Buying Guide: Perforated Metal For Sale — What Specs Actually Matter

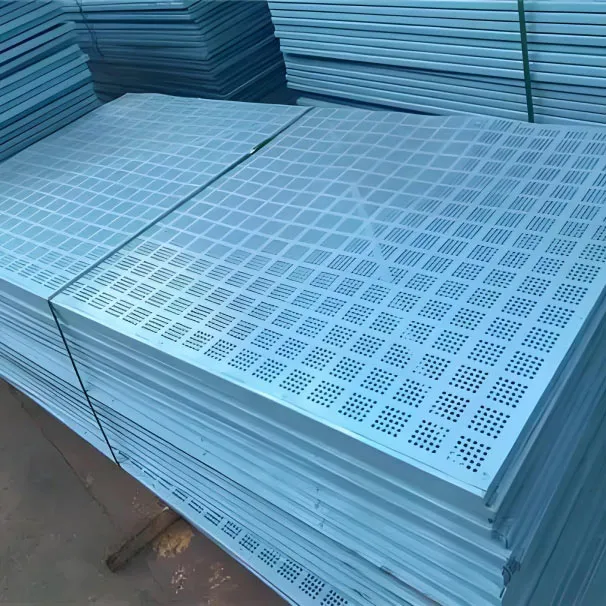

I visit fabrication floors more than I sit at my desk, and that’s where you hear the truth. Buyers want clean tolerances, predictable lead times, and no surprises on finish. Perforated Metal Mesh (yes, the humble “punch-and-go” sheet) has quietly become the backbone of acoustic baffles, HVAC guards, and some very slick façades. If you’re scanning catalogs for Perforated Metal For Sale, here’s the insider rundown—minus the fluff.

What it is and why it’s trending

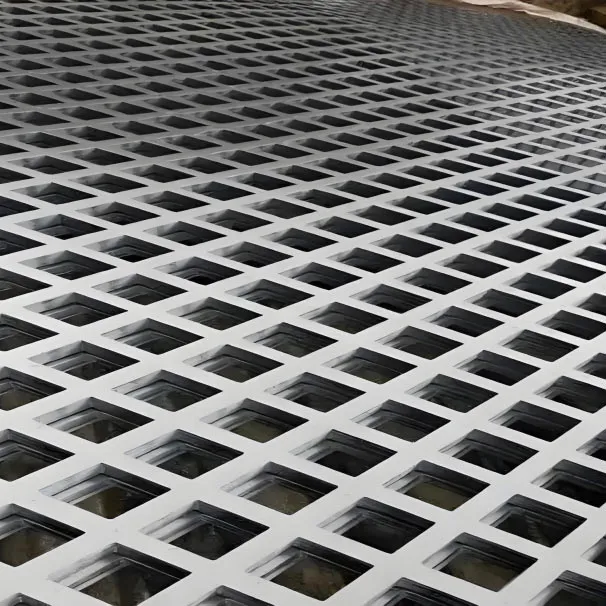

Perforated mesh is sheet metal with a controlled pattern of holes. Shapes range from round and slotted to square, hex, or micro-perf. What’s new? Designers are pairing micro-perfs with powder coats for acoustic interiors, while industrial buyers are asking for tighter pitch and higher open area for airflow. Sustainability drives demand for aluminum and 304/316 stainless; galvanized still wins for cost.

Quick spec table (real-world ranges)

| Base Materials | SS 304/316, Aluminum 1100/3003/5052, Mild Steel (CR), Galvanized (ASTM A653) |

| Thickness | ≈0.5–3.0 mm standard; up to 6 mm on request |

| Hole Types | Round, slotted (oblong), square, hex, micro-perf |

| Hole Ø / Pitch | Ø 0.5–20 mm; pitch as low as 1.2×Ø (DIN 24041 guidance) |

| Open Area | 8–60% typical; airflow and acoustics increase with OA (context matters) |

| Sheet Size | 1000×2000 mm, 1250×2500 mm, 1500×3000 mm; custom available |

| Finishes | Mill, powder coat, anodize (Al), hot-dip galvanize, passivation (SS) |

| Tolerances | Hole Ø ±0.1–0.2 mm; pitch ±0.15–0.3 mm (setup and thickness dependent) |

Process flow (how good sheets are made)

- Materials: certified coils per ASTM A240 (SS), ASTM B209 (Al), ASTM A653 (GI).

