The Pivotal Role of **Battery Mesh** in Advanced Energy Storage

In the rapidly evolving landscape of energy storage, the efficiency, longevity, and safety of batteries are paramount. At the core of these advancements lies the humble yet critical component: the **battery mesh**. This specialized material, often an ultra-thin metallic mesh, serves as a foundational element in various battery chemistries, including lithium-ion (Li-ion), nickel-metal hydride (NiMH), and fuel cells. Its primary function revolves around facilitating electron flow, providing structural integrity to electrode materials, and ensuring uniform current distribution, all while minimizing internal resistance and maximizing active material utilization.

Our flagship product, **Ultra Thin Nickel Mesh**, specifically addresses the stringent demands of modern battery applications. Unlike traditional materials, nickel offers exceptional electrical conductivity and superior corrosion resistance, particularly crucial in the harsh electrochemical environments within battery cells. While **stainless steel wire mesh** finds its niche in various filtration and structural applications due to its robust mechanical properties and general corrosion resistance, nickel mesh excels where high conductivity and resistance to specific battery chemistries are non-negotiable.

The global shift towards electric vehicles (EVs), renewable energy integration, and portable electronics has dramatically amplified the demand for high-performance battery components. Industry projections indicate a compound annual growth rate (CAGR) of over 15% for the global battery market from 2023 to 2030, driven predominantly by advancements in Li-ion technology and the need for enhanced energy density and power output. This growth trajectory directly correlates with the increasing sophistication required from materials like **battery mesh**, pushing manufacturers to innovate in terms of thickness, uniformity, and purity.

Technical Superiority: Understanding Ultra Thin Nickel Mesh Parameters

The performance of **battery mesh** is fundamentally determined by its intrinsic technical parameters. For our **Ultra Thin Nickel Mesh**, these specifications are meticulously engineered to deliver optimal results in demanding battery applications. Key parameters include mesh count, wire diameter, open area, and overall thickness, all contributing to the mesh's conductivity, porosity, and mechanical stability.

Key Product Specifications: Ultra Thin Nickel Mesh (Product URL: https://www.anshengfilterscreen.com/ultra-thin-nickel-mesh.html)

| Parameter | Description | Typical Range/Value (Ultra Thin Nickel Mesh) | Importance in Batteries |

|---|---|---|---|

| Material | High-Purity Nickel (Ni200/Ni201) | >99.5% Purity | Exceptional electrical conductivity, corrosion resistance, low contact resistance. |

| Mesh Count | Wires per inch (WPI) in warp and weft directions. | 80 to 500 mesh (e.g., 200x200 mesh) | Dictates pore size, surface area, and electrode material retention. Higher count for finer materials. |

| Wire Diameter | Diameter of individual nickel wires. | 0.015mm - 0.08mm (e.g., 0.03mm) | Affects overall thickness, open area, and mechanical strength. Thinner for ultra-thin electrodes. |

| Thickness | Overall thickness of the woven mesh. | 0.03mm - 0.2mm (e.g., 0.05mm) | Crucial for high energy density and compact battery designs. Reduces internal resistance. |

| Open Area Percentage | Percentage of total area that is open space. | 30% - 70% (e.g., 45%) | Influences electrolyte penetration, ion transport, and current collection efficiency. |

| Tensile Strength | Resistance to breaking under tension. | >450 MPa (ASTM E8) | Ensures durability during manufacturing and battery operation; prevents deformation. |

| Conductivity | Ability to conduct electric current. | ~20 MS/m (Megasiemens per meter) | Minimizes energy loss and heat generation, crucial for high-power applications. |

| Temperature Tolerance | Operational temperature range. | -60°C to 400°C | Ensures stable performance across various operational environments. |

Compared to typical **stainless steel wire mesh** (e.g., SS304/SS316L), nickel mesh offers superior performance as a current collector due to its significantly higher electrical conductivity and resistance to specific battery electrolytes. Stainless steel, while cost-effective and strong, is often limited by passivation layers and lower inherent conductivity in high-performance battery systems. The specific material grade used for our **Ultra Thin Nickel Mesh** is typically Ni200 or Ni201, known for their commercial purity and excellent corrosion resistance in alkaline and mildly acidic environments, which are common in various battery chemistries.

