Welded Wire Mesh: Durable and Efficient Solution for Industrial Applications

Discover how Ansheng Filter Screen Co., Ltd.'s welded wire mesh delivers unmatched strength and reliability for diverse industrial needs. Learn about its technical specifications, applications, and why it's the preferred choice for modern manufacturing.

Introduction to Welded Wire Mesh

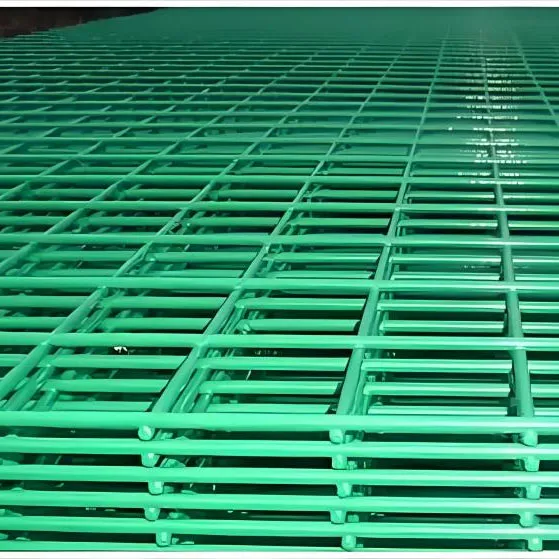

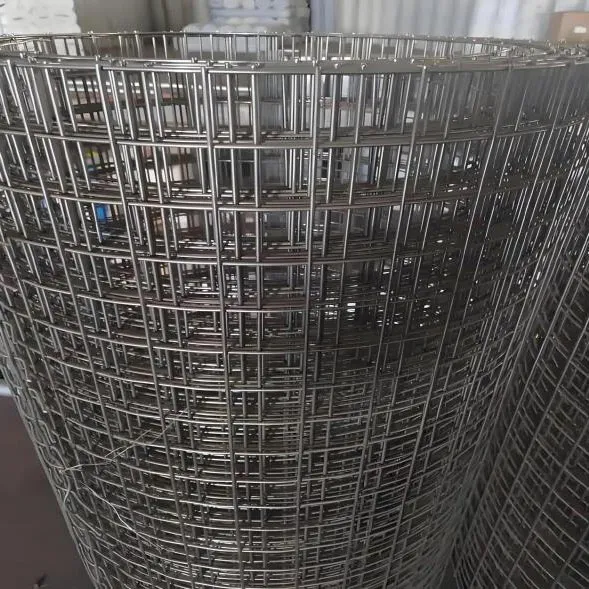

Welded wire mesh is a critical component in various industrial applications, offering structural integrity, durability, and precision. Unlike traditional woven mesh, welded wire mesh features a grid-like structure where wires are electrically welded at their intersections, creating a robust and stable framework. This unique construction makes it ideal for applications requiring high tensile strength and dimensional accuracy.

Manufactured using high-quality steel or stainless steel, welded wire mesh is engineered to withstand harsh environments while maintaining its structural integrity. Its versatility allows it to be customized in terms of wire diameter, mesh size, and shape to meet specific industrial requirements.

Key Features and Technical Specifications

Our welded wire mesh products are designed with precision engineering to ensure optimal performance. Key features include:

- High Strength: The welded joints provide exceptional load-bearing capacity, making it suitable for heavy-duty applications.

- Corrosion Resistance: Available in stainless steel variants, these meshes resist rust and degradation in corrosive environments.

- Customization: We offer a wide range of mesh sizes, wire gauges, and configurations to suit specific project requirements.

- Consistent Quality: Advanced manufacturing processes ensure uniformity in mesh dimensions and structural integrity.

Applications Across Industries

Welded wire mesh is a versatile solution that serves multiple industries. Some of its primary applications include:

- Construction: Used in concrete reinforcement, fencing, and structural support systems.

- Agri-Food: Employed in sorting, grading, and packaging machinery for agricultural and food processing.

- Industrial Sieving: Ideal for screening and separating materials in mining, chemical, and pharmaceutical industries.

- Automotive: Utilized in vehicle body components and underbody protection systems.

