Wire Mesh Discs is a key solution in the manufacturing industry, specifically within Grinding tools and abrasives and Sand grinding disc. This article explores how Anping County Ansheng Wire Meshes Product Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Wire Mesh Discs Overview

- Benefits & Use Cases of Wire Mesh Discs in Sand grinding disc

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Wire Mesh Discs from Anping County Ansheng Wire Meshes Product Co., Ltd.

Wire Mesh Discs Overview

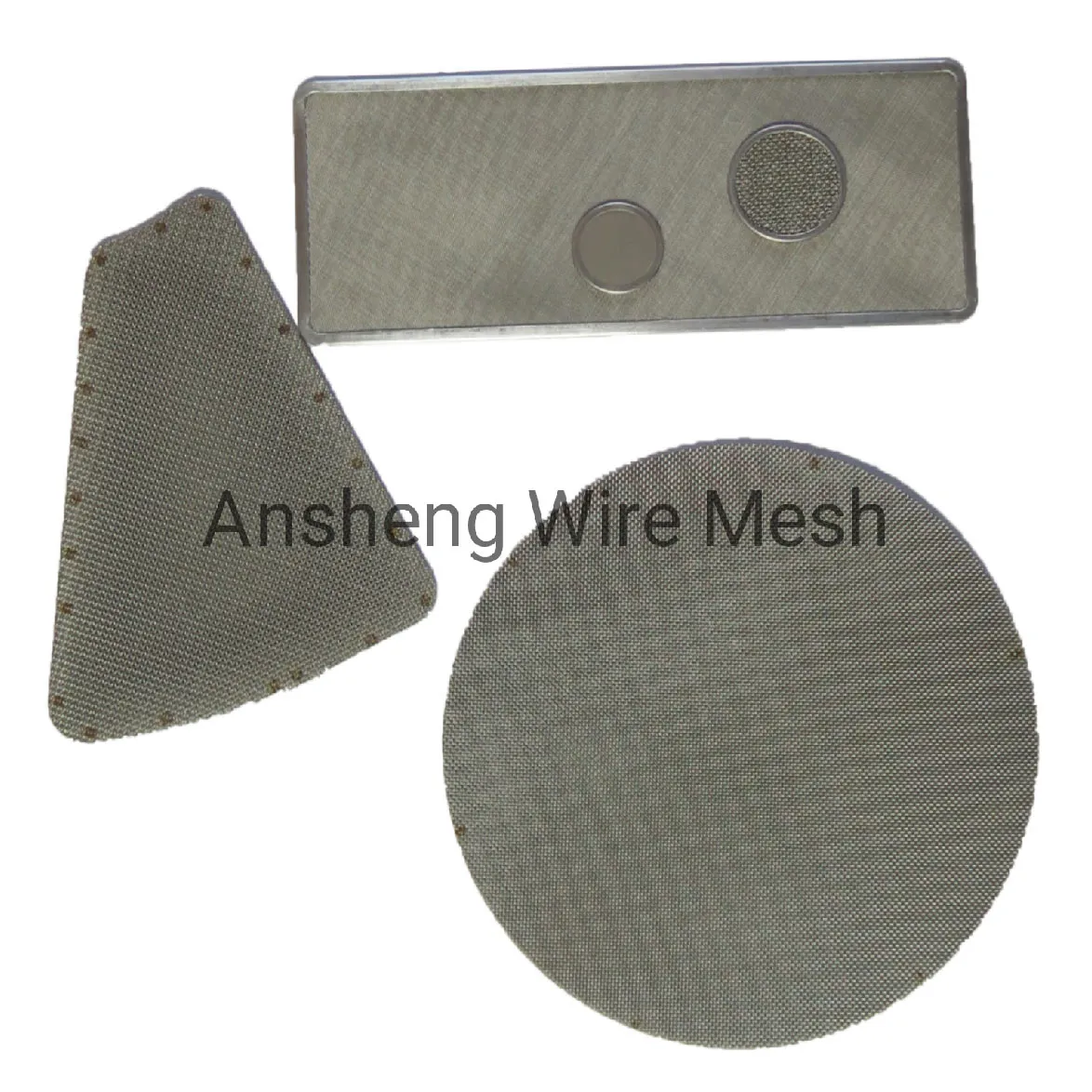

Wire Mesh Discs are precision-cut circular screens made from stainless steel or specialty alloys, engineered to deliver stable structure, uniform aperture, and high airflow in abrasive systems. In the manufacturing chain for grinding tools and abrasives—especially sand grinding disc applications—these discs act as reinforcement layers, dust-extraction interfaces, and process filters. Anping County Ansheng Wire Meshes Product Co., Ltd. fabricates multi-layer mesh with welding spots, then die-cuts to tight tolerances for repeatable performance at industrial scale. Typical constructions include single- to multi-layer stainless steel (e.g., 304/316) with spot-welded interfaces to lock alignment and maintain rigidity under dynamic loads.

