Introduction to Advanced Filtration Solutions

In industrial operations worldwide, the integrity of fluid systems and the purity of processed materials are paramount. This is where the critical role of filtration components, specifically the mesh filter, becomes indispensable. A mesh filter, often working in conjunction with a screen filter, provides precise separation, preventing contaminants from compromising equipment, product quality, and operational efficiency. From safeguarding sensitive machinery against particulate damage to ensuring the purity of consumer goods, these filtration elements are the silent guardians of industrial processes.

This comprehensive guide delves into the intricate world of mesh filters, exploring their evolving role, technical specifications, diverse applications, and the competitive landscape of their manufacturing. We will emphasize the high standards of production, particularly for products like the Iron Plain Weave Wire Mesh, and underscore the commitment to quality and performance that underpins modern filtration technology.

Industry Trends in Filtration Technology

The filtration industry is experiencing a dynamic evolution, driven by increasing demands for efficiency, sustainability, and stricter regulatory compliance. Key trends impacting the design and application of the mesh filter include:

- Miniaturization and High-Density Filtration: There's a growing need for compact yet highly efficient filtration solutions. This involves developing finer mesh weaves and advanced fabrication techniques to achieve higher filtration area within smaller footprints.

- Advanced Materials Science: Research into new alloys and composite materials is leading to filters with enhanced corrosion resistance, higher temperature tolerance, and improved mechanical strength, extending service life in extreme environments.

- Smart Filtration Systems: Integration of sensors for real-time monitoring of pressure drop, flow rate, and contamination levels is becoming standard. This allows for predictive maintenance, optimizing filter replacement schedules, and reducing downtime.

- Sustainability and Recyclability: A focus on eco-friendly manufacturing processes, reduced waste generation, and the development of recyclable or reusable filter elements is gaining traction, driven by global environmental initiatives.

- Customization and Application-Specific Design: Generic filters are giving way to highly customized solutions tailored to specific fluid properties, flow rates, and particulate sizes, ensuring optimal performance and cost-effectiveness.

These trends highlight a shift towards more intelligent, durable, and environmentally conscious filtration, with the screen filter playing a foundational role in many of these innovations.

Manufacturing Process Flow of Wire Mesh Filters

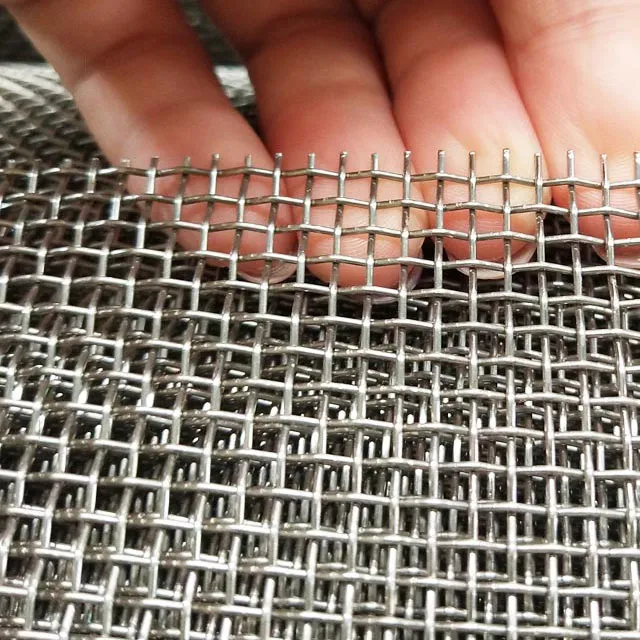

The production of a high-quality mesh filter is a multi-stage process requiring precision, advanced machinery, and rigorous quality control. For products like the Iron Plain Weave Wire Mesh, the meticulous attention to detail ensures superior performance and longevity. Below is a simplified representation of the typical manufacturing process:

1. Raw Material Sourcing & Preparation

High-grade iron wire, often carbon steel or stainless steel depending on application, is sourced. Material composition is verified against standards like ASTM A276. Wire is cleaned and straightened, ensuring uniform diameter and surface integrity.

2. Weaving Process

Using precision weaving looms, warp and weft wires are interlaced. For plain weave, each warp wire passes alternately over and under each weft wire, creating a strong, stable mesh with uniform openings. Automated weaving ensures consistency across large batches.

3. Annealing & Post-Weaving Treatment

The woven mesh undergoes annealing to relieve internal stresses and enhance flexibility and workability. Depending on requirements, it may also receive surface treatments such as galvanization for corrosion resistance or powder coating for specific aesthetic or protective properties.

