Stainless Steel Twill Weave Wire Mesh: field notes, specs, and what buyers really ask

If you work in filtration or screening, you already know how many projects quietly depend on Twill Weave Mesh. To be honest, it doesn’t get the glamour. But talk to maintenance engineers and you’ll hear the same thing: when the weave is right, downtime falls. I’ve visited mills from Wuxi to Houston, and the best results tend to come from stable twill in the right alloy—304 for general use, 316/316L when corrosion won’t leave you alone.

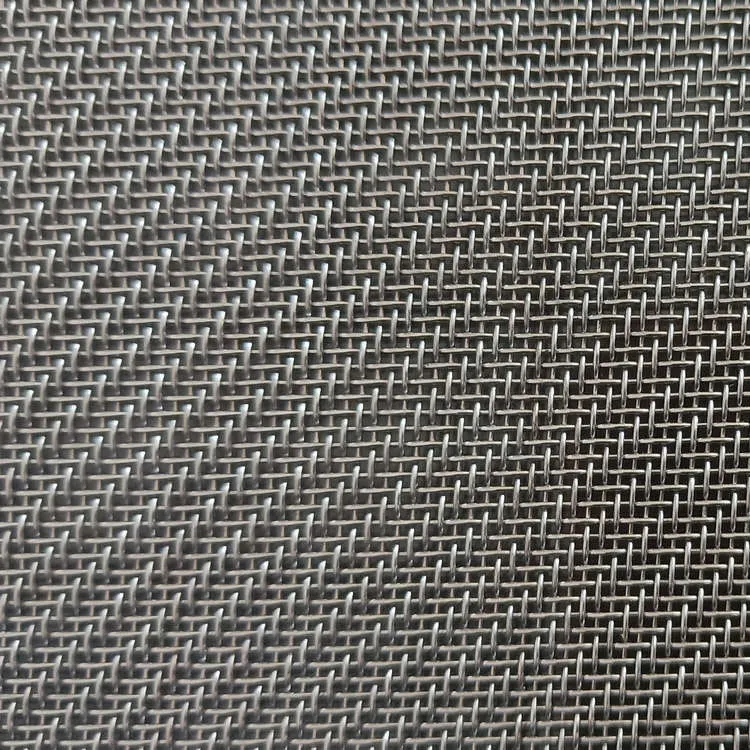

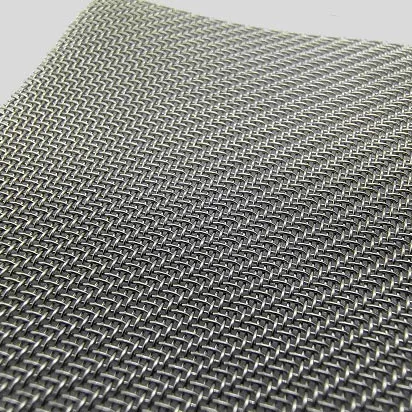

What makes Twill Weave Mesh different?

