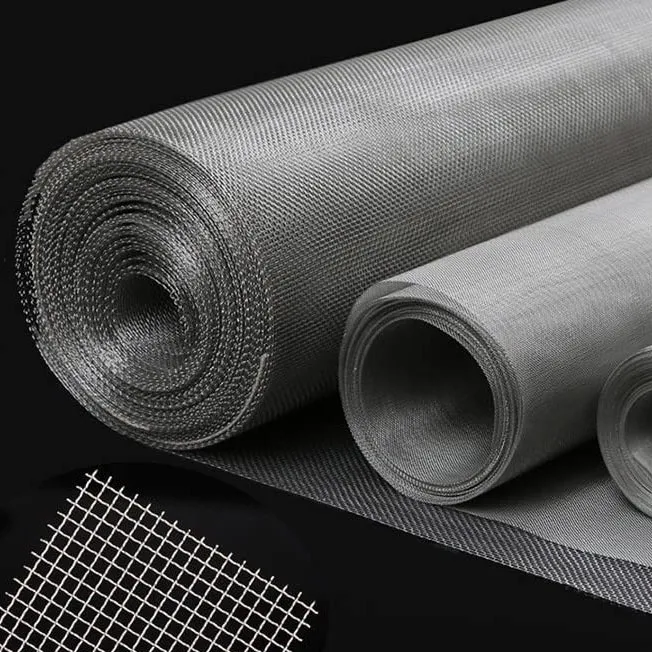

Nickel Plain Weave Wire Mesh: field notes, specs and real-world lessons

I spent a morning walking the looms in Anping—No.346 Xinying East Street, if you’re curious—where nickel wire mesh is still woven the old-fashioned way, only with better metrology and tighter QC. The result? Stable apertures, clean edges, and the kind of corrosion resistance that chemical plants quietly rely on. To be honest, it’s not glamorous, but it’s critical.

What makes nickel wire mesh different

Material purity is the headline. Using N6/N4 and Nickel 200 grades, this mesh holds up where stainless stalls—chlor-alkali cells, cathode protection, alkaline battery tabs, and high-temp filtration. Many customers say the real surprise is its electrical stability over time; resistivity drift is minimal, even after long exposure to caustic media.

Process flow (how it’s actually made)

Wire drawing from certified billets → multi-stage annealing → precision weaving (plain or twill) → degreasing/pickling → flattening and tension-set → dimensional and aperture verification → optional passivation. QC references include ASTM E2016 for woven wire cloth, with aperture checks under optical microscopes, tensile tests per ISO 6892, and corrosion screening that loosely mirrors ASTM G85 (real-world use may vary).

Industry trend snapshot

Demand is shifting toward tighter meshes (≥300) for electrolyzers and battery current collectors, plus wider rolls for continuous chemical lines. Certification requests—RoHS, REACH, and ISO 9001—are now table stakes. Surprisingly, we’re also seeing interest from semiconductor wet benches where copper simply can’t be trusted.

| Material Grades | N6 / Nickel 200 / N4 (≥99% Ni typical) |

| Mesh Range | 1–600 mesh |

| Wire Diameter | 0.02–8.0 mm |

| Width | ≈1–2 m standard; custom on request |

| Roll Length | ≈30 m standard; up to 350 m |

| Weaves | Plain (standard), Twill (for finer mesh) |

| Electrical Resistivity | ≈0.099 Ω·mm²/m at 20°C (Nickel 200) |

| Temperature Window | Up to ~600°C continuous; melting ≈1455°C |

| Certifications | ISO 9001; RoHS & REACH compliant |

Applications and service life

- Electrolysis/corrosion-resistant electrodes and current collectors

- High-temp filtration in chemical and petrochemical units

- Battery tabs and EMI/RFI shielding in electronics

- Lab sieving and catalyst support grids

In alkaline/chloride environments, well-installed nickel wire mesh often runs 5–10 years. It’s not a promise, just an honest average; pH, temperature, and current density matter.

Testing notes (a quick peek)

On a recent 300 mesh, 0.03 mm wire sample: measured pitch ≈0.084 mm; opening ≈55 μm; open area ≈41–42%. Tensile tests hit spec, and aperture variation stayed within ASTM E2016 standard tolerances. That’s the stuff buyers quietly look for.

Vendor comparison (what to check before buying)

| Vendor | Traceability | Customization | Lead Time | Certs |

|---|---|---|---|---|

| Ansheng Filter Screen (Anping, China) | Heat/batch IDs; material reports | Widths to 2 m+, lengths to 350 m | ≈10–20 days | ISO 9001, RoHS, REACH |

| Importer A | Limited on request | Standard widths; limited custom | ≈3–6 weeks | Varies |

| Marketplace Seller | Unclear | Minimal | Uncertain | Unverified |

Customization and QA

You can tweak mesh counts (1–600), wire diameters (0.02–8 mm), roll width/length, and choose plain vs. twill. For critical electrochemical use, ask for ASTM E2016 compliance certificates, aperture maps, and salt-spray or immersion notes. A quick tip from the floor: specify edge trimming and flatness—saves headaches in frame mounting.

Mini case studies

- Chemical plant, Southeast Asia: upgraded cathode grids to nickel wire mesh, cut maintenance by ≈25% over 18 months.

- Electrolyzer startup: 400 mesh twill, low-resistivity Nickel 200, improved current distribution uniformity (customer lab data).

- Battery line: thin-gauge plain weave as tab precursor; weldability praised—“less spatter, cleaner joints.”

Notes and standards you can cite: ASTM E2016 for cloth tolerances, ASTM B160 for Nickel 200 wire/rod chemistry, ISO 9044 for wire cloth definitions, and NACE MR0175 guidance when H2S may be lurking.

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ASTM B160 – Standard Specification for Nickel (UNS N02200/N02201) Rod, Bar, and Wire.

- ISO 9044 – Industrial Woven Wire Cloth: Technical requirements and tolerances.

- NACE MR0175/ISO 15156 – Materials for use in H2S-containing environments.

Post time: Oct . 20, 2025 16:25