Epoxy Coated Wire Mesh For Concrete is a key solution in the manufacturing industry, specifically within Building materials manufacturing industry and Concrete reinforcement material. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Epoxy Coated Wire Mesh For Concrete Overview

- Benefits & Use Cases of Epoxy Coated Wire Mesh For Concrete in Concrete reinforcement material

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Epoxy Coated Wire Mesh For Concrete from Anping County Ansheng Wire Meshes Product Co., Ltd.

Epoxy Coated Wire Mesh For Concrete Overview

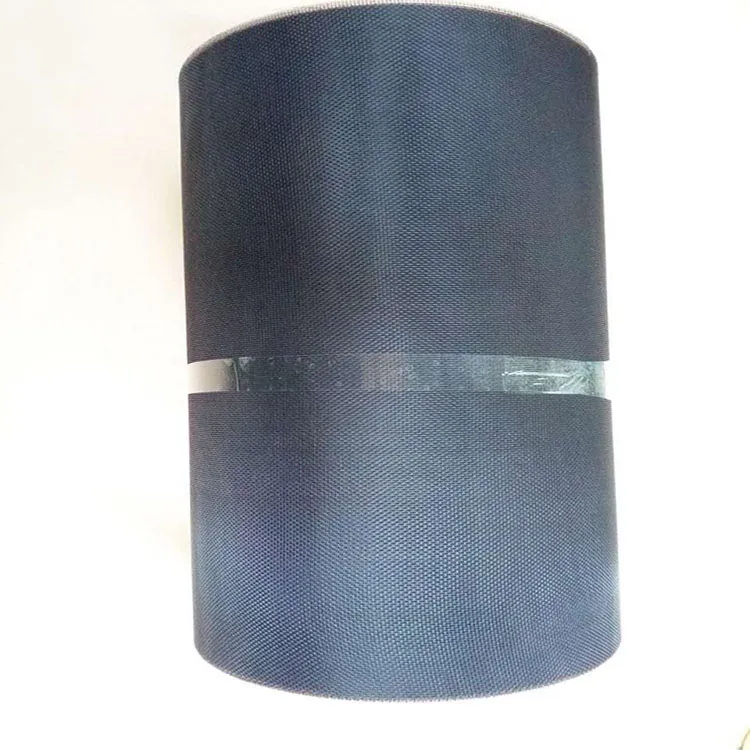

Epoxy Coated Wire Mesh For Concrete—also referred to as epoxy coated wire mesh, epoxy coated welded wire mesh, or simply epoxy mesh—is a welded grid of low-carbon steel wires that is fusion-bonded with an epoxy coating to resist corrosion in aggressive concrete environments. The coating provides a barrier against chlorides, moisture, and carbonation, helping control cracking and extend service life in infrastructure and building projects. Typical options include wire diameters from about 2.5–8.0 mm, apertures such as 50×50 mm and 100×100 mm, and panel or roll formats, with coating thicknesses commonly in the 60–130 μm range. Colors are often green or black, with custom hues available to aid site identification and QA.

From highways to precast components, epoxy coated mesh is selected when durability is mission-critical. Depending on project specifications, supply can be aligned with widely recognized standards for welded wire reinforcement and epoxy coatings. Anping County Ansheng Wire Meshes Product Co., Ltd. manufactures epoxy coated mesh on modern welding and powder-coating lines, combining consistent weld shear strength with uniform coverage. Rigorous quality checks—such as adhesion and holiday detection—help ensure a robust coating over welds and wire intersections, supporting reliable, repeatable performance for B2B customers.

Benefits & Use Cases of Epoxy Coated Wire Mesh For Concrete in Concrete reinforcement material

In concrete reinforcement, epoxy coated welded wire mesh excels in environments with chloride exposure, cyclical wetting, or de-icing salts. It is widely used in bridge decks, parking structures, coastal and marine works, wastewater facilities, tunnel linings, shotcrete walls, industrial floors, and precast panels. Compared with uncoated mesh, epoxy coated mesh reduces the risk of early corrosion initiation, helps maintain steel cross-section over time, and improves aesthetics by minimizing rust staining during staging and pour phases. For contractors, the welded grid format speeds placement and maintains bar spacing, optimizing labor and schedule certainty.

