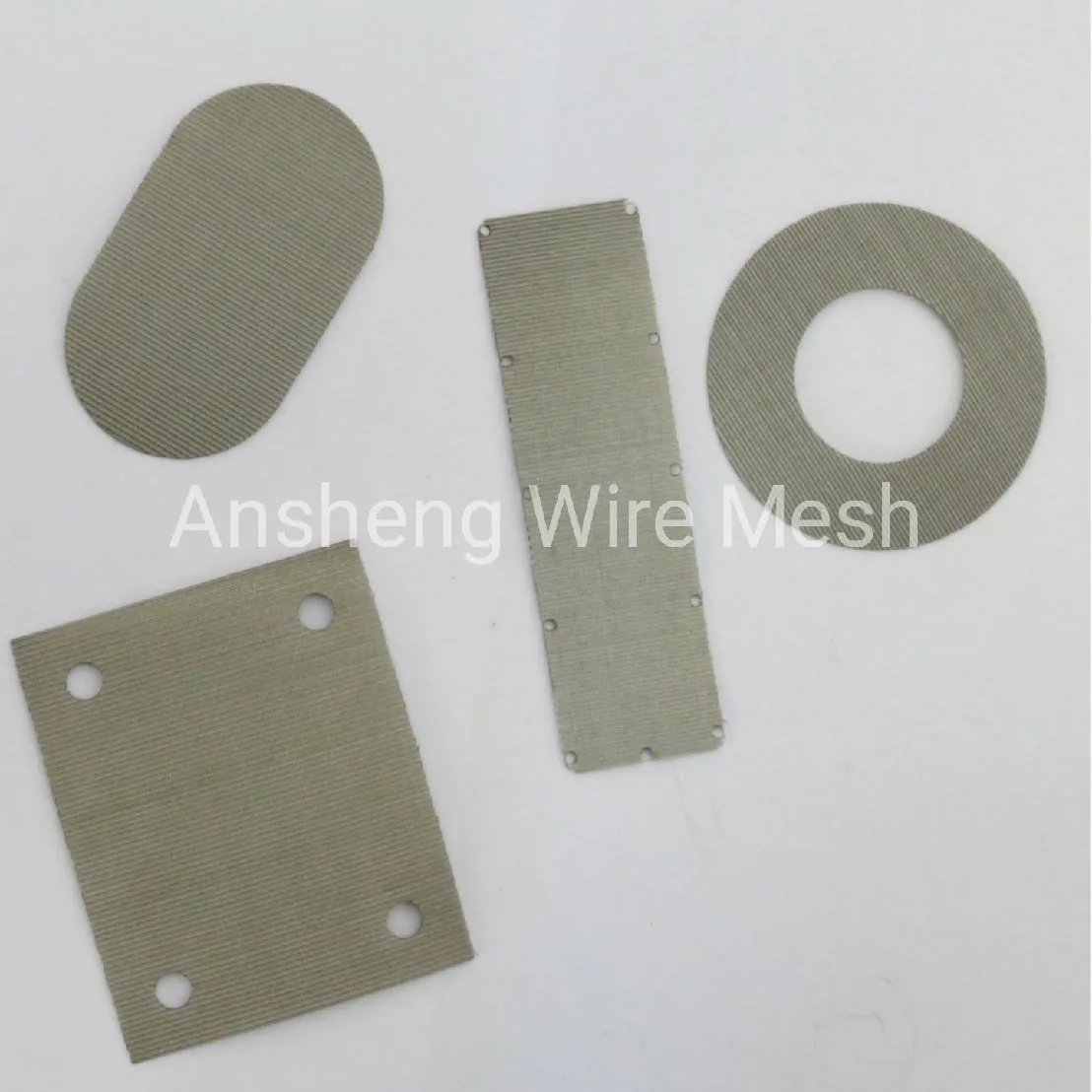

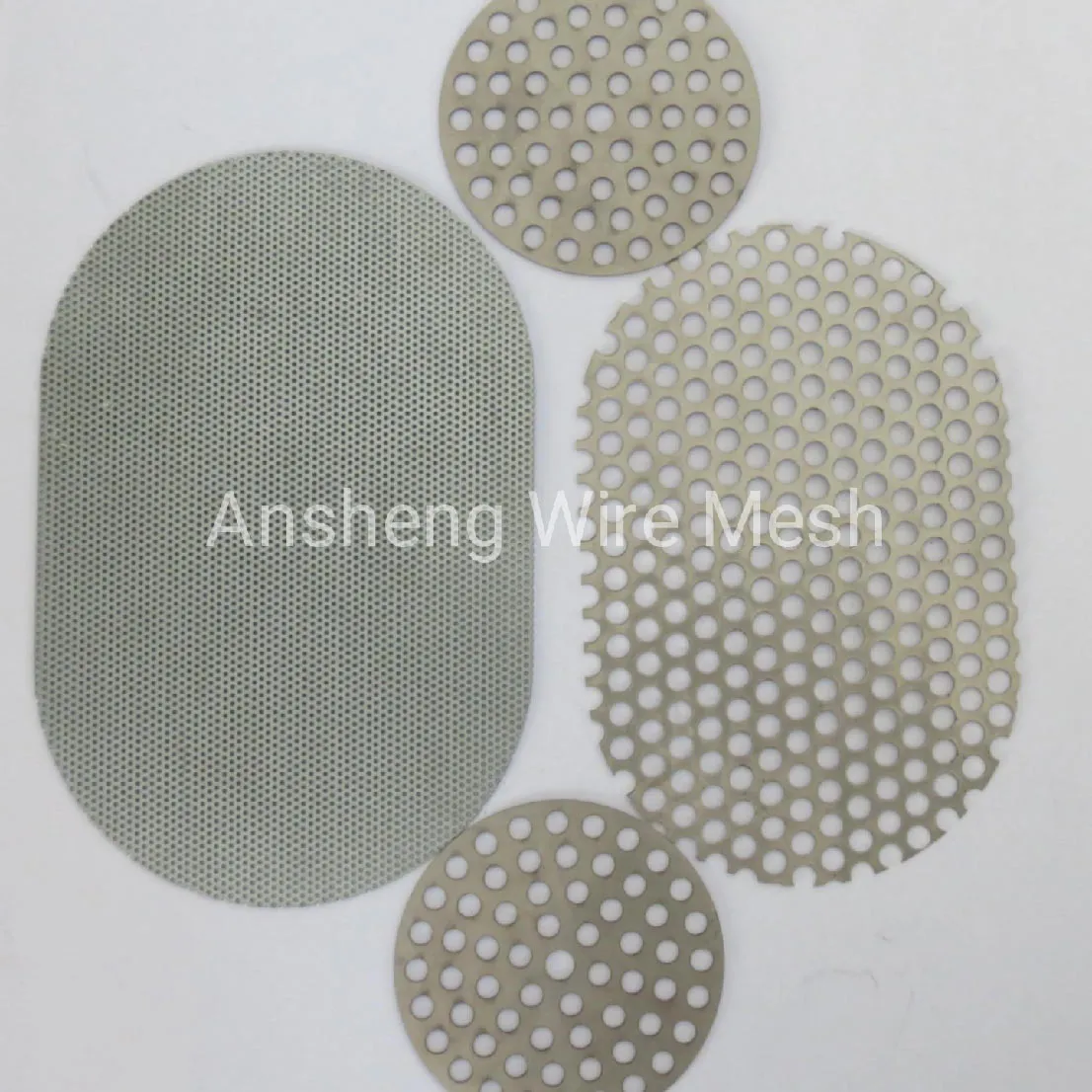

Single Layer Wire Mesh Discs: What Buyers Are Really Asking For

If you spec filters for a living, you know the drill: tight timelines, shifting media requirements, and a plant manager who just wants it to work. The Wire Mesh Disc in its Single Layer form is still the dependable workhorse I see most on production floors—precise, durable, surprisingly configurable. And yes, there are nuances that separate a good disc from one that sheds burrs into your process (you don’t want that).

