Brass Wire Mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire ropes and their products. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Brass Wire Mesh Overview

- Benefits & Use Cases of Brass Wire Mesh in Manufacturing of metal wire ropes and their products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Brass Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Brass Wire Mesh Overview

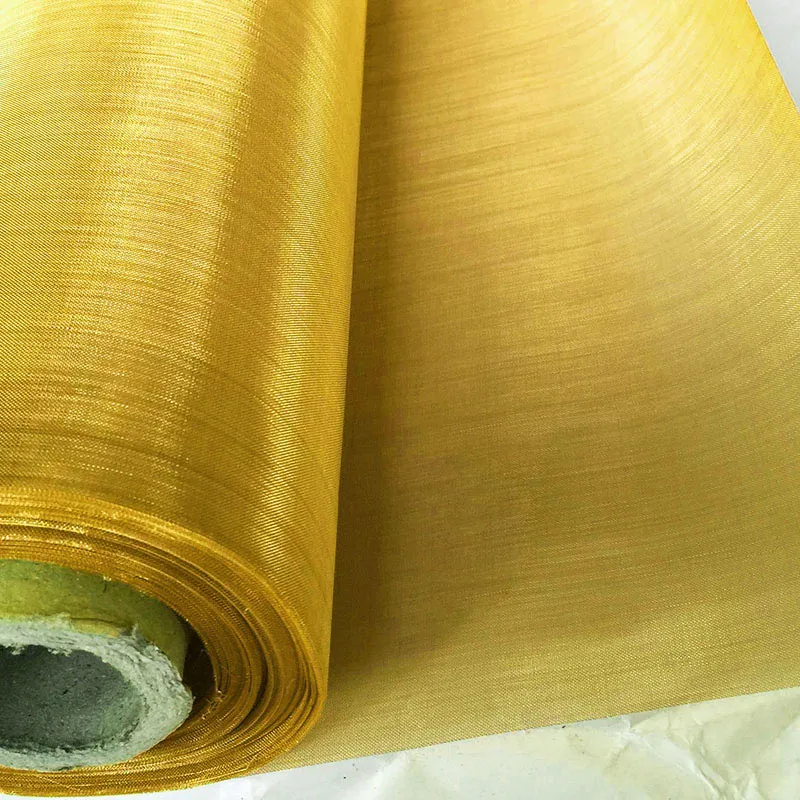

Brass wire mesh is a precision-woven screen made from copper–zinc alloys (commonly C260/C270), prized for its stable aperture, formability, and electrical conductivity. In the fabricated metal products sector and in the manufacturing of metal wire ropes and related products, it is used for filtration, sieving, EMI/RFI shielding, safety guarding, and architectural accents. Typical specifications range from 2–500 mesh, with wire diameters from 0.03–2.0 mm, plain or twill weave, supplied in rolls or cut-to-size parts. Aperture sizes can be tailored to process needs—from coarse protection screens to fine lubrication and coolant filtration around drawing, stranding, and closing equipment.

Anping County Ansheng Wire Meshes Product Co., Ltd. delivers consistent brass woven wire mesh that aligns with international tolerances (e.g., ISO 9044/ASTM E2016-equivalent). Precision slitting, edge treatments, and deburring help minimize fraying and speed installation. For plant offices and equipment enclosures, the company also supplies attractive, durable options such as brass wire mesh for cabinets and brass wire mesh for cabinet doors—leveraging the same dimensional stability demanded on the shop floor. With responsive engineering support and rapid sampling, Ansheng helps B2B buyers specify the right mesh count, open area, and alloy for critical duty cycles.

