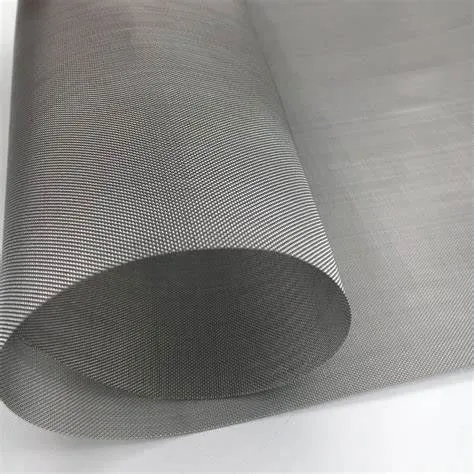

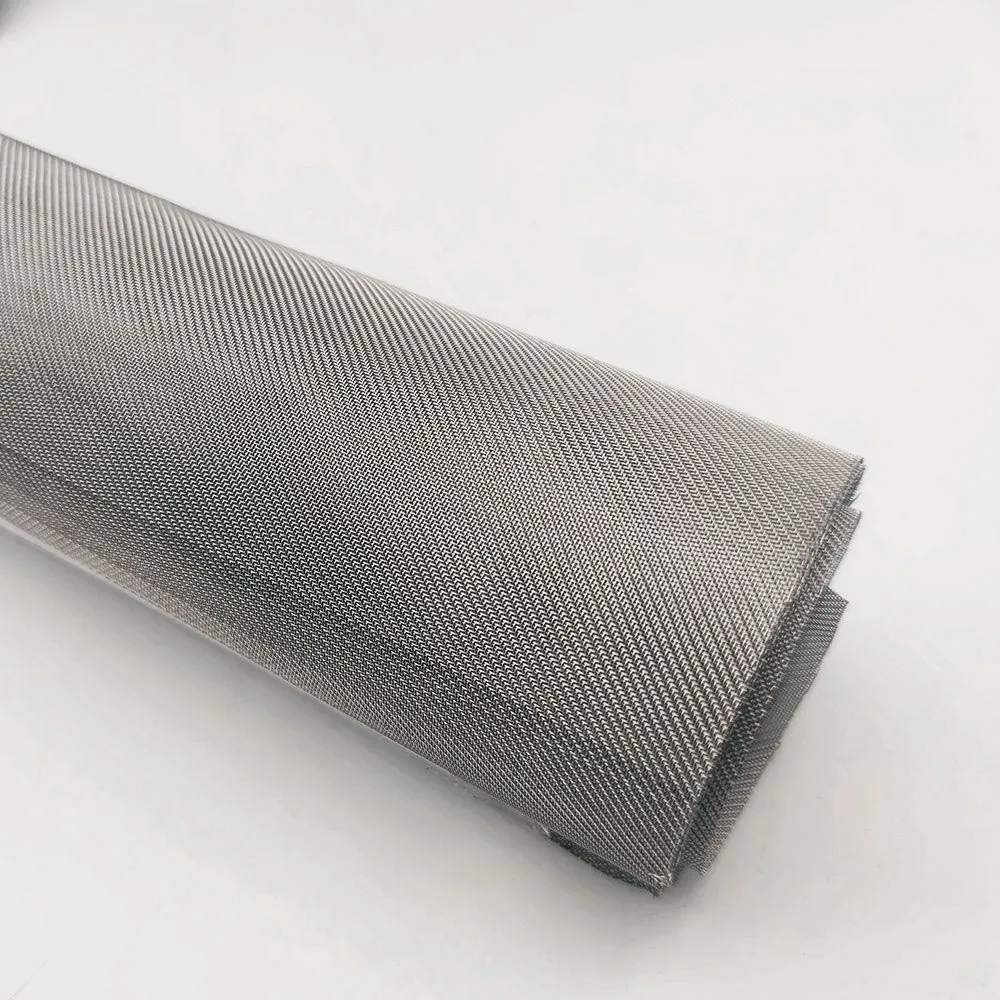

Nickel Twill Weave Wire Mesh: High-Performance Solution for Industrial Filtration

As a leading manufacturer in the filtration industry, Ansheng Filter Screen Co., Ltd. offers innovative solutions to meet the demanding requirements of modern industrial applications. Our Nickel Twill Weave Wire Mesh combines advanced metallurgical engineering with precision manufacturing to deliver superior performance in challenging environments.