Technical options span open-area percentages tailored to dust evacuation, wire diameters selected for strength-to-weight ratio, and mesh counts configured for fine to coarse extraction paths. Common outer diameters align with shop-floor standards such as mesh sanding discs 125mm, 150mm mesh sanding discs, and 225mm mesh sanding discs; custom formats are available for niche orbital or floor-sanding machines. For SEO variations often seen in the market, you may also encounter “.125mm mesh sanding discs” in listings. Backed by controlled cutting, burr-free edges, and consistent flatness, Ansheng’s Wire Mesh Discs integrate seamlessly beneath abrasive nets or within multi-component disc stacks used in sanding, deburring, and surface preparation lines.

Benefits & Use Cases of Wire Mesh Discs in Sand grinding disc

In sand grinding disc assemblies, Wire Mesh Discs serve three core roles: reinforcing the abrasive carrier, enabling multi-hole dust extraction, and acting as a protective barrier for backing pads. The open mesh structure allows superior airflow compared with solid backers, improving dust capture on orbital sanders and floor sanders. This translates to cleaner cutting action, reduced loading, and more consistent surface finish on composites, hardwoods, stone, and coated metals. In high-duty cycles—like furniture finishing lines or metal fabrication shops—multi-layer, spot-welded discs resist deformation and temperature rise, maintaining dimensional stability over prolonged runs.

Competitive advantages include customizable apertures for targeted chip removal, alloy selection for corrosion resistance, and precise OD control to fit standard sizes (mesh sanding discs 125mm, 150mm mesh sanding discs, and 225mm mesh sanding discs). Anping County Ansheng Wire Meshes Product Co., Ltd. leverages expertise in multi-layer mesh with welding spots to deliver discs that align with modern abrasive net technologies. Whether paired with hook-and-loop sanding nets or integrated into heavy-duty floor-sanding heads, Ansheng’s discs help extend abrasive life, stabilize cut rates, and reduce nuisance dust—key priorities for B2B operations seeking predictable throughput and higher first-pass yield.

Cost, Maintenance & User Experience

Total cost of ownership for Wire Mesh Discs centers on durability, reduced abrasive consumption, and fewer unscheduled stops for cleaning or changeover. By improving airflow and preventing premature loading, the discs help maintain cutting efficiency, which can reduce net disc usage over long shifts. For maintenance teams, the robust spot-welded multi-layer build resists fraying and edge damage, lowering the frequency of replacement parts. The result is steadier cycle times and less rework—critical factors in calculating ROI for sanding cells, finishing booths, and mobile sanding crews.

Users in the grinding tools and abrasives sector typically highlight consistent flatness, reliable fit with standard diameters (including mesh sanding discs 125mm and 150mm mesh sanding discs), and burr-free edges that protect pads and operators. Feedback also points to smoother vacuum extraction and a cleaner work envelope, which can improve visibility at the point of cut. Anping County Ansheng Wire Meshes Product Co., Ltd. supports predictable procurement with stable quality, clear specifications, and responsive lead times—helping B2B buyers harmonize consumables planning with production schedules and avoid costly line interruptions.

Sustainability & Market Trends in manufacturing

Sustainability in abrasives is shifting toward extended tool life, dust reduction, and recyclable components. Wire Mesh Discs contribute by enabling effective dust extraction, which supports cleaner air in compliance-focused facilities and helps meet evolving workplace exposure guidelines. Stainless steel meshes are also recyclable, aligning with circular economy goals and material recovery programs many manufacturers are adopting. As orbital and net-sanding technologies proliferate, the market favors high-open-area backers that maintain airflow without sacrificing structural integrity—a sweet spot for multi-layer mesh with welding spots designs.

Forward-looking B2B buyers also evaluate suppliers on transparency, traceability, and engineering support. Anping County Ansheng Wire Meshes Product Co., Ltd. positions itself as a partner that understands both environmental priorities and production realities. By offering tailored specifications across popular sizes—like 225mm mesh sanding discs or compact formats—and by advising on mesh count and alloy selection, Ansheng helps customers hit sustainability targets without compromising throughput or finish quality. This consultative approach, coupled with durable Wire Mesh Discs, equips manufacturers to scale responsibly in fast-evolving abrasive markets.

Conclusion on Wire Mesh Discs from Anping County Ansheng Wire Meshes Product Co., Ltd.

From reinforcing abrasive assemblies to optimizing dust extraction, Wire Mesh Discs provide measurable value across manufacturing, grinding tools and abrasives, and sand grinding disc applications. Anping County Ansheng Wire Meshes Product Co., Ltd. delivers multi-layer mesh with welding spots engineered for precision, durability, and consistent fit across standard sizes, including mesh sanding discs 125mm, 150mm mesh sanding discs, and 225mm mesh sanding discs. Ready to upgrade sanding performance and stability? Contact us: email: sales@anshengwiremesh.com — Visit our website: https://www.anshengfilterscreen.com

Post time: Oct . 25, 2025 08:10