Herringbone Mesh is a key solution in the industrial manufacturing industry, specifically within Wire mesh products and Weaving wire mesh. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Herringbone Mesh Overview

- Benefits & Use Cases of Herringbone Mesh in Weaving wire mesh

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in industrial manufacturing

- Conclusion on Herringbone Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Herringbone Mesh Overview

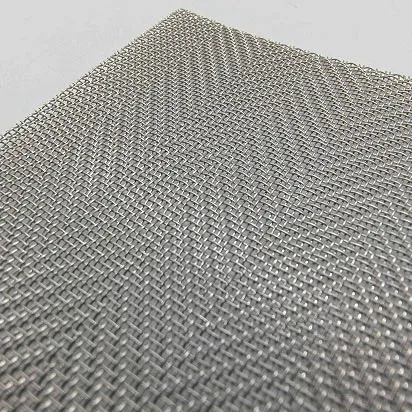

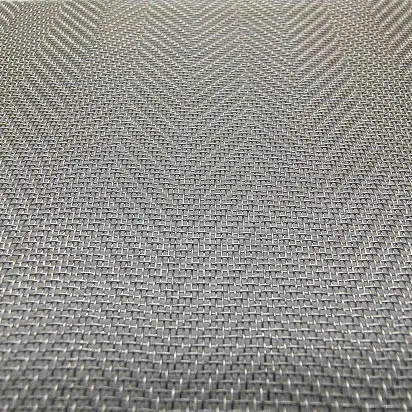

In industrial weaving wire mesh, herringbone refers to a reversing twill pattern that alternates left- and right-hand twills to form characteristic V-shaped chevrons. For buyers asking “what is herringbone weave,” think of it as a precision-engineered structure that stabilizes the cloth while creating a tortuous path for flow and particle capture. This geometry delivers robust mechanical strength across both warp and weft, consistent pore distribution, and excellent resistance to blinding compared with standard plain or straight twill weaves.

Typical specifications supplied by Anping County Ansheng Wire Meshes Product Co., Ltd. include stainless steel grades 304, 304L, 316, and 316L, wire diameters commonly from about 0.03–0.50 mm, and nominal openings down to fine micron levels depending on the application. Rolls are available in standard and custom widths with tight flatness and thickness control; optional calendaring, heat treatment, edge trimming, and laser cutting help meet downstream assembly needs. In filtration packs, herringbone mesh can serve either as the working layer for precise separation or as a supportive outer layer that stabilizes finer meshes under pressure and thermal load.

With decades of weaving experience and stringent in-process inspection, Anping County Ansheng Wire Meshes Product Co., Ltd. is a reliable manufacturer for B2B decision makers who need repeatable performance, flexible customization, and on-time delivery across global supply chains.

Benefits & Use Cases of Herringbone Mesh in Weaving wire mesh

Herringbone Mesh excels in applications requiring fine yet stable filtration and uniform flow distribution. Common use cases include polymer melt and resin filtration, chemical and petrochemical media separation, protective layers for sintered laminates, fiber spinning screens, edible oil clarification, catalyst recovery, and precision sieving in powder processing. The chevron channels promote secondary flow paths that reduce clogging, while the alternating twill sequence improves sheet stability under differential pressure and thermal cycling.

Key advantages for plant engineers and procurement teams include higher dirt-holding capacity, improved cake release during backflushing, flatter pressure-drop curves versus equivalent plain weave, and better dimensional stability for multi-layer packs. Anping County Ansheng Wire Meshes Product Co., Ltd. tailors reversal frequency, wire diameter combinations, and warp/weft ratios to tune filtration cut points and mechanical strength. Value-added options such as calendaring for controlled caliper, deburring for safer handling, and cleanliness-prepared packaging support fast integration into OEM assemblies and MRO programs. The result is a predictable, long-life media choice for demanding manufacturing lines.

Cost, Maintenance & User Experience

Total cost of ownership with herringbone weave often proves favorable because the structure resists deformation and blinding, extending changeout intervals and reducing unplanned downtime. While the initial unit price can be higher than commodity plain weave, the ROI typically improves through longer service life, fewer screen packs carried in inventory, and lower labor required for maintenance. For multi-shift operations, fewer line stoppages can translate directly into higher yield and more stable throughput.

Maintenance is straightforward: proper tensioning during installation, scheduled backflushing or ultrasonic cleaning when appropriate, and careful handling to protect edges and maintain flatness. Feedback from users in the wire mesh products sector highlights consistent thickness after calendaring, clean cut edges that minimize fray, and repeatable filtration curves from lot to lot. Anping County Ansheng Wire Meshes Product Co., Ltd. supports customers with application-driven recommendations—helping select the right alloy, weave reversal, and post-treatment to balance pressure drop, particle retention, and cleanability for the best lifecycle economics.

Sustainability & Market Trends in industrial manufacturing

Industrial buyers increasingly evaluate filtration media through the lens of sustainability, safety, and regulatory alignment. Stainless steel Herringbone Mesh is inherently durable and recyclable, supporting waste reduction and circularity targets. Longer service intervals help minimize disposal of spent media; stable performance allows process optimization that can reduce energy and solvent consumption. Across sectors—polymers, fine chemicals, food, and renewables—demand is rising for tighter separations at higher temperatures and pressures, while maintaining cleanability and operator safety.

Anping County Ansheng Wire Meshes Product Co., Ltd. positions customers for these trends with precision weaving, careful material traceability, and options that extend media life, such as calendaring and tailored pack designs. The company champions good manufacturing practices, rigorous inspection, and resource-conscious operations, including efficient raw material utilization and thoughtful packaging. For B2B decision makers, partnering with a forward-thinking weaving specialist enables confident compliance today and agility as sustainability and quality requirements continue to evolve.

Conclusion on Herringbone Mesh from Anping County Ansheng Wire Meshes Product Co., Ltd.

Herringbone Mesh delivers the balanced strength, stability, and filtration precision that modern industrial manufacturing demands. From polymer melt lines to fine chemical separations, its reversing twill structure resists blinding, holds shape under load, and supports consistent throughput. As a dependable manufacturer, Anping County Ansheng Wire Meshes Product Co., Ltd. provides tailored specifications, meticulous finishing, and responsive service to help you achieve lower total cost of ownership and reliable, repeatable performance. Contact us: email: sales@anshengwiremesh.com. Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 27, 2025 08:25