4. Cutting & Fabrication

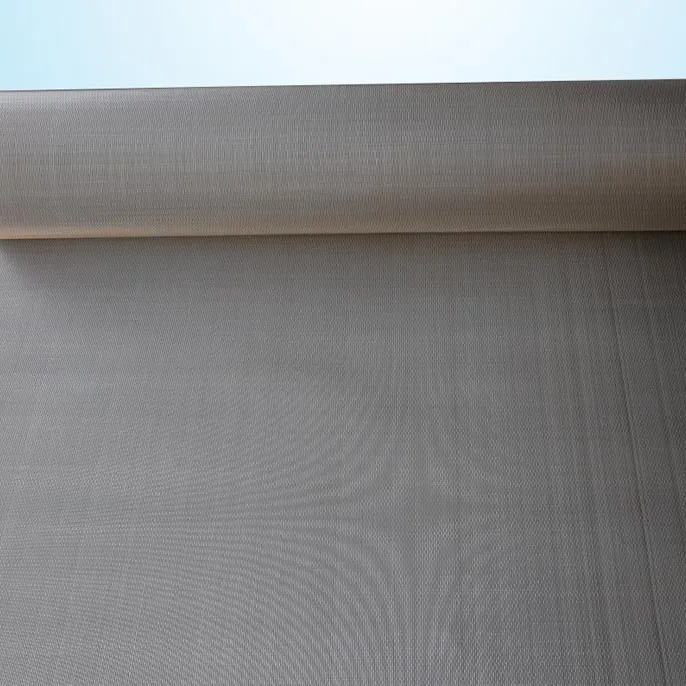

The large rolls of woven mesh are cut into desired shapes and sizes using CNC machining or precision laser cutting, ensuring accurate dimensions for various applications. This stage also includes forming into filter elements (e.g., cylinders, cones) if required.

5. Quality Assurance & Testing

Each batch undergoes rigorous testing to comply with international standards like ISO 9001, ASTM E2016, and sometimes ANSI/AWWA. This includes mesh count verification, aperture size measurement, material tensile strength tests, and visual inspections for defects. Service life is often modeled based on material fatigue limits.

6. Packaging & Dispatch

Finished products are carefully packaged to prevent damage during transit, often using moisture-proof materials and reinforced crating, before dispatch to target industries such as petrochemical, metallurgy, power generation, and water supply & drainage.

Advantages in typical application scenarios include significant energy saving due to optimized flow characteristics and superior corrosion resistance, contributing to extended equipment lifespan and reduced maintenance costs.

Technical Specifications and Parameters

The effectiveness of any mesh filter hinges on its precise technical specifications. Understanding these parameters is crucial for engineers and procurement specialists to select the optimal filtration solution for their unique requirements. For our Iron Plain Weave Wire Mesh, key structural parameters include mesh count, wire diameter, and aperture size.

- Mesh Count: Refers to the number of wires per linear inch, indicating the fineness of the weave. Higher mesh counts correspond to finer filtration.

- Wire Diameter: The thickness of the individual wires. This parameter influences the mechanical strength, rigidity, and overall open area of the mesh.

- Aperture Size (Micron Rating): The clear opening between adjacent wires. This is the most critical parameter for filtration, directly determining the smallest particle size that can be retained.

- Open Area: The percentage of the total mesh area that is open, which directly affects flow rate and pressure drop. A higher open area generally allows for higher flow rates and lower pressure drop.

- Material Grade: Specifies the alloy composition, influencing corrosion resistance, temperature tolerance, and suitability for various chemical environments. For Iron Plain Weave, common grades include low carbon steel, offering robust mechanical properties.

Iron Plain Weave Wire Mesh - Typical Specifications

| Mesh Count (per inch) | Wire Diameter (mm) | Aperture Size (µm) | Open Area (%) | Material | Width (m) |

|---|---|---|---|---|---|

| 2 | 1.00 | 11700 | 88.3 | Low Carbon Steel | 1.0 - 1.5 |

| 5 | 0.50 | 4580 | 83.6 | Low Carbon Steel | 1.0 - 1.5 |

| 10 | 0.30 | 2240 | 79.8 | Low Carbon Steel | 1.0 - 1.5 |

| 20 | 0.18 | 1090 | 78.4 | Low Carbon Steel | 1.0 - 1.2 |

| 40 | 0.12 | 515 | 78.8 | Low Carbon Steel | 1.0 - 1.2 |

| 80 | 0.07 | 248 | 78.8 | Low Carbon Steel | 1.0 - 1.2 |

Note: Specifications may vary based on exact manufacturing processes and specific customer requirements. Custom sizes and materials are available upon request.

Application Scenarios and Technical Advantages

The versatility of the mesh filter makes it a cornerstone component across a multitude of industries. Its ability to perform precise separation, withstand harsh conditions, and maintain structural integrity under pressure provides significant technical advantages:

- Petrochemical Industry: Used in distillation columns, reactors, and heat exchangers to prevent catalyst carryover, protect downstream equipment from fouling, and ensure product purity. The corrosion resistance of selected mesh materials is critical here.

