Single Layer Filter Screen: Enhancing Efficiency and Reliability for Industrial Applications

Ansheng Filter Screen Co., Ltd. is a leading manufacturer of high-performance filtration solutions, dedicated to providing innovative products that meet the evolving needs of industries worldwide. Our Single Layer Filter Screen stands out as a premier choice for businesses seeking reliable and efficient filtration systems. Designed with advanced technology and precision engineering, this product is engineered to deliver exceptional performance in diverse industrial applications.

Introduction to Single Layer Filter Screen

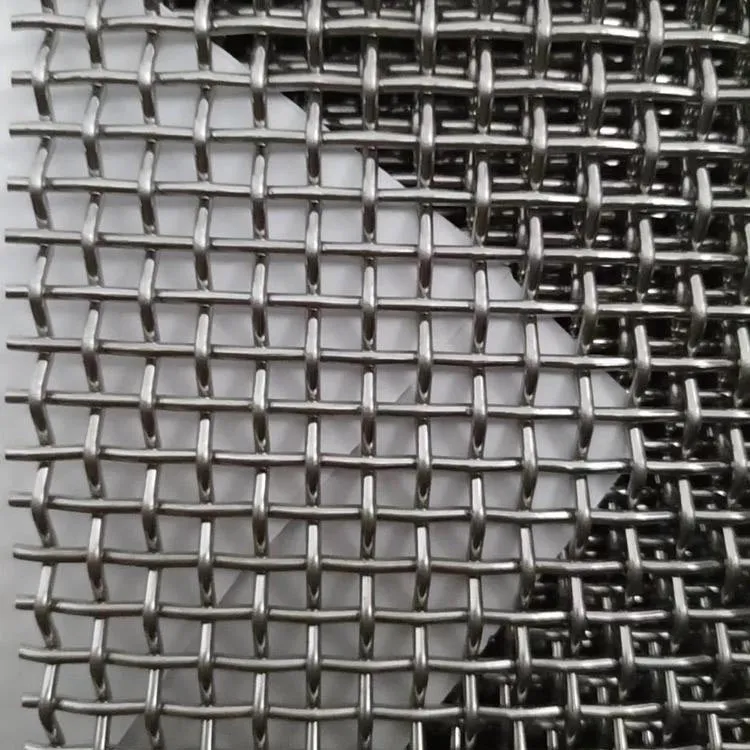

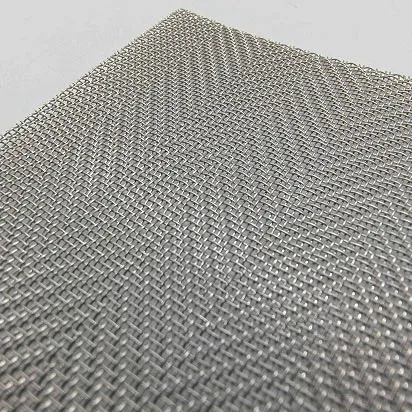

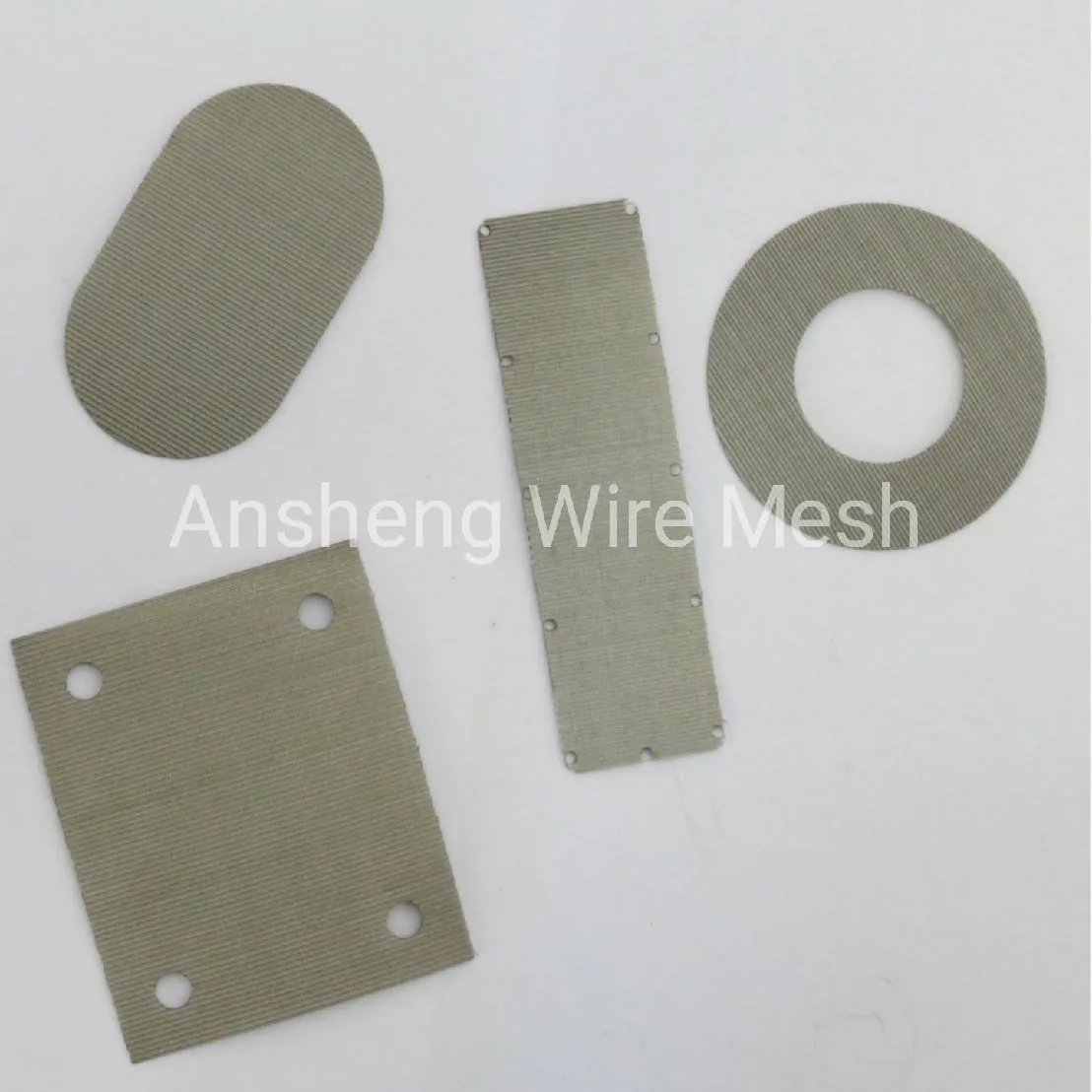