Product Overview and Technical Specifications

The Nickel Twill Weave Wire Mesh is engineered with a unique twill weave pattern that enhances its structural integrity while maintaining optimal flow characteristics. This specialized weaving technique creates a balanced combination of strength, flexibility, and filtration efficiency. The mesh is manufactured from high-purity nickel alloy, offering exceptional resistance to corrosion, high-temperature environments, and chemical degradation.

Key technical specifications include:

- Material: High-purity nickel alloy

- Weave Pattern: Twill weave for enhanced durability

- Mesh Size: Customizable to meet specific filtration requirements

- Surface Finish: Smooth and uniform for consistent performance

- Temperature Resistance: Up to 800°C (1472°F)

Industrial Applications and Market Demand

Our Nickel Twill Weave Wire Mesh is widely used in critical industrial applications where reliability and performance are paramount. Key industries include:

- Chemical processing: For high-temperature and corrosive environments

- Energy production: In gas turbines and heat exchangers

- Metal refining: For molten metal filtration

- Aerospace: In high-stress components requiring dimensional stability

The global filtration market is experiencing significant growth due to increasing demands for efficiency and sustainability. Traditional filtration materials often struggle with maintaining performance under extreme conditions, leading to frequent replacements and increased operational costs. Our nickel mesh provides a durable, long-lasting solution that reduces maintenance requirements and enhances system reliability.

Company Expertise and Technological Innovation

Ansheng Filter Screen Co., Ltd. has established itself as a premier supplier of specialized filtration solutions. With over 15 years of experience in the industry, we have developed proprietary manufacturing techniques that ensure consistent quality and performance. Our state-of-the-art facilities are equipped with advanced metallurgical testing equipment to guarantee that every product meets stringent industry standards.

Our R&D team continuously innovates to improve product performance. Recent advancements include:

- Enhanced surface treatment processes for improved chemical resistance

- Custom mesh design software for precise specifications

- Automated quality control systems for consistent production

Proven Performance and Customer Testimonials

Customers across various industries have reported significant improvements in system performance after switching to our Nickel Twill Weave Wire Mesh. One major chemical processing plant in Germany reported a 40% reduction in maintenance costs and a 25% increase in operational efficiency. Another client in the energy sector noted improved heat transfer efficiency in their turbine systems.

John Smith, Operations Manager at TechChem Industries, states: "The reliability of Ansheng's nickel mesh has transformed our filtration processes. We've experienced fewer system downtime incidents and improved product quality."

Implementation and Customization Options

We offer comprehensive support for integrating our nickel mesh into existing systems. Our technical team provides:

- Custom design services for specific application requirements

- Installation guidance and on-site support

- Comprehensive training programs for maintenance personnel

For large-scale operations, we offer bulk purchasing options with flexible packaging solutions. Our logistics team ensures timely delivery through a network of trusted carriers, with real-time tracking available for all shipments.

Environmental Compliance and Safety Standards

All our products comply with international safety and environmental regulations. The Nickel Twill Weave Wire Mesh is manufactured using eco-friendly processes that minimize waste and energy consumption. It is certified to ISO 9001 and meets the requirements of RoHS and REACH directives.

Contact Us for Expert Consultation

For detailed specifications, pricing information, or to discuss your specific requirements, please contact Ansheng Filter Screen Co., Ltd. Our team of experts is available to provide personalized solutions that meet your industrial filtration needs.

Contact Information:

Phone: +86-21-5588-9922

Email: sales@anshengfilterscreen.com

Website: www.anshengfilterscreen.com

FAQ

Q: What makes nickel mesh superior to other filtration materials?

A: Nickel offers exceptional resistance to high temperatures and corrosion, making it ideal for demanding industrial applications.

Q: Can the mesh be customized for specific applications?

A: Yes, we offer custom design services to meet unique filtration requirements.

Q: What is the typical lead time for orders?

A: Standard orders are processed within 10-15 business days, with expedited options available for urgent requirements.

Q: Are there any special handling requirements?

A: While no special handling is required, we recommend storing the mesh in a dry environment to maintain its performance characteristics.

Conclusion

Ansheng Filter Screen Co., Ltd.'s Nickel Twill Weave Wire Mesh provides an advanced filtration solution that combines durability, efficiency, and cost-effectiveness. Contact us today to learn how our products can enhance your industrial operations.

Post time: Jul . 13, 2025 12:07