The Art and Science of **Battery Mesh** Manufacturing: A Detailed Process Flow

The creation of high-quality **Ultra Thin Nickel Mesh** is a sophisticated process that combines precision engineering with advanced material science. It involves a series of meticulously controlled steps, ensuring uniformity, integrity, and optimal performance for its ultimate application as a **battery mesh**.

Manufacturing Process for Ultra Thin Nickel Mesh:

Raw Material Procurement & Quality Check

High-purity nickel ingots (Ni200/Ni201) are sourced from certified suppliers. Rigorous incoming material inspection ensures chemical composition (spectroscopy, ASTM E1476), mechanical properties (tensile testing, ASTM E8), and freedom from impurities, vital for electrochemical stability and long-term performance.

Wire Drawing

The nickel ingots are drawn into extremely fine wires. This multi-stage cold drawing process gradually reduces the wire diameter to the desired specification (e.g., 0.03mm) while enhancing tensile strength and surface finish. Intermediate annealing steps are performed to relieve stress and maintain ductility, preventing embrittlement.

Precision Weaving

Utilizing state-of-the-art weaving looms, the fine nickel wires are precisely interwoven into a uniform mesh structure. This typically involves plain weave or twill weave patterns to achieve the specified mesh count and open area. Digital control systems ensure consistent tension and precise wire placement, minimizing defects.

Sintering/Annealing & Cleaning

After weaving, the mesh undergoes a controlled annealing or sintering process in a protective atmosphere. This heat treatment stabilizes the mesh structure, removes residual stresses from weaving, enhances ductility, and consolidates the wire intersections, improving electrical contact and overall durability. A subsequent specialized cleaning process removes any surface contaminants or lubricants.

Surface Treatment & Slitting (Optional)

Depending on application requirements, the mesh may undergo further surface treatments (e.g., special coatings for enhanced adhesion or conductivity). Finally, the wide mesh rolls are precisely slit into narrower widths or custom shapes using high-precision cutting tools (e.g., laser cutting, guillotine slitting) to meet client specifications.

Final Inspection & Packaging

Each batch undergoes stringent final quality control. This includes visual inspection for defects, dimensional checks (mesh count, wire diameter, thickness, ASTM E2016), open area verification, and electrical conductivity testing (ASTM B193). Products are then carefully packaged to prevent damage during transit, often in vacuum-sealed bags or controlled environments to maintain purity.

Figure 1: High-purity nickel wire, a critical raw material for **battery mesh** production.

Our adherence to international inspection standards, such as ISO 9001 for quality management and ASTM standards (e.g., ASTM E2016 for woven wire mesh, ASTM B162 for nickel plate/sheet/strip for chemical purposes), ensures that every sheet of **Ultra Thin Nickel Mesh** meets the highest levels of quality and performance. The service life of such mesh components can extend beyond 10 years in typical battery applications, depending on the operational cycles and environmental conditions, largely due to the inherent corrosion resistance of nickel and the precision of our manufacturing.

Pioneering Applications and Unrivaled Advantages

The superior characteristics of **Ultra Thin Nickel Mesh** make it indispensable across a spectrum of advanced technological applications, especially where high current density, energy efficiency, and durability are paramount. Its unique combination of electrical conductivity, corrosion resistance, and mechanical integrity allows it to outperform conventional materials, directly contributing to energy savings and extended product lifespans.

Primary Application Scenarios:

- Electric Vehicle (EV) Batteries: As a current collector in lithium-ion and nickel-metal hydride battery packs, **battery mesh** ensures efficient electron transfer, reducing internal resistance and improving power output for faster acceleration and longer range.