Quick Specs (Real-World Friendly)

| Product | Single Layer Wire Mesh Disc |

| Materials | SS304, SS201, SS316, SS316L, Nickel N6/N4/200, Low-carbon steel, Galvanized, others on request |

| Mesh range | 1–635 mesh (ISO/ASTM; actual retention ≈ 20 μm–6 mm; real-world use may vary) |

| Sizes | Ø1 mm to 1 m; thickness typically ≈ 0.1–1.2 mm depending on mesh and type |

| Shapes | Circle, Square, Oval, Kidney, Rectangle, Irregular |

| Types | Woven wire, Perforated, Expanded metal |

| Finish | Smooth edges, burr-free; optional anneal, passivation |

| Origin | No.346 Xinying East Street, Anping County, Hebei, China |

Where they’re used (and why)

I see Single Layer Wire Mesh Disc units in polymer melt filtration, hydraulic systems, petrochemical strainers, solvent pre-filtration, water treatment skids, lab sampling, even coffee roasters (no kidding). The appeal is simple: accurate aperture, good strength-to-weight, easy to clean, and a predictable pressure drop.

How it’s made (process flow)

- Material selection: SS316/316L for corrosion, nickel grades for high-temp/corrosive media.

- Mesh forming: woven to ISO 9044/ASTM E2016, or perforated/expanded depending on load/flow.

- Cutting: CNC die-cut, laser, or waterjet (laser for tight tolerances ≈ ±0.10 mm on small discs).

- Edge finishing: deburr and flatten; optional rim ring if needed.

- Cleaning: ultrasonic + solvent rinse; oil-free packaging for critical lines.

- Inspection: aperture check, thickness, flatness, visual defects per ISO 9044; MTRs on request (EN 10204 3.1).

- Testing: bubble-point or gas-diffusion (ASTM F316) for woven; burst/pressure test where applicable.

Service life? It varies. In moderate hydraulic duty, a stainless Single Layer Wire Mesh Disc often runs months between changeouts; in polymer lines, changeouts track batch lengths and backflush discipline.

Performance snapshot (indicative)

Internal test: 200-mesh SS316L, Ø20 mm, IPA bubble-point ≈ 1.4–1.6 bar (ASTM F316); water flow at 0.1 bar ≈ 7–9 L/min through 50 cm² equivalent. Your media and fouling will swing these numbers.

Vendor landscape (what differs in practice)

| Vendor | Lead time | Customization | Certs/Testing | Notes |

|---|---|---|---|---|

| Factory (Anping origin) | ≈ 7–15 days | Shapes, rings, tight tolerances | ISO 9001 (commonly), MTRs, ASTM F316 on request | Direct control over mesh and cutting |

| Trading house | around 15–30 days | Limited specials | Varies by upstream source | Good for spot buys |

| Local fab shop | Quick for low qty | Custom shapes | Basic inspection | Higher unit cost |

Customization tips

- Specify media: chemistry, temp, viscosity. Many customers say switching to 316L quickly paid back in caustic CIP lines.

- Call out edge treatment and flatness; it seems minor, but gasket sealing depends on it.

- For abrasive slurries, consider perforated or expanded Wire Mesh Disc as a support under a finer woven layer (even on “single layer” projects, a support screen is sometimes nested in the housing).

Field notes and mini case studies

- Beverage plant (CIP-heavy): 80-mesh SS316L Wire Mesh Disc cut changeouts by ~30% after switching to passivated finish.

- Polymer line: dual housing with staged 40/100 mesh Wire Mesh Disc reduced pressure spikes; operators said “less babysitting.”

Compliance and paperwork

Common requests: ISO 9001 quality system, EN 10204 3.1 MTRs, RoHS/REACH statements. Standards referenced include ISO 9044 and ASTM E2016 for mesh; ASTM F316 for bubble-point testing.

If you need steady supply from Anping (the wire mesh capital), the Single Layer Wire Mesh Disc from the address above is a sensible, proven option—accurate size, uniform mesh, smooth edges, burr-free, and priced sanely.

References

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial wire screens and cloth – Technical requirements and tests.

- ASTM F316 – Determining Bubble Point and Mean Flow Pore Test of Porous Materials.

Post time: Oct . 21, 2025 15:15