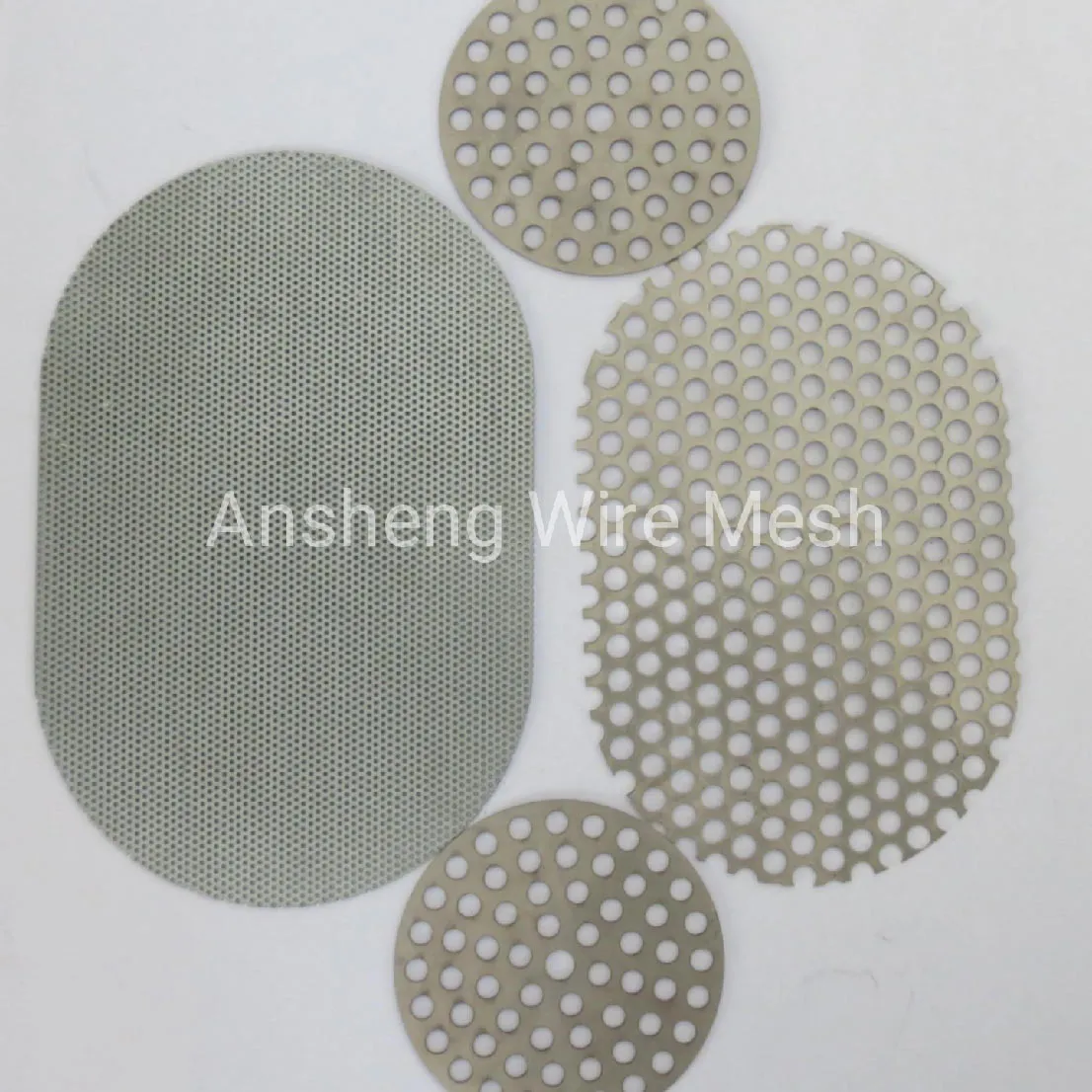

The Single Layer Filter Screen is a specialized filtration solution designed to remove impurities and particulate matter from liquids and gases. Its unique design ensures high flow rates while maintaining a low pressure drop, making it ideal for applications where efficiency and durability are critical. The product is available in various mesh sizes and materials, allowing for customization to suit specific industry requirements.

Key Features and Benefits

- High Efficiency: The single-layer design maximizes filtration efficiency by allowing optimal flow while capturing even the finest particles.

- Durability: Constructed from high-quality materials, the filter screen resists corrosion and wear, ensuring a long service life even in harsh environments.

- Easy Maintenance: The straightforward design simplifies cleaning and replacement, reducing downtime and maintenance costs.

- Customization: Available in multiple materials (e.g., stainless steel, nylon, and polypropylene) and mesh sizes, the product can be tailored to meet specific filtration needs.

Industry Applications

The Single Layer Filter Screen is widely used across various industries, including:

- Chemical Processing: Filtering solvents, acids, and other chemicals to ensure product purity.

- Pharmaceuticals: Maintaining sterile conditions during drug production and formulation.

- Food and Beverage: Removing contaminants from liquids such as juices, syrups, and brewing solutions.