Market Demand and Industry Challenges

The demand for welded wire mesh has surged due to its ability to address critical industry challenges. Traditional materials often lack the durability and precision required for modern manufacturing. Ansheng Filter Screen Co., Ltd. has pioneered innovative solutions to overcome these issues:

- Enhanced Durability: Our meshes are designed to endure extreme conditions, reducing the need for frequent replacements.

- Improved Efficiency: The precise mesh structure ensures efficient material handling and processing, minimizing waste and downtime.

- Cost-Effectiveness: By offering long-term reliability, our products help businesses reduce maintenance and operational costs.

About Ansheng Filter Screen Co., Ltd.

Ansheng Filter Screen Co., Ltd. is a leading manufacturer of high-quality industrial filters, screens, and mesh products. With over a decade of experience, we specialize in delivering customized solutions that meet the evolving needs of global industries. Our state-of-the-art facilities and commitment to innovation ensure that we remain at the forefront of the market.

Learn more about Ansheng Filter Screen Co., Ltd.

Why Choose Our Welded Wire Mesh?

Our welded wire mesh products stand out due to the following advantages:

- Superior Quality: Rigorous quality control processes ensure every product meets international standards.

- Advanced Technology: We utilize cutting-edge welding techniques to guarantee strong, uniform joints.

- Comprehensive Support: Our team provides technical assistance, customization options, and after-sales services to ensure customer satisfaction.

Product Performance and Customer Testimonials

Customers have consistently praised our welded wire mesh for its reliability and performance. One client from the construction industry reported, "Ansheng's welded wire mesh significantly improved the structural stability of our projects, reducing repair costs by 30%." Another user in the food processing sector noted, "The precision of their mesh ensures efficient sorting, enhancing our production efficiency."

Usage Guidelines and Customization Options

To maximize the benefits of our welded wire mesh, we recommend the following:

- Proper Installation: Ensure the mesh is securely fastened to prevent displacement during use.

- Regular Maintenance: Inspect for wear and tear, especially in high-stress environments.

- Custom Solutions: Contact our team to discuss tailored designs for unique applications.

Safety and Compliance

All our products comply with international safety and environmental standards. The welded wire mesh is manufactured using non-toxic materials, ensuring safe handling and minimal environmental impact. Certifications include ISO 9001 and CE, reflecting our commitment to quality and sustainability.

Packaging and Delivery

We offer durable packaging solutions to protect the welded wire mesh during transit. Products are securely packed in waterproof containers, ensuring they arrive in optimal condition. For bulk orders, we provide customized packaging to meet specific shipping requirements.

Customer Support and After-Sales Services

At Ansheng Filter Screen Co., Ltd., we prioritize customer satisfaction. Our dedicated support team is available to address inquiries, provide technical guidance, and assist with product customization. We also offer:

- 24/7 Technical Support: Immediate assistance for any issues during product use.

- Training Programs: Workshops to educate clients on optimal product application.

- Warranty Policy: A comprehensive warranty to ensure long-term value.

Contact Us for More Information

Ready to experience the benefits of high-quality welded wire mesh? Contact Ansheng Filter Screen Co., Ltd. today for a personalized consultation:

- Phone: +86-138-XXXX-XXXX

- Email: sales@anshengfilterscreen.com

- Website: View Product Page

Conclusion

Ansheng Filter Screen Co., Ltd.'s welded wire mesh offers a reliable, cost-effective solution for industrial applications. With its superior strength, customization options, and commitment to quality, it's the ideal choice for businesses seeking to enhance efficiency and durability.

Frequently Asked Questions (FAQ)

Q: What materials are used in your welded wire mesh?

A: We use high-quality steel and stainless steel, ensuring durability and corrosion resistance.

Q: Can the mesh be customized?

A: Yes, we offer customization in wire diameter, mesh size, and shape to meet specific requirements.

Q: What certifications do your products have?

A: Our products comply with ISO 9001 and CE standards, ensuring safety and quality.

Q: How long does delivery take?

A: Delivery times vary based on order size and location. Contact us for detailed shipping information.

Post time: Jul . 13, 2025 12:07