Key advantages include: high corrosion resistance, consistent apertures for crack control, compatibility with standard cutting and tying practices, and clean handling on-site. Ends or field cuts can be sealed with compatible touch-up epoxy to maintain protection continuity. Anping County Ansheng Wire Meshes Product Co., Ltd. supports tailored specifications—panel sizes, apertures, wire gauges, and coating colors—enabling engineers to meet project performance targets without overdesign. Their expertise in epoxy coated wire mesh production and logistics helps B2B decision-makers minimize risk across procurement, installation, and life-cycle performance.

Cost, Maintenance & User Experience

While epoxy coated wire mesh carries a modest premium over bare steel, the total cost of ownership typically favors epoxy in corrosive exposures. Reduced corrosion risk lowers the probability of early repairs, patching, and service interruptions—key drivers of life-cycle cost. For asset owners and contractors, the ROI comes from durability, predictable performance, and the ability to keep projects on schedule. In precast plants, epoxy coated mesh supports cleaner casting surfaces and helps maintain dimensional stability, reducing rework and scrap. In cast-in-place work, the welded grid speeds placement versus individual bars, improving placement productivity and site safety.

Users in the Building materials manufacturing industry report positive handling characteristics and less rust bloom during storage versus uncoated alternatives. Basic best practices—store panels off the ground, cover to limit prolonged UV and moisture exposure, avoid sharp impact, and perform touch-up on cut ends or abrasions—help preserve coating integrity. Anping County Ansheng Wire Meshes Product Co., Ltd. provides guidance on storage and installation, plus optional touch-up materials to simplify field maintenance and support consistent project quality from delivery through concrete placement.

Sustainability & Market Trends in manufacturing

Durability is a core pillar of sustainable construction. By delaying corrosion initiation and slowing deterioration, epoxy coated mesh helps extend service life, reducing the frequency of repairs, lane closures, and material consumption over the asset’s life. Many public and private specifications increasingly prioritize life-cycle performance in coastal, humid, or de-icing climates—driving wider adoption of epoxy coated welded wire mesh alongside alternative solutions such as galvanized or stainless reinforcement. As infrastructure investment grows, engineers continue to balance initial cost with long-term resilience, making epoxy coated mesh a compelling, cost-effective option in the durability toolbox.

Anping County Ansheng Wire Meshes Product Co., Ltd. is committed to responsible manufacturing, leveraging efficient powder-coating processes, reclaiming overspray where feasible, and supporting lower-VOC finishing compared with many liquid systems. The company tracks evolving standards and market requirements so clients can specify epoxy coated mesh that aligns with project sustainability goals and procurement frameworks. With ongoing investment in equipment and QA, Ansheng positions its epoxy coated mesh to meet the next generation of performance, compliance, and environmental expectations in global manufacturing supply chains.

Conclusion on Epoxy Coated Wire Mesh For Concrete from Anping County Ansheng Wire Meshes Product Co., Ltd.

Epoxy Coated Wire Mesh For Concrete delivers dependable corrosion resistance and installation efficiency for the Building materials manufacturing industry. From bridge decks and precast to industrial slabs and tunnels, epoxy coated mesh helps extend service life while controlling costs. Anping County Ansheng Wire Meshes Product Co., Ltd. stands out for manufacturing rigor, customization, and responsive support—key advantages for B2B decision-makers managing risk and schedule.

- Choose epoxy coated welded wire mesh to unlock durability, productivity, and predictable performance in concrete reinforcement applications.

- Partner with Anping County Ansheng Wire Meshes Product Co., Ltd. for proven quality and reliable supply.

- Strong CTA: Contact us: email: sales@anshengwiremesh.com — Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 21, 2025 08:55