Dutch Weave Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Dutch Weave Mesh Overview

- Benefits & Use Cases of Dutch Weave Mesh in Manufacturing of metal wire ropes and their products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Dutch Weave Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Dutch Weave Mesh Overview

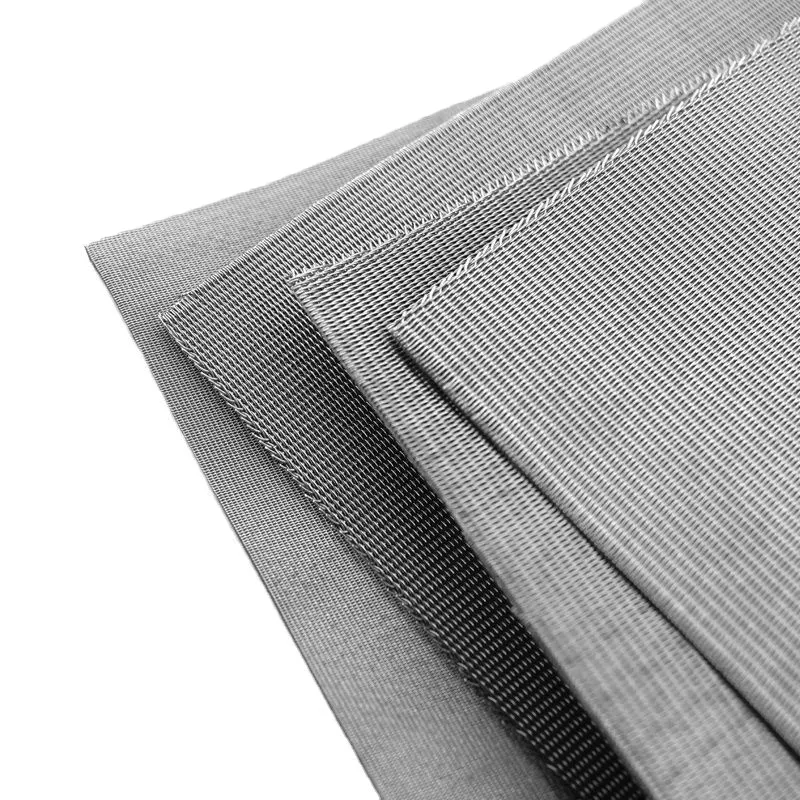

Dutch Weave Mesh—often called dutch weave wire mesh, dutch mesh, or dutch weave screen—is a precision-woven stainless steel cloth engineered for fine filtration under pressure. Unlike plain square meshes, a dutch weave utilizes thicker warp wires and a higher number of finer weft wires to create a tight, tortuous flow path and reliable particle retention. Two common variants are plain dutch weave and dutch twill weave; the latter allows extremely fine micronic ratings while maintaining mechanical strength and excellent ΔP tolerance. Typical industry specifications include 304/304L or 316/316L stainless steel, mesh combinations such as 30×150, 80×700, or 200×1400, and nominal retention from single-digit microns to ~200 microns, depending on weave and wire diameters.

For B2B buyers in fabricated metal products and wire-rope manufacturing, this construction delivers stable filtration for coolants, lubricants, polymer coatings, and process water—without shedding fibers or deforming easily. Rolls are commonly supplied in standard widths with consistent flatness, and can be converted into discs, candle elements, screen packs, or pleated cartridges. Anping County Ansheng Wire Meshes Product Co., Ltd., based in the global mesh hub of Anping, manufactures stainless steel dutch weave mesh with tight tolerances, traceable raw materials, and repeatable quality—helping production teams standardize filtration across plants and lines.

Benefits & Use Cases of Dutch Weave Mesh in Manufacturing of metal wire ropes and their products

In wire-rope manufacturing, dutch weave mesh is integral to clean operations and consistent product quality. It is widely used for filtering wire-drawing lubricants and coolants to remove metal fines; protecting spray and pickling nozzles from clogging; screening shot-blast media; and as screen packs in polymer/resin coating lines for cable cores or jacketing. Dutch twill weave excels in high-pressure, high-viscosity streams where fine retention and longer on-stream life are critical. Its robust warp foundation prevents elongation, while the dense weft layer provides stable micron cut-offs, enabling predictable filtration performance and fewer unplanned stoppages.

- Process stability: tight particle control improves surface finish of strands and extends die life.

- Durability: stainless steel construction resists abrasion from fines and wire chips better than polymer media.

- Backwashable: many dutch weave screen packs can be cleaned and reused, reducing consumable cost and waste.

- Temperature/chemicals: suitable for typical wire-drawing oils, alkaline cleaners, and various process fluids.

Anping County Ansheng Wire Meshes Product Co., Ltd. supports OEMs and plants with conversion services—cut-to-size discs, multilayer laminates, and edge-welded packs—to shorten procurement cycles and ensure ready-to-install dutch mesh components that match line specifications.

Cost, Maintenance & User Experience

Total cost of ownership for Dutch Weave Mesh is driven by service life, cleanability, and production uptime. While stainless dutch mesh can have a higher unit cost than disposable media, its mechanical resilience and ability to withstand backwashing/ultrasonic cleaning often lead to fewer changeouts, less inventory, and reduced downtime. This translates to measurable ROI for high-throughput wire-drawing and closing lines where stoppages are costly. Selecting the appropriate weave (plain dutch vs. dutch twill weave), wire diameter, and layer configuration helps balance pressure drop, retention, and cycle length.

- Maintenance practices: scheduled backflushing, solvent or alkaline cleaning compatible with your fluids, and careful reinstallation preserve mesh geometry.

- User feedback: fabricated metal producers value the mesh’s shape stability and consistent micron performance, noting cleaner baths and fewer nozzle blockages when replacing aging screens with new dutch weave screen packs.

Anping County Ansheng Wire Meshes Product Co., Ltd. offers guidance on mesh selection and maintenance intervals based on process conditions, helping procurement and operations teams standardize SKUs, extend service life, and optimize working capital tied to spares.

Sustainability & Market Trends in manufacturing

Manufacturers are prioritizing circularity, resource efficiency, and regulatory compliance across the supply chain. Stainless steel dutch weave mesh supports these goals: it is durable, reusable through cleaning cycles, and fully recyclable at end of life. Fine filtration keeps lubricants and process water cleaner for longer, reducing chemical consumption and waste haulage. As ESG frameworks advance and regulations tighten around effluent quality, more plants are adopting higher-efficiency media and multilayer packs to enhance retention without sacrificing throughput.

Market trends also include increased demand for traceability, tighter tolerances, and engineered laminates that combine strength with ultra-fine retention. Anping County Ansheng Wire Meshes Product Co., Ltd. aligns with these priorities by focusing on consistent weave quality, material certificates upon request, and application-driven conversion services. By delivering long-life dutch mesh solutions, the company helps B2B decision makers lower lifecycle impacts while meeting quality and compliance targets in wire-rope and fabricated metal operations.

Conclusion on Dutch Weave Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

For fabricated metal products and wire-rope manufacturing, Dutch Weave Mesh delivers reliable fine filtration, stability under pressure, and repeatable quality—key to cleaner baths, longer tool life, and steady throughput. Whether you require plain dutch or dutch twill weave, Anping County Ansheng Wire Meshes Product Co., Ltd. provides dependable materials and conversion support to meet your line specifications.

- Partner with a proven supplier for dutch weave wire mesh and engineered screen packs.

- Contact us: email: sales@anshengwiremesh.com

- Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 24, 2025 07:40