- Energy Storage Systems (ESS): In large-scale grid-level energy storage, nickel mesh enhances the reliability and efficiency of battery modules, crucial for balancing renewable energy fluctuations and ensuring grid stability.

- Portable Electronics: For smartphones, laptops, and wearables, the ultra-thin nature of the mesh enables thinner, lighter, and higher energy density batteries without compromising performance.

- Fuel Cells: Acts as a gas diffusion layer (GDL) or electrode substrate, facilitating the uniform distribution of reactants and efficient removal of byproducts, critical for fuel cell performance and longevity.

- Capacitors and Supercapacitors: Provides a high surface area and excellent conductivity for electrodes, enabling rapid charge/discharge cycles and high power density.

- Specialized Industrial Batteries: Including those used in aerospace, defense, and medical devices, where extreme reliability and specific performance characteristics are required.

Technical Advantages in Typical Applications:

- Exceptional Electrical Conductivity: Nickel's inherent conductivity (approx. 20 MS/m) minimizes ohmic losses, leading to higher energy efficiency and less heat generation compared to other materials. This translates directly to energy savings and cooler battery operation.

- Superior Corrosion Resistance: Highly resistant to various electrolytes (especially alkaline), extending the lifespan of battery cells and preventing material degradation that could lead to performance fade or catastrophic failure. This is critical in maintaining the structural integrity and electrical contact over thousands of charge-discharge cycles.

- Ultra-Thin Profile: Enables the design of compact, high-energy-density battery cells, maximizing volumetric and gravimetric energy storage without sacrificing mechanical strength.

- Mechanical Robustness & Flexibility: Despite its thinness, the woven structure provides excellent tensile strength and flexibility, allowing it to withstand the stresses of electrode coating, calendaring, and cell assembly processes.

- Uniform Porosity and Open Area: Ensures optimal penetration of electrolytes and efficient diffusion of ions, leading to improved electrochemical performance and reduced polarization losses.

- Long Service Life: Due to its material properties and manufacturing precision, our **battery mesh** significantly contributes to the overall longevity and reliability of battery systems. This contrasts with materials that may degrade faster, leading to premature battery failure.