- Metallurgy and Mining: Essential for screening ore, classifying aggregates, and filtering slurries. High tensile strength and abrasion resistance are key to longevity in these demanding applications.

- Water Treatment and Wastewater Management: Employed as pre-filters in municipal water treatment plants, industrial wastewater facilities, and irrigation systems to remove suspended solids, protecting pumps and finer filtration stages. Offers excellent flow rates with minimal pressure drop.

- Food and Beverage Processing: Used for straining liquids, separating solids from juices, milk, or brewing mash, and ensuring hygienic production environments. Materials must comply with FDA and other food-grade standards.

- Pharmaceuticals: Critical for precision filtration in drug manufacturing, active pharmaceutical ingredient (API) production, and sterile processing, where purity is paramount and precise micron ratings are non-negotiable.

- Aerospace and Automotive: Integrated into fuel systems, hydraulic circuits, and lubrication systems to protect critical components from microscopic debris, ensuring operational reliability and safety.

Key Technical Advantages:

- Exceptional Mechanical Strength: Plain weave construction provides inherent rigidity and resistance to deformation under differential pressure, crucial for sustained performance.

- Precise Filtration Efficiency: Uniform aperture sizes ensure consistent and reliable removal of particles, meeting stringent industrial purity requirements.

- Corrosion and Temperature Resistance: Available in materials resistant to a wide range of corrosive chemicals and extreme temperatures, expanding application versatility.

- High Flow Rate & Low Pressure Drop: Optimized open area designs facilitate efficient fluid passage, reducing energy consumption for pumping systems.

- Durability and Extended Service Life: Robust construction and material selection contribute to a longer operational lifespan, minimizing replacement frequency and maintenance costs.

- Ease of Cleaning and Maintenance: Many wire mesh filters are backwashable or easily cleaned, supporting reusability and reducing operational expenditure.

Vendor Comparison and Customized Solutions

Choosing the right vendor for industrial filtration components like a mesh filter is a strategic decision that impacts operational performance, cost, and long-term reliability. A comparative analysis often reveals critical differentiators beyond just price.

Comparative Analysis of Mesh Filter Providers

| Feature/Vendor | Ansheng Filters (Example) | Vendor B (Competitor) | Vendor C (Specialty) |

|---|---|---|---|

| Material Range | Low Carbon Steel, SS304, SS316, Galvanized Iron | Primarily Stainless Steel grades | Exotic alloys (Hastelloy, Monel) |

| Customization Options | High (Mesh count, wire diameter, size, shape, fabrication) | Limited (Standard sizes only) | High, but at premium cost |

| Quality Certifications | ISO 9001, Material Test Certificates | ISO 9001 | ISO 9001, ASME (for pressure vessels) |

| Lead Time (Standard) | 2-4 weeks | 3-6 weeks | 4-8 weeks |

| Technical Support | Dedicated engineering support, application consultation | Standard customer service | Specialized technical consultants |

| Pricing Model | Competitive, volume-based discounts | Standard list price | Premium |

Tailored Customized Solutions

Recognizing that no two industrial applications are identical, leading manufacturers offer robust customized solutions. This includes:

- Material Selection: Beyond standard iron and stainless steel, options for brass, copper, nickel alloys, or specialized coatings for specific chemical resistance or temperature requirements.

- Mesh Configuration: Custom mesh counts and wire diameters to achieve exact micron ratings and open area percentages for optimized flow and filtration efficiency.

- Fabrication and Forming: Filters can be custom-fabricated into discs, cylinders, cones, baskets, or complex shapes to integrate seamlessly into existing equipment or new designs. This often involves advanced welding, stamping, and edging techniques.

- Frame and Support Structures: Custom frames or reinforcements can be added to enhance mechanical stability for high-pressure or high-vibration environments, ensuring the longevity of the screen filter element.

Our engineering team collaborates closely with clients to understand specific operational parameters, fluid characteristics, and performance targets, developing tailored solutions that deliver maximum value and operational reliability.

Application Case Studies

Real-world application demonstrates the tangible benefits and reliability of a well-engineered mesh filter. Our commitment to excellence is reflected in the success of our clients across diverse industries.

Case Study 1: Enhanced Protection in a Petrochemical Plant

- Client: Major Middle Eastern Petrochemical Producer

- Challenge: Frequent clogging and damage to critical heat exchangers due to solid particulates (scale, rust) in cooling water lines, leading to unscheduled downtime and high maintenance costs. Existing coarse filters were inadequate.

