Stainless Welded Wire Mesh — field notes from the factory floor

If you’ve specced industrial screens or machine guards in the last few years, you’ve probably noticed the same thing I have: demand for Stainless Welded Wire Mesh is climbing, while ad-hoc mild-steel fixes fade out. Why? Consistency and compliance. Hygiene rules tightened, corrosion costs got more visible, and (to be honest) procurement teams finally have better access to certified suppliers. Our network in Anping—No.346 Xinying East Street, Anping County, Hebei, China—turns out a lot of stainless grid every month; they also run copper lines, but I’ll get to that.

What it is and where it’s going

At its core, Stainless Welded Wire Mesh is a resistance-welded grid: straightened stainless wire (304/304L/316/316L) laid orthogonally and fused at each intersection. Unlike woven cloth, welded mesh holds shape under load with minimal creep—great for guards, enclosures, architectural screens, and filtration support layers. Trend-wise, I’m seeing more requests for 316L with post-weld passivation, plus electropolished finishes for food and pharma. Surprisingly, panelized formats now rival rolls because installers want plug-and-play.

Process flow (shop-floor version)

- Materials: ASTM A580/A580M wire (304/304L/316/316L), heat lot-traceable.

- Wire drawing → straightening → resistance welding (programmable) → trimming/flattening.

- Finishes: degrease → pickling/passivation (per ASTM A967) → optional electropolish.

- Testing: weld shear (ISO 14270), bend test (ASTM E290), salt spray for finish (ASTM B117), dimensional tolerances (ISO 1461/house spec; real-world use may vary).

- Service life: ≈10–25 years outdoors for 316L (industrial atmosphere); 304 indoors often >15 years.

- Industries: food and beverage, pharma, petrochem, architectural, mining, HVAC, agriculture.

Typical specifications

| Mesh/Aperture | Wire Ø | Grade | Format | Finish | Notes |

|---|---|---|---|---|---|

| 6×6 mm to 50×50 mm | ≈0.8–4.0 mm | 304 / 304L / 316 / 316L | Rolls (1–2 m wide, ≈30 m) or panels | Passivated, optional electropolish | Tolerances per order drawing |

| Custom apertures | >4.0 mm on request | Duplex on request | Framed panels | Pickle-only for economy | Edge trims, tags, lot trace |

Where it shines

- Machine guarding and safety cages (stiff, predictable load path).

- Food/pharma trays and partitions (smooth welds, cleanability).

- Architectural facades and rails (316L, low-maintenance aesthetics).

- Filter support layers in corrosive duty (stable geometry vs woven).

Customization (real projects rarely fit a catalog)

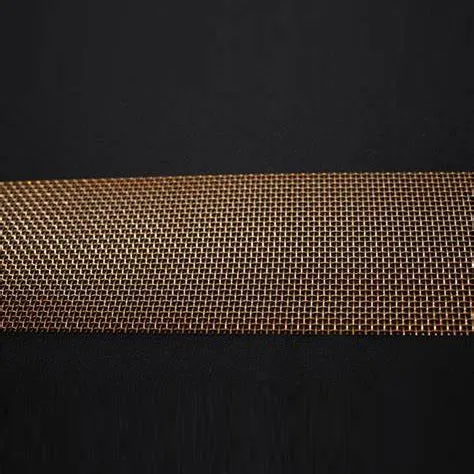

We regularly do oddball apertures, mixed wire diameters, laser-cut openings, and frame welding per AWS D1.6. For hygiene zones, electropolishing reduces Ra and makes cleanup faster. Side note: the same plant also offers phosphor copper wire mesh (QSn6.5-0.1 / QSn6.5-0.4) for non-magnetic or specialty screening—handy when you need conductivity or wear resistance in parallel lines.

Vendor snapshot (what buyers compare)

| Vendor | Grades | MOQ | Lead Time | Certs | Notes |

|---|---|---|---|---|---|

| Ansheng (Anping) | 304/316/316L | ≈100 m or 50 panels | 2–4 weeks | ISO 9001, RoHS | Custom frames; copper mesh line on site |

| Local Distributor | 304 | Stock only | Immediate | Basic CoC | Fast pickup; limited sizes |

| Overseas Trader | 304/316 | Container | 5–8 weeks | Varies | Price-led; check weld QA |

Case notes and feedback

Food plant retrofit: 316L, 25×25 mm aperture, 2.0 mm wire, electropolished. Weld shear averaged >380 N/weld on coupons; salt spray 500 h no red rust. Downtime for washdowns dropped ~12% (maintenance team’s estimate).

“Panels arrived flat. No rework, no burrs. That’s rare.” — Production supervisor, beverage line

Origin: No.346 Xinying East Street, Anping County, Hebei, China.

Citations

- ASTM A580/A580M — Stainless Steel Wire Specification.

- ASTM A967 — Chemical Passivation of Stainless Steel.

- ASTM B117 — Standard Practice for Salt Spray (Fog) Testing.

- ISO 14270 — Resistance Spot Welds, Tensile Shear Test Method.

- AWS D1.6 — Structural Welding Code – Stainless Steel.

Post time: Oct . 27, 2025 17:15