Benefits & Use Cases of Brass Wire Mesh in Manufacturing of metal wire ropes and their products

In wire-rope manufacturing, brass wire mesh plays several roles. For process fluids, fine mesh (e.g., 60–120 mesh) is used to filter drawing oils and emulsions, helping maintain die integrity and surface finish. Coarser mesh serves as inline screens on coolant return lines, catch-baskets beneath capstans, and protective guards on payoff and take-up stations. Its conductivity enables EMI shielding in instrument cabinets and control panels on stranding lines. Non-sparking behavior compared to steel makes brass a prudent choice around flammable lubricants. Off the production line, brass mesh for cabinet doors and equipment enclosures offers ventilation with a premium industrial aesthetic in labs, QA rooms, and plant offices.

Key advantages include consistent aperture for repeatable filtration, good formability for custom frames and screens, and corrosion resistance in neutral environments. Compared with stainless steel, brass can be easier to form and offers superior electrical conductivity for shielding; compared with phosphor bronze, it often delivers a cost-effective balance of strength and durability. Anping County Ansheng Wire Meshes Product Co., Ltd. supports OEMs and rope producers with quick-turn cut parts, framed screens, and kitted spares that reduce changeover time. Whether you need industrial grades or decorative brass wire mesh for cabinets in customer-facing areas, Ansheng provides dependable quality and dimensional control that keeps operations lean.

Cost, Maintenance & User Experience

Total cost of ownership for brass wire mesh is driven by mesh count selection, alloy grade, and fabrication details. For filtration screens, specifying the tightest mesh tolerance your process truly requires avoids over-engineering and unnecessary cost. Brass’s formability reduces fabrication labor for frames and housings, while its stable openings help extend fluid life and protect downstream tooling, improving ROI via fewer unplanned stoppages. In many facilities, standardized panel sizes and swap-in frames cut changeover minutes to seconds, keeping utilization high across drawing and stranding assets.

Maintenance is straightforward: periodic backflushing or ultrasonic cleaning restores flow, and mild neutral detergents help remove oil residues without attacking the alloy. Users in the fabricated metal products sector report smoother starts after maintenance cycles and more consistent finish quality on wire and strand when filtration meshes are kept within spec. Anping County Ansheng Wire Meshes Product Co., Ltd. supports lifecycle value with edge-welded trims to resist fray, identification tags for traceability, and replenishment programs that align with your preventive maintenance schedule—reducing stockouts and emergency freight costs.

Sustainability & Market Trends in manufacturing

Sustainability in metalworking is increasingly shaped by recyclability, safer chemistries, and resource efficiency. Brass is highly recyclable, and scrap from trimming or end-of-life screens can be reclaimed, supporting circularity and lowering embodied impact. Many buyers now request low-lead brass options and documentation for RoHS/REACH compliance. On the shop floor, right-sized mesh counts reduce energy consumption by maintaining clean coolants, aiding heat transfer control, and cutting consumable use across wire-drawing and stranding operations. Packaging moves toward recyclable materials and optimized roll widths to minimize waste.

Market trends include shorter lead times, digital QC records, and tighter tolerances for automated lines. Anping County Ansheng Wire Meshes Product Co., Ltd. aligns with these needs by offering consistent, spec-driven brass woven wire mesh, documented traceability, and flexible MOQs that fit both high-volume rope producers and specialized OEMs. For facility aesthetics and ergonomics, the company also provides brass mesh for cabinet doors in maintenance and QA areas, blending ventilation with visibility—an increasingly popular choice in modern industrial design. Forward-looking sourcing from Ansheng means reliable delivery, application support, and materials that meet evolving environmental and regulatory expectations.

Conclusion on Brass Wire Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

For manufacturers in fabricated metal products and the wire-rope value chain, brass wire mesh delivers reliable filtration, shielding, protection, and design versatility. From production-grade screens to brass wire mesh for cabinets and cabinet doors, Anping County Ansheng Wire Meshes Product Co., Ltd. supplies consistent, application-ready solutions that help reduce downtime and keep quality on target. If your next project requires dependable brass wire mesh performance, talk to the team that understands both the process and the product.

- Contact us: email: sales@anshengwiremesh.com

- Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 23, 2025 08:40