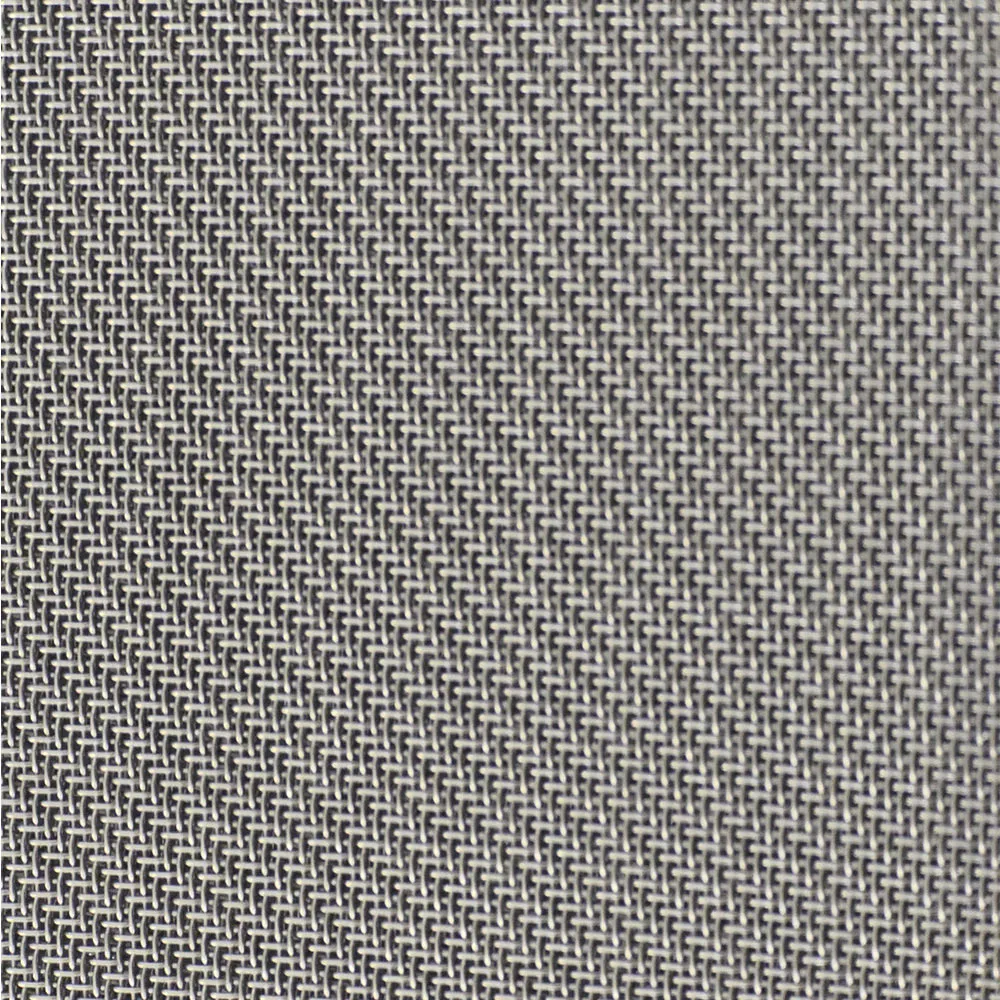

In twill, each wire passes over two and under two, offset by one. The payoff is flexibility and higher mesh counts with finer wire versus plain weave. The product here—Stainless Steel Twill Weave Wire Mesh from Ansheng (origin: No.346 Xinying East Street, Anping County, Hebei, China)—covers 1–635 mesh with wire diameters around 1 mm down to ≈0.001 mm, widths typically 0.915–2.0 m, and standard roll length of 30 m. Many customers say 316L twill rides out caustic CIP cycles better than they expected.

Process flow and QA (the short, honest version)

- Materials: SS 201/304/316/316L wires (ASTM A580/A580M)

- Wire drawing + intermediate annealing; cleanliness check

- Weaving: shuttle/rapier looms; twill, plus options: plain, herringbone, dutch, reverse dutch

- Finishing: degrease, ultrasonic clean, passivation (as needed)

- Testing: mesh count to ASTM E2016/ISO 9044, aperture via calibrated optics, tensile per ASTM A370; corrosion by ASTM B117; pore tests for fine mesh to ASTM F316 (bubble point)

- Traceability and lot certificates; ISO 9001 QMS

Specification snapshot

| Parameter | Typical Range (≈, real-world use may vary) |

|---|---|

| Mesh count | 1–635 mesh |

| Wire diameter | 1.0 mm to 0.001 mm |

| Alloys | 201, 304, 316, 316L |

| Width | 0.915–2.0 m (custom on request) |

| Length | 30 m per roll (standard) |

| Tensile strength | 304: ~600–850 MPa; 316L: ~530–750 MPa |

Quick test notes from recent lots: 316L twill 400 mesh showed bubble point in IPA around 1.0–1.3 bar; 96 h ASTM B117 with no red rust; dimensional tolerance met ASTM E2016-15 Table 1. Service life? Indoors ≈8–15 years; coastal outdoor 3–10 years, strongly alloy-dependent.

Where Twill Weave Mesh shines

- Chemical and petrochemical filtration (catalyst retention, slurry screens)

- Food and beverage pre-filtration (316L, post-passivation)

- Battery and new energy: electrode support, slurry sieving

- Automotive and aerospace: fuel filter pleats, vent protection

- Mining and pigments: fine classification where plain weave plugs

- Architecture: protective façades where a tight, smooth finish helps

Vendor comparison (what buyers usually weigh)

| Vendor | MOQ | Lead Time | Certs | QC/Testing | Customization |

|---|---|---|---|---|---|

| Ansheng (Anping, CN) | ≈ 1 roll | 7–15 days typical | ISO 9001 | ASTM E2016, B117, F316 options | Widths, alloys, special weaves |

| Market Vendor A | 3–5 rolls | 10–20 days | ISO 9001 | Basic mesh/aperture check | Limited widths |

| Market Vendor B | Low (sample-friendly) | 14–25 days | ISO 9001 | Optical only | Standard SKUs |

Customization and ordering tips

For Twill Weave Mesh, specify mesh count, wire dia, alloy, roll width/length, and intended media/chemistry. If your process is aggressive (chlorides, low pH), jump straight to 316L and ask for passivation records. For ultra-fine grades, request bubble point data and permeability. It seems obvious, but confirm coil direction and splice policy—surprisingly, that detail has halted more than one installation.

Mini case study

A Southeast Asia chemical plant swapped plain weave 304 for 316L Twill Weave Mesh at 325×2300 mesh (reverse dutch alternative considered). Result: pressure drop fell ≈12%, media changeout interval extended from 6 to 9 weeks, and B117 exposure matched prior runs with zero red rust. Operators noted smoother backflushing—likely the twill’s surface lay aiding cake release.

Industry trend check

Right now the market is nudging toward tighter tolerances and documented pore performance. More specs reference ISO 9044 and ASTM E2016, with bubble point traceability for battery and pharma pre-stages. Also: demand for 2.0 m wide rolls is rising as OEMs consolidate pleat geometries.

Citations

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial wire screens and woven wire cloth – Technical requirements and tests.

- ASTM A580/A580M – Standard Specification for Stainless Steel Wire.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ASTM A370 – Standard Test Methods and Definitions for Mechanical Testing of Steel Products.

- ASTM F316 – Standard Test Methods for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test.

Post time: Oct . 26, 2025 16:35