- Water Treatment: Purifying water in industrial and municipal systems.

Addressing Industry Challenges

Modern industries face significant challenges in maintaining efficient filtration processes while minimizing costs. Traditional filtration systems often struggle with clogging, high maintenance requirements, and inconsistent performance. The Single Layer Filter Screen addresses these issues by offering a robust, low-maintenance solution that ensures consistent filtration quality. Its design reduces the frequency of replacements and minimizes operational disruptions, helping businesses save time and resources.

Company Expertise and Innovation

As a trusted name in the filtration industry, Ansheng Filter Screen Co., Ltd. has built a reputation for excellence through decades of research and development. Our team of engineers continuously innovates to enhance product performance, ensuring that our solutions stay ahead of industry demands. With a focus on quality and customer satisfaction, we provide cutting-edge filtration technologies that drive operational efficiency and sustainability.

Proven Results and Customer Testimonials

Customers across multiple sectors have reported significant improvements in their filtration processes after adopting the Single Layer Filter Screen. For instance, a leading chemical manufacturer noted a 30% reduction in maintenance costs and a 20% increase in production efficiency. Another client in the food industry praised the product's reliability, stating, "The Single Layer Filter Screen has transformed our filtration workflow, ensuring consistent quality and minimal downtime."

Implementation and Support

Implementing the Single Layer Filter Screen is straightforward, with detailed installation guides and technical support available to ensure seamless integration into existing systems. Our team offers personalized consultations to help clients select the optimal specifications for their applications. Additionally, we provide ongoing technical assistance and maintenance services to maximize the product's lifespan and performance.

Environmental and Safety Compliance

Sustainability and safety are core values at Ansheng Filter Screen Co., Ltd. Our Single Layer Filter Screen is manufactured using eco-friendly materials and processes, complying with international environmental standards. The product is also designed to meet rigorous safety regulations, ensuring that it can be safely used in sensitive applications without compromising health or environmental integrity.

Shipping and Packaging

We understand the importance of secure and timely delivery for industrial clients. The Single Layer Filter Screen is packaged in durable, custom-fit containers to prevent damage during transit. For bulk orders, we offer cost-effective shipping solutions tailored to meet the logistics needs of our customers. Our global distribution network ensures that products reach clients efficiently, regardless of location.

Comprehensive Customer Support

At Ansheng Filter Screen Co., Ltd., we are committed to providing exceptional customer support. Our dedicated team offers 24/7 technical assistance, product training, and customized solutions to address specific client requirements. Whether you need guidance on product selection, installation, or troubleshooting, our experts are here to help you achieve optimal results.

Contact Us for More Information

Ready to experience the benefits of the Single Layer Filter Screen? Visit our official website to explore product details, specifications, and customer reviews. For direct inquiries, contact us at sales@anshengfilterscreen.com or call +86-123-456-7890. Our team is eager to assist you in finding the perfect filtration solution for your business.

Frequently Asked Questions (FAQ)

Q1: What materials are used in the Single Layer Filter Screen?

A: The product is available in stainless steel, nylon, and polypropylene, among other materials, to suit different industrial needs.

Q2: How often should the filter screen be replaced?

A: The lifespan depends on usage conditions, but regular inspections and cleaning can significantly extend its service life.

Q3: Can the product be customized for specific applications?

A: Yes, we offer tailored solutions based on your filtration requirements, including mesh size and material selection.

Q4: Is the product environmentally friendly?

A: Absolutely. Our manufacturing processes adhere to strict environmental standards, and the materials used are recyclable.

Q5: What support is available after purchase?

A: We provide technical support, installation guidance, and maintenance services to ensure optimal performance of the product.

Transform your filtration processes with the Single Layer Filter Screen from Ansheng Filter Screen Co., Ltd. Contact us today to learn more about how we can help you achieve greater efficiency and reliability in your operations.

Post time: Jul . 12, 2025 22:39