) | Certifications |

|---|---|---|---|---|---|---|

| Locker Group | Australia | 304, 316, 316L | 10–200 | 25–45 | 10–20 | ISO 9001, AS 5039 |

| Boegger Industrial | China | 201, 304, 316 | 6–150 | 12–28 | 15–25 | ISO 9001, SGS |

| TWP Inc. | USA | 304, 316 | 12–250 | 30–48 | 7–15 | ISO 9001 |

Distinct differences are notable in terms of material selection, pricing, delivery speed, and compliance with regional safety standards. For large-scale industrial orders, lead time and certification significance become crucial. Professional buyers often procure samples from multiple vendors before finalizing bulk orders, ensuring that mesh tolerance, flatness, and weld quality meet specified benchmarks.

Tailored Customization Solutions for Unique Requirements

The versatility of screen stainless steel mesh is heightened through custom manufacturing, which offers clients a competitive edge and optimized performance. With advanced weaving and welding technology, manufacturers are able to deliver solutions based on:

- Mesh Count & Aperture: Customized down to 1/1000th of an inch for demanding filtration or specific pest exclusion.

- Panel Sizes & Shapes: Available in rolls, sheets, discs, and framed panels, accommodating intricate architectural and engineering designs.

- Specialty Coatings: Options such as black powder-coating for glare reduction or Teflon-lining for chemical resistance.

- Reinforcement Features: Crimped, welded, or double-layer configurations provide augmented strength where extreme forces or impacts are anticipated.

Real-World Applications & Success Stories

The adoption of fine screen mesh stainless steel is evidenced by a diverse spectrum of successful applications, demonstrating both functional and economic impact.

- Residential Security Screens: According to a 2023 survey by the International Security Association, homes fitted with stainless steel security mesh reported a 62% lower incidence of break-ins compared to conventional mesh screens.

- Industrial Filtration Plants: In large-scale water treatment facilities, the mesh's chemical resistance enabled continuous operations for over 24 months without replacement, reducing operational costs by 38%.

- Commercial Pest Protection: The hospitality industry has adopted fly screen stainless steel mesh on doors and window panels to achieve compliance with international hygiene regulations, eliminating >96% of airborne pest intrusions without chemical usage.

| Sector | Application | Outcomes |

|---|---|---|

| Residential | Security window and door screens | Break-in rates dropped 62%; 100% mesh integrity after 10 years |

| Industrial | Filtration in wastewater treatment | Operational lifespan extended by 24 months; 38% cost savings |

| Food & Beverage | Hygienic fly screen barriers | Regulatory compliance; >96% pest control efficiency |

| Architecture | Decorative building façades | Durability in coastal climate; corrosion-free for 15+ years |

These data-driven cases emphasize why industries depend on the robust, adaptable performance of stainless steel screen mesh in mission-critical and high-visibility roles.

Best Practices for Installation and Maintenance

Maximizing the performance of fly screen stainless steel mesh begins with precise installation and is sustained by minimal but effective maintenance routines.

- Proper Fitting: Always use correctly dimensioned frames or clamps to avoid mesh distortion. Fasten with rustproof screws or rivets for structural reliability.

- Cleaning: Routine washing with mild detergent and water removes environmental deposits, pollutants, and biological matter, preserving airflow and translucency.

- Inspection Protocol: Annual inspections detect rare cases of frame corrosion or accidental damage, allowing for prompt remediation before performance is affected.

- Repair & Replacement: Small tears or bent sections can be spot-repaired using dedicated stainless clips or patch kits, extending overall system lifespan and reducing costs.

The Enduring Value of Screen Mesh Stainless Steel in Modern Applications

In conclusion, screen mesh stainless steel and its specialized forms—screen stainless steel mesh, fly screen stainless steel mesh, and fine screen mesh stainless steel—stand as benchmarks for quality, endurance, and versatility. Through rigorous technical enhancements and value-adding customization, they meet ever-evolving requirements of security, hygiene, and industrial filtration while delivering tangible ROI across project scales.

As evidenced by comparative tables and real-world deployments, these meshes outperform alternatives in resilience, lifespan, and ease of maintenance. When procuring next-generation screening solutions, integrating screen mesh stainless steel ensures reduced risk, lower lifecycle costs, and sustained operational superiority.

Ultimately, the choice of stainless steel mesh is an investment in safety, efficiency, and peace of mind, attested by data and trusted by market leaders worldwide.

(screen mesh stainless steel)

FAQS on screen mesh stainless steel

Q: What are the main advantages of using screen mesh stainless steel?

A: Screen mesh stainless steel is highly durable, corrosion-resistant, and can withstand harsh environments. Its strength ensures long-term performance, making it ideal for security and filtering applications.Q: Can screen stainless steel mesh be used for insect and fly screens?

A: Yes, fly screen stainless steel mesh is perfect for keeping out insects while allowing airflow and visibility. It is rust-resistant and suitable for both indoor and outdoor use.Q: What applications require fine screen mesh stainless steel?

A: Fine screen mesh stainless steel is used in filtration, sieving, and protection where fine particle separation is needed. Industries like food processing, pharmaceuticals, and chemical processing often use it.Q: How do I clean and maintain a stainless steel screen mesh?

A: Cleaning is easy: simply wash with mild soap and water, then rinse and dry. Regular cleaning maintains its appearance and prevents buildup or corrosion.Q: Is screen stainless steel mesh customizable in terms of size and weave?

A: Yes, screen stainless steel mesh is available in various sizes, mesh counts, and weave patterns to meet different requirements. Custom options ensure an optimal solution for any project.Post time: Jul . 05, 2025 08:02