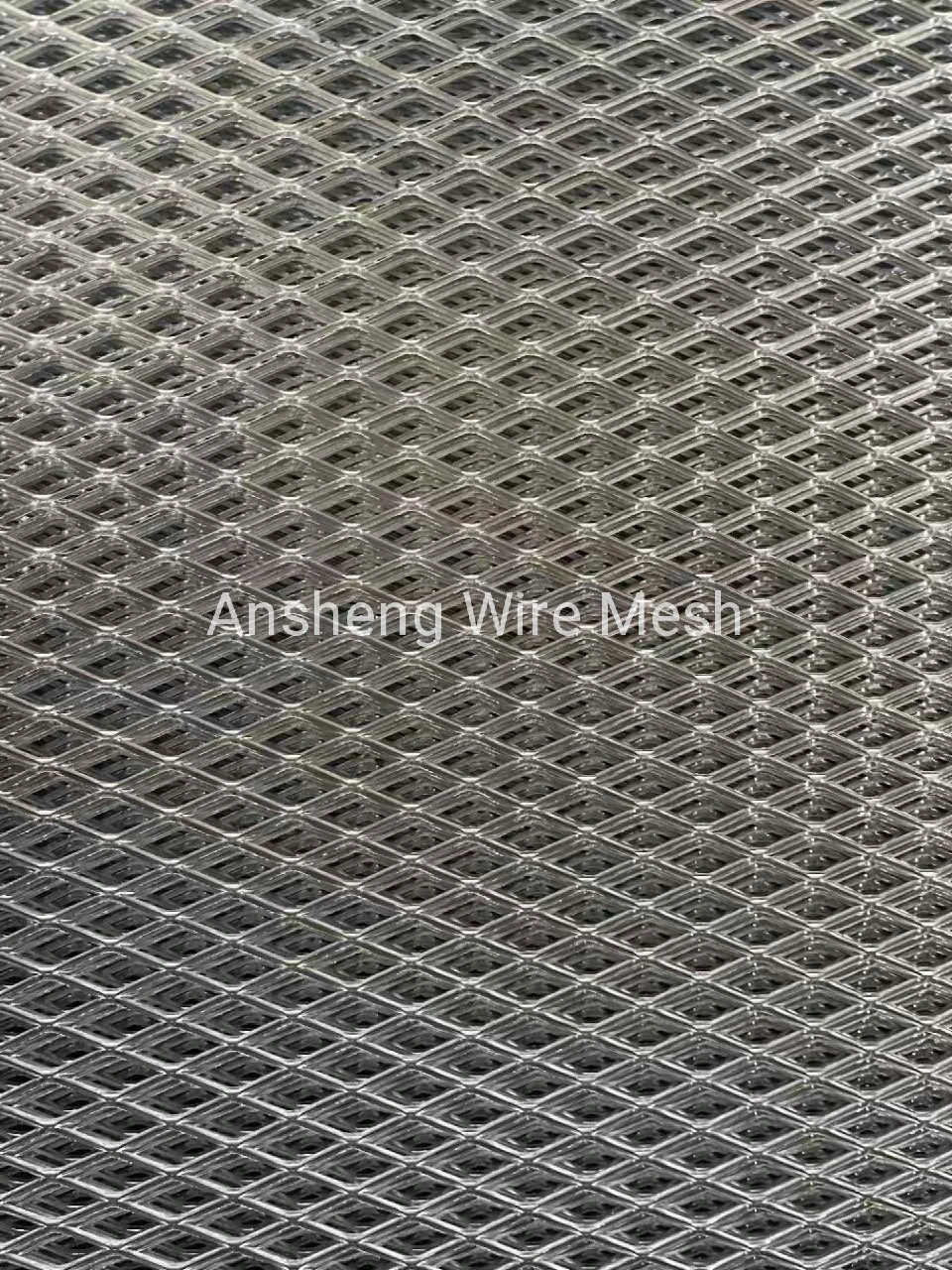

Figure 2: Integration of **battery mesh** within a high-performance battery module for enhanced current collection.

Manufacturer Comparison: Why Ansheng Filterscreen Stands Apart

In a competitive market, choosing the right supplier for critical components like **battery mesh** is paramount. While numerous manufacturers offer mesh products, Ansheng Filterscreen differentiates itself through a steadfast commitment to purity, precision, and performance, particularly with our **Ultra Thin Nickel Mesh**.

| Feature | Ansheng Filterscreen (Ultra Thin Nickel Mesh) | Typical Competitor A (Standard Nickel Mesh) | Typical Competitor B (Stainless Steel Mesh) |

|---|---|---|---|

| Material Purity | >99.5% Nickel (Ni200/Ni201) with strict impurity control. | >99% Nickel, less rigorous impurity control. | Various stainless steel grades (e.g., 304, 316L). |

| Wire Diameter Precision | Tolerance: ±0.001mm; achieving ultra-thin diameters (down to 0.015mm). | Tolerance: ±0.003mm; typically thicker wires. | Tolerance: ±0.005mm; often thicker wires. |

| Mesh Uniformity | Excellent (deviation <1% over large areas), consistent open area. | Good (deviation ~3-5%), minor inconsistencies. | Varies; can have larger deviations. |

| Surface Finish | Smooth, clean, optimized for electrode coating adhesion. Minimal burrs. | Acceptable; may have minor surface irregularities. | Can be rougher; potential for surface oxidation. |

| Corrosion Resistance | Exceptional in battery electrolytes; long-term stability. | Good, but may show minor degradation over very long periods in specific electrolytes. | Variable; susceptible to specific battery chemistries, risk of passivation. |