- Solution: We designed and supplied custom-fabricated Iron Plain Weave Wire Mesh filters with a specific mesh count (30 mesh, 600 µm aperture) for the intake of the cooling water system. These were integrated into a robust basket filter housing. The material chosen offered enhanced corrosion resistance against saline water.

- Results:

- Reduced heat exchanger fouling by 75% within the first six months.

- Eliminated unscheduled downtime related to particulate damage.

- Extended service life of the heat exchangers by an estimated 3 years.

- Client feedback: "The new mesh filters proved exceptionally effective, significantly improving our operational reliability and reducing maintenance load."

Case Study 2: Optimizing Water Intake for Municipal Water Supply

- Client: Large Metropolitan Water Authority, North America

- Challenge: Inefficient pre-filtration at their primary river intake led to high sediment load entering subsequent treatment stages, increasing chemical consumption and wear on pumps and fine filters. They required a durable, high-capacity screen filter.

- Solution: We provided large-format, heavy-duty Iron Plain Weave Wire Mesh panels with a 4-mesh count (4750 µm aperture) for their rotating drum screens. The panels were treated for enhanced resistance to biological fouling and abrasion from river debris.

- Results:

- Reduced sediment load to primary clarifiers by 40%.

- Decreased chemical flocculant usage by 15%, leading to significant operational cost savings.

- Extended lifespan of downstream pump impellers by 2 years.

- Official certification (ISO/FDA) of our materials provided confidence in water quality.

Commitment to Trustworthiness and Support

Frequently Asked Questions (FAQ)

Q: What is the typical service life of your Iron Plain Weave Wire Mesh?

A: The service life of a mesh filter largely depends on the specific application, operating conditions (temperature, pressure, fluid corrosivity), and maintenance schedule. Under optimal conditions and regular cleaning, our Iron Plain Weave Wire Mesh can last for many years, often exceeding 5-7 years in moderate environments. We provide detailed material specifications and usage guidelines to help clients estimate lifespan.

Q: How do you ensure the quality and consistency of your mesh filters?

A: Our manufacturing process adheres strictly to ISO 9001 quality management standards. We implement multi-stage quality control, including raw material inspection, in-process checks during weaving, and final product verification using calibrated instruments for mesh count, wire diameter, and aperture size. Material certifications and test reports are available for all shipments.

Q: Can your mesh filters be cleaned and reused?

A: Yes, many of our wire mesh filters, particularly those in robust plain weave constructions, are designed for cleanability and reuse. Depending on the contaminant and application, methods such as backwashing, ultrasonic cleaning, or chemical cleaning can effectively restore filtration performance, thereby extending the life cycle and reducing operational costs.

Lead Time and Fulfillment

We understand the importance of timely delivery for industrial projects. Our standard lead time for off-the-shelf Iron Plain Weave Wire Mesh products typically ranges from 2 to 4 weeks, depending on order volume and specific requirements. For highly customized solutions, lead times are quoted on a project-specific basis after detailed engineering review. We maintain strategic inventory levels of popular mesh specifications to facilitate expedited orders when possible.

Warranty Commitments

All our wire mesh products, including the Iron Plain Weave Wire Mesh, are backed by a comprehensive 1-year limited warranty against manufacturing defects and material failures under normal operating conditions. This commitment reflects our confidence in the quality and durability of our products, ensuring peace of mind for our clients.

Customer Support and After-Sales Service

Our dedication to client success extends beyond product delivery. We provide robust after-sales support, including technical assistance for installation, operation, and troubleshooting. Our experienced engineering team is available for consultation to optimize filtration systems, address performance inquiries, and assist with any custom requirements. We also offer maintenance guidance and replacement part services to ensure the continuous and efficient operation of your filtration infrastructure.

Conclusion

The modern industrial landscape demands filtration solutions that are not only effective but also highly durable, efficient, and adaptable. The mesh filter, particularly in its plain weave configurations like the Iron Plain Weave Wire Mesh, stands as a testament to precision engineering and material science. By understanding the intricate manufacturing processes, adhering to stringent quality standards, and offering comprehensive customization and support, manufacturers can deliver superior filtration components that drive operational excellence, reduce environmental impact, and enhance overall system longevity. As industries continue to evolve, so too will the sophistication and critical role of advanced filtration technologies.

References

- International Organization for Standardization. ISO 9001:2015, Quality management systems – Requirements.

- American Society for Testing and Materials. ASTM E2016-15, Standard Guide for Industrial Woven Wire Cloth.

- Perry, R. H., & Green, D. W. (Eds.). (2007). Perry's Chemical Engineers' Handbook (8th ed.). McGraw-Hill Education.

- Journal of Fluid Mechanics. (Various Issues). Cambridge University Press.

- American Water Works Association (AWWA) Standards. (Ongoing publications).

Post time: Aug . 31, 2025 07:00