- Methods: CNC turret punching or step-and-repeat presses; micro-perf via precision tooling; deburring + leveling.

- Finishing: powder coating (ISO 12944 guidance for systems), anodizing, HDG for outdoor duty.

- Testing: salt spray per ASTM B117, coating thickness checks, flatness and hole-pitch audits (DIN 24041), adhesion per ASTM D3359.

- Service life: ≈10–25 years depending on alloy, finish, and environment; coastal sites demand SS 316 or robust coating.

- Industries: architecture, HVAC, transportation, food equipment, agriculture, mining screens, acoustics.

Applications and advantages

Use it for acoustic ceilings (round 2 mm on 4 mm pitch with black fleece backing), safety guards (3 mm round on 5 mm pitch), intake grilles, sunshades, retail fixtures—honestly, I’ve even seen clever furniture makers using it for cabinet doors. Advantages: predictable airflow, good stiffness-to-weight, easy to cut and fold, and—with the right finish—clean aesthetics.

Vendor snapshot (what buyers compare)

| Vendor | Lead Time | MOQ | Certs | Customization | Notes |

|---|---|---|---|---|---|

| Ansheng (Anping, Hebei) | 10–18 days | ≈50–100 sheets | ISO 9001 | Hole/pitch/finishes to drawing | Consistent flatness; DFM help |

| Generic Importer | 3–6 weeks | High | Varies | Limited patterns | Cheaper, but tooling delays |

| Local Fabricator | Fast (stock dependent) | Small | — | Good for prototypes | Higher unit cost |

Customization tips

- Pattern: 60° staggered round gives better open area and visual flow than straight rows.

- Margins: define unperforated borders for bending and fastening—saves headaches later.

- Acoustics: pair 1–3 mm holes with backing fleece; several customers report ≈8–12 dB perceived reduction in office installs (setup dependent).

- Corrosion: coastal projects—favor SS 316 or powder over HDG; test per ASTM B117.

Case notes from the field

Transit hub façade: 2 mm round on 3.5 mm pitch, aluminum 2.0 mm, anodized. Architect said, “Surprisingly rigid for the weight.” Wind load calcs passed with minimal stiffeners.

Food equipment guards: SS 304, 1.2 mm, 3/5 pattern; passivated. Maintenance team noted fewer burr-related glove snags—small win, big morale boost.

Origin matters: sheets here are produced in Anping (No.346 Xinying East Street, Anping County, Hebei, China)—a region that lives and breathes metal mesh work. If you’re hunting Perforated Metal For Sale for a fast-moving project, ask for coil lot certs, hole-pitch CMM reports, and a salt-spray snapshot. To be honest, that checklist weeds out 90% of future pain.

Standards and references

- DIN 24041: Perforated plates — Terms and tolerances. Beuth Verlag: https://www.beuth.de/en/standard/din-24041/

- ASTM A240/A240M: Chromium and Chromium-Nickel Stainless Steel Sheet. ASTM International: https://www.astm.org/a0240_a0240m-23.html

- ASTM B117: Salt Spray (Fog) Testing. ASTM International: https://www.astm.org/b0117-23.html

- ASTM A653/A653M: Zinc-Coated (Galvanized) Steel Sheet. ASTM International: https://www.astm.org/a0653_a0653m-22.html

- ISO 9001:2015 Quality management systems. ISO: https://www.iso.org/standard/62085.html

Post time: Oct . 23, 2025 18:45