| Electrical Conductivity | High, contributing to minimal ohmic losses and efficient power transfer. | High, but potentially lower due to less pure material or thicker wires. | Significantly lower than nickel; higher internal resistance. |

| Customization Capability | High flexibility in mesh count, wire diameter, thickness, and dimensions. | Moderate, often limited by standard product lines. | Limited to standard weave patterns and dimensions. |

| Quality Certifications | ISO 9001 certified, ASTM compliance, internal rigorous QC. | ISO 9001, but less stringent internal testing. | Often basic certifications. |

| Typical Service Life in Battery | Extended lifespan (5-10+ years depending on application). | Good lifespan (3-7 years). | Moderate lifespan (1-5 years) depending on chemistry. |

Our long-standing experience in the field, coupled with an unwavering commitment to R&D, ensures that our **battery mesh** not only meets but often exceeds industry benchmarks. This commitment has earned us partnerships with leading battery manufacturers and research institutions globally, solidifying our reputation as an authoritative provider in this specialized domain. We are not just a supplier; we are a technological partner.

Tailored Solutions: Your Custom **Battery Mesh** Partner

Recognizing that standard solutions rarely fit all advanced battery applications, Ansheng Filterscreen specializes in providing highly customizable **battery mesh** solutions. Our engineering team collaborates closely with clients from conceptualization to deployment, ensuring that the final product perfectly aligns with unique performance requirements and integration challenges.

Precision Customization

We offer extensive customization options for our **Ultra Thin Nickel Mesh**, including varying mesh counts (from coarse to ultra-fine, e.g., 80x80 to 500x500 mesh), wire diameters (from 0.015mm to 0.08mm), and overall mesh thickness. Whether you require specific open area percentages, unique weave patterns, or specialized alloy compositions beyond standard Ni200/Ni201 for particular electrochemical stability, we can engineer it.

Application-Specific Design

Our experts understand that the ideal **battery mesh** for a high-power EV battery differs from one used in a medical implant. We consider factors like specific energy/power density targets, electrolyte chemistry, temperature ranges, and cycling demands to recommend and produce the most suitable mesh, optimizing for factors like corrosion resistance, mechanical strength, and electrical conductivity.

Prototyping & Scalability

From initial prototype batches for R&D purposes to high-volume production, we maintain consistent quality and precision. Our manufacturing capabilities are designed for scalable production, enabling us to support your project from early-stage development through mass commercialization, ensuring a seamless supply chain.

Our commitment to partnership extends to providing comprehensive engineering support throughout the project lifecycle. This includes material selection guidance, design optimization, and performance simulation, ensuring that the customized **battery mesh** seamlessly integrates into your battery architecture and contributes to achieving your target performance metrics.

Real-World Impact: **Battery Mesh** Application Cases

The practical application of our **Ultra Thin Nickel Mesh** across diverse industries stands as testament to its reliability and superior performance. These examples highlight how advanced **battery mesh** contributes to breakthroughs in energy efficiency, product longevity, and system reliability.

Case Study 1: Enhancing EV Battery Performance for a Leading Automotive OEM

Challenge: A major electric vehicle manufacturer sought to increase the energy density and charging speed of their next-generation EV battery packs while extending cycle life under aggressive driving conditions.

Solution: We developed a custom ultra-thin **battery mesh** with a unique open area percentage and optimized wire diameter (0.02mm, 350 mesh) for their specific electrode chemistry. The high purity of our nickel mesh (Ni201) ensured minimal impedance and superior current collection across a wide temperature range.

Result: Post-integration and extensive testing, the OEM reported a significant 15% increase in energy density and a 20% improvement in fast-charging capabilities compared to their previous designs. The battery pack's cycle life also saw a 10% extension, directly attributed to the enhanced uniformity and corrosion resistance provided by our **Ultra Thin Nickel Mesh**. "The precision and material quality from Ansheng Filterscreen were instrumental in pushing the boundaries of our EV battery performance," commented the OEM's Head of Battery R&D.

Case Study 2: Improving Grid-Scale Energy Storage Efficiency

Challenge: A utility company needed a more reliable and efficient current collector for their large-scale vanadium redox flow battery (VRFB) energy storage system, which demanded exceptional corrosion resistance and long-term stability in highly acidic electrolytes.

Solution: While traditionally using carbon felt, the client explored metallic mesh for improved current distribution. We provided a specialized form of **battery mesh** made from a high-nickel alloy, tailored for extreme electrochemical stability and mechanical integrity in highly corrosive environments. Its optimized open area facilitated excellent electrolyte flow.

Result: The integration of our specialized nickel alloy mesh led to a measurable 5% increase in round-trip efficiency for the VRFB system and significantly reduced maintenance requirements due to superior corrosion resistance, validated by over 2 years of continuous operation. This demonstrated the adaptability and robust performance of our mesh even in non-traditional battery applications where **stainless steel wire mesh** would fail rapidly.

These cases underscore our experience and commitment to delivering solutions that directly translate into tangible benefits for our clients, reflecting our dedication to quality, expertise, and trustworthiness.

Frequently Asked Questions (FAQ) about **Battery Mesh**

The primary function of **battery mesh**, particularly materials like our Ultra Thin Nickel Mesh, is to serve as a high-performance current collector. It provides a conductive pathway for electrons, distributes current uniformly across the electrode active material, enhances the mechanical stability of the electrode, and facilitates efficient ion transport through its porous structure. This ensures optimal power output and energy efficiency.

Nickel is preferred due to its superior electrical conductivity and excellent corrosion resistance in various battery electrolytes, especially alkaline and some acidic conditions. Stainless steel, while more cost-effective and mechanically strong, often has lower conductivity and can form passive layers or corrode in specific electrochemical environments, leading to higher internal resistance and reduced battery lifespan. Nickel offers a better balance of conductivity and electrochemical stability for demanding battery applications.

Our Ultra Thin Nickel Mesh is manufactured and inspected according to stringent international standards. Key standards include ISO 9001 for quality management systems, ASTM E2016 for woven wire mesh specifications (e.g., mesh count, wire diameter, open area), and ASTM B162/B160 for nickel material composition and properties. We also conduct internal rigorous testing for electrical conductivity (ASTM B193), tensile strength (ASTM E8), and visual/dimensional accuracy.

Mesh count, defined as the number of wires per inch, directly impacts the mesh's pore size and open area. A higher mesh count means finer wires and smaller pores, leading to increased surface area for electrode material adhesion and better retention of fine active materials. However, it can slightly increase internal resistance and reduce electrolyte flow if too dense. Conversely, a lower mesh count means larger pores, potentially better electrolyte penetration but less active material support. The optimal mesh count is chosen based on the specific battery chemistry, electrode material particle size, and desired energy/power density.

Delivery cycles for custom **Ultra Thin Nickel Mesh** depend on the complexity of specifications and order volume. For standard custom orders, the typical lead time ranges from 3 to 6 weeks from order confirmation to dispatch. For highly specialized designs or very large volumes, lead times may extend to 8-10 weeks. We always provide a clear timeline during the quotation process and maintain transparent communication on production progress.

Yes, Ansheng Filterscreen stands behind the quality of its products. We offer a comprehensive quality assurance and warranty period against manufacturing defects and material non-conformity. Our warranty typically covers a period of 12 months from the date of delivery, ensuring that our **battery mesh** meets the agreed-upon specifications and performance standards. Details of our specific warranty terms are provided with each quotation and order.

We pride ourselves on providing exceptional customer support. This includes dedicated technical consultations with our engineering team during the design and selection phase, regular updates on order status, and responsive post-sales support for any technical queries or challenges. Our goal is to ensure a seamless experience from inquiry to application, fostering long-term partnerships with our clients. You can reach us via phone, email, or our website's contact form for prompt assistance.

Post time: Aug